Introduction

When it comes to aircraft manufacturing, precision and quality are of utmost importance. This is where Aircraft CNC Machining comes into play. Utilizing advanced computer numerical control (CNC) technology, this method has revolutionized the aerospace industry by offering unparalleled accuracy and efficiency in producing aircraft components.

Understanding Aircraft CNC Machining

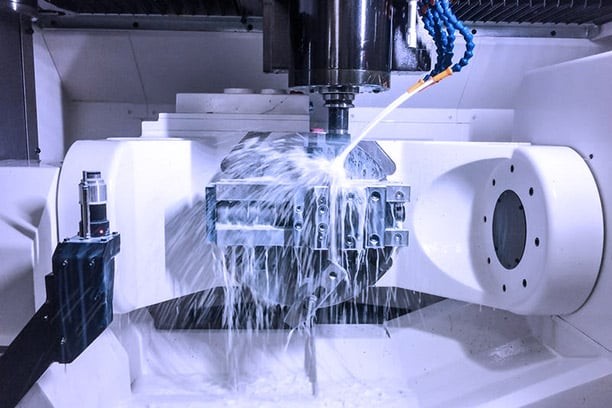

Aircraft CNC Machining involves the use of computer-controlled machines to precisely shape and form metal parts for aircraft construction. This technology allows for intricate designs and complex shapes to be manufactured with exceptional accuracy, meeting the stringent requirements of the aerospace industry.

The Role of CNC Machining in Aerospace Industry

CNC Machining plays a pivotal role in the aerospace industry by providing the capability to produce high-quality, custom parts for aircraft. From engine components to structural elements, CNC machining ensures that every piece meets exact specifications, contributing to the safety and performance of aircraft.

Benefits of Using CNC Machining in Aircraft Manufacturing

The benefits of utilizing CNC machining in aircraft manufacturing are numerous. It offers unmatched precision, reduces production time, enhances repeatability, and allows for cost-effective production of complex parts. These advantages make it an indispensable tool in meeting the demands of modern aircraft construction.

What is CNC in Aircraft?

CNC, or Computer Numerical Control, is a technology that utilizes computer software to control machine tools and 3D printers for manufacturing aircraft parts. This advanced method allows for precise and efficient production of complex components, ensuring high-quality and reliable aircraft performance.

Definition and Basics of CNC Machining in Aircraft Industry

CNC machining in the aircraft industry involves the use of computer-controlled machines to produce aircraft parts from various materials such as aluminum, titanium, and composites. The process begins with a CAD model, which is then translated into a set of instructions that guide the cutting tools to shape the material into the desired part with exceptional accuracy.

CNC machining in the aircraft industry is crucial for producing parts that meet strict precision and quality standards. The use of computer-controlled machines ensures that each part is manufactured with exceptional accuracy, reducing the margin for error and ensuring consistency across all components. This level of precision is essential for aircraft safety and performance, as even the smallest deviation in part dimensions can have a significant impact on the overall functionality of the aircraft.

Importance of Precision in CNC Machined Parts for Aircraft

Precision is crucial in CNC machined parts for aircraft due to the demanding nature of aerospace applications. Even the slightest deviation from specifications can compromise safety and performance. Therefore, CNC machining ensures that every component meets strict tolerances and exact specifications required for reliable operation in aviation.

With the increasing complexity of aircraft designs, the need for precision in CNC machined parts has become even more critical. The intricate components of modern aircraft demand a level of accuracy that can only be achieved through advanced CNC machining techniques. As a result, SYIL CNC machines have emerged as a game-changer in the aerospace industry, providing the high level of precision required for reliable and safe operation.

SYIL CNC Machine: A Game-Changer in Aircraft CNC Machining

SYIL's state-of-the-art CNC machines have revolutionized aircraft manufacturing by delivering unparalleled precision, speed, and efficiency. With advanced features such as multi-axis capabilities and high-speed cutting, SYIL machines are at the forefront of producing complex aerospace components with uncompromising quality.

What is a CNC Aerospace Machinist?

A CNC aerospace machinist is a highly skilled professional responsible for operating and maintaining CNC machines used in the production of aircraft parts. They must have a strong understanding of machining processes, blueprint reading, and precision measurement tools.

Skills and Qualifications of a CNC Aerospace Machinist

To excel in this role, a CNC aerospace machinist must possess strong technical skills, attention to detail, and problem-solving abilities. They should also have a solid understanding of CAD/CAM software and be able to interpret complex engineering drawings. Additionally, a CNC aerospace machinist should be able to work well under pressure and meet tight deadlines in a fast-paced manufacturing environment. Being adaptable and able to quickly learn new machining techniques and technologies is also crucial in this role, as the aerospace industry is constantly evolving.

The Role of CNC Machinist in Aircraft Manufacturing Process

CNC machinists play a crucial role in the aircraft manufacturing process by programming, setting up, and operating CNC machines to produce precision parts that meet strict industry standards. Their expertise ensures the quality and accuracy of components used in aircraft assembly.

CNC machinists must have a strong understanding of blueprints, technical drawings, and specifications to accurately produce parts that meet the unique requirements of aircraft manufacturing. They also need to be skilled in using various tools and equipment to measure, inspect, and test finished components to ensure they meet the necessary quality standards. Additionally, CNC machinists play a critical role in troubleshooting any issues that may arise during the machining process, utilizing their problem-solving skills to make adjustments and modifications as needed.

Training and Education for Aspiring Aerospace CNC Machinists

Aspiring aerospace CNC machinists typically pursue formal training programs or apprenticeships to acquire the necessary skills for this specialized field. These programs often include coursework in machine tool operations, blueprint reading, and computer-aided manufacturing (CAM) technology.

In addition to technical coursework, aspiring aerospace CNC machinists may also benefit from hands-on experience through internships or co-op programs with aerospace manufacturers. These opportunities provide valuable practical skills and industry knowledge that can complement formal training programs. By gaining exposure to real-world production environments, aspiring machinists can learn about the specific requirements and challenges of aerospace manufacturing, further preparing them for a career in this field.

What is Aerospace CNC Machining?

Aerospace CNC machining involves the use of computer numerical control (CNC) machines to precisely manufacture aircraft parts and components. This advanced manufacturing process allows for high levels of accuracy and repeatability, crucial in the aerospace industry where safety and reliability are paramount.

Overview of CNC Machining Techniques in Aerospace Industry

Aerospace CNC machining techniques include milling, turning, drilling, and grinding to create complex geometries and tight tolerances required for aircraft components. These techniques ensure that parts meet strict aviation standards for quality and performance, making CNC machining an indispensable part of aircraft manufacturing.

Advancements in CNC Machining for Aircraft Parts & Components

Advancements in aerospace CNC machining have led to the development of multi-axis machines capable of producing intricate and precise aircraft parts. These advancements have also resulted in the use of innovative materials such as titanium and composites, further pushing the boundaries of what can be achieved in aircraft manufacturing.

SYIL CNC Machine Shop: Leading the Way in Aerospace CNC Machining

SYIL's state-of-the-art CNC machine shop is at the forefront of aerospace machining, utilizing cutting-edge technology to produce high-quality aircraft components with unparalleled precision. With a focus on innovation and continuous improvement, SYIL is setting new standards for excellence in aerospace CNC machining.

CNC Machine Shop for the Aircraft Industry

When it comes to aircraft manufacturing, choosing the right CNC machine shop is crucial. The precision and quality of the machined parts can make or break the performance and safety of an aircraft. It's important to select a CNC machine shop with a proven track record in producing high-quality, reliable aircraft components.

Importance of Choosing the Right CNC Machine Shop for Aircraft Parts

Selecting a CNC machine shop that specializes in aerospace machining is essential for ensuring that the parts meet stringent industry standards. The right machine shop will have experience working with materials commonly used in aircraft manufacturing, such as aluminum, titanium, and composites. They will also have the expertise to produce complex geometries and tight tolerances required for aircraft components.

Quality Control in CNC Machining for Aircraft Components

Quality control is paramount when it comes to producing components for aircraft. A reputable CNC machine shop will have stringent quality control processes in place to ensure that every part meets the required specifications. This includes thorough inspection and testing throughout the machining process to identify any deviations from design parameters and ensure dimensional accuracy.

How SYIL CNC Machine Shop Meets the Demands of Aircraft Industry

SYIL CNC Machine Shop stands out as a leading provider of precision machined parts for the aerospace industry. With state-of-the-art equipment and a team of highly skilled machinists, SYIL delivers top-quality components that meet the strict requirements of aircraft manufacturers. Their commitment to excellence and dedication to continuous improvement make them a trusted partner in aerospace manufacturing.

Precision CNC Machined Parts for Aircraft

Importance of Precision in CNC Machined Parts for Aircraft

Precision in CNC machined parts for aircraft is crucial to ensure the safety and efficiency of the aircraft. The intricate components of an aircraft require precise machining to guarantee proper functionality and performance, making precision a top priority in the aerospace industry.

Challenges and Solutions in Producing Precision Aircraft Components

Producing precision aircraft components comes with its challenges, such as material limitations and complex geometries. However, advanced CNC machining technologies have provided solutions to these challenges, enabling the production of highly precise aircraft parts with tight tolerances and impeccable accuracy.

SYIL CNC Machined Parts: Setting the Standard for Aircraft Precision

The SYIL CNC machine shop has set the standard for precision in aircraft components with state-of-the-art equipment and cutting-edge technology. Their expertise in producing high-precision parts has made them a trusted partner in the aerospace industry, delivering top-quality components that meet the stringent requirements of aircraft manufacturing.

Conclusion

Utilizing CNC machining in the aerospace industry offers numerous advantages, including increased precision, efficiency, and cost-effectiveness in producing aircraft components. The future of CNC machining in aircraft manufacturing looks promising as technology continues to advance. Choosing the right CNC machining partner for aircraft production is crucial for ensuring high-quality and reliable parts.

Advantages of Utilizing CNC Machining in the Aerospace Industry

CNC machining in the aerospace industry provides unparalleled precision, allowing for the production of complex and accurate aircraft parts. This technology also enhances efficiency by reducing manual labor and minimizing errors, resulting in faster turnaround times for manufacturing critical components.

Future of CNC Machining in Aircraft Manufacturing

As technology continues to evolve, the future of CNC machining in aircraft manufacturing is bright. Advancements such as 5-axis machining and real-time monitoring systems will further improve the quality and speed of producing aircraft parts. Additionally, the integration of AI and automation will revolutionize the entire manufacturing process.

Choosing the Right CNC Machining Partner for Aircraft Production

Selecting a reliable and experienced CNC machining partner is essential for ensuring the success of aircraft production. The right partner should have a proven track record of delivering high-quality precision parts while adhering to strict industry standards and regulations. Collaborating with a reputable CNC machine shop will ultimately contribute to the overall success of aerospace projects.