Introduction

CNC machining has become an integral part of the aircraft industry, revolutionizing the way aerospace components are manufactured. From precision to efficiency, CNC machining plays a crucial role in ensuring the safety and performance of aircraft. One company at the forefront of this innovation is SYIL CNC Machine, which is transforming aircraft manufacturing with its cutting-edge technology.

Understanding CNC Machining in Aircraft Industry

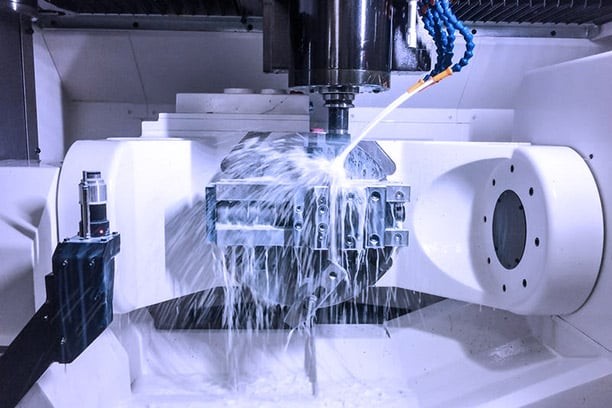

CNC machining in the aircraft industry involves using computer-controlled machines to precisely shape and cut aerospace materials such as aluminum, titanium, and composites. This advanced manufacturing process allows for the creation of complex and intricate components that are vital for aircraft performance and safety.

Importance of CNC Machining in Aerospace

The importance of CNC machining in aerospace cannot be overstated. It enables the production of high-precision parts with tight tolerances, ensuring that every component meets stringent quality standards. This level of accuracy is crucial for maintaining the structural integrity and aerodynamic efficiency of aircraft.

SYIL CNC Machine: Revolutionizing Aircraft Manufacturing

SYIL CNC Machine has been a game-changer in the aerospace industry by providing state-of-the-art CNC machines that streamline and optimize aircraft production processes. With their innovative technology and commitment to excellence, SYIL is leading the way in advancing aerospace manufacturing capabilities.

What is CNC Machining in Aircraft?

CNC machining in aircraft refers to the use of computer numerical control (CNC) technology to manufacture precise and complex components for aircraft. This advanced manufacturing process allows for the production of high-quality parts with tight tolerances, essential for the safety and performance of aerospace vehicles.

Role of CNC Machining in Aircraft Manufacturing

The role of CNC machining in aircraft manufacturing is crucial, as it enables the production of intricate components such as engine parts, landing gear, and structural elements with exceptional accuracy and consistency. This precision is essential for ensuring the reliability and safety of aircraft, making CNC machining a cornerstone of aerospace manufacturing.

CNC machining also allows for the production of complex and unique components that would be difficult or impossible to manufacture using traditional methods. This capability gives aircraft designers the freedom to create innovative and efficient designs, pushing the boundaries of what is possible in aerospace engineering. By utilizing CNC machining, manufacturers can bring these cutting-edge designs to life, contributing to advancements in aircraft performance and efficiency.

Advantages of CNC Machining for Aerospace Components

The advantages of CNC machining for aerospace components are numerous. This technology allows for the efficient production of complex geometries, reduces material waste, and ensures superior surface finishes. Additionally, CNC machining enables rapid prototyping and flexible production processes, making it an ideal choice for the dynamic needs of the aerospace industry.

Furthermore, CNC machining offers high precision and repeatability, ensuring that aerospace components meet strict industry standards. This level of accuracy is essential for the safety and reliability of aircraft, making CNC machining a crucial technology for the aerospace sector. In addition, the automation of CNC machines reduces the risk of human error, resulting in consistently high-quality parts that are essential for the demanding requirements of aerospace applications.

SYIL CNC Machine: Enhancing Aircraft Production

The SYIL CNC machine has revolutionized aircraft production by offering state-of-the-art precision, speed, and versatility. With its advanced capabilities and user-friendly interface, SYIL's CNC machines have become indispensable tools in aerospace machine shops worldwide. By enhancing efficiency and quality in aircraft component manufacturing, SYIL's technology has elevated the standards of aerospace engineering.

Furthermore, SYIL's CNC machines have significantly reduced production time and costs by streamlining the manufacturing process. This has allowed aerospace companies to meet tight deadlines and produce high-quality components with minimal waste. The ability to program complex designs with precision has also enabled manufacturers to push the boundaries of innovation in aircraft construction, leading to advancements in aerodynamics and fuel efficiency.

What is a CNC Aerospace Machinist?

Skills and Expertise Required for CNC Machining in Aerospace

To excel as a CNC aerospace machinist, one needs to possess strong technical skills, attention to detail, and the ability to interpret complex blueprints and schematics. Expertise in operating CNC machines, understanding aerospace materials, and knowledge of precision measurement tools are also essential for this role.

The Role of CNC Aerospace Machinists in Aircraft Production

CNC aerospace machinists play a crucial role in aircraft production by programming, setting up, and operating CNC machines to fabricate precision components for aerospace applications. They are responsible for ensuring that the manufactured parts meet strict industry standards and specifications, contributing to the overall safety and performance of aircraft.

Career Opportunities for CNC Aerospace Machinists

With the growing demand for aircraft components, there are abundant career opportunities for CNC aerospace machinists in aerospace machine shops, manufacturing facilities, and aviation companies. As technology continues to advance in the aerospace sector, the need for skilled machinists who can adapt to new machining techniques and equipment is on the rise.

What is ATC in CNC Machining?

Automatic Tool Changer (ATC) in CNC Machining for Aerospace is a crucial feature that allows for seamless tool changes during the machining process. This technology enables the machine to automatically swap out tools, reducing downtime and increasing efficiency in aircraft component manufacturing.

Automatic Tool Changer (ATC) in CNC Machining for Aerospace

The ATC system in CNC machining for aerospace is designed to hold multiple cutting tools, allowing for quick and precise tool changes without manual intervention. This feature is essential for producing complex aerospace components with varying geometries and material requirements, ensuring consistent quality and accuracy in aircraft production.

Benefits of ATC in Aircraft Component Manufacturing

The benefits of ATC in aircraft component manufacturing are numerous, including reduced setup time, increased productivity, and enhanced flexibility in machining operations. With the ability to automatically switch tools based on programmed instructions, CNC machines equipped with ATC significantly improve overall efficiency and cost-effectiveness in aerospace manufacturing.

SYIL CNC Machine: Optimizing ATC for Aerospace Applications

SYIL CNC Machine has revolutionized the aerospace industry by optimizing ATC technology for aerospace applications. With advanced tool-changing capabilities and precision engineering, SYIL's CNC machines ensure seamless production of high-quality aircraft components while maximizing operational efficiency.

What is the Difference Between CNC and VMC?

CNC machining in the aircraft industry refers to the use of computer numerical control (CNC) machines to create aerospace components, while vertical machining centers (VMC) are a type of CNC machine commonly used in aircraft manufacturing. The main difference lies in their structure and capabilities, with VMCs typically being more compact and versatile for various machining operations.

Understanding CNC Machining vs. Vertical Machining Centers (VMC) in Aircraft Industry

CNC machining in aircraft involves using computer-controlled machines to precisely cut, shape, and form aerospace components based on digital designs. On the other hand, VMCs are a specific type of CNC machine that operates vertically with a spindle mounted on a column, allowing for greater flexibility and accuracy in producing complex aircraft parts.

Applications and Limitations of CNC and VMC in Aerospace Manufacturing

The applications of CNC machining for aerospace are vast, as it enables the production of intricate parts with high precision and repeatability. VMCs offer similar benefits but may have limitations in terms of size and capacity compared to other types of CNC machines used in the aerospace sector.

Choosing the Right Machining Technology for Aircraft Production

When selecting machining technology for aircraft production, it's essential to consider factors such as part complexity, material requirements, production volume, and cost-effectiveness. While both CNC and VMC have their advantages, choosing the right technology depends on specific manufacturing needs within an aerospace machine shop.

CNC Machining in the Aerospace Sector

Evolution of CNC Machining in Aerospace Industry

CNC machining has played a pivotal role in revolutionizing the aerospace industry, offering precise and efficient manufacturing solutions for aircraft components. Over the years, advancements in technology have led to the development of sophisticated CNC machines tailored to meet the specific needs of aerospace manufacturers. One notable trend in aerospace machining is the integration of additive manufacturing techniques, which allows for the production of complex geometries and lightweight structures that were previously unattainable through traditional machining methods. This innovation has significantly contributed to the design and production of advanced aerospace components, leading to improved performance and fuel efficiency in modern aircraft.

Current Trends and Innovations in Aerospace Machining

The aerospace machining sector is witnessing a surge in technological advancements, with a focus on automation, digitalization, and additive manufacturing. This has led to the emergence of state-of-the-art CNC machines equipped with advanced features such as real-time monitoring, predictive maintenance, and adaptive control systems to enhance productivity and quality in aircraft component production.

SYIL CNC Machine: Pioneering CNC Machining Solutions for Aerospace

SYIL CNC Machine has been at the forefront of driving innovation in aerospace machining by offering cutting-edge solutions that cater to the unique demands of aircraft manufacturing. With a focus on precision, reliability, and efficiency, SYIL's range of CNC machines are designed to optimize production processes and elevate the standards of quality in aerospace component manufacturing.

SYIL CNC Machine's commitment to innovation is evident in its continuous research and development efforts, resulting in the introduction of advanced features and capabilities in its CNC machines. This dedication to staying ahead of industry trends ensures that aerospace manufacturers have access to the latest technology, enabling them to produce components with unparalleled precision and efficiency. By embracing cutting-edge solutions from SYIL, aerospace companies can maintain a competitive edge in a rapidly evolving market.

Conclusion

The future of CNC machining in aircraft manufacturing is incredibly promising, with the industry continually evolving and embracing innovative technologies. As the demand for precision and efficiency in aerospace components grows, the implementation of SYIL CNC machines will undoubtedly lead to advancements in aircraft production.

Future of CNC Machining in Aircraft Manufacturing

The future of CNC machining in aircraft manufacturing is set to revolutionize the aerospace industry, with advancements in technology and automation leading to increased productivity and precision. As the demand for complex and high-quality aerospace components continues to rise, CNC machining will play a pivotal role in meeting these requirements.

With the increasing complexity of aerospace components, the need for advanced CNC machining capabilities is more crucial than ever. SYIL CNC machines offer the precision and flexibility required to produce intricate parts with tight tolerances, ensuring that aircraft meet stringent safety and performance standards. By leveraging the latest advancements in CNC technology, aerospace manufacturers can streamline their production processes and reduce lead times, ultimately enhancing their competitive edge in the market.

Implementing SYIL CNC Machine for Aerospace Advancements

Implementing SYIL CNC machines for aerospace advancements will result in significant improvements in aircraft manufacturing processes. With its cutting-edge technology and advanced capabilities, SYIL CNC machines are poised to enhance efficiency, accuracy, and overall productivity within aerospace machine shops.

SYIL CNC machines offer unparalleled precision and repeatability, ensuring that aerospace components are manufactured to the highest standards. This level of accuracy is crucial in the aerospace industry, where the slightest deviation can have significant consequences. By implementing SYIL CNC machines, aerospace manufacturers can confidently produce complex parts with tight tolerances, leading to safer and more reliable aircraft.

Embracing CNC Machining for Aerospace Innovation

Embracing CNC machining for aerospace innovation is crucial for staying ahead in a highly competitive industry. By leveraging the capabilities of CNC technology, aerospace manufacturers can drive innovation, improve component quality, and streamline production processes to meet the evolving demands of the aerospace sector.

By embracing CNC machining, aerospace manufacturers can also enhance their ability to produce complex and intricate components with precision and accuracy. This level of precision is essential for meeting the strict safety and quality standards of the aerospace industry. Furthermore, CNC technology allows for greater flexibility in design iterations, enabling manufacturers to quickly adapt to changing customer requirements and market trends.