Introduction

In the world of aerospace engineering, precision and reliability are paramount. Aerospace machined parts are crucial components that make up the intricate systems of aircraft and spacecraft. These parts undergo rigorous manufacturing processes to meet the demanding standards of the industry. From engine components to structural elements, aerospace machined parts play a vital role in ensuring the safety and performance of aerospace vehicles.

Understanding Aerospace Machined Parts

Aerospace machined parts refer to the specialized components used in aircraft and spacecraft, which are manufactured through precision machining processes. These parts are designed to withstand extreme conditions such as high temperatures, pressure differentials, and intense vibrations while maintaining their structural integrity and functionality. They are essential for the overall performance and safety of aerospace vehicles.

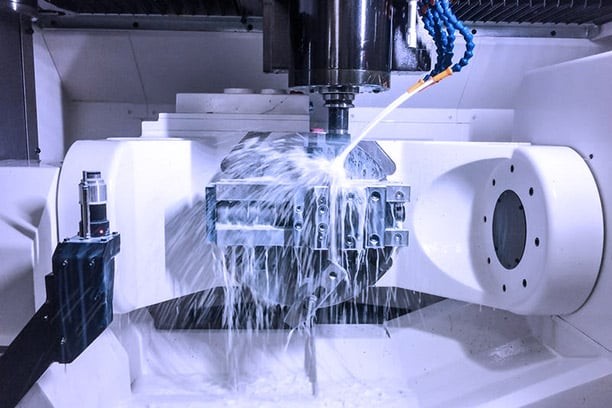

Importance of Aerospace CNC Machining

Aerospace CNC machining plays a critical role in producing high-quality aerospace components with unparalleled accuracy and consistency. The use of advanced CNC machines allows for complex geometries and tight tolerances required for aerospace applications. This level of precision is essential for ensuring the reliability and efficiency of aerospace systems.

Applications of Aerospace Machined Parts

Aerospace machined parts find application in a wide range of areas within the aerospace industry, including propulsion systems, landing gear, avionics, airframes, and more. These components are engineered to meet stringent performance requirements while adhering to strict regulatory standards for quality and safety.

Aerospace machined parts are crucial in ensuring the safety and performance of aircraft. From the intricate components of propulsion systems to the durable materials used in landing gear, these machined parts play a vital role in the functionality of aerospace vehicles. Additionally, the precision engineering required for avionics and airframes demonstrates the versatility and complexity of these essential components.

What are Machined Parts?

Definition and Characteristics of Machined Parts

Machined parts refer to components that have been shaped and formed through the process of machining, which involves the use of various tools and machinery to achieve precision and accuracy. These parts are known for their durability, high strength, and resistance to wear and tear, making them essential in aerospace applications.

Machined parts are crucial in the aerospace industry due to their ability to withstand extreme conditions, such as high temperatures and pressure changes. These components play a vital role in ensuring the safety and reliability of aircraft and spacecraft, as they are often subjected to intense stress during flight. The precision and accuracy achieved through machining processes result in parts that meet strict industry standards, contributing to the overall performance of aerospace systems.

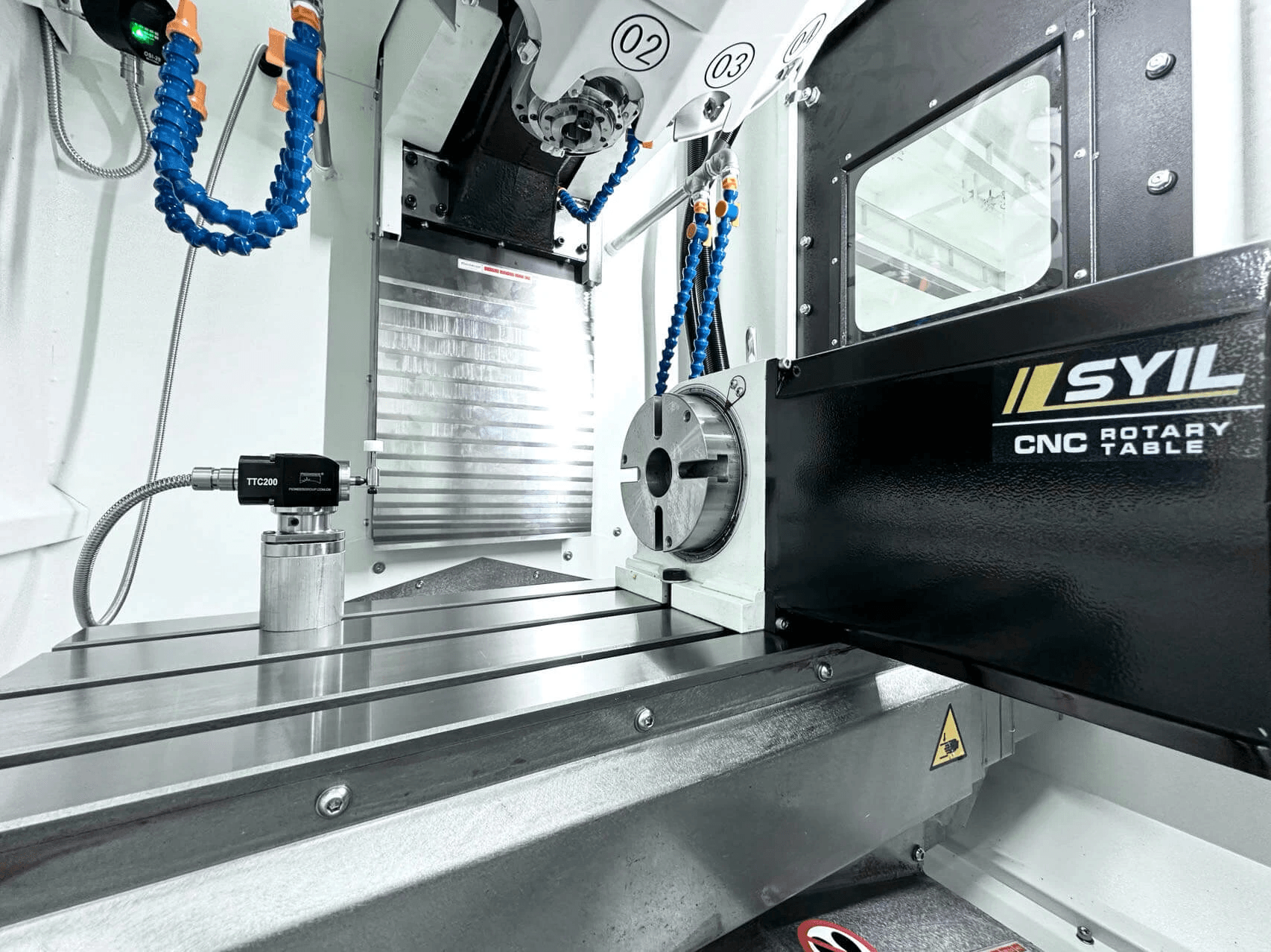

SYIL CNC Machine in Aerospace Machining

The SYIL CNC machine plays a crucial role in aerospace machining by offering advanced capabilities for precision engineering and manufacturing of aerospace components. With its cutting-edge technology and superior performance, the SYIL CNC machine ensures the production of high-quality machined parts that meet the stringent requirements of the aerospace industry.

Furthermore, the SYIL CNC machine offers increased efficiency and productivity in aerospace machining, allowing for faster turnaround times and reduced production costs. This is essential in the aerospace industry where precision and speed are of utmost importance. Additionally, the advanced capabilities of the SYIL CNC machine enable complex geometries and intricate designs to be machined with unparalleled accuracy, meeting the intricate demands of aerospace components.

Benefits of Using Machined Parts in Aerospace Industry

The use of machined parts in the aerospace industry brings numerous benefits, including exceptional dimensional accuracy, tight tolerances, and superior surface finishes. These parts also exhibit excellent material properties, allowing them to withstand extreme conditions such as high temperatures, pressure differentials, and corrosive environments typically encountered in aerospace operations.

Furthermore, machined parts offer exceptional strength and durability, ensuring the safety and reliability of aerospace equipment. Their precise construction also contributes to the overall efficiency of aircraft and spacecraft, reducing the risk of mechanical failures during critical missions. Additionally, the use of machined parts allows for greater design flexibility, enabling engineers to create complex and innovative components that meet the evolving demands of the aerospace industry.

Aerospace CNC Machining Process

Aerospace CNC machining process involves the use of computer numerical control (CNC) machines to produce aerospace machined parts and components with high precision and accuracy. These machines are programmed to follow specific design instructions, ensuring consistent and reliable results for critical aerospace applications.

Overview of Aerospace CNC Machining Process

The aerospace CNC machining process begins with the creation of a digital design for the required aerospace component. This design is then translated into a set of instructions that guide the CNC machine in shaping raw materials such as aluminum, titanium, or composites into the final part. The process involves cutting, drilling, milling, and turning to achieve the desired shape and dimensions.

After the raw materials are shaped, the aerospace component undergoes a series of quality checks to ensure that it meets the precise specifications required for its intended function. This involves using advanced measuring equipment such as coordinate measuring machines (CMM) and laser scanners to verify the accuracy of dimensions and surface finishes. Any deviations from the design specifications are meticulously addressed to guarantee that the final part meets the stringent quality standards demanded by the aerospace industry.

Precision and Accuracy in Aerospace CNC Machining

Precision and accuracy are paramount in aerospace machining due to the critical nature of the components involved. The use of advanced CNC machines allows for extremely tight tolerances to be achieved, ensuring that each part meets exact specifications. This level of precision is essential for components such as engine parts, landing gear components, and structural elements used in aircraft construction.

The use of advanced CNC machines not only allows for tight tolerances to be achieved but also enables the production of complex and intricate components that would be nearly impossible to manufacture using traditional methods. This level of precision is crucial in ensuring the safety and reliability of aircraft, as even the smallest deviation from specifications could result in catastrophic failure. Additionally, the ability to consistently produce high-precision parts contributes to overall cost savings by reducing the need for rework or scrapping of components that do not meet requirements.

Advanced Technologies in Aerospace Machining

The field of aerospace machining continues to benefit from advanced technologies that enhance efficiency and quality. High-speed machining techniques, multi-axis milling capabilities, and adaptive control systems are just a few examples of innovations that have improved the manufacturing process for aerospace machined parts. These advancements enable faster production times without compromising on quality or precision.

By leveraging aerospace CNC machining processes, manufacturers can produce high-quality components that meet stringent industry standards while maintaining cost-effectiveness. This approach ensures that aircraft operate safely and efficiently while minimizing downtime due to part failure or maintenance issues.

Manufacturing Aerospace Machined Parts

Key Considerations in Manufacturing Aerospace Machined Parts

When it comes to manufacturing aerospace machined parts, precision and reliability are of utmost importance. Each component must meet strict industry standards and regulations to ensure safety and performance in aircraft applications. The use of advanced CNC machining technology allows for intricate designs and complex geometries, making it essential to consider the capabilities of the machining process when manufacturing aerospace components.

In addition to precision and reliability, material selection is another critical consideration in manufacturing aerospace machined parts. The choice of materials must take into account factors such as strength, weight, and resistance to high temperatures and corrosion. Furthermore, the compatibility of the materials with the machining process and other components in the aircraft must also be carefully evaluated to ensure optimal performance and longevity.

Quality Control and Inspection in Aerospace Machining

Quality control and inspection play a crucial role in aerospace machining, as any defects or imperfections in machined parts can compromise the integrity of an aircraft. Rigorous testing procedures, including dimensional inspections, surface finish evaluations, and material analysis, are conducted to verify the quality of aerospace machined components. This ensures that each part meets the required specifications and standards before being integrated into aircraft systems.

In addition to testing procedures, material selection is also a critical aspect of aerospace machining. The choice of materials for machined parts must take into account factors such as strength, weight, and resistance to corrosion and fatigue. Aerospace engineers carefully select materials that can withstand the extreme conditions experienced during flight, ensuring the overall safety and performance of the aircraft. This involves thorough research and testing to identify the most suitable materials for each specific component, from structural elements to smaller precision parts.

Material Selection for Aerospace Machined Parts

The selection of materials for aerospace machined parts is a critical decision that directly impacts the performance and durability of aircraft components. High-strength alloys, titanium, aluminum, and composites are commonly used in aerospace manufacturing due to their lightweight properties and exceptional strength-to-weight ratios. The choice of material is carefully evaluated based on factors such as mechanical properties, corrosion resistance, thermal stability, and compatibility with CNC machining processes.

In addition to the mechanical properties and corrosion resistance, the material selection for aerospace machined parts also takes into account the specific environmental conditions that the aircraft will be exposed to during its operational life. Factors such as temperature variations, exposure to high-velocity airflow, and potential contact with abrasive particles all play a role in determining the most suitable material for a particular component. For example, components located near the engine may require materials with higher heat resistance, while those exposed to high levels of vibration may need materials with greater fatigue strength.

Examples of Aerospace Machined Components

Case Studies of Aerospace Machined Parts

Aerospace machined parts have played a crucial role in the development of aircraft components, such as turbine blades, landing gear, and structural components. These machined parts are manufactured with precision and accuracy to ensure optimal performance and safety in aerospace applications. For example, the CNC machining of aircraft engine components has significantly improved fuel efficiency and reduced emissions, making it a vital aspect of aerospace manufacturing.

Innovative Designs in Aerospace Machined Components

Innovative designs in aerospace machined components have revolutionized the industry by integrating advanced materials and complex geometries to enhance performance and reliability. For instance, additive manufacturing techniques have been utilized to create intricate lattice structures for lightweight yet durable aerospace parts. Additionally, advancements in multi-axis CNC machining have enabled the production of complex shapes and contours that were previously unattainable, leading to more efficient aircraft designs.

Performance and Reliability of Aerospace Machined Parts

The performance and reliability of aerospace machined parts are critical factors that determine the overall safety and functionality of aircraft systems. With stringent quality control measures and material selection criteria, aerospace machined components exhibit exceptional durability and resistance to extreme conditions such as high temperatures, pressure differentials, and dynamic loads. As a result, these precision-engineered parts contribute to the overall efficiency and longevity of aerospace systems.

Conclusion

Future of Aerospace Machining

The future of aerospace machining is promising, with advancements in technology and materials leading to more efficient and precise manufacturing processes. As the demand for lighter and stronger aerospace components continues to grow, the industry will need to adapt and innovate to meet these challenges.

Advancements in Aerospace CNC Machining

Advancements in aerospace CNC machining have revolutionized the way machined parts and components are manufactured for the aerospace industry. With the use of advanced technologies such as 5-axis machining and high-speed cutting, manufacturers can now produce complex aerospace parts with unparalleled precision and efficiency.

Ensuring Quality in Aerospace Machined Parts

Ensuring quality in aerospace machined parts is crucial for the safety and reliability of aircraft. Manufacturers must adhere to strict quality control standards and inspection processes to guarantee that every component meets the rigorous requirements of the aerospace industry. By utilizing state-of-the-art equipment and materials, they can deliver superior products that withstand the demanding conditions of flight.

With continuous advancements in technology and a relentless pursuit of excellence, the future of aerospace machining holds great promise for creating innovative solutions that push the boundaries of what is possible in aviation engineering.