Introduction

In the fast-paced world of aerospace manufacturing, precision is paramount. This is where aerospace CNC machining comes into play, revolutionizing the production of intricate components for aircraft and spacecraft. With the help of advanced CNC machines, the aerospace industry can achieve unparalleled accuracy and efficiency in component manufacturing. One such machine making waves in this industry is the SYIL CNC machine, playing a pivotal role in transforming aerospace manufacturing processes.

Understanding Aerospace CNC Machining

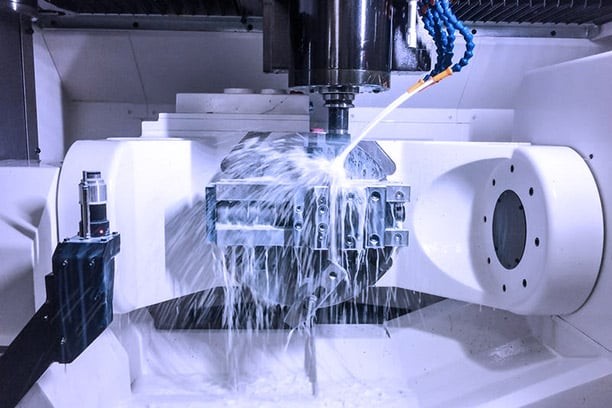

Aerospace CNC machining involves the use of computer numerical control (CNC) technology to manufacture precision components for aerospace applications. This process allows for intricate designs and complex shapes to be accurately produced with minimal human intervention, ensuring high-quality components for aircraft and spacecraft.

Importance of Precision Components in Aerospace Industry

Precision components are crucial in the aerospace industry, as even the smallest deviation from specifications can have significant implications on safety and performance. From engine parts to structural elements, precision is non-negotiable when it comes to aerospace components.

Role of SYIL CNC Machine in Aerospace Manufacturing

The SYIL CNC machine has emerged as a game-changer in aerospace manufacturing by offering advanced capabilities that cater to the demanding requirements of this industry. Its precision engineering and cutting-edge technology make it an indispensable tool for producing high-quality components that meet stringent aerospace standards.

What is Aerospace CNC Machining?

Aerospace CNC machining refers to the process of using computer numerical control (CNC) machines to produce precision components for aircraft and spacecraft. These machines are equipped with advanced software and tools that enable them to cut, drill, and shape metal and other materials with incredible accuracy.

Definition and Explanation of Aerospace CNC Machining

Aerospace CNC machining involves the use of specialized CNC machines to manufacture complex and intricate parts for aerospace applications. These machines are programmed to follow precise instructions, ensuring that each component meets the strict quality standards required in the aerospace industry.

Benefits of Using CNC Machines in Aerospace Industry

The aerospace industry benefits greatly from using CNC machines due to their ability to produce high-precision components consistently. This results in reduced material waste, faster production times, and improved overall quality of the parts used in aircraft and spacecraft.

Examples of Precision Components Produced through Aerospace CNC Machining

Some examples of precision components produced through aerospace CNC machining include turbine blades, engine mounts, landing gear parts, and structural components for airframes. These parts require extremely tight tolerances and complex geometries, making them ideal candidates for production using CNC machines

Role of Precision CNC Components in Aerospace Industry

Importance of Precision in Aerospace Components

Precision in aerospace components is crucial for ensuring the safety and efficiency of aircraft. The exact measurements and tight tolerances required in aerospace machining guarantee that all parts fit together seamlessly, reducing the risk of mechanical failure during flight. Without precision, the structural integrity and performance of aircraft could be compromised, leading to potentially catastrophic consequences.

Impact of Precision CNC Components on Aircraft Performance

The use of precision CNC components directly impacts aircraft performance by enhancing aerodynamics, reducing weight, and improving fuel efficiency. These components are meticulously crafted to minimize drag and optimize airflow, ultimately contributing to smoother flights and reduced fuel consumption. Additionally, the precise manufacturing process ensures that each part meets stringent quality standards, further enhancing overall aircraft performance.

SYIL CNC Machine's Contribution to Precision Component Manufacturing

The SYIL CNC machine plays a pivotal role in manufacturing precision components for the aerospace industry. With its advanced technology and high-precision capabilities, this machine enables the production of intricate parts with unparalleled accuracy. By utilizing state-of-the-art CNC technology, aerospace manufacturers can rely on SYIL machines to consistently deliver precision components that meet the stringent requirements of the industry.

What is a CNC Aerospace Machinist?

Job Responsibilities of CNC Aerospace Machinists

CNC aerospace machinists are responsible for setting up and operating CNC machines to produce precision components for the aerospace industry. They interpret blueprints, program the machines, and monitor the production process to ensure accuracy and efficiency. They also perform quality checks on finished parts to meet strict aerospace standards.

Skills and Qualifications Required for CNC Aerospace Machining

To excel in CNC aerospace machining, individuals need strong technical skills in reading blueprints, programming CNC machines, and using measurement tools. Attention to detail and problem-solving abilities are crucial for identifying and resolving issues during production. Additionally, a background in mechanical engineering or a related field is often required for this specialized role.

Career Opportunities in Aerospace CNC Machining Industry

The demand for skilled CNC aerospace machinists is high due to the precision requirements of aerospace components. With the right qualifications and experience, individuals can pursue various career opportunities such as CNC programmer, aerospace machinist supervisor, or quality control inspector within leading aerospace manufacturing companies.

SYIL CNC Machine: Revolutionizing Aerospace Manufacturing

Features and Capabilities of SYIL CNC Machine

The SYIL CNC machine is a cutting-edge aerospace machine designed to meet the demanding requirements of precision component manufacturing in the aerospace industry. With its advanced technology, high-speed machining capabilities, and superior accuracy, the SYIL CNC machine ensures the production of top-quality components that are essential for aircraft performance and safety.

Furthermore, the SYIL CNC machine is equipped with state-of-the-art control systems that allow for seamless integration with CAD/CAM software, enabling efficient programming and simulation of complex aerospace components. This ensures that the machine can handle intricate designs and produce parts with utmost precision and accuracy. Additionally, the machine's rigid construction and vibration-dampening features contribute to its stability during high-speed machining operations, resulting in superior surface finishes and dimensional accuracy.

Case Studies of Aerospace Companies Utilizing SYIL CNC Machine

Several leading aerospace companies have successfully integrated the SYIL CNC machine into their manufacturing processes, resulting in significant improvements in efficiency, productivity, and component quality. These case studies demonstrate how the SYIL CNC machine has revolutionized aerospace manufacturing by enabling companies to produce complex precision components with unmatched precision and consistency.

The successful implementation of SYIL CNC machines in aerospace companies has not only improved efficiency and productivity but has also led to a significant reduction in production costs. By automating the manufacturing process, these companies have been able to streamline their operations, minimize errors, and achieve faster turnaround times. This has allowed them to stay competitive in the aerospace industry and meet the increasing demand for high-quality precision components.

Future Prospects of SYIL CNC Machine in Aerospace Industry

As the aerospace industry continues to evolve and demand for high-quality precision components grows, the future prospects of the SYIL CNC machine are extremely promising. With ongoing advancements in technology and innovation, the SYIL CNC machine is poised to play an even more crucial role in shaping the future of aerospace manufacturing by delivering unparalleled precision, reliability, and efficiency.

Aerospace CNC Machining Companies

Overview of Leading Aerospace CNC Machining Companies

When it comes to aerospace CNC machining, there are several leading companies that stand out in the industry. These companies specialize in producing precision components for aircraft and spacecraft, utilizing advanced CNC machines and cutting-edge technology to meet the high demands of the aerospace sector. Some of these top companies include Boeing, Airbus, Lockheed Martin, and Northrop Grumman.

In addition to producing precision components, these leading aerospace CNC machining companies also offer a range of other services to meet the needs of their clients. This includes prototyping, design assistance, and engineering support to ensure that the final product meets all necessary specifications and requirements. With their expertise in aerospace manufacturing, these companies are able to provide comprehensive solutions for complex projects, from initial concept to final production.

Services Offered by Aerospace CNC Machining Companies

Aerospace CNC machining companies offer a wide range of services to cater to the needs of the aerospace industry. These services include precision machining of complex components such as engine parts, landing gear, structural components, and more. Additionally, they provide expertise in material selection, prototyping, assembly, and quality control to ensure that all components meet strict aerospace standards for safety and performance.

Aerospace CNC machining companies also offer advanced CAD/CAM programming capabilities to ensure precise and accurate machining of complex components. This technology allows for the creation of intricate designs and the efficient production of high-quality parts, helping to streamline the manufacturing process for aerospace applications. By leveraging cutting-edge software and machinery, these companies can deliver components that meet the stringent requirements of the aerospace industry while minimizing production time and costs.

SYIL CNC Machine's Partnership with Aerospace Machining Companies

SYIL CNC Machine has established strong partnerships with leading aerospace machining companies to provide them with state-of-the-art CNC machines tailored specifically for aerospace manufacturing needs. By collaborating with these companies, SYIL has been able to contribute significantly to the production of precision components for various aerospace applications. This partnership has enabled aerospace manufacturers to enhance their production capabilities and meet the growing demands of the industry.

Furthermore, the collaboration between SYIL CNC Machine and aerospace machining companies has facilitated the exchange of industry knowledge and expertise. This sharing of insights has led to the development of innovative machining techniques and processes that have improved the efficiency and accuracy of aerospace component production. As a result, aerospace manufacturers have been able to reduce lead times, minimize material waste, and ultimately lower production costs, making them more competitive in the market.

Conclusion

Advantages of Aerospace CNC Machining for Precision Components

Aerospace CNC machining offers numerous advantages for precision components, including high accuracy, repeatability, and efficiency in production. The use of CNC machines in aerospace manufacturing ensures that critical components are produced with the utmost precision, meeting strict industry standards for safety and performance.

Future of Aerospace Manufacturing with SYIL CNC Machine

The future of aerospace manufacturing is bright with the integration of SYIL CNC machines. These cutting-edge machines are revolutionizing the industry by delivering unparalleled precision and efficiency in component production. As technology continues to advance, SYIL CNC machines will play a pivotal role in shaping the future of aerospace manufacturing.

Innovations in Precision CNC Components for Aerospace Industry

Innovations in precision CNC components are driving advancements in the aerospace industry, leading to improved aircraft performance and safety. With the use of state-of-the-art CNC machines, aerospace companies can produce complex components with intricate designs that were previously unattainable, pushing the boundaries of what is possible in aerospace engineering.

Advantages of Aerospace CNC Machining for Precision Components

Aerospace CNC machining offers numerous advantages for precision components, including high accuracy, repeatability, and efficiency in production. The use of CNC machines in aerospace manufacturing ensures that critical components are produced with the utmost precision, meeting strict industry standards for safety and performance.

Future of Aerospace Manufacturing with SYIL CNC Machine

The future of aerospace manufacturing is bright with the integration of SYIL CNC machines. These cutting-edge machines are revolutionizing the industry by delivering unparalleled precision and efficiency in component production. As technology continues to advance, SYIL CNC machines will play a pivotal role in shaping the future of aerospace manufacturing.

Innovations in Precision CNC Components for Aerospace Industry

Innovations in precision CNC components are driving advancements in the aerospace industry, leading to improved aircraft performance and safety. With the use of state-of-the-art CNC machines, aerospace companies can produce complex components with intricate designs that were previously unattainable, pushing the boundaries of what is possible in aerospace engineering.