Introduction

In the aerospace industry, CNC machining plays a crucial role in producing high-precision components for aircraft and spacecraft. CNC (Computer Numerical Control) technology is used to automate the manufacturing of complex parts, ensuring accuracy and consistency in every piece. As an essential part of aerospace manufacturing, CNC machining is relied upon for creating intricate components that meet stringent industry standards.

What is Aerospace CNC Machining?

Aerospace CNC machining involves the use of computer-controlled machines to fabricate precise components for aircraft and spacecraft. This advanced manufacturing process allows for the production of complex parts with tight tolerances, ensuring optimal performance and safety in aerospace applications.

Importance of CNC Aerospace Parts

CNC aerospace parts are vital for the functioning and safety of aircraft and spacecraft. These components are designed to withstand extreme conditions and rigorous performance requirements, making precision manufacturing essential for their reliability and longevity.

Advantages of Using SYIL CNC Machine

The SYIL CNC machine offers numerous advantages for aerospace manufacturers, including high-speed production, exceptional accuracy, and versatility in handling various materials. With its advanced capabilities, the SYIL CNC machine is a valuable asset in producing top-quality aerospace components efficiently and cost-effectively.

The Evolution of Aerospace CNC Machining

Early Methods and Techniques

In the early days of aerospace CNC machining, manual processes were predominantly used for shaping and forming aerospace components. Machinists relied on traditional tools such as lathes, mills, and grinders to meticulously craft intricate parts for aircraft and spacecraft. These methods required extensive skill and precision, resulting in longer production times and higher costs for aerospace manufacturers.

As technology advanced, aerospace machining saw a shift towards computer numerical control (CNC) machining. This allowed for greater automation and precision in the production of aerospace components. CNC machines could follow complex instructions to create intricate parts with minimal human intervention, reducing the reliance on manual processes and traditional tools. This innovation resulted in faster production times and lower costs for aerospace manufacturers, making it a game-changer for the industry.

Modern Innovations in Aerospace Machining

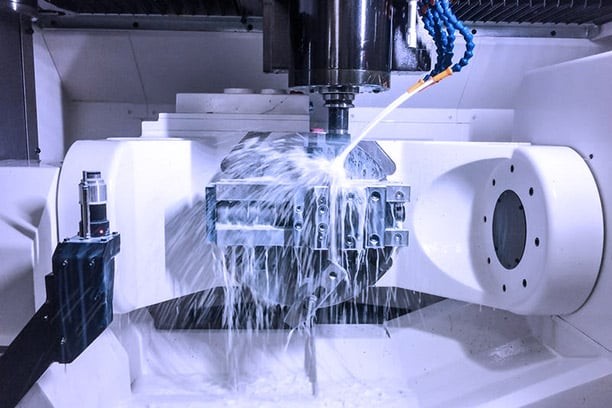

With advancements in technology, modern aerospace CNC machining has seen a significant shift towards automation and computer-controlled processes. High-precision CNC machines have revolutionized the industry by enabling faster production rates, improved accuracy, and enhanced repeatability. This has allowed aerospace manufacturers to meet the increasing demand for complex components while maintaining stringent quality standards. Additionally, the integration of advanced software systems has further optimized the production process by allowing for real-time monitoring and adjustments, resulting in more efficient operations and reduced downtime.

Role of Advanced Technologies in CNC Aerospace Parts Production

The integration of advanced technologies such as 5-axis machining, laser cutting, and additive manufacturing has further elevated the capabilities of aerospace CNC machining. These cutting-edge tools enable the production of intricate geometries, lightweight structures, and high-performance materials that are essential for modern aircraft design. As a result, the aerospace industry has experienced a paradigm shift in terms of efficiency and innovation.

The utilization of 5-axis machining has revolutionized the production process by allowing for simultaneous cutting from multiple angles, resulting in faster and more efficient manufacturing. This advanced technology also enables the creation of complex and intricate part geometries that were previously unattainable, providing aerospace engineers with greater design flexibility and creativity. As a result, aircraft components can now be manufactured with higher precision and accuracy, leading to improved performance and safety standards.

Precision and Quality in Aerospace CNC Machining

Importance of Accuracy in Aerospace Components

In aerospace CNC machining, accuracy is crucial as even the smallest deviation can lead to catastrophic consequences. Precision in aerospace components ensures safety, reliability, and optimal performance of aircraft systems. From engine parts to structural components, every piece must be manufactured with utmost accuracy to meet stringent industry standards.

Quality Control Measures in CNC Aerospace Parts

Quality control measures in CNC aerospace parts production involve rigorous testing and inspection processes to ensure that each component meets the required specifications. This includes dimensional checks, material testing, and surface finish evaluations. These measures are essential for maintaining the high standards of quality and safety in the aerospace industry.

SYIL CNC Machine in Ensuring Precision

The SYIL CNC machine plays a pivotal role in ensuring precision in aerospace machining. With its advanced technology and high-performance capabilities, the SYIL machine is designed to deliver exceptional accuracy and repeatability, meeting the demanding requirements of aerospace manufacturing. Its state-of-the-art features make it an ideal choice for producing complex and critical aerospace components with unparalleled precision.

Materials and Processes in Aerospace CNC Machining

Common Materials Used in Aerospace Machining

In the aerospace industry, CNC machining is used to work with a variety of materials, including aluminum, titanium, stainless steel, and composites. These materials are chosen for their lightweight properties, strength, and resistance to corrosion, making them ideal for aerospace components. CNC aerospace parts are often made from these materials to ensure durability and performance in aircraft.

In addition to their lightweight properties, strength, and corrosion resistance, the materials used in aerospace machining also offer excellent thermal conductivity. This is crucial for aerospace components as it allows for efficient heat dissipation, ensuring that the parts can withstand extreme temperatures experienced during flight. The ability of these materials to maintain their structural integrity at high temperatures makes them indispensable for critical aircraft components such as engine parts and heat shields.

Machining Processes for Different Aerospace Components

CNC machining in the aerospace industry involves various processes such as milling, turning, drilling, and grinding to create different components like engine parts, landing gear components, and structural elements. Each process requires precision and expertise to meet the strict standards of the aerospace sector. The use of advanced CNC machines ensures that these processes are carried out with accuracy and efficiency.

In addition to the standard aerospace materials like aluminum and titanium, SYIL CNC machines are capable of handling a wide range of materials commonly used in the aerospace industry. From high-strength steels to composites, our CNC machines can accommodate the diverse material requirements for different aerospace components. This versatility allows for greater flexibility in manufacturing processes and enables our machines to meet the specific needs of each aerospace project.

SYIL CNC Machine Capabilities in Handling Various Materials

The SYIL CNC machine is equipped with advanced technology that allows it to handle a wide range of materials used in aerospace machining. Its high-speed spindle and multi-axis capabilities enable it to work with aluminum, titanium, stainless steel, and composites with precision and consistency. This makes it a valuable asset for producing complex CNC aerospace parts that meet the stringent requirements of the industry.

Future Trends in Aerospace CNC Machining

As the aerospace industry continues to advance, automation and robotics are becoming increasingly prevalent in aerospace machining. These technologies are revolutionizing the production of CNC aerospace parts by streamlining processes, reducing human error, and increasing efficiency. With the integration of automation and robotics, aerospace CNC machining is poised to reach new levels of precision and productivity.

Automation and Robotics in Aerospace Machining

Automation and robotics are transforming the way CNC machining is carried out in the aerospace industry. By utilizing automated systems and robotic arms, manufacturers can significantly increase production rates while maintaining high levels of accuracy in the creation of complex aerospace components. This trend is reshaping the role of a traditional aerospace CNC machinist, as they now work alongside advanced technology to oversee and optimize production processes.

With the implementation of automation and robotics in aerospace machining, manufacturers are also able to minimize material waste and energy consumption. The advanced technology allows for precise control over the machining process, resulting in less material being wasted during production. Additionally, automated systems can be programmed to optimize energy usage, reducing the environmental impact of aerospace parts manufacturing. This sustainable approach not only benefits the environment but also contributes to cost savings for aerospace companies.

Sustainable Practices in CNC Aerospace Parts Production

In response to growing environmental concerns, sustainable practices are gaining traction in the production of CNC aerospace parts. Manufacturers are increasingly adopting eco-friendly materials and implementing energy-efficient processes to minimize their carbon footprint. Additionally, recycling initiatives for waste materials generated during machining operations are being prioritized to reduce environmental impact.

As the aerospace industry continues to evolve, SYIL CNC Machines is at the forefront of driving innovation and sustainability in aerospace manufacturing. Our state-of-the-art CNC machines are designed to optimize material usage and minimize waste, contributing to a more sustainable production process. By utilizing advanced technology and precision engineering, SYIL CNC Machines enables manufacturers to achieve higher efficiency and accuracy in producing aerospace parts while reducing environmental impact.

SYIL CNC Machine's Role in Shaping the Future of Aerospace Manufacturing

The SYIL CNC machine is at the forefront of shaping the future of aerospace manufacturing by integrating cutting-edge technologies into its systems. With its advanced capabilities, including automation features and sustainable production practices, SYIL machines are leading the way towards a more efficient and environmentally conscious approach to producing high-quality aerospace components.

The SYIL CNC machine's innovative approach to aerospace manufacturing extends beyond just technological advancements. Its commitment to sustainability and eco-friendly production practices sets it apart from traditional manufacturing methods. By incorporating sustainable materials and energy-efficient processes, SYIL machines are not only improving efficiency but also reducing the environmental impact of aerospace manufacturing. This forward-thinking approach positions SYIL as a leader in shaping the future of the industry towards a more sustainable and responsible direction.

Conclusion

The Future of Aerospace Machining

The future of aerospace machining is poised for groundbreaking advancements, with CNC technology playing a pivotal role. As the demand for precision and quality in aerospace components continues to rise, CNC machining will become even more integral in meeting these requirements. The integration of automation and robotics will further revolutionize the industry, leading to unparalleled efficiency and productivity.

As CNC technology continues to evolve, the aerospace industry will see an increase in the use of advanced materials such as composites and titanium. These materials present unique challenges for traditional machining processes, but CNC technology is well-equipped to handle their complex properties with precision and accuracy. This will open up new possibilities for designing and manufacturing aerospace components that are lighter, stronger, and more fuel-efficient.

Advancements in CNC Aerospace Parts Production

Advancements in CNC aerospace parts production are driven by the need for greater accuracy, speed, and cost-effectiveness. With the continuous development of cutting-edge technologies, such as 5-axis machining and high-speed milling, manufacturers can produce complex aerospace components with unprecedented precision. This evolution in CNC machining capabilities is propelling the aerospace industry towards new heights of innovation and excellence.

SYIL CNC Machine: Revolutionizing Aerospace Machining Industry

The SYIL CNC machine has emerged as a game-changer in the aerospace machining industry, offering unmatched versatility and performance. Its ability to handle various materials and intricate machining processes makes it an indispensable asset for producing high-quality aerospace components. With its advanced features and user-friendly interface, the SYIL CNC machine is reshaping the landscape of aerospace manufacturing.

The SYIL CNC machine's impact on the aerospace machining industry is undeniable, as it offers a level of versatility and performance that was previously unheard of. Its ability to handle a wide range of materials and intricate machining processes has positioned it as an indispensable tool for producing top-quality aerospace components. Moreover, the advanced features and user-friendly interface of the SYIL CNC machine have set a new standard for efficiency and precision in aerospace manufacturing, revolutionizing the way components are produced.

By embracing cutting-edge technologies like CNC machining, the aerospace industry is paving the way for a future marked by unparalleled precision, efficiency, and sustainability. As manufacturers continue to push the boundaries of innovation, the role of CNC technology will only grow more significant in shaping the future of aerospace manufacturing.