Introduction

In the world of precision engineering, aerospace CNC machining plays a crucial role in producing high-quality components for aircraft and spacecraft. This advanced manufacturing process involves the use of computer numerical control (CNC) machines to create intricate parts with unparalleled accuracy and consistency. The aerospace industry heavily relies on CNC machining to meet the stringent demands of modern aviation, making it a cornerstone of aircraft manufacturing. With the introduction of SYIL CNC Machine, the aerospace sector has witnessed significant improvements in efficiency, productivity, and overall quality.

Understanding Precision Aerospace CNC Machining

Precision aerospace CNC machining refers to the specialized process of using computer-controlled machines to fabricate complex components for use in aircraft and space vehicles. This method allows for precise cutting, shaping, and finishing of materials such as aluminum, titanium, and composites to exact specifications required for aerospace applications.

Importance of Aerospace CNC Machining

Aerospace CNC machining is vital for ensuring the structural integrity and performance of aircraft components. From engine parts to airframe components, every aspect of an aircraft relies on precision machining to meet strict safety standards and operational requirements. With SYIL CNC machines, aerospace manufacturers can benefit from advanced technology that allows for complex and intricate designs to be executed with utmost precision, resulting in superior quality and reliability. Additionally, SYIL CNC machines offer high-speed machining capabilities, allowing for faster production times without compromising on accuracy or quality. This means that aerospace companies can meet tight deadlines and keep up with the demands of the industry while maintaining the highest standards of excellence in their products.

Advantages of SYIL CNC Machine in Aerospace Sector

The SYIL CNC Machine has revolutionized aerospace manufacturing by offering unmatched precision, speed, and versatility in producing critical aerospace components. Its advanced capabilities have significantly reduced production time while maintaining exceptional quality standards in the aerospace sector.

Furthermore, the SYIL CNC Machine's ability to work with a wide range of materials, including aluminum, titanium, and composites, makes it an ideal choice for aerospace manufacturing. This versatility allows for greater flexibility in design and production, leading to more innovative and efficient aerospace components. Additionally, the machine's precise control and accuracy ensure that complex geometries and intricate details can be achieved with ease, meeting the stringent requirements of the aerospace industry.

What is Aerospace CNC Machining?

Aerospace CNC machining refers to the process of using computer numerical control (CNC) machines to manufacture precision components for the aerospace industry. This involves the use of advanced machinery and software to produce complex parts with tight tolerances required for aircraft and spacecraft.

Definition of Aerospace CNC Machining

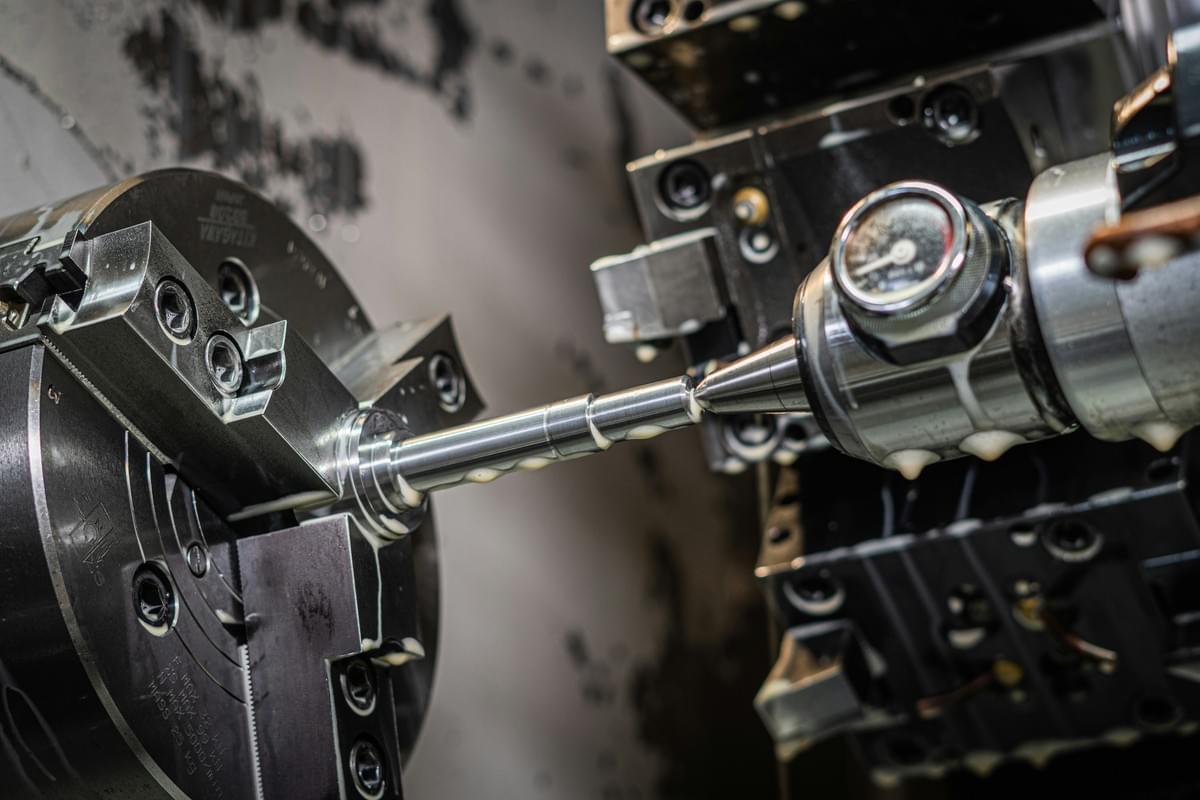

Aerospace CNC machining involves the use of CNC machines to fabricate components such as engine parts, landing gear, and structural elements for aircraft and spacecraft. These machines are programmed to follow precise instructions, allowing for high accuracy and repeatability in the manufacturing process.

Application in Aircraft Manufacturing

In aircraft manufacturing, aerospace CNC machining is crucial for producing lightweight yet durable components that meet stringent safety and performance standards. From fuselage parts to avionics enclosures, CNC machines play a vital role in creating the intricate pieces needed for modern aircraft.

Role of SYIL CNC Machine in Aerospace Industry

The SYIL CNC machine has revolutionized aerospace manufacturing by offering high precision, reliability, and efficiency. Its advanced capabilities make it well-suited for producing complex aerospace components, contributing to improved safety and performance in the aviation sector.

With its state-of-the-art technology and superior performance, the SYIL CNC machine has become a game changer in the aerospace industry. As manufacturers continue to push boundaries in aerospace engineering, this innovative machine provides the necessary tools to meet evolving demands while maintaining uncompromising quality standards.

The Aerospace Machining Process

Aerospace CNC machining is a complex and precise process that involves several steps to ensure the production of high-quality aerospace components. From initial design to final inspection, the aerospace machining process requires meticulous attention to detail and adherence to strict industry standards.

Steps Involved in Aerospace CNC Machining

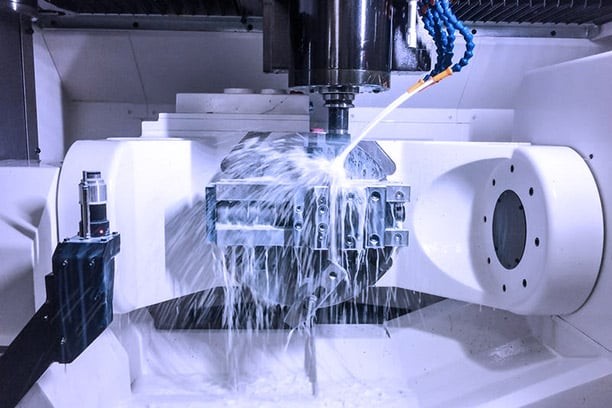

The aerospace machining process begins with the design phase, where engineers use CAD software to create detailed blueprints of the parts to be manufactured. Once the designs are finalized, they are translated into machine code using CAM software, which guides the CNC machine in cutting and shaping raw materials such as aluminum, titanium, or composites. After machining, the parts undergo rigorous inspection and testing to ensure they meet strict aerospace quality standards.

High Precision Requirements in Aerospace Sector

Aerospace CNC machining demands unparalleled precision due to the critical nature of aircraft components. Even minor deviations from specifications can have catastrophic consequences, making precision a non-negotiable requirement in this sector. The use of advanced CNC machines like those offered by SYIL ensures that parts are manufactured with extreme accuracy and consistency.

Quality Control in Aerospace CNC Machining

Quality control is paramount in aerospace CNC machining to guarantee the integrity and reliability of aircraft components. Every step of the manufacturing process is closely monitored and inspected for dimensional accuracy, surface finish, and material integrity. This stringent quality control ensures that only parts meeting exacting standards make their way into critical aerospace applications.

With a comprehensive understanding of what aerospace CNC machining entails, it's evident that precision is key at every stage - from design to final inspection - ensuring that only top-quality components make their way into aircraft manufacturing processes.

Roles in Aerospace CNC Machining

Aerospace CNC machining requires skilled professionals to operate the machinery and ensure precision in the manufacturing process. The role of an aerospace machinist involves programming, setting up, and operating CNC machines to produce complex aerospace components with tight tolerances. They play a crucial role in ensuring that the final products meet the high standards required for use in aircraft and spacecraft.

The Role of Aerospace Machinist

An aerospace machinist is responsible for interpreting engineering drawings, programming CNC machines, and selecting the appropriate cutting tools and materials for each aerospace component. They must possess a deep understanding of machining processes, materials, and quality control standards to produce parts that meet the stringent requirements of the aerospace industry. With attention to detail and precision, they play a vital role in ensuring the safety and performance of aerospace vehicles.

Importance of Skilled Operators in Aerospace CNC Machining

Skilled operators are essential in aerospace CNC machining as they are responsible for setting up the machines, monitoring the production process, and making any necessary adjustments to ensure accuracy and quality. Their expertise is crucial in achieving the high precision required for aerospace components while minimizing waste and maximizing efficiency. Skilled operators also contribute to problem-solving during production, making them invaluable assets in this specialized field.

Career Opportunities in Aerospace CNC Machining

The demand for skilled professionals in aerospace CNC machining continues to grow as advancements in technology drive innovation within the industry. Aspiring individuals can pursue careers as aerospace machinists, CNC machine operators, quality control technicians, or manufacturing engineers within companies specializing in aircraft manufacturing or space exploration. With opportunities for career growth and development, a career in aerospace CNC machining offers a promising future for those with a passion for precision engineering.

Technologies in Aerospace Machining

Innovation in Aerospace CNC Machinery has revolutionized the aerospace sector, with cutting-edge equipment designed to meet the high precision requirements of aircraft manufacturing. SYIL CNC machines, for instance, are equipped with advanced technology to ensure accuracy and efficiency in producing aerospace components.

Innovation in Aerospace CNC Machinery

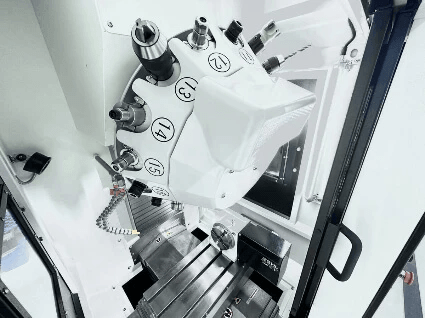

The latest innovation in aerospace CNC machinery includes the use of multi-axis machining centers and advanced tooling systems to achieve intricate shapes and tight tolerances required for aerospace parts. SYIL's state-of-the-art CNC machines are engineered with high-speed spindles and rigid structures to deliver exceptional performance in aerospace machining processes.

Integration of Automation in Aerospace CNC Machining

Automation has significantly transformed aerospace CNC machining by enhancing productivity and reducing lead times. SYIL's CNC machines are integrated with automation features such as robotic loading/unloading systems, tool changers, and real-time monitoring capabilities for seamless operation and improved efficiency in the production of aerospace components.

Advancements in Aerospace CNC Software

Advancements in aerospace CNC software have played a crucial role in optimizing machining processes and ensuring accurate programming for complex parts. SYIL's CNC machines are compatible with advanced CAM software that enables efficient toolpath generation, simulation, and optimization for precise machining operations within the aerospace industry.

Challenges in Aerospace CNC Machining

Aerospace CNC machining presents several challenges, including tight tolerances in aerospace parts. The precision required for aerospace components is extremely high, with minimal margin for error. This necessitates advanced CNC machinery and skilled operators to ensure the accuracy of the final product.

Tight Tolerances in Aerospace Parts

Achieving tight tolerances in aerospace parts is crucial for ensuring the safety and performance of aircraft. The intricate nature of aerospace components demands precise machining processes to meet the strict requirements set by aviation authorities. This calls for cutting-edge CNC technology and meticulous attention to detail from machinists to deliver high-quality results.

Material Selection for Aerospace Components

Another challenge in aerospace CNC machining lies in the selection of materials for manufacturing components. Aerospace-grade materials need to possess specific characteristics such as lightweight yet durable properties, resistance to high temperatures, and exceptional strength-to-weight ratios. Machinists must have a deep understanding of material science and advanced CNC equipment capable of handling these specialized materials.

Compliance with Aerospace Regulations

Compliance with stringent aerospace regulations is a critical challenge faced by manufacturers engaged in aerospace CNC machining. Adhering to industry standards and regulations is non-negotiable, as any deviation can compromise the safety and reliability of aircraft components. Machinists must stay updated on evolving regulations and ensure that their processes align with the latest requirements.

With these challenges at hand, it's evident that aerospace CNC machining demands expertise, cutting-edge technology, and unwavering commitment to quality and safety standards. Overcoming these obstacles requires a holistic approach that integrates advanced machinery, skilled professionals, and a thorough understanding of regulatory frameworks within the aerospace industry.

Remember that when it comes to creating content about topics like this one, it's important to maintain an engaging tone while providing valuable information that resonates with your audience!

Conclusion

When it comes to the future of aerospace CNC machining, the possibilities are endless. With the rapid advancements in technology, we can expect to see even greater precision, efficiency, and innovation in this field. SYIL CNC Machine has proven to be a game changer in the aerospace industry, offering unmatched quality and performance for aerospace machining needs. As for the evolving role of aerospace CNC machinists, we can anticipate a shift towards more specialized skills and a greater emphasis on technological expertise.

Future of Aerospace CNC Machining

The future of aerospace CNC machining is bright, with continuous improvements in precision and efficiency. As technology continues to evolve, we can expect to see even more sophisticated machinery that can meet the stringent demands of the aerospace sector. This will ultimately lead to enhanced safety and performance in aircraft manufacturing processes.

With the increasing demand for lightweight and durable materials in aerospace manufacturing, CNC machining is expected to play a crucial role in meeting these requirements. Advanced CNC machines can handle a wide range of materials, including titanium and composites, with high precision and efficiency. This capability will enable aerospace manufacturers to produce lighter and stronger components, contributing to improved fuel efficiency and overall performance of aircraft.

SYIL CNC Machine: A Game Changer in Aerospace Industry

The SYIL CNC Machine has revolutionized aerospace CNC machining with its cutting-edge technology and superior capabilities. Its ability to deliver high precision and reliability makes it a valuable asset in the aerospace industry. With its advanced features and user-friendly interface, it has set a new standard for excellence in aerospace machining.

Evolving Role of Aerospace CNC Machinist

As technology continues to advance, the role of an aerospace CNC machinist is also evolving. With an increasing focus on automation and digitalization, machinists will need to adapt to new technologies and develop specialized skills to operate advanced machinery effectively. The future will bring about a shift towards more complex tasks that require a deep understanding of cutting-edge equipment.

Remember that success lies not just in meeting current demands but also anticipating future needs – especially when it comes to precision engineering solutions like those provided by SYIL's innovative machines!