Introduction

When it comes to aerospace parts machining, precision is paramount. The intricate components used in aerospace applications require exacting standards to ensure safety and performance. This is where CNC machines play a crucial role in the aerospace industry, enabling the production of complex parts with unparalleled accuracy.

Understanding Aerospace Machining

Aerospace machining involves the manufacturing of components used in aircraft, spacecraft, and other aviation systems. This specialized process demands high precision and adherence to strict quality standards to meet the rigorous requirements of the aerospace industry. Precision is crucial in aerospace parts as even the smallest deviation can lead to catastrophic consequences in flight. From engine components to structural elements, each part must be meticulously crafted to ensure optimal performance and safety in the air. As a result, aerospace machining requires state-of-the-art equipment and highly skilled machinists who can consistently deliver parts with unparalleled accuracy.

Importance of Precision in Aerospace Parts

The importance of precision in aerospace parts cannot be overstated. Even the smallest deviation from specifications can have catastrophic consequences in flight. From engine components to structural elements, every part must be meticulously crafted to ensure safety and reliability.

The use of CNC (Computer Numerical Control) machines has revolutionized the aerospace industry by allowing for the precise and efficient manufacturing of complex parts. These machines are capable of producing intricate components with incredibly tight tolerances, ensuring that every piece meets the exact specifications required for safe and reliable operation. By utilizing CNC machines, aerospace manufacturers can achieve a level of precision that was previously unattainable, leading to improved performance and safety in aircraft design and production.

Role of CNC Machines in Aerospace Industry

CNC machines have revolutionized aerospace machining by providing unmatched precision and repeatability. These advanced tools enable manufacturers to produce complex, high-precision components with tight tolerances, meeting the stringent demands of the aerospace sector.

Furthermore, CNC machines have significantly reduced the margin of error in aerospace machining, leading to a higher level of safety and reliability in aircraft components. With their ability to consistently produce parts with exact specifications, CNC machines have played a crucial role in ensuring the structural integrity of aerospace vehicles. This level of precision has also contributed to advancements in aerodynamics and fuel efficiency, ultimately benefiting the industry as a whole.

What is Aerospace Machining?

Aerospace machining refers to the process of manufacturing precision components for use in aircraft, spacecraft, and other aerospace applications. This specialized form of machining requires high levels of accuracy and reliability to meet the stringent demands of the aerospace industry.

Definition of Aerospace Machining

Aerospace machining involves the use of advanced machinery and cutting-edge techniques to produce complex parts with tight tolerances. It encompasses a wide range of processes such as milling, turning, drilling, and grinding, all tailored to meet the unique requirements of aerospace parts machining.

Key Techniques in Aerospace Machining

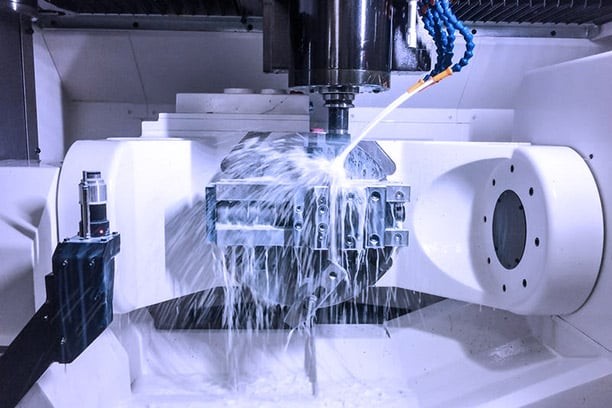

Key techniques in aerospace machining include multi-axis CNC milling and turning, which allow for intricate shapes and contours to be machined with utmost precision. Additionally, advanced tooling and fixturing are used to ensure consistent quality and accuracy in the finished components.

Materials Used in Aerospace Machining

Aerospace components are typically machined from high-strength materials such as titanium, aluminum alloys, stainless steel, and composites. These materials are chosen for their lightweight properties, corrosion resistance, and high strength-to-weight ratios, making them ideal for aerospace applications.

How SYIL CNC Machines are Used in Aerospace Machining

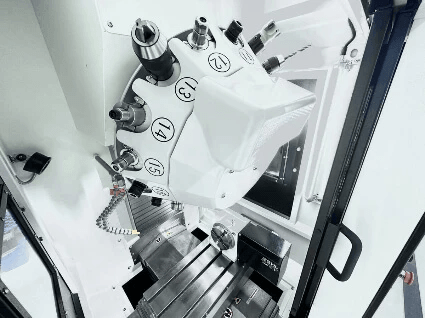

SYIL CNC machines offer several advantages for aerospace parts machining. These machines provide high precision and accuracy, crucial for manufacturing complex aerospace components. With their advanced technology and automation, SYIL CNC machines ensure efficient production of high-quality aerospace parts.

Advantages of SYIL CNC Machines

One advantage of using SYIL CNC machines in aerospace machining is their ability to produce precision CNC components with tight tolerances. These machines can consistently manufacture high-quality parts, meeting the strict requirements of the aerospace industry. Additionally, SYIL CNC machines offer versatility in producing various types of aerospace components, from engine parts to structural elements.

Applications of SYIL CNC Machines in Aerospace Industry

SYIL CNC machines are widely used in the aerospace industry for manufacturing critical components such as turbine blades, landing gear parts, and structural elements. Their ability to handle a wide range of materials, including aluminum, titanium, and composites, makes them suitable for diverse aerospace applications. These machines play a pivotal role in producing complex geometries required for advanced aircraft designs.

In addition to their material versatility, SYIL CNC machines are known for their precision and accuracy, making them ideal for producing aerospace parts with tight tolerances. This is crucial in the aerospace industry, where components must meet strict quality standards to ensure safety and performance. Furthermore, the advanced automation features of SYIL CNC machines allow for efficient production processes, reducing lead times and overall manufacturing costs for aerospace companies.

SYIL CNC Machine Features for Aerospace Parts

SYIL CNC machines come equipped with features specifically tailored for aerospace parts machining. These include multi-axis capabilities for intricate part geometries, high spindle speeds for efficient material removal, and advanced tooling options to accommodate various cutting operations. The robust build and stability of these machines ensure consistent performance in the demanding environment of aerospace component manufacturing.

In addition to the advanced features tailored for aerospace parts machining, SYIL CNC machines also offer high precision and accuracy, ensuring that every component meets the stringent quality standards of the aerospace industry. This level of precision is essential for producing parts with complex geometries and tight tolerances, allowing aerospace manufacturers to maintain the highest levels of safety and performance in their products. Furthermore, the user-friendly interface and programming capabilities of SYIL CNC machines enable machinists to efficiently program and execute intricate machining operations, contributing to increased productivity and reduced lead times in aerospace part production.

The Role of CNC Machinists in Aerospace Industry

Responsibilities of CNC Aerospace Machinists

CNC aerospace machinists are responsible for programming, setting up, and operating CNC machines to produce high-precision aerospace parts. They must interpret blueprints, use precision measuring tools, and ensure that the finished products meet strict quality standards for aerospace components machining.

In addition to their technical skills, CNC aerospace machinists must also possess strong problem-solving abilities to troubleshoot any issues that may arise during the machining process. They need to be able to think critically and make quick, accurate decisions in order to ensure that production runs smoothly and efficiently. Being able to adapt to new technologies and learn new techniques is also crucial in this fast-paced industry.

Skills and Training for Aerospace Machinists

Aerospace machinists require a strong understanding of machining processes, materials, and CNC programming. They need to be skilled in using CAD/CAM software and have a keen eye for detail to achieve the necessary precision in aerospace parts machining. Training programs often include hands-on experience with CNC machines and specialized aerospace component manufacturing techniques.

Aerospace machinists also need to have a strong grasp of quality control processes and procedures to ensure that all parts meet the strict standards required for aerospace applications. This includes the ability to interpret engineering drawings and specifications accurately, as well as performing thorough inspections of finished components. Additionally, knowledge of lean manufacturing principles and continuous improvement techniques is essential for optimizing production processes and minimizing waste in aerospace machining operations.

Career Opportunities in Aerospace Machining

With the demand for high-precision aerospace parts on the rise, there are abundant career opportunities for CNC machinists in the aerospace industry. From entry-level positions to advanced roles as lead machinists or production supervisors, individuals with expertise in CNC machining aerospace parts are highly sought after by leading manufacturers.

Precision CNC Components in Aerospace Machining

Importance of Precision in Aerospace Parts

Precision is crucial in aerospace parts machining to ensure the safety, reliability, and performance of aircraft. Even the smallest deviation can have catastrophic consequences, making precision a top priority in aerospace manufacturing.

Precision in aerospace parts machining is not only essential for the safety and reliability of aircraft, but it also plays a critical role in the overall performance of the vehicle. Even the tiniest deviation in measurements or specifications can lead to significant issues during flight, making it imperative for aerospace manufacturers to prioritize precision in their machining processes. With the lives of passengers and crew at stake, there is simply no room for error when it comes to the production of aerospace parts.

Quality Control in Aerospace Machining

Quality control is essential in aerospace machining to guarantee that every part meets strict industry standards. From initial inspection to final testing, rigorous quality control measures are implemented to maintain the highest level of precision and accuracy.

Techniques for Achieving High-Precision Aerospace Parts

Aerospace machining employs advanced techniques such as multi-axis CNC machining, high-speed cutting, and computer-aided design (CAD) to achieve high-precision aerospace parts. These techniques enable intricate designs and complex geometries to be manufactured with exceptional accuracy.

Remember that precision is paramount when it comes to aerospace parts machining. Quality control measures are crucial for maintaining high standards throughout the manufacturing process. Advanced techniques like multi-axis CNC machining play a key role in achieving the level of precision required for aerospace components.

Future of CNC Machining in Aerospace

As the aerospace industry continues to evolve, so does the manufacturing of aerospace components. Innovations in aerospace component manufacturing are driven by the need for lightweight, durable, and high-performance parts. Advanced materials and additive manufacturing techniques are revolutionizing the way aerospace parts are produced, leading to increased efficiency and reduced production costs. The future of CNC machining in aerospace will see an even greater emphasis on precision and quality as these innovations continue to reshape the industry.

Innovations in Aerospace Component Manufacturing

Innovations in aerospace component manufacturing include the use of advanced materials such as composites and superalloys, which offer superior strength-to-weight ratios and thermal resistance. Additive manufacturing processes like 3D printing are also being integrated into traditional CNC machining methods to create complex geometries with minimal waste. These advancements enable manufacturers to produce highly intricate and customized aerospace parts that meet stringent performance requirements while reducing lead times.

Furthermore, advancements in aerospace component manufacturing also involve the use of advanced coatings and surface treatments to enhance the durability and performance of parts exposed to extreme conditions. These coatings can provide protection against corrosion, wear, and high temperatures, extending the lifespan of critical components such as turbine blades and engine casings. By integrating these innovative coating technologies into the manufacturing process, aerospace manufacturers can ensure the reliability and longevity of their products in demanding operational environments.

Impact of Technology on Aerospace Machining

The impact of technology on aerospace machining is profound, with advancements in automation, robotics, and digitalization driving significant improvements in precision and efficiency. CNC machines equipped with advanced software and sensors enable real-time monitoring and adjustments, resulting in tighter tolerances and reduced scrap rates. Additionally, virtual reality (VR) and augmented reality (AR) technologies are being used for simulation and training purposes, enhancing machinists' capabilities while minimizing errors.

Furthermore, the integration of additive manufacturing technologies, such as 3D printing, has revolutionized the production of complex aerospace components. This method allows for the creation of intricate designs with minimal material waste, leading to more sustainable machining practices. By utilizing lightweight yet durable materials and reducing energy consumption during production, aerospace manufacturers can minimize their environmental impact while still meeting stringent performance requirements.

Sustainable Practices in Aerospace Machining

Sustainable practices in aerospace machining are becoming increasingly important as environmental concerns continue to grow. Manufacturers are exploring eco-friendly alternatives for coolant fluids, as well as implementing energy-efficient machining processes to minimize carbon footprint. Additionally, recycling programs for metal chips and other waste materials generated during machining operations are being adopted to reduce overall environmental impact.

Conclusion

Advancements in Aerospace Machining

The aerospace industry is constantly evolving, with new technologies and techniques being developed to improve the manufacturing process of aerospace parts machining. From advanced materials to innovative CNC machines, the industry is always pushing the boundaries of what is possible in precision engineering.

Ensuring Quality in Aerospace Parts

Quality control is paramount in aerospace machining, as even the smallest error can have catastrophic consequences. With stringent regulations and standards to adhere to, manufacturers must invest in state-of-the-art equipment and highly skilled machinists to guarantee the highest quality aerospace components.

In addition to investing in cutting-edge equipment and skilled machinists, manufacturers must also prioritize ongoing training and education for their workforce. With technology constantly evolving, it's crucial for machinists to stay up-to-date with the latest advancements in aerospace machining. By providing continuous learning opportunities, companies can ensure that their team is equipped to handle the complexities of aerospace component production, ultimately contributing to the overall quality and safety of the final products.

SYIL CNC Machines: Shaping the Aerospace Industry

SYIL CNC machines have revolutionized aerospace machining, offering unparalleled precision and efficiency. With their advanced features and applications specifically designed for aerospace part manufacturing, SYIL machines are at the forefront of shaping the future of the industry. As aerospace technology continues to evolve, the demand for more complex and intricate components will only increase. SYIL's commitment to innovation and adaptability positions them as a key player in meeting these evolving needs, ensuring that they remain an indispensable partner for aerospace manufacturers.