Introduction

When it comes to precision engineering in the aerospace industry, aerospace CNC machining plays a crucial role. This advanced manufacturing process involves the use of computer-controlled machines to produce highly accurate and complex components for aircraft and spacecraft. The importance of precision in aerospace CNC machining cannot be overstated, as even the smallest error can have catastrophic consequences in the aerospace industry. From engine parts to structural components, CNC machines are widely utilized in the aerospace industry for their ability to deliver high-precision results consistently.

Understanding Aerospace CNC Machining

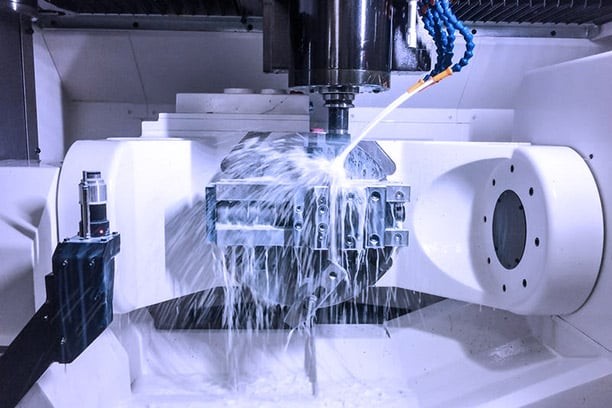

Aerospace CNC machining refers to the process of using computer-controlled machines to shape and fabricate metal and other materials into precise components for use in aircraft and spacecraft. These machines are capable of performing a wide range of operations, including cutting, drilling, milling, and turning, with unparalleled accuracy and repeatability.

Aerospace CNC machining is crucial in the production of components for aircraft and spacecraft, as these machines are capable of achieving levels of precision that are unmatched by traditional machining methods. This precision is essential in ensuring the safety and reliability of aerospace vehicles, as even the smallest deviation from design specifications can have catastrophic consequences. Additionally, the ability of CNC machines to produce identical parts with high accuracy and repeatability is vital for maintaining consistency in aerospace manufacturing, where uniformity and quality are paramount.

Importance of Precision in Aerospace CNC Machining

Precision is paramount in aerospace CNC machining due to the critical nature of the components being produced. The slightest deviation from design specifications can compromise safety and performance, making precision an absolute necessity in this industry.

Precision in aerospace CNC machining is not only crucial for safety and performance, but it also plays a significant role in fuel efficiency. Components that are precisely machined will fit together seamlessly, reducing friction and ultimately saving on fuel consumption. This is particularly important in the aerospace industry where every ounce of weight and every drop of fuel can make a difference in the overall performance of an aircraft.

Applications of CNC Machines in Aerospace Industry

CNC machines find extensive applications across various areas within the aerospace industry, from producing intricate engine parts to crafting lightweight yet durable structural elements for aircraft and spacecraft.

CNC machines have revolutionized the aerospace industry by enabling the production of complex and precise components that are essential for the functioning of aircraft and spacecraft. These machines are capable of creating intricate engine parts with high accuracy, ensuring optimal performance and safety. Additionally, CNC machining is used to craft lightweight yet durable structural elements, such as wings and fuselage components, contributing to the overall efficiency and reliability of aerospace vehicles.

What is Aerospace CNC Machining?

Aerospace CNC machining refers to the use of computer numerical control (CNC) machines to manufacture precision components for the aerospace industry. These machines utilize advanced software and cutting-edge technology to produce highly accurate and complex parts that are essential for aircraft and spacecraft.

Definition of Aerospace CNC Machining

Aerospace CNC machining involves the use of specialized CNC machines to fabricate components such as engine parts, landing gear, and structural elements for aerospace applications. These machines are capable of working with a wide range of materials, including aluminum, titanium, and composites, to meet the stringent requirements of the aerospace industry.

Aerospace CNC machining is highly precise, allowing for the production of complex and intricate components that are vital to the performance and safety of aerospace equipment. The use of CNC machines ensures consistent quality and accuracy, reducing the likelihood of errors or defects in the finished parts. This level of precision is essential in meeting the rigorous standards and regulations set forth by the aerospace industry, where even the smallest imperfection can have serious consequences.

Advantages of Aerospace CNC Machining

The advantages of aerospace CNC machining are numerous, including high precision, repeatability, and efficiency in producing complex parts with tight tolerances. This method also allows for reduced lead times and costs compared to traditional manufacturing processes, making it a preferred choice for aerospace component production.

Another advantage of aerospace CNC machining is the ability to produce parts with intricate designs and features that may be impossible or extremely difficult to achieve using traditional manufacturing methods. This allows for greater innovation and flexibility in design, ultimately leading to improved performance and functionality of aerospace components. Additionally, CNC machining offers the capability to work with a wide range of materials, from aluminum and titanium to composites, providing versatility in creating parts that meet the specific requirements of aerospace applications.

SYIL CNC Machine in Aerospace Industry

The SYIL CNC machine has established itself as a reliable solution for aerospace manufacturing needs. With its advanced technology and precision capabilities, the SYIL CNC machine is well-suited for producing critical components that meet the rigorous standards of the aerospace industry.

The SYIL CNC machine's ability to produce complex and intricate components with utmost precision makes it an invaluable asset in the aerospace industry. Its advanced technology allows for efficient manufacturing processes, reducing production time and costs while maintaining high quality standards. As a result, aerospace companies can rely on the SYIL CNC machine to deliver consistent, reliable results for critical components used in aircraft and spacecraft.

The Role of CNC Machinists in Aerospace Industry

Responsibilities of CNC Aerospace Machinists

CNC aerospace machinists are responsible for setting up and operating CNC machines to produce precision parts and instruments used in aircraft and spacecraft. They interpret blueprints, program machines, and monitor the production process to ensure quality and accuracy.

Skills required for CNC Machinists in Aerospace Industry

Aerospace CNC machinists need to have a strong understanding of engineering principles, as well as proficiency in computer-aided design (CAD) software and programming languages such as G-code. Attention to detail, problem-solving skills, and the ability to work with complex machinery are essential for success in this field.

Importance of High Precision CNC Machining in Aerospace

High precision CNC machining is crucial in the aerospace industry because even the smallest error can have catastrophic consequences. Precision parts are vital for ensuring the safety and performance of aircraft, making the role of CNC machinists indispensable. With the increasing complexity of aircraft designs, the demand for high precision CNC machining has never been greater. This technology allows for intricate and complex components to be manufactured with unparalleled accuracy, meeting the rigorous standards of the aerospace industry.

Application of CNC Machines in Aerospace Industry

Components Manufactured using Aerospace CNC Machining

Aerospace CNC machining is crucial in producing a wide range of components for the aerospace industry, including engine parts, landing gear, and structural components. These parts require high precision and complex geometries, making CNC machines the ideal choice for their production.

Importance of High Precision in Aircraft Components

High precision is paramount in aircraft components to ensure safety and reliability. Any deviation from the required specifications can have catastrophic consequences. Aerospace CNC machining guarantees the accuracy and tight tolerances needed for critical aircraft parts, making it indispensable in the industry.

Aerospace CNC machining not only ensures the accuracy and tight tolerances needed for critical aircraft parts, but it also allows for complex shapes and designs that are essential in modern aircraft components. The ability to produce intricate and intricate parts with high precision is a key factor in the advancement of aviation technology. With the use of advanced CNC machines, aerospace engineers can push the boundaries of what is possible in aircraft design, leading to safer and more efficient aircraft.

SYIL CNC Machine in Aerospace Component Manufacturing

The SYIL CNC machine has revolutionized aerospace component manufacturing by delivering unparalleled precision and efficiency. With advanced features and cutting-edge technology, SYIL machines are capable of producing complex aerospace parts with uncompromising accuracy, meeting the stringent requirements of the industry.

Furthermore, the SYIL CNC machine's ability to work with a wide range of materials, including aluminum, titanium, and composites, makes it a versatile and indispensable tool in aerospace manufacturing. Its flexibility allows for the production of various components such as engine parts, structural elements, and intricate pieces for avionics systems. This adaptability ensures that aerospace manufacturers can rely on SYIL machines for all their production needs without compromising quality or efficiency.

Benefits of Aerospace CNC Machining Solutions

Efficiency and Cost-effectiveness of Aerospace CNC Machining

When it comes to aerospace CNC machining, efficiency and cost-effectiveness are key benefits. With the use of high precision CNC machining, aerospace components can be manufactured with minimal material wastage, reducing production costs. This results in a more efficient manufacturing process, ultimately saving time and money for aerospace companies.

Quality Assurance in Aerospace CNC Machining

Aerospace CNC machining solutions offer unparalleled quality assurance for the production of aircraft components. The high precision capabilities of CNC machines ensure that each part is manufactured to exact specifications, meeting the stringent quality standards required for aerospace applications. This level of quality assurance is crucial in ensuring the safety and reliability of aircraft. Furthermore, the use of advanced CAD/CAM software in aerospace CNC machining allows for intricate designs to be translated into precise, flawless components, reducing the margin for error and ensuring optimal performance.

SYIL CNC Machine: A Trusted Solution for Aerospace Industry

The SYIL CNC machine has established itself as a trusted solution for the aerospace industry, providing advanced technology and precision engineering for aerospace CNC machining needs. With its cutting-edge features and capabilities, the SYIL CNC machine offers unmatched performance and reliability, making it an ideal choice for manufacturing high-quality aircraft components.

The SYIL CNC machine's state-of-the-art technology and precision engineering enable it to meet the demanding requirements of the aerospace industry. Its advanced features and capabilities ensure that it can produce high-quality, precise components for aircraft with unparalleled performance and reliability. Whether it's manufacturing engine parts, landing gear, or structural components, the SYIL CNC machine is a trusted solution that consistently delivers exceptional results.

Conclusion

The Future of Aerospace CNC Machining

As technology continues to advance, the future of aerospace CNC machining looks promising. With the integration of AI and automation, aerospace CNC machines are becoming more efficient and accurate than ever before. This will lead to faster production times and higher quality components for the aerospace industry. Additionally, advancements in 3D printing technology are also revolutionizing the aerospace industry by allowing for the production of complex, lightweight parts that were previously impossible to manufacture. This will result in aircraft that are not only more fuel-efficient but also have improved performance and safety features.

Innovations in Aerospace CNC Machining

Innovations in aerospace CNC machining are constantly evolving, with new materials and techniques being developed to meet the demands of modern aircraft design. From 3D printing to multi-axis machining, the industry is pushing the boundaries of what is possible, leading to more innovative and lightweight aircraft components.

In addition to advancements in materials and techniques, aerospace CNC machining is also benefiting from the use of advanced software and automation. Computer-aided design (CAD) and computer-aided manufacturing (CAM) software are enabling engineers to create more complex and intricate designs, while automation is streamlining the production process. This combination of advanced software and automation is not only increasing efficiency but also improving accuracy, leading to higher quality aerospace components.

Advancements in High Precision CNC Machining

Advancements in high precision CNC machining are crucial for the aerospace industry, where even the smallest error can have catastrophic consequences. With advancements in metrology and tooling technology, CNC machines are now capable of achieving even greater levels of precision, ensuring that every component meets the strict standards required for aircraft safety.