Introduction

In the ever-evolving world of aerospace, CNC (Computer Numerical Control) machining technology plays a pivotal role in ensuring that aircraft components are crafted with unparalleled precision and efficiency. The aerospace industry demands not only innovation but also an unwavering commitment to quality, making CNC machining an essential part of the manufacturing process. As we delve into what is aerospace manufacturing technology, it becomes clear that the integration of advanced machining techniques is crucial for meeting stringent safety and performance standards.

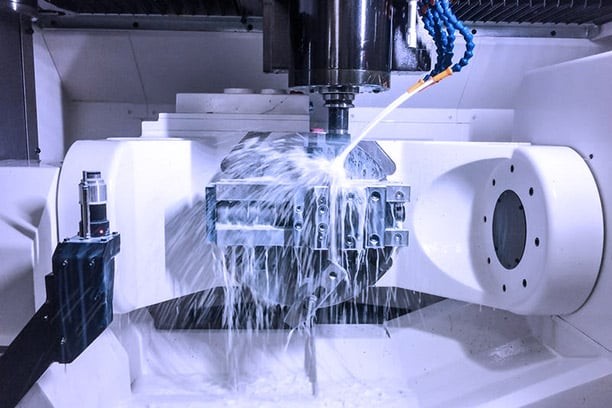

The Role of CNC in Aerospace

CNC machines are at the heart of modern aerospace machining technology, allowing for the creation of complex parts with remarkable accuracy. These machines automate the cutting and shaping processes, resulting in reduced human error and increased production speed—key factors in a competitive industry where every second counts. By understanding how to become an aerospace machinist, individuals can tap into this exciting field that combines engineering prowess with cutting-edge technology.

Importance of Precision in Machining

Precision is non-negotiable in aerospace manufacturing; even the slightest deviation can lead to catastrophic failures. This is where CNC machining shines, offering repeatability and consistency that manual methods simply cannot match. As we explore what technology is used in aerospace today, it's evident that precision-engineered components are vital for ensuring safety and reliability in flight operations.

Overview of Aerospace Manufacturing Technology

Aerospace manufacturing technology encompasses a range of processes designed to produce high-quality components from advanced materials like titanium and composites. This sector integrates various technologies—from additive manufacturing to sophisticated CNC setups—each contributing uniquely to the final product's integrity and performance. Understanding aerospace machined parts' significance helps underscore why continuous innovation is critical as we look toward future advancements in this dynamic field.

Understanding Aerospace Machining Technology

Aerospace machining technology is a specialized field that combines precision engineering with advanced manufacturing processes to create components for the aerospace industry. This technology encompasses various techniques, tools, and machines specifically designed to meet the stringent requirements of aerospace applications. When we ask, What is aerospace manufacturing technology? it becomes clear that it involves cutting-edge methods aimed at producing high-quality parts that can withstand extreme conditions.

Definition and Key Components

At its core, aerospace machining technology refers to the processes used to manufacture critical components for aircraft and spacecraft. Key components include CNC (Computer Numerical Control) machines, which automate the machining process for enhanced accuracy and efficiency. Other essential elements involve advanced tooling, materials like titanium and carbon composites, and sophisticated software systems that ensure precision in aerospace machined parts.

Common Applications in Aerospace

In the realm of aerospace, machining technology finds application in producing a vast array of components such as engine parts, landing gear assemblies, and structural elements of aircraft bodies. The need for lightweight yet durable materials makes CNC machining particularly valuable; it allows manufacturers to create complex geometries while maintaining high strength-to-weight ratios. Moreover, understanding how to become an aerospace machinist requires knowledge of these applications since they directly influence training programs and skill development.

Benefits of CNC Machining in Aerospace

CNC machining offers numerous benefits for producing aerospace machined parts compared to traditional methods. First off, it significantly reduces production time while enhancing precision—two crucial factors when dealing with safety-critical components in aviation. Additionally, this technology allows for greater design flexibility; engineers can easily modify designs without needing extensive retooling or downtime—a huge plus in an industry where innovation is key.

How to Become an Aerospace Machinist

Embarking on a career in aerospace machining technology is an exciting journey that combines technical prowess with creativity. As the aerospace industry continues to evolve, the demand for skilled machinists who understand CNC machining aerospace parts is on the rise. If you're wondering how to become an aerospace machinist, you've landed in the right place.

Essential Skills and Qualifications

To thrive in the realm of aerospace machining technology, certain skills and qualifications are non-negotiable. First and foremost, a solid grasp of mathematics and mechanical principles is essential; after all, precision is key when working with intricate aerospace machined parts. Additionally, familiarity with CNC machinery and programming languages will give you a competitive edge in this high-tech field.

Moreover, attention to detail cannot be overstated—one small error can lead to significant consequences in aviation safety. Problem-solving skills are vital as well; machinists often encounter challenges that require quick thinking and innovative solutions. Lastly, effective communication skills are crucial for collaborating with engineers and other professionals within aerospace manufacturing technology.

Training and Certification Programs

So, what training should you pursue? Many aspiring machinists start by enrolling in vocational schools or community colleges that offer specialized programs focusing on CNC machining aerospace parts. These programs typically cover essential topics such as blueprint reading, machine operation, and quality control processes specific to the aerospace sector.

Certification can further bolster your credentials; organizations like the National Institute for Metalworking Skills (NIMS) offer certifications that validate your skills in various machining processes. Additionally, hands-on experience through internships or apprenticeships can provide invaluable insights into real-world applications of aerospace machining technology. This combination of education and practical experience prepares you for a successful career path.

Career Opportunities in Aerospace Industry

The career landscape for those skilled in aerospace machining technology is both diverse and promising. Opportunities abound within aircraft manufacturers, defense contractors, and even space exploration companies—each requiring precision-engineered components produced by talented machinists. Positions range from entry-level roles to specialized positions focused on advanced materials or complex assemblies.

Moreover, as technologies evolve—think automation or robotics—the need for skilled workers who can adapt becomes increasingly critical. With ongoing advancements in what technology is used in aerospace manufacturing processes, there’s always room for growth and specialization within this dynamic sector. Whether you're aiming for a role as a CNC operator or looking toward engineering management positions down the line, your journey starts with mastering the essentials of machining.

CNC Machines Used in Aerospace Industry

In the ever-evolving world of aerospace machining technology, CNC machines play a pivotal role in producing high-precision components that meet stringent industry standards. These machines are designed to execute complex tasks with remarkable accuracy, ensuring that every aerospace machined part is crafted to perfection. As we delve into the types of CNC machines used in the aerospace industry, it becomes evident how integral they are to modern manufacturing processes.

Types of CNC Machines for Aerospace Parts

When it comes to what is aerospace manufacturing technology, several types of CNC machines stand out for their specialized functions. Vertical and horizontal milling machines are commonly employed for machining intricate shapes and contours essential in aerospace designs. Additionally, CNC lathes are utilized for creating cylindrical components, while multi-axis machining centers allow manufacturers to work on complex geometries without having to reposition the part multiple times—saving time and enhancing precision.

These various types of CNC machines cater specifically to the unique demands of aerospace machining technology by allowing manufacturers to handle advanced materials like titanium and composite fibers effectively. The ability to maintain tight tolerances throughout the production process ensures that each component meets safety regulations and performance benchmarks critical in aviation applications. As such, understanding these machine types is vital for anyone considering how to become an aerospace machinist.

Popular Brands: SYIL CNC Machines

Among the notable brands making waves in the field of CNC machining aerospace parts is SYIL. Renowned for their commitment to quality and innovation, SYIL offers a range of affordable yet highly capable machines designed specifically for precision engineering in aerospace applications. Their products include compact desktop models as well as robust industrial-grade machinery that can tackle large-scale projects with ease.

SYIL’s reputation stems from their focus on delivering user-friendly interfaces combined with powerful capabilities—making them an excellent choice for both seasoned professionals and those just starting out in the industry. By investing in SYIL CNC machines, companies can enhance productivity while maintaining high standards necessary for producing reliable aerospace machined parts. This brand exemplifies how innovation within CNC technology can propel advancements across various sectors.

Innovation in CNC Technology for Aerospace

The landscape of what technology is used in aerospace has dramatically shifted due to continuous innovations within CNC machining systems. Advanced features such as automation, real-time monitoring, and adaptive control systems have transformed traditional manufacturing processes into highly efficient operations capable of meeting increasing demands from the aviation sector. These innovations not only improve production speed but also significantly reduce waste—a crucial factor when working with expensive materials.

Furthermore, developments like 5-axis machining have revolutionized how complex geometries are approached within aerospace manufacturing technology by allowing simultaneous movement along multiple axes during production. This level of versatility enables manufacturers to create intricate designs that were previously challenging or impossible using conventional methods. As we look toward future trends within this space, it's clear that ongoing advancements will continue shaping how we approach creating reliable and innovative solutions for aircraft design.

The Technology Behind Aerospace Manufacturing

In the ever-evolving world of aerospace machining technology, innovation is key to meeting the rigorous demands of the industry. From advanced materials to cutting-edge automation, each facet plays a crucial role in enhancing efficiency and precision. Understanding these technologies not only sheds light on current practices but also paves the way for future advancements in aerospace manufacturing technology.

Advanced Materials in Aerospace Machining

When it comes to aerospace machining technology, the choice of materials is paramount. Lightweight yet strong materials like titanium alloys and carbon fiber composites are increasingly being utilized for their superior performance characteristics. These advanced materials not only contribute to fuel efficiency but also enhance the longevity and durability of aerospace machined parts, making them essential for modern aircraft design.

Moreover, these materials often require specialized CNC machining techniques tailored to their unique properties. For instance, titanium's toughness can pose challenges during machining, necessitating precise tooling and cutting strategies that ensure optimal results. As such, understanding what is aerospace manufacturing technology also means recognizing how material selection directly influences machining processes and outcomes.

Role of Automation and Robotics

The integration of automation and robotics into aerospace manufacturing technology has revolutionized how components are produced. Automated systems streamline operations by minimizing human error while maximizing speed—traits that are critical when producing complex aerospace machined parts with tight tolerances. This shift towards automation not only enhances productivity but also allows skilled machinists to focus on more intricate tasks requiring human creativity and problem-solving skills.

Robots equipped with advanced sensors and AI capabilities can perform repetitive tasks with remarkable precision, ensuring consistent quality across all manufactured parts. This technological synergy between CNC machines used in the aerospace industry and robotic systems is paving the way for a new era in production efficiency. As we explore how to become an aerospace machinist today, familiarity with these automated systems becomes a valuable asset in navigating this high-tech landscape.

Future Trends in Aerospace Technology

Looking ahead, several exciting trends are set to shape the future of aerospace machining technology significantly. One notable trend is the increasing use of additive manufacturing techniques—commonly known as 3D printing—which allow for rapid prototyping and production of complex geometries that traditional methods struggle to achieve. This adaptability not only reduces waste but also shortens lead times dramatically.

Additionally, advancements in artificial intelligence will likely continue transforming how we approach CNC machining aerospace parts by optimizing processes through predictive analytics and machine learning algorithms that enhance decision-making capabilities on the shop floor. Sustainability will also play a pivotal role as manufacturers strive for greener practices through recycling efforts and energy-efficient processes.

As these trends unfold within the broader context of what technology is used in aerospace today, they promise exciting opportunities for those looking to enter or advance within this dynamic field.

Aerospace Machined Parts and Their Importance

Aerospace machined parts play a pivotal role in ensuring the safety, efficiency, and performance of aircraft and spacecraft. These components are meticulously crafted using advanced aerospace machining technology to meet stringent industry standards. Understanding the various types of aerospace machined parts is essential for grasping their significance in the aerospace manufacturing process.

Types of Aerospace Machined Parts

Aerospace machining technology encompasses a wide range of components, including structural parts, engine components, and intricate assemblies. Common types include fuselage frames, wing structures, turbine blades, and landing gear assemblies. Each part requires precision CNC machining to achieve the necessary tolerances and material properties that ensure reliability under extreme conditions.

When exploring what is aerospace manufacturing technology?, it’s clear that it involves not only the machining of these parts but also their integration into larger systems. For instance, turbine blades must withstand high temperatures and pressures while maintaining aerodynamic efficiency; therefore, they are often made from advanced materials like titanium or nickel alloys through specialized CNC machining processes. The diversity in aerospace machined parts highlights the complexity and innovation inherent in this field.

Quality Control in Aerospace Components

Quality control in aerospace components is non-negotiable; even minor defects can lead to catastrophic failures. To ensure that each machined part meets rigorous specifications, various quality assurance methods are employed throughout the manufacturing process. Techniques such as dimensional inspection, non-destructive testing (NDT), and material verification are integral to maintaining high standards.

The importance of quality control cannot be overstated when considering how to become an aerospace machinist? Aspiring machinists must be well-versed in these practices as they directly impact safety and performance outcomes in aviation operations. Implementing robust quality control measures not only enhances product integrity but also boosts customer confidence in aerospace manufacturing technology.

Case Studies of Successful Aerospace Projects

Several successful aerospace projects demonstrate the critical role that CNC machining plays within this sector. For example, Boeing's 787 Dreamliner showcases how innovative design paired with precise CNC machining has revolutionized fuel efficiency through lightweight materials like carbon fiber composites. This project exemplifies how advancements in aerospace machining technology can lead to significant improvements in aircraft performance.

Another notable case is SpaceX's Falcon 9 rocket, which utilizes highly engineered machined components for its engines and structural framework—showcasing what technology is used in aerospace? The successful reuse of rocket stages further emphasizes the importance of durable CNC machined parts capable of withstanding extreme conditions while maintaining performance standards over multiple flights. These case studies highlight not only technological advancements but also the collaborative efforts behind successful aerospace projects driven by precision engineering.

Conclusion

In the rapidly evolving field of aerospace machining technology, significant advancements are being made that enhance efficiency and precision. These innovations not only improve the production of aerospace machined parts but also ensure that safety and quality standards are met. The integration of advanced materials and sophisticated CNC machines has revolutionized what is possible in aerospace manufacturing technology.

Advancements in Aerospace Machining Technology

The landscape of aerospace machining technology is continuously changing, driven by the need for more efficient production methods and higher quality standards. New CNC machines designed specifically for the aerospace industry are being developed to handle complex geometries with unparalleled precision, making them indispensable for creating intricate aerospace machined parts. Additionally, advancements in software and automation are streamlining processes, reducing lead times, and increasing overall productivity in manufacturing environments.

Pathways to a Career in Aerospace Machining

If you're wondering how to become an aerospace machinist, there are several pathways available that can lead you into this exciting field. Essential skills include proficiency in CNC programming, a strong understanding of materials used in aerospace manufacturing technology, and attention to detail during machining processes. Training programs often offer hands-on experience with state-of-the-art CNC machines used in the aerospace industry, equipping aspiring machinists with the knowledge needed to excel.

Future Outlook for CNC Machining in Aerospace

The future outlook for CNC machining in aerospace is promising as technologies continue to advance at a brisk pace. With ongoing innovations such as additive manufacturing and smart automation systems becoming integral components of what technology is used in aerospace today, we can expect even greater efficiencies and capabilities moving forward. As industries adapt to these changes, professionals skilled in cnc machining aerospace parts will be increasingly sought after, ensuring a vibrant career landscape for those entering this specialized field.