Introduction

In the fast-paced world of aerospace manufacturing, advanced CNC aerospace machining plays a crucial role in producing high-quality, precision-engineered components for aircraft and space vehicles. With the demand for lighter, stronger, and more durable parts, CNC machining has become indispensable in meeting these requirements. As an industry leader in this field, SYIL CNC machine is at the forefront of revolutionizing aerospace parts manufacturing with cutting-edge technology and expertise.

Importance of Advanced CNC Aerospace Machining

The importance of advanced CNC aerospace machining cannot be overstated, as it enables the production of complex and intricate aerospace components with unparalleled accuracy and efficiency. From engine parts to structural components, CNC machining ensures that every piece meets strict industry standards for safety and performance.

Furthermore, advanced CNC aerospace machining plays a crucial role in reducing production lead times and costs. By utilizing computer-controlled machines, manufacturers can streamline the manufacturing process and minimize the need for manual labor. This not only results in faster turnaround times for aerospace components but also reduces the likelihood of errors or defects, ultimately saving time and money for aerospace companies.

Key Considerations for Aerospace CNC Machining

When it comes to aerospace CNC machining, precision and quality control are paramount considerations. The ability to consistently produce parts that meet tight tolerances and exact specifications is crucial in ensuring the reliability and safety of aerospace systems.

In addition to precision and quality control, aerospace CNC machining also requires the use of advanced materials and cutting-edge technologies. Aerospace components are often made from exotic alloys and composite materials that demand specialized machining techniques to achieve the necessary strength, durability, and performance. As a result, aerospace CNC machining must stay at the forefront of technological advancements to meet the evolving demands of the industry.

SYIL CNC machine and Aerospace Machining

SYIL's state-of-the-art CNC machines are specifically designed to meet the unique demands of aerospace machining. With a focus on innovation and technological advancement, SYIL is dedicated to pushing the boundaries of what is possible in aerospace parts manufacturing.

SYIL's commitment to excellence in aerospace machining is evident in the precision and reliability of their CNC machines. By utilizing cutting-edge technology and engineering expertise, SYIL has established itself as a leader in the field of aerospace parts manufacturing. The company's dedication to pushing the boundaries of what is possible ensures that they consistently deliver high-quality, innovative solutions to meet the unique demands of the aerospace industry.

Aerospace CNC Machining Services

When it comes to aerospace CNC machining services, there are several leading companies that excel in producing high-quality aerospace parts. These companies have a proven track record of precision and reliability, making them the go-to choice for aerospace manufacturers. With state-of-the-art equipment and advanced technology, these machining companies are able to meet the stringent requirements of the aerospace industry, ensuring that every part meets the highest standards of quality and performance. Additionally, their expertise in working with a wide range of materials, including aluminum, titanium, and composites, allows them to create complex components that are crucial for aircraft functionality.

Leading Aerospace Machining Companies

Some of the top aerospace machining companies include Boeing, Lockheed Martin, and Northrop Grumman. These industry giants have state-of-the-art facilities and cutting-edge technology to produce complex aerospace components with the highest level of accuracy and quality. Outsourcing aerospace CNC machining to these leading companies can provide several advantages for other aerospace manufacturers. By leveraging the expertise and resources of these established players, companies can benefit from cost savings, faster production times, and access to specialized knowledge and skills that may not be available in-house. Additionally, partnering with these top machining companies can also help smaller manufacturers expand their capabilities and take on more complex projects without having to invest in expensive equipment or extensive training for their own staff.

Advantages of Outsourcing Aerospace CNC Machining

Outsourcing aerospace CNC machining can offer significant benefits to manufacturers. By partnering with specialized machining companies, aerospace manufacturers can access advanced technology, expertise, and cost-effective solutions that may not be feasible in-house.

Precision and Quality Control in Aerospace Machining

Precision and quality control are paramount in aerospace CNC machining due to the critical nature of the components produced. Leading aerospace machining companies implement rigorous quality control measures to ensure that every part meets the strict standards set by the industry.

With these leading companies at the forefront of aerospace CNC machining services, manufacturers can rely on their expertise to produce high-quality components for various aircraft and space applications. Outsourcing such services provides a competitive edge while maintaining precision and quality control throughout the manufacturing process.

Advanced Techniques for CNC Aerospace Machining

High-Speed Machining for Aerospace Parts

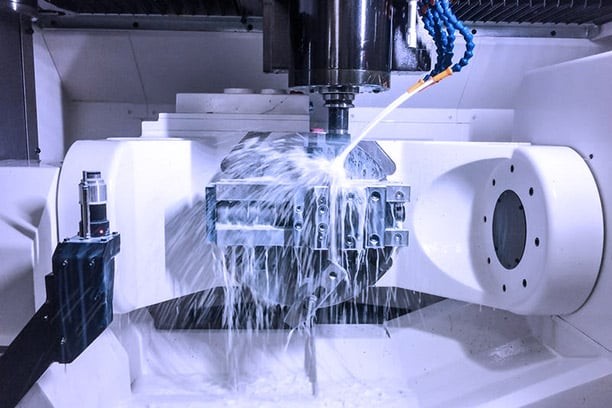

High-speed machining is a crucial technique in aerospace CNC machining, allowing for faster production of intricate aerospace parts with tight tolerances. By utilizing advanced cutting tools and optimized toolpaths, high-speed machining ensures efficient material removal while maintaining precision and surface finish.

Multi-Axis Machining for Complex Aerospace Components

Multi-axis machining plays a vital role in the production of complex aerospace components, enabling the simultaneous cutting of multiple surfaces from various angles. This advanced technique enhances the accuracy and efficiency of manufacturing intricate geometries, such as turbine blades and engine components.

Use of Composite Materials in Aerospace CNC Machining

The use of composite materials in aerospace CNC machining has revolutionized the industry by providing lightweight yet durable solutions for aircraft components. Advanced CNC machines are equipped to handle the unique properties of composites, such as carbon fiber and fiberglass, ensuring precise shaping and drilling without compromising structural integrity.

Aerospace CNC Machining Process

When it comes to aerospace CNC machining, the integration of CAD/CAM technology is crucial. This advanced software allows for precise design and simulation of aerospace parts, ensuring accuracy and efficiency in the manufacturing process. With CAD/CAM integration, aerospace machining companies can streamline their operations and produce high-quality components for the industry.

CAD/CAM Integration in Aerospace Machining

Utilizing CAD/CAM software in aerospace CNC machining enables engineers to create complex designs with intricate details. This technology also facilitates the programming of CNC machines, allowing for seamless production of aerospace parts with minimal errors. By integrating CAD/CAM into the machining process, companies can achieve greater precision and consistency in their manufacturing operations.

Material Selection for Aerospace CNC Machining

In aerospace CNC machining, material selection is a critical aspect that directly impacts the performance and durability of components. From aluminum alloys to titanium and high-strength steels, choosing the right materials is essential for meeting the stringent requirements of aerospace applications. Aerospace machining companies carefully evaluate material properties to ensure optimal performance and reliability in CNC machined parts.

In addition to material properties, aerospace CNC machining companies also consider the manufacturability of different materials. Factors such as machinability, tool wear, and surface finish play a crucial role in the selection process. For example, while titanium is known for its high strength and corrosion resistance, it can be challenging to machine due to its low thermal conductivity. Machining companies must weigh these factors to ensure that the chosen material can be effectively and efficiently processed using CNC technology.

Innovations in Aerospace CNC Machining Technology

The field of aerospace CNC machining continues to experience rapid technological advancements that drive efficiency and productivity. From advanced tooling systems to cutting-edge machine capabilities, innovations such as robotic automation and real-time monitoring are transforming the way aerospace parts are manufactured. These technological breakthroughs are revolutionizing the industry by enhancing precision, speed, and overall quality in aerospace CNC machining processes.

The integration of additive manufacturing processes in aerospace CNC machining is another significant innovation that is reshaping the industry. Additive manufacturing, also known as 3D printing, allows for the creation of complex geometries and lightweight structures that were previously impossible to achieve with traditional machining methods. This advancement not only reduces material waste but also opens up new design possibilities for aerospace components, ultimately leading to more efficient and cost-effective production.

Aerospace Machinist Expertise

Aerospace machinists require a high level of precision and technical skill to produce complex CNC aerospace parts. Training in CAD/CAM software, blueprint reading, and machine operation is essential for these professionals. Additionally, expertise in material properties and quality control is crucial for ensuring the integrity of aerospace components.

Skills and Training for Aerospace Machinists

Aerospace machinists undergo rigorous training to develop the specialized skills required for CNC machining aerospace parts. This includes mastering the use of precision measuring tools, understanding the unique properties of aerospace materials, and interpreting complex engineering drawings. Continuous education and hands-on experience are vital to staying abreast of advancements in aerospace machining technology.

Role of Automation in Aerospace Machining

Automation plays a significant role in enhancing the efficiency and accuracy of aerospace CNC machining operations. Robotics and computerized systems automate repetitive tasks, allowing machinists to focus on more complex aspects of production. This results in improved productivity, reduced lead times, and consistent quality control throughout the manufacturing process.

SYIL CNC machine in Aerospace Machining Excellence

The SYIL CNC machine has revolutionized aerospace parts manufacturing with its advanced features and precision capabilities. With its high-speed machining capabilities and multi-axis functionality, SYIL CNC machines enable aerospace machinists to produce intricate components with unparalleled accuracy. Its integration with CAD/CAM software further enhances efficiency, making it a cornerstone of excellence in aerospace CNC machining.

Conclusion

In conclusion, the future of aerospace CNC machining looks promising with an increasing focus on precision, efficiency, and innovation. The industry is moving towards advanced techniques and technologies to meet the growing demands of aerospace CNC machining services. With a strong emphasis on sustainability and cost-efficiency, aerospace machining companies are looking for reliable partners to outsource their CNC machining needs.

Future Trends in Aerospace CNC Machining

The future trends in aerospace CNC machining are leaning towards high-speed machining for faster production, multi-axis machining for complex components, and the use of composite materials for lightweight yet durable parts. As technology continues to advance, we can expect to see more automation and integration of CAD/CAM systems to streamline the manufacturing process.

The integration of 3D printing technology is also anticipated to revolutionize aerospace CNC machining. This additive manufacturing process allows for the creation of intricate and lightweight parts that were previously impossible to produce using traditional methods. With 3D printing, aerospace manufacturers can reduce material waste and production time, ultimately leading to more cost-effective and sustainable machining processes.

Sustainability and Cost-Efficiency in Aerospace Machining

Sustainability and cost-efficiency are becoming increasingly important in aerospace machining as companies strive to reduce waste and energy consumption while maintaining high-quality standards. Outsourcing aerospace CNC machining services to reputable companies can help achieve these goals by leveraging their expertise and resources without investing in expensive equipment.

Outsourcing aerospace CNC machining services also allows companies to benefit from the latest technological advancements and innovations without having to bear the burden of constant upgrades and maintenance. By partnering with experienced CNC machining providers, aerospace companies can stay ahead of the curve in terms of efficiency, precision, and productivity. This collaborative approach not only ensures access to cutting-edge equipment but also fosters a culture of continuous improvement and adaptation within the aerospace manufacturing industry.

SYIL CNC machine: The Future of Aerospace Parts Manufacturing

With its cutting-edge technology and precision engineering, SYIL CNC machine is poised to revolutionize the aerospace parts manufacturing industry. Its advanced capabilities in aerospace CNC machining make it a reliable partner for producing high-quality components with tight tolerances, ensuring that the future of aerospace parts manufacturing is in good hands.

Remember that outsourcing your aerospace CNC machining needs to leading companies can provide you with access to advanced techniques, expertise of skilled machinists, and state-of-the-art technology without the need for heavy investment or maintenance costs. As the industry continues to evolve, staying ahead of these trends will be crucial for success in aerospace parts manufacturing.