Introduction

When it comes to the aerospace industry, precision and quality are non-negotiable. This is where CNC aerospace machining comes into play, revolutionizing the way aircraft parts are manufactured. But what exactly is aerospace CNC machining? It's a cutting-edge technology that utilizes computer numerical control to automate the machining process, ensuring unparalleled accuracy and efficiency in producing aerospace components.

Exploring CNC Aerospace Machining

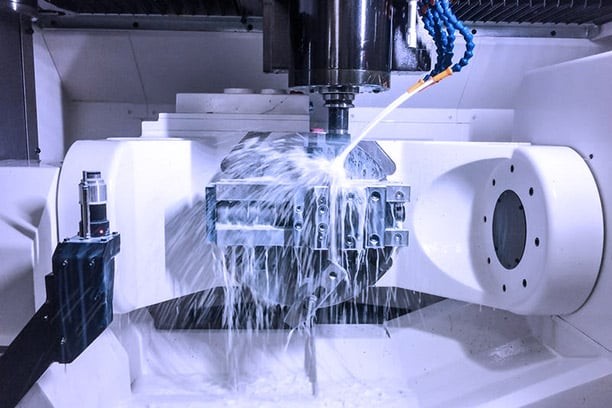

CNC aerospace machining involves the use of specialized machinery to carve, cut, and shape raw materials into intricate components for aircraft. These machines are operated by highly skilled CNC aerospace machinists who program them to execute precise movements with minimal human intervention.

The Impact of CNC Technology in Aerospace

The impact of CNC technology in aerospace has been monumental, as it has significantly improved the speed and accuracy of manufacturing critical aircraft parts. This has led to enhanced safety standards and reduced production costs in the aviation industry.

The Future of Aerospace Machining

As technology continues to advance, so does the future of aerospace machining. With ongoing research and development, we can expect even more sophisticated CNC machines and processes that will further elevate the precision and quality of aerospace components.

Understanding Aerospace CNC Machining

What is aerospace CNC machining?

Aerospace CNC machining refers to the process of using computer numerical control (CNC) technology to manufacture precision aerospace parts and components. This advanced manufacturing method allows for the automated and precise shaping of materials such as aluminum, titanium, and composites to create complex aerospace components.

Aerospace CNC machining is essential for creating parts that meet the strict requirements of the aerospace industry. With CNC technology, manufacturers can achieve incredibly tight tolerances and intricate designs that are necessary for aircraft and spacecraft components. This precision is crucial for ensuring the safety and performance of aerospace vehicles, making CNC machining a cornerstone of the industry.

The aerospace machining process

The aerospace machining process involves the use of CNC machines to cut, drill, and shape raw materials into specific parts required for aircraft construction. This process typically begins with the design of the part using CAD software, followed by the programming of the CNC machine to execute the necessary operations with high precision and accuracy.

Furthermore, CNC machining in aerospace offers the advantage of producing highly complex and intricate parts with minimal human intervention, reducing the risk of errors and ensuring consistent quality. This level of precision is essential in aerospace manufacturing, where even the smallest deviation can have significant consequences for safety and performance. Additionally, CNC machines can work with a wide range of materials, including aluminum, titanium, and composites, allowing for greater flexibility in design and engineering.

Benefits of CNC machining in aerospace

The use of CNC machining in aerospace offers numerous benefits, including increased productivity, reduced lead times, enhanced precision, and improved repeatability. Additionally, CNC technology enables the production of complex geometries that would be challenging or impossible to achieve using traditional manufacturing methods.

The Role of CNC in Aircraft Manufacturing

CNC technology plays a crucial role in aircraft manufacturing, revolutionizing the production of aerospace parts. With CNC, manufacturers can precisely and efficiently create complex components for aircraft, ensuring high-quality and reliable performance. This technology has transformed the way aerospace parts are produced, offering advanced capabilities that traditional machining methods cannot match.

What is CNC in aircraft?

CNC in aircraft refers to the use of computer numerical control technology to automate the machining process of aerospace parts. This technology allows for precise and accurate cutting, shaping, and finishing of components used in aircraft manufacturing. By utilizing CNC machines, manufacturers can achieve tight tolerances and intricate designs required for aerospace applications.

By utilizing CNC machines in aircraft manufacturing, manufacturers can also reduce the risk of human error and ensure consistent quality across all parts. This is especially crucial in aerospace applications where precision and reliability are paramount. Additionally, CNC technology allows for faster production times, ultimately contributing to more efficient and cost-effective manufacturing processes.

SYIL CNC machine in aerospace parts manufacturing

The SYIL CNC machine has become an integral tool in aerospace parts manufacturing, offering advanced features and capabilities that meet the stringent requirements of the industry. With its high precision and efficiency, SYIL CNC machines enable the production of complex aerospace components with exceptional accuracy and repeatability. These machines play a vital role in ensuring the quality and reliability of critical aircraft parts.

The advancements in aerospace CNC technology have revolutionized the manufacturing process, allowing for greater precision, efficiency, and flexibility in producing complex parts. SYIL CNC machines are at the forefront of these technological advancements, offering state-of-the-art features that cater to the specific needs of aerospace manufacturing. From multi-axis machining capabilities to advanced software integration, these machines are equipped to handle the intricacies of aerospace components with ease and accuracy.

Advancements in aerospace CNC technology

Advancements in aerospace CNC technology have led to significant improvements in speed, accuracy, and versatility for machining aerospace components. New developments such as multi-axis machining, adaptive control systems, and enhanced tooling technologies have further optimized the manufacturing process for aerospace parts. These advancements continue to push the boundaries of what is possible in terms of precision and complexity for aircraft components.

Precision and Quality in Aerospace CNC Machining

Precision is crucial in aerospace machining to ensure the accuracy and reliability of aircraft components. CNC technology allows for incredibly precise cuts and shapes, ensuring that every part meets the strict standards required for aerospace applications. This level of precision is essential for the safety and performance of aircraft.

The importance of precision in aerospace machining

Precision in aerospace machining refers to the ability to create highly accurate and consistent parts that meet exact specifications. This is vital in aerospace manufacturing, where even the smallest deviation from design can have serious consequences. CNC technology enables machinists to achieve this level of precision through automated processes that eliminate human error.

CNC technology has revolutionized the aerospace machining industry by allowing for incredibly precise and consistent production of parts. This level of accuracy is crucial in aerospace manufacturing, where any deviation from design specifications can lead to catastrophic failures. With CNC technology, machinists can rely on automated processes to eliminate the potential for human error, ensuring that every part meets the exacting standards required for safe and reliable aerospace components.

Ensuring quality in aerospace CNC parts

Quality control is a top priority in aerospace manufacturing, and CNC technology plays a key role in ensuring that every part meets rigorous quality standards. With automated cutting and shaping processes, CNC machines produce parts with consistent quality, minimizing defects and variations that could compromise safety or performance.

Furthermore, CNC technology allows for the production of complex aerospace parts with high precision and accuracy, ensuring that every component fits perfectly within the overall assembly. This level of precision is essential in aerospace manufacturing, where even the smallest deviation can have significant consequences. Additionally, CNC machines can operate continuously, leading to faster production times and shorter lead times for aerospace parts, ultimately benefiting the overall efficiency of the manufacturing process.

Advantages of using CNC technology for aerospace parts

The use of CNC technology offers several advantages for producing aerospace parts, including increased efficiency, reduced lead times, and improved accuracy. By automating the manufacturing process, CNC machines can produce complex parts with minimal human intervention, leading to faster production times and lower costs while maintaining high precision.

Furthermore, CNC technology allows for greater flexibility in design and production. With the ability to easily reprogram the machines, aerospace manufacturers can quickly adapt to changes in part specifications or design requirements without significant downtime or retooling. This means that companies can respond more effectively to customer demands and market fluctuations, ultimately improving their competitiveness in the aerospace industry.

Advancements in Aerospace CNC Technology

In the world of aerospace CNC machining, innovations are constantly shaping the industry. From advanced tooling technologies to cutting-edge software solutions, aerospace CNC machining continues to evolve at a rapid pace. These innovations are revolutionizing the way aerospace parts are manufactured, leading to increased efficiency and precision.

Innovations in aerospace CNC machining

In recent years, there have been significant advancements in aerospace CNC machining, such as the development of multi-axis machining centers and high-speed cutting tools. These innovations have allowed for more complex and intricate aerospace parts to be produced with unparalleled accuracy and speed. Additionally, the integration of artificial intelligence and machine learning has further optimized the manufacturing process, leading to reduced lead times and improved overall quality.

SYIL CNC machine in aerospace manufacturing

The SYIL CNC machine has become a game-changer in aerospace parts manufacturing. With its state-of-the-art technology and advanced capabilities, the SYIL CNC machine has proven to be instrumental in producing high-precision components for various aircraft applications. Its versatility and reliability make it a preferred choice for many aerospace manufacturers looking to stay ahead in this competitive industry.

Future trends in aerospace CNC technology

Looking ahead, the future of aerospace CNC technology holds even more exciting possibilities. Additive manufacturing, also known as 3D printing, is expected to play a significant role in producing complex geometries with reduced material waste. Furthermore, advancements in automation and robotics are poised to further streamline production processes while maintaining stringent quality control standard

Conclusion

CNC technology has revolutionized aerospace machining, offering precision and efficiency like never before. The use of CNC in aircraft manufacturing has streamlined the production process, resulting in high-quality aerospace parts. As the industry continues to evolve, embracing the future of aerospace CNC technology is essential for staying competitive and meeting the demands of the market.

The significance of CNC technology in aerospace

The significance of CNC technology in aerospace cannot be overstated. It has transformed the way aerospace parts are manufactured, allowing for complex designs and tight tolerances that were once impossible to achieve. With CNC machining, aerospace components can be produced with unparalleled accuracy, ensuring safety and reliability in aircraft performance.

Why aerospace CNC machining is essential

Aerospace CNC machining is essential for meeting the rigorous standards and demands of the aviation industry. The precision and consistency offered by CNC technology are crucial for producing high-quality aerospace parts that meet strict regulatory requirements. Without CNC machining, it would be nearly impossible to achieve the level of accuracy needed for critical aircraft components.

Embracing the future of aerospace CNC technology

As advancements continue to unfold, embracing the future of aerospace CNC technology is vital for staying ahead in a competitive market. Innovations such as SYIL CNC machines are paving the way for even greater efficiency and precision in aerospace manufacturing. By incorporating these advancements into production processes, manufacturers can ensure they remain at the forefront of technological progress.