Introduction

In the fast-paced world of aerospace manufacturing, precision and accuracy are paramount. This is where CNC machining comes into play, offering a level of precision that is unmatched by traditional machining methods. Aerospace CNC machining involves the use of computer-controlled machines to create intricate and complex parts for aircraft and spacecraft. These machines are capable of producing high-quality components with tight tolerances, making them indispensable in the aerospace industry.

Understanding CNC Machining in Aerospace

CNC machining in aerospace involves the use of advanced computer software to control and operate machine tools such as lathes, mills, and routers. This technology allows for the production of highly precise components that meet the stringent requirements of the aerospace industry. With CNC machining, manufacturers can achieve a level of accuracy that is not possible with manual machining methods, ensuring that every part meets exact specifications.

Importance of Precision Machining in Aerospace

Precision machining plays a crucial role in ensuring the safety and reliability of aircraft parts. The ability to produce components with extremely tight tolerances is essential for maintaining the structural integrity and performance of aerospace systems. From engine components to airframe parts, precision machining is vital for meeting the rigorous demands of aerospace engineering.

Evolution of Aerospace CNC Machining

Over the years, aerospace CNC machining has evolved significantly to keep pace with technological advancements in materials, tooling, and manufacturing processes. The integration of advanced software systems and automation has revolutionized the way aircraft components are produced, leading to greater efficiency and consistency in manufacturing operations.

The Role of CNC Machining in Aerospace Industry

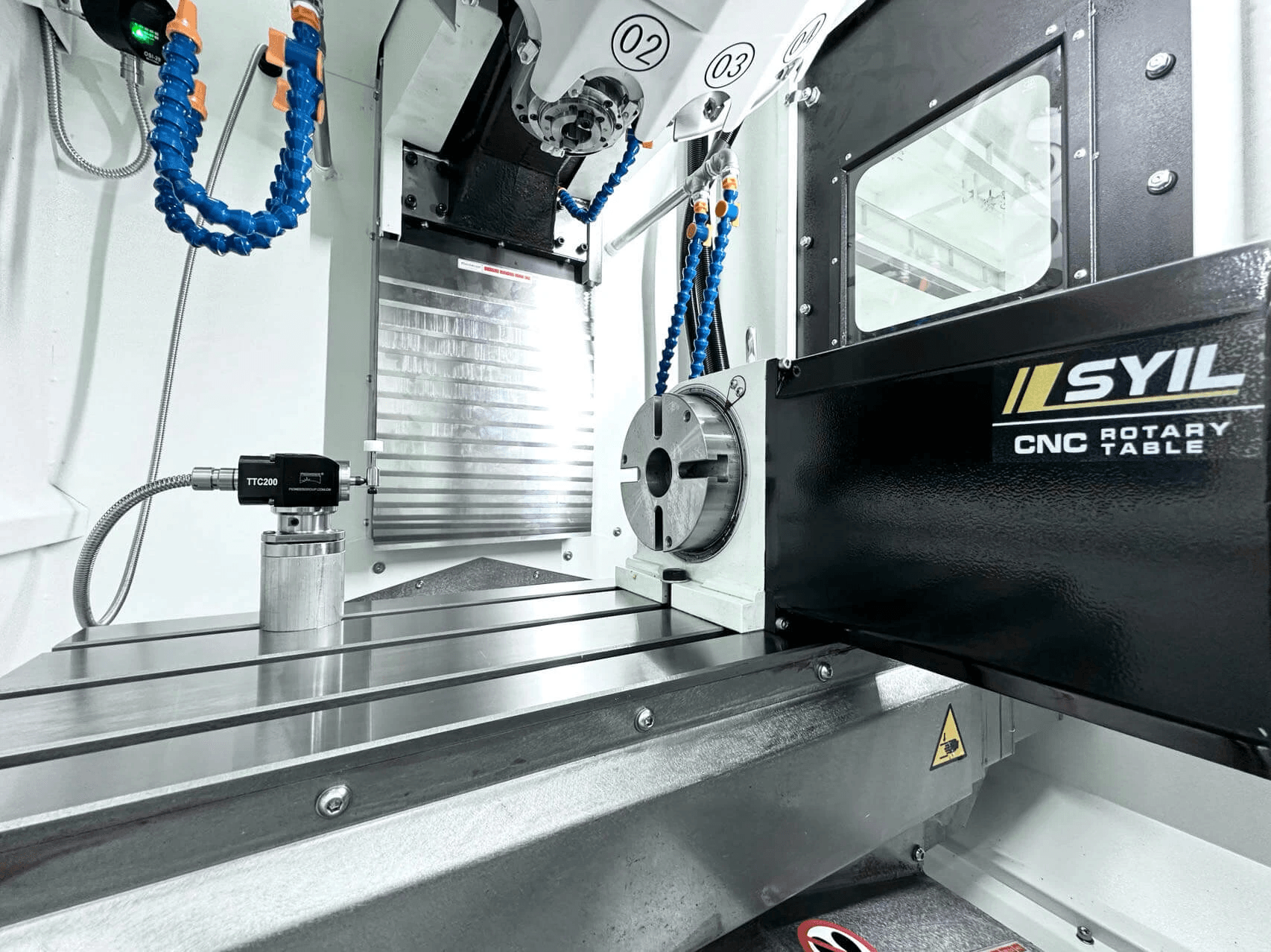

CNC machining plays a pivotal role in the aerospace industry, enabling the production of complex and high-precision components essential for aircraft performance and safety. With the advent of advanced CNC machines, such as the SYIL CNC Machine, aerospace machining has been revolutionized, allowing for faster production and greater accuracy in component manufacturing.

SYIL CNC Machine: Revolutionizing Aerospace Machining

The SYIL CNC Machine has transformed aerospace machining by offering unparalleled precision and efficiency in producing intricate aircraft parts. Its state-of-the-art technology and advanced features have made it a game-changer in the industry, allowing manufacturers to meet stringent quality standards while significantly reducing production time.

Benefits of Precision Machining in Aerospace Industry

Precision machining is crucial in aerospace manufacturing as it ensures that components meet exact specifications, leading to enhanced aircraft performance and safety. With precision machining, manufacturers can achieve tight tolerances and produce parts with minimal error, ultimately contributing to the overall reliability of aircraft systems.

Advancements in Aerospace CNC Machining Technology

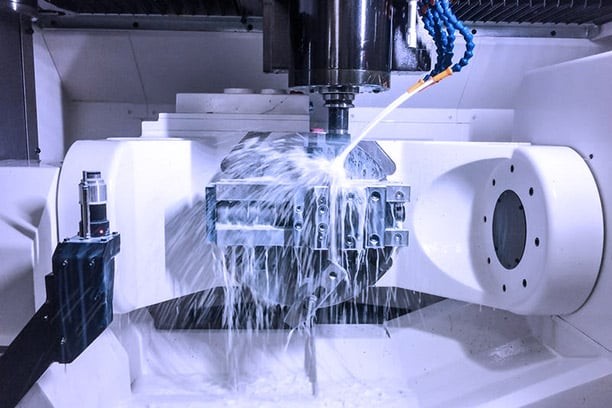

The advancements in aerospace CNC machining technology have led to improved capabilities for producing complex geometries and materials used in modern aircraft design. From multi-axis machining to high-speed cutting, these technological advancements have enabled manufacturers to push the boundaries of what is possible in aerospace component manufacturing.

With its cutting-edge features and precision capabilities, the SYIL CNC Machine has become a game-changer in aerospace manufacturing. This image showcases the machine's sleek design and advanced technology at work, highlighting its ability to revolutionize the production of intricate aircraft components.

What is a CNC Aerospace Machinist?

Key Skills and Expertise Required

To excel as a CNC aerospace machinist, one must possess a strong understanding of precision machining techniques and the ability to interpret complex engineering drawings. Attention to detail, problem-solving skills, and proficiency in using CNC machines are essential. Additionally, knowledge of aerospace materials and an understanding of industry regulations are crucial for producing high-quality aircraft components.

Training and Education for Aerospace CNC Machinists

Becoming a skilled aerospace CNC machinist typically requires completing a vocational program or apprenticeship in machining or manufacturing. Many professionals also pursue advanced training in computer-aided design (CAD) and computer-aided manufacturing (CAM) software to enhance their skills. Continuous education on the latest advancements in aerospace machining technology is vital for staying competitive in the field.

Career Opportunities in Aerospace Machining

Aerospace CNC machinists have diverse career opportunities within the aviation industry, working for aircraft manufacturers, maintenance facilities, or specialized machining companies. With experience and expertise, individuals can advance to supervisory or managerial roles, leading teams of machinists to produce critical components for various aerospace applications.

The Impact of Precision Machining on Aerospace Industry

Ensuring Safety and Reliability in Aircraft Parts

Precision machining plays a crucial role in ensuring the safety and reliability of aircraft parts in the aerospace industry. CNC machining technology allows for the production of highly accurate and consistent components, which are essential for the proper functioning of critical aircraft systems. By maintaining strict tolerances and precise measurements, aerospace CNC machining helps to minimize the risk of part failure and enhances overall safety standards.

Meeting Stringent Quality Standards in Aerospace Manufacturing

The aerospace industry demands the highest quality standards, and precision machining is instrumental in meeting these requirements. CNC machine aerospace industry ensures that components are manufactured with unparalleled accuracy and adherence to strict specifications. This level of precision is essential for achieving optimal performance, durability, and reliability in aerospace applications, thereby upholding the stringent quality standards set by regulatory bodies.

Enhancing Efficiency and Productivity in Aerospace Production

Aerospace CNC machining significantly enhances efficiency and productivity in aerospace production processes. By automating complex manufacturing tasks with high precision, CNC machines enable faster production cycles while maintaining exceptional quality control. This not only streamlines operations but also reduces lead times, ultimately contributing to increased productivity within the aerospace manufacturing sector.

Aerospace CNC Machining: Ensuring Compliance and Regulation

Aerospace CNC machining plays a crucial role in ensuring compliance with regulatory standards in aircraft manufacturing. From the production of critical components to the assembly of complex structures, precision machining is essential for meeting stringent industry regulations and safety requirements. CNC machines are equipped with advanced software and tools to guarantee that every part meets the exact specifications outlined by regulatory bodies.

Meeting Regulatory Standards in Aircraft Manufacturing

In the aerospace industry, meeting regulatory standards is non-negotiable. CNC machining for aerospace must adhere to strict guidelines set forth by organizations such as the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA). These standards cover everything from material specifications to manufacturing processes, ensuring that each component meets the highest safety and quality standards.

Quality Control Measures in CNC Machining for Aerospace

Quality control measures are integral to aerospace CNC machining, as they ensure that every part produced meets the highest quality standards. From initial material inspection to final product testing, precision machining involves rigorous quality control processes at every stage of production. This meticulous attention to detail is essential for maintaining the integrity and reliability of aircraft components.

Adhering to Industry Standards for Precision Machining in Aerospace

Adhering to industry standards is paramount in aerospace CNC machining, as it guarantees that all parts are manufactured with precision and accuracy. Whether it's dimensional tolerances or surface finish requirements, precision machining must align with industry-specific standards to ensure consistency and reliability across all aerospace components. By adhering to these standards, manufacturers can uphold the highest levels of quality in their products.

Future Trends in Aerospace CNC Machining

Integration of AI and Automation in Aerospace Manufacturing

The integration of artificial intelligence (AI) and automation in aerospace manufacturing is revolutionizing the industry. With AI-powered CNC machines, aerospace manufacturers can optimize production processes, reduce errors, and improve efficiency. Automation also allows for continuous operation, leading to increased productivity and cost savings in precision machining for aerospace.

The use of AI and automation in aerospace manufacturing not only improves efficiency but also contributes to sustainable practices. By optimizing production processes, manufacturers can reduce waste and minimize the environmental impact of machining operations. Additionally, automation allows for precise control over resource usage, leading to a more sustainable approach to aerospace machining. This integration of technology is not only revolutionizing the industry but also promoting environmental responsibility in manufacturing.

Sustainable Practices in Aerospace Machining

As sustainability becomes a top priority across industries, aerospace CNC machining is no exception. Manufacturers are implementing sustainable practices such as recycling coolant fluids, reducing energy consumption, and minimizing waste in precision machining for aerospace. Sustainable materials and processes are being adopted to minimize environmental impact while maintaining high-quality standards. In addition to these efforts, aerospace machining is also seeing advancements in the development of biodegradable cutting fluids and lubricants. These environmentally friendly alternatives not only reduce the carbon footprint of machining operations but also contribute to a healthier work environment for operators.

Innovations in Materials and Tooling for Aerospace Machining

Innovations in materials and tooling are driving advancements in aerospace CNC machining. High-performance materials like titanium alloys and composites are being developed to enhance the strength-to-weight ratio of aircraft components. Advanced cutting tools with longer tool life and improved wear resistance are also being introduced to meet the demands of precision machining for aerospace.

By incorporating these future trends into aerospace CNC machining, the industry is poised to achieve greater efficiency, sustainability, and performance while meeting the stringent quality standards required for aircraft manufacturing. Embracing these advancements will drive innovation and propel the aerospace industry into a new era of precision machining excellence.

Conclusion

In conclusion, the future of aerospace CNC machining is bright, with technology and innovation driving the industry forward. The precision machining for aerospace is evolving rapidly, and the role of CNC machinists in aerospace is more crucial than ever. As the demand for high-quality aircraft parts continues to grow, SYIL CNC Machine is at the forefront of empowering the aerospace industry with cutting-edge technology.

Embracing the Future of Aerospace CNC Machining

Embracing the future of aerospace CNC machining means being open to the potential for 3D printing to revolutionize the industry. Additive manufacturing offers the ability to create complex and lightweight components that were previously impossible with traditional machining methods. By embracing this technology, aerospace manufacturers can reduce material waste and production time while also increasing design flexibility and part performance.

Driving Innovation in Precision Machining for Aerospace

The driving force behind innovation in precision machining for aerospace is the need for safety, reliability, and efficiency. As aircraft designs become more complex, so do the requirements for precision-machined parts. The ongoing advancements in materials and tooling are driving innovation in aerospace CNC machining, ensuring that manufacturers can meet stringent quality standards while enhancing productivity.

The demand for precision machining in aerospace has also been fueled by the need for lightweight yet durable components. With the push for fuel efficiency and reduced emissions, manufacturers are constantly seeking ways to make aircraft lighter without compromising safety and reliability. This has led to the development of innovative machining techniques and processes that can produce intricate parts with minimal material waste, contributing to the overall sustainability of aerospace manufacturing.

SYIL CNC Machine: Empowering the Aerospace Industry

SYIL CNC Machine's impact on the aerospace industry cannot be overstated. With its revolutionary technology and commitment to quality, it has become a game-changer in precision machining for aerospace. By providing cutting-edge solutions that meet regulatory standards and industry requirements, SYIL CNC Machine is empowering manufacturers to produce high-quality aircraft parts efficiently and reliably. Furthermore, the company's dedication to research and development ensures that it stays ahead of the curve, constantly adapting to new challenges and opportunities in the aerospace sector. As a result, SYIL CNC Machine continues to set the standard for excellence in CNC machining for aerospace applications.