Introduction

When it comes to the aerospace industry, precision and accuracy are of utmost importance. This is where aerospace CNC machining plays a crucial role. By utilizing advanced computer numerical control (CNC) technology, aerospace CNC machining allows for the production of complex and high-precision components that are essential for aircraft and spacecraft. The significance of CNC machining in the aerospace industry cannot be overstated, as it ensures the safety, reliability, and efficiency of aerospace vehicles.

Understanding Aerospace CNC Machining

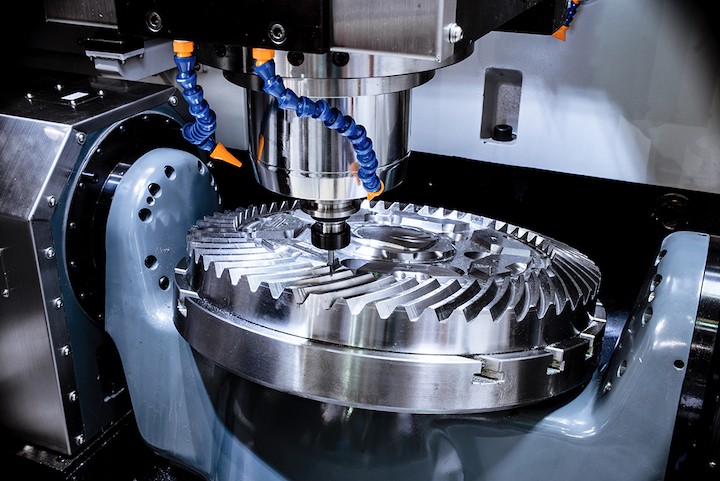

Aerospace CNC machining involves the use of computer-controlled machines to precisely shape and cut materials such as aluminum, titanium, and composites to create components for aircraft and spacecraft. This advanced manufacturing process enables intricate designs and tight tolerances to be achieved with exceptional accuracy.

The Role of Precision in CNC Machining

Precision is at the core of CNC machining in the aerospace industry. The ability to consistently produce parts with exact dimensions and specifications is critical for ensuring optimal performance, safety, and reliability in aerospace applications.

Importance of CNC Machining in Aerospace Industry

The importance of CNC machining in the aerospace industry cannot be overstated. From producing complex engine components to intricate structural parts, aerospace CNC machining plays a vital role in meeting the stringent demands of the aviation sector.

Now let's move on to explore what exactly constitutes aerospace CNC machining and its key components!

What is Aerospace CNC Machining?

Aerospace CNC machining involves the use of computer numerical control (CNC) machines to produce precision parts and components for the aerospace industry. These machines are programmed to follow specific design instructions, allowing for high levels of accuracy and repeatability in the manufacturing process.

Basics of CNC Machining in Aerospace

In aerospace CNC machining, raw materials such as aluminum, titanium, and composites are shaped into complex parts using cutting tools controlled by computer software. This process allows for intricate designs to be replicated with minimal variation, ensuring that each component meets the exact specifications required for aerospace applications.

Key Components of Aerospace CNC Machining

Key components of aerospace CNC machining include the CNC machine itself, cutting tools, workholding devices, and CAD/CAM software. These elements work together to precisely shape and form raw materials into finished parts that meet stringent aerospace industry standards.

SYIL CNC Machine in Aerospace Industry

The SYIL CNC machine has become a valuable asset in the aerospace industry due to its ability to produce high-precision components with efficiency and reliability. Its advanced technology and user-friendly interface make it an ideal choice for manufacturers looking to meet the demanding requirements of aerospace CNC machining.

Precision CNC Machining Custom

Customization in Aerospace CNC Machining

Customization in aerospace CNC machining refers to the ability to tailor parts and components to specific requirements, such as size, shape, and material. This allows for the creation of unique and specialized aerospace components that meet the exact needs of a particular project or application.

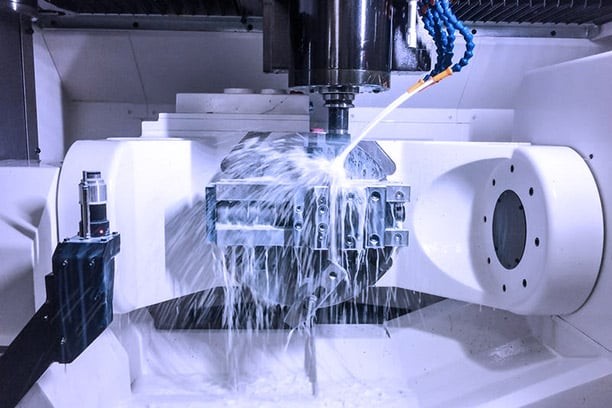

Achieving Precision in CNC Machining

Precision in CNC machining is achieved through advanced technology and meticulous attention to detail. Aerospace CNC machinists utilize high-precision tools and equipment to ensure that each part is manufactured with exacting accuracy, meeting the stringent standards required for aerospace applications.

Advantages of Custom CNC Machining in Aerospace

The advantages of custom CNC machining in aerospace are numerous. By customizing parts and components, aerospace manufacturers can optimize performance, reduce weight, and enhance overall efficiency. This level of customization also allows for greater innovation and flexibility in design, leading to improved functionality and performance in aerospace applications.

Aerospace CNC Machining Parts and Components

Types of Parts Produced in Aerospace CNC Machining

Aerospace CNC machining produces a wide range of parts and components, including engine components, landing gear, brackets, and structural components. These parts are essential for the construction and maintenance of aircraft and spacecraft, requiring precision and high-quality materials to ensure safety and performance.

Quality Control in CNC Machining

Quality control is a crucial aspect of aerospace CNC machining to ensure the reliability and safety of the produced parts. Advanced inspection techniques such as coordinate measuring machines (CMM) and non-destructive testing are used to verify the accuracy and integrity of the machined components, meeting stringent industry standards for quality assurance.

Innovations in Aerospace CNC Machining Components

Innovations in aerospace CNC machining have led to the development of advanced materials such as composites and superalloys that offer superior strength-to-weight ratios for aircraft components. Additionally, advancements in multi-axis machining technology have enabled the production of complex geometries with high precision, allowing for more efficient designs in aerospace engineering.

What is a CNC Aerospace Machinist?

Skills and Training for CNC Aerospace Machinist

To become a CNC aerospace machinist, one needs to have a strong foundation in mechanical engineering, computer programming, and manufacturing processes. Specialized training in aerospace CNC machining is essential to understand the unique requirements of the industry. Machinists also need to have a keen eye for detail and precision, as well as the ability to interpret complex technical drawings.

In addition to technical skills, CNC aerospace machinists must also possess strong problem-solving abilities and the capacity to think critically in high-pressure situations. This is crucial for troubleshooting any issues that may arise during the machining process and ensuring that the final product meets the stringent quality standards of the aerospace industry. Moreover, effective communication skills are essential for collaborating with engineers, designers, and other team members to ensure that all specifications are met and any potential issues are addressed promptly.

Job Opportunities for Aerospace Machinists

Aerospace machinists play a crucial role in the production of precision components for aircraft and spacecraft. They can find employment with aerospace manufacturers, defense contractors, and aviation companies. With the increasing demand for aerospace CNC machining, job opportunities for skilled machinists are on the rise, offering competitive salaries and opportunities for career growth.

With the advancement of technology in aerospace manufacturing, aerospace machinists are required to have specialized skills in operating CNC machines and interpreting complex blueprints. This demand for expertise has led to a shortage of skilled machinists, creating even more job opportunities for those with the right qualifications. As aerospace companies continue to invest in cutting-edge machinery and technology, the need for highly skilled machinists will only continue to grow, making it an exciting time to pursue a career in this field.

SYIL CNC Machine and Aerospace Machinist Careers

The SYIL CNC machine has revolutionized the role of aerospace machinists by providing advanced technology that enhances precision and efficiency in manufacturing aerospace components. As a result, careers in aerospace machining have become more dynamic and rewarding, with machinists being able to work on cutting-edge projects that shape the future of aviation and space exploration.

With the SYIL CNC machine leading the way in aerospace machining, machinists now have the opportunity to work on projects that were once considered impossible. The precision and efficiency of this advanced technology allow for the creation of complex aerospace components that push the boundaries of what is achievable in aviation and space exploration. As a result, careers in aerospace machining have evolved to be more exciting and fulfilling, attracting individuals who are passionate about contributing to groundbreaking advancements in the industry.

CNC Machining in Aerospace Industry

Growth and Future Trends in Aerospace CNC Machining

As the aerospace industry continues to advance, the demand for precision and efficiency in aerospace CNC machining is on the rise. The future of aerospace CNC machining is expected to be driven by technological advancements, such as automation and artificial intelligence, leading to increased productivity and reduced lead times. With the growing need for lightweight components and complex designs in aerospace, CNC machining is set to play a crucial role in meeting these demands.

Economic and Environmental Impact of CNC Machining

Aerospace CNC machining has a significant economic impact, contributing to the overall growth of the aerospace industry by providing high-quality components with tight tolerances. Additionally, the environmental impact of CNC machining in aerospace is being addressed through sustainable manufacturing practices and efficient use of resources. With advancements in technology, aerospace CNC machining is becoming more environmentally friendly, reducing waste and energy consumption.

Furthermore, the use of CNC machining in the aerospace industry has led to improved safety and reliability in aircraft components. The high precision and accuracy of CNC machining ensure that parts fit together seamlessly, reducing the risk of mechanical failure. This has a direct impact on the overall safety of aerospace vehicles, contributing to a positive reputation for the industry and increasing consumer confidence in air travel.

SYIL CNC Machine in Modern Aerospace Industry

The SYIL CNC machine has revolutionized the modern aerospace industry by offering advanced capabilities for precision manufacturing. Its ability to produce complex components with high accuracy makes it an essential tool for meeting the stringent requirements of aerospace applications. With its user-friendly interface and reliable performance, the SYIL CNC machine has become a cornerstone of modern aerospace manufacturing, driving innovation and efficiency.

The SYIL CNC machine has also played a crucial role in reducing production time and costs in the aerospace industry. By streamlining the manufacturing process and minimizing human error, this advanced technology has enabled aerospace companies to deliver high-quality components at a faster pace. As a result, the SYIL CNC machine has not only enhanced precision and accuracy but has also contributed to significant improvements in overall operational efficiency within the aerospace sector.

Conclusion

Advancements in Aerospace CNC Machining have revolutionized the industry, allowing for more precise and efficient production of aerospace components. With the use of state-of-the-art technology and innovative techniques, aerospace CNC machining has reached new heights, ensuring the highest quality and accuracy in manufacturing.

Advancements in Aerospace CNC Machining

The advancements in aerospace CNC machining have led to significant improvements in precision, speed, and efficiency. With cutting-edge tools and software, aerospace manufacturers can produce complex components with unparalleled accuracy, meeting the stringent requirements of the industry.

SYIL CNC Machine: Revolutionizing Aerospace Industry

The SYIL CNC machine has played a pivotal role in revolutionizing the aerospace industry by providing advanced capabilities for precision manufacturing. Its user-friendly interface and high-performance features make it an indispensable tool for producing intricate aerospace components with utmost accuracy.

The SYIL CNC machine has not only transformed the aerospace industry but has also set a new standard for precision manufacturing. Its cutting-edge technology and seamless integration with CAD/CAM software have streamlined the production process, minimizing human error and maximizing efficiency. As a result, aerospace companies can now rely on the SYIL CNC machine to consistently deliver high-quality components that meet stringent industry standards.

The Future of Precision CNC Machining in Aerospace

As technology continues to evolve, the future of precision CNC machining in aerospace looks promising. With ongoing research and development, we can expect even greater advancements in manufacturing processes, leading to enhanced efficiency and quality control within the industry.

By embracing these advancements and leveraging modern technologies like the SYIL CNC machine, the aerospace industry is poised to achieve unprecedented levels of precision and productivity. The future of precision CNC machining in aerospace is bright as it continues to drive innovation and excellence within the industry.