Introduction

Are you fascinated by the intricate world of aerospace engineering? Do you have a passion for precision and innovation? If so, then you may want to consider a career as an aerospace CNC machinist. This exciting field plays a crucial role in the production of aircraft components, making it an integral part of the aerospace industry.

Understanding the Role of Aerospace CNC Machinist

As an aerospace CNC machinist, your main responsibility is to operate computer numerical control (CNC) machines to produce high-precision components for aircraft and spacecraft. You will be tasked with reading and interpreting blueprints, programming machines, and ensuring that the finished products meet strict quality standards.

Importance of CNC Machining in Aerospace Industry

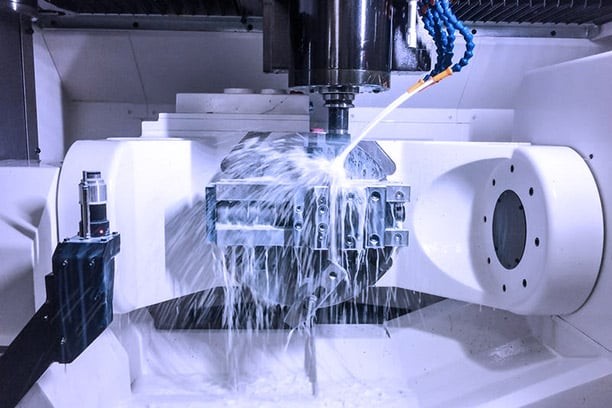

CNC machining is essential in the aerospace industry as it allows for the production of complex parts with unparalleled accuracy and consistency. From engine components to structural elements, CNC machining plays a vital role in ensuring the safety and performance of aircraft.

Exploring Career Opportunities in Aerospace CNC Machining

A career as an aerospace CNC machinist offers numerous opportunities for growth and advancement. With the increasing demand for skilled professionals in this field, there are plenty of job openings available with competitive salaries and benefits.

What Is an Aerospace Machinist?

As an aerospace CNC machinist, you are responsible for setting up and operating computer numerical control (CNC) machines to produce precision parts for aircraft and spacecraft. This requires a keen eye for detail, strong problem-solving skills, and the ability to interpret complex engineering drawings. In addition to operating machinery, aerospace CNC machinists also perform quality checks to ensure that parts meet strict industry standards.

Responsibilities and Skills of an Aerospace CNC Machinist

Aerospace CNC machinists must possess a strong understanding of machining processes, including milling, turning, and grinding. They are also responsible for programming CNC machines using computer-aided design (CAD) software to create intricate components with tight tolerances. Attention to detail is crucial in this role, as aerospace components must meet rigorous safety and performance standards.

Training and Education for Aerospace CNC Machinist

To become an aerospace CNC machinist, individuals typically pursue vocational training or an apprenticeship program in precision machining. Many employers also prefer candidates with a certificate or associate's degree in machine tool technology or related fields. Ongoing training is essential in this rapidly evolving industry, as new technologies and techniques continue to reshape the aerospace manufacturing landscape.

Advancements in Aerospace CNC Machining Technology

Advancements in aerospace CNC machining technology have revolutionized the way aircraft components are manufactured. From multi-axis machining capabilities to high-speed cutting tools, these innovations have significantly improved efficiency and precision in aerospace manufacturing processes. As a result, aerospace CNC machinists must stay abreast of these advancements to remain competitive in the industry.

CNC Machining in Aerospace Industry

Aerospace CNC machinists play a crucial role in the production of aircraft components, utilizing advanced CNC machines to create precision parts for airplanes and spacecraft. These professionals are responsible for programming, operating, and maintaining the CNC equipment to ensure the highest quality standards in aerospace manufacturing.

Applications of CNC Machining in Aerospace

CNC machining is widely used in aerospace for producing complex components such as engine parts, landing gear, and structural elements. The high precision and repeatability of CNC machines make them ideal for creating intricate designs with tight tolerances required for safe and reliable aircraft operation.

Benefits of Precision Machining in Aerospace Engineering

Precision machining offers several advantages in aerospace engineering, including enhanced accuracy, improved efficiency, and cost-effectiveness. By utilizing CNC technology, aerospace manufacturers can achieve consistent quality control while reducing material waste and production time.

SYIL CNC Machine in Aerospace Manufacturing

The SYIL CNC machine has revolutionized aerospace manufacturing by providing advanced capabilities for producing intricate aircraft components with unparalleled precision. Its cutting-edge features enable aerospace machinists to meet the exacting demands of the industry while maximizing productivity and minimizing errors.

Furthermore, the SYIL CNC machine offers a user-friendly interface that allows aerospace machinists to easily program and execute complex machining operations. This intuitive system reduces the learning curve for new operators and enables experienced machinists to work more efficiently. Additionally, the machine's seamless integration with CAD/CAM software streamlines the design-to-production process, ensuring that aerospace components are manufactured with utmost accuracy and consistency.

What is aerospace CNC machining?

Aerospace CNC machining involves the use of computer numerical control (CNC) technology to manufacture precise and complex components for aerospace applications. This process utilizes automated machinery to cut, shape, and finish metal parts according to exact specifications, ensuring high precision and quality in aerospace manufacturing.

Overview of CNC Machining Processes in Aerospace

In aerospace CNC machining, various processes such as milling, turning, drilling, and grinding are used to create intricate parts for aircraft and spacecraft. These processes require advanced programming and tooling to achieve the tight tolerances and surface finishes demanded by the aerospace industry. From engine components to structural elements, CNC machining plays a critical role in producing reliable and efficient aerospace systems.

Quality Control and Standards in Aerospace CNC Machining

Quality control is paramount in aerospace CNC machining to ensure that parts meet stringent industry standards for safety, performance, and durability. Advanced inspection techniques such as coordinate measuring machines (CMM) and non-destructive testing (NDT) are employed to verify the accuracy of machined components. Adherence to strict quality control measures is essential for maintaining the integrity of aerospace systems.

Future Trends in Aerospace CNC Machining

The future of aerospace CNC machining is marked by advancements in automation, robotics, additive manufacturing, and digital twin technology. These developments aim to enhance productivity, reduce lead times, and improve part complexity capabilities. Additionally, the integration of artificial intelligence (AI) into CNC machines is expected to optimize processes and enable predictive maintenance for increased efficiency in aerospace manufacturing.

What is a CNC aerospace machinist?

Role of CNC Machinist in Aerospace Production

A CNC aerospace machinist plays a crucial role in the production of aerospace components by operating computer numerical control (CNC) machines to precisely cut and shape metal parts according to engineering specifications. They are responsible for setting up, programming, and monitoring these machines to ensure the accuracy and quality of the finished products, playing a vital role in the safety and performance of aircraft.

CNC aerospace machinists also face the challenge of staying updated with the latest technological advancements in CNC machines and software. With rapid developments in technology, machinists must constantly adapt to new tools and techniques to remain competitive in the aerospace industry. This presents an opportunity for machinists to expand their skill set and become proficient in operating cutting-edge equipment, positioning themselves as valuable assets to aerospace production companies.

Challenges and Opportunities for CNC Aerospace Machinists

One of the main challenges for aerospace CNC machinists is to keep up with rapidly advancing technology and evolving industry standards. However, this also presents exciting opportunities for career growth and professional development as they adapt to new tools and techniques. With the demand for skilled workers in aerospace manufacturing on the rise, there are plentiful opportunities for CNC machinists to secure stable employment with competitive salaries.

As aerospace CNC machinists adapt to new tools and techniques, they have the opportunity to become experts in cutting-edge technologies such as 5-axis machining and additive manufacturing. This not only enhances their skill set but also makes them more valuable assets to aerospace companies seeking to stay ahead of the competition. Additionally, the need for precision and attention to detail in aerospace machining provides machinists with the chance to take pride in their workmanship and contribute to the production of high-quality components essential for safe and efficient aircraft operation.

Innovations in CNC Machining Tools for Aerospace Industry

In recent years, there have been significant innovations in CNC machining tools specifically designed for the aerospace industry. These advancements include high-speed machining capabilities, multi-axis machining centers, and improved automation features that enhance productivity while maintaining precision. Additionally, the integration of additive manufacturing technologies has opened up new possibilities for creating complex geometries and lightweight structures that were previously unattainable.

What is CNC in aircraft?

Integration of CNC Technology in Aircraft Manufacturing

The integration of CNC technology in aircraft manufacturing has revolutionized the industry, allowing for the production of highly precise and complex components. Aerospace CNC machinists play a crucial role in programming and operating these machines to create parts that meet strict aviation standards.

The precision and efficiency of CNC machining have significantly improved the performance of aircraft. With the ability to produce highly accurate components, aircraft can now operate with greater reliability and safety. Additionally, the use of CNC technology has led to reduced weight in aircraft parts, contributing to improved fuel efficiency and overall performance.

Impact of CNC Machining on Aircraft Performance

CNC machining has significantly improved aircraft performance by ensuring the production of lightweight, durable, and aerodynamic components. The precision and accuracy achieved through CNC technology contribute to enhanced fuel efficiency, reduced maintenance needs, and overall improved flight capabilities.

CNC machining has also revolutionized the design and production process of aircraft components, allowing for more intricate and complex shapes to be manufactured with ease. This has led to improved aerodynamics and overall performance, as engineers are able to create parts that were previously unattainable using traditional manufacturing methods. The ability to optimize the design of components through CNC technology has resulted in reduced drag, increased speed, and better maneuverability for aircraft, ultimately enhancing their overall performance in the skies.

Career Growth and Salary Potential for CNC Aerospace Machinists

As the demand for aerospace CNC machinists continues to rise, there are ample opportunities for career growth in this field. With experience and specialized skills, aerospace machinists can advance to higher positions such as lead machinist or manufacturing supervisor. The salary potential for skilled aerospace CNC machinists is also impressive, with the opportunity to earn competitive wages within the industry.

Furthermore, as technology continues to advance, aerospace CNC machinists will need to stay current with the latest software and equipment in order to remain competitive in the industry. This presents opportunities for ongoing professional development and training, allowing machinists to expand their skill set and take on more complex projects. By staying at the forefront of technological advancements, aerospace CNC machinists can position themselves for even greater career growth and salary potential.

Conclusion

Advancing Your Career as an Aerospace CNC Machinist

As an aerospace CNC machinist, the potential for career growth is immense. With the increasing demand for precision parts in the aerospace industry, honing your skills and staying updated with the latest CNC machining technology will open doors to advanced positions and higher pay grades.

With the advent of automation and smart manufacturing, aerospace CNC machinists need to adapt to new technologies and processes. This may involve learning how to program and operate advanced CNC machines, as well as understanding how to integrate them with other production systems. By embracing these changes and continuously improving your skills, you can position yourself as a valuable asset in the aerospace industry and increase your chances for career advancement.

Embracing the Future of Aerospace CNC Machining

The future of aerospace CNC machining is filled with exciting advancements and innovations. Embrace the shift towards automation, robotics, and additive manufacturing to stay ahead in this ever-evolving industry. By adapting to new technologies, you can position yourself as a valuable asset in aerospace manufacturing.

The integration of automation, robotics, and additive manufacturing in aerospace CNC machining is revolutionizing the industry. Embracing these technological advancements will not only enhance efficiency and precision but also open up new opportunities for innovation and creativity. By staying ahead of the curve and adapting to these new technologies, you can position yourself as a leader in aerospace manufacturing, setting yourself apart from the competition.

SYIL CNC Machine: A Game-Changer in Aerospace Manufacturing

The SYIL CNC Machine has revolutionized aerospace manufacturing with its cutting-edge technology and precision capabilities. Its ability to produce complex parts with utmost accuracy has made it a game-changer in the industry, setting new standards for efficiency and quality control.

With a focus on precision engineering and technological advancements, aerospace CNC machining offers a promising career path with ample opportunities for growth and development. Embrace the future of aerospace manufacturing by staying updated with the latest trends and leveraging innovative tools like the SYIL CNC Machine to excel in this dynamic field.