Introduction

In the world of manufacturing, precision is paramount, and CNC Swiss precision machining stands at the forefront of this quest for accuracy. This innovative technology has revolutionized how components are crafted, especially in industries requiring intricate designs and tight tolerances. As we delve into the nuances of what a CNC Swiss machine entails, it becomes clear that understanding its mechanics is essential for anyone looking to enhance their production capabilities.

Understanding CNC Swiss Precision Machining

CNC Swiss precision machining employs a unique approach to turning parts that allows for exceptional detail and efficiency. At the core of this technology lies a rotating workpiece and a sliding headstock, which enables tools to move along multiple axes simultaneously. This sophisticated method not only minimizes waste but also maximizes output quality, making it an attractive option for manufacturers across various sectors.

The Rise of Traditional CNC Machining

While CNC Swiss machines have gained popularity, traditional CNC machining has laid the groundwork for modern manufacturing techniques. With its straightforward operation and versatility, traditional CNC machining became a staple in many workshops over the years. However, as industries evolve and demands shift towards higher precision and complexity, it's clear that relying solely on traditional methods may not suffice.

Why It Matters: Choosing the Right Technology

Selecting between different machining technologies can significantly impact both production efficiency and product quality. Understanding what is CNC precision machining versus its Swiss counterpart will help businesses make informed decisions tailored to their specific needs. As we explore these technologies further, including insights on Swiss Precision Turning and considerations like CNC Swiss machine price, you'll be better equipped to determine which solution aligns best with your project goals.

What is a CNC Swiss Machine?

CNC Swiss machines are specialized tools designed for precision machining of complex parts, primarily utilizing the Swiss turning method. This technology allows for high-speed, accurate production of small, intricate components that are often challenging to manufacture using traditional CNC methods. Understanding what a CNC Swiss machine is can help manufacturers make informed decisions about their machining processes and technology investments.

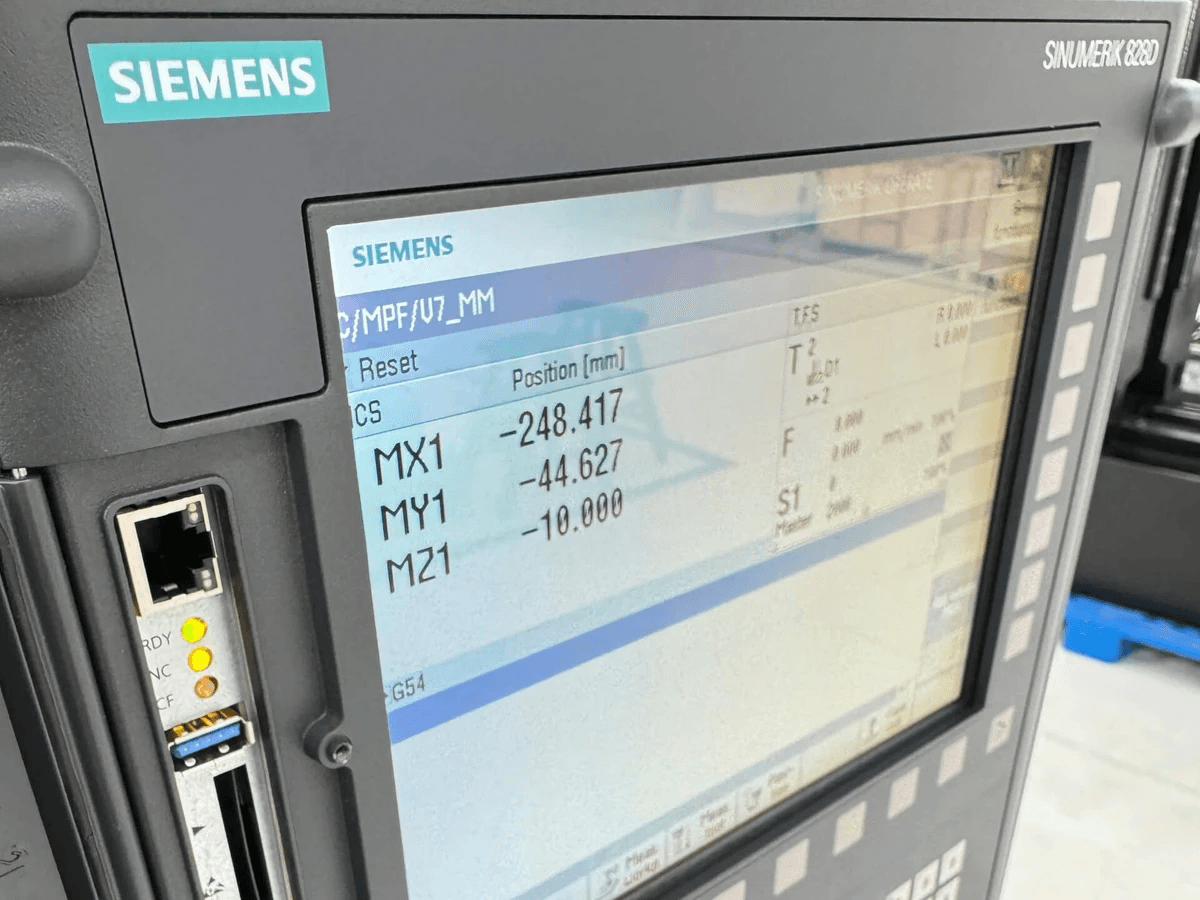

Mechanics Behind Swiss CNC Machines

At the heart of a CNC Swiss machine lies its unique mechanics, which enable it to produce parts with exceptional accuracy and efficiency. The design features a sliding headstock that moves along a guide rail, allowing for precise control over the workpiece as it rotates and is machined simultaneously by various cutting tools. This motion minimizes tool wear and enhances production speed, making CNC Swiss precision machining ideal for high-volume manufacturing of small parts.

In addition to its sliding headstock, the Swiss machine employs multiple spindles and tool holders that can be configured in various ways to accommodate different machining tasks. The ability to perform several operations—such as drilling, milling, and turning—on one setup reduces cycle times significantly compared to traditional methods. Ultimately, these mechanics contribute to the machine's reputation for producing consistently high-quality components with tight tolerances.

Key Features of CNC Swiss Precision Machining

CNC Swiss precision machining boasts several key features that set it apart from other machining technologies. One such feature is its ability to handle long workpieces without sacrificing accuracy or stability during the cutting process. This capability allows manufacturers to produce elongated parts efficiently while maintaining tight dimensional tolerances.

Another notable feature is the extensive range of tooling options available on most CNC Swiss machines. With interchangeable tools and quick-change systems, operators can easily switch between different operations without lengthy downtime or setup changes. Furthermore, these machines often come equipped with advanced software that enables real-time monitoring and adjustments during production—ensuring optimal performance throughout each machining cycle.

Lastly, many modern CNC Swiss machines incorporate automation technologies such as robotic loading systems or integrated bar feeders. These advancements not only streamline production but also enhance safety by reducing manual handling requirements in potentially hazardous environments—making them an attractive option for various industries looking to optimize their manufacturing processes.

Applications in Modern Manufacturing

The applications of CNC Swiss machines span numerous industries due to their versatility and precision capabilities in producing complex geometries at scale. In aerospace manufacturing, for example, these machines are used extensively for creating intricate components like valve bodies or fuel system parts where reliability is paramount. Their ability to maintain tight tolerances ensures that each part meets stringent industry standards while minimizing waste during production.

Similarly, medical device manufacturing has also embraced CNC swiss precision machining due to its capacity for producing small-scale components like surgical instruments or implantable devices with utmost accuracy and consistency. The healthcare industry demands high-quality products that meet regulatory requirements; thus using advanced technologies like CNC swiss machines helps manufacturers achieve compliance while optimizing efficiency.

Furthermore, automotive applications benefit from this technology when producing critical components such as fuel injectors or transmission parts—where performance directly impacts vehicle reliability and safety metrics on the road today! As industries continue evolving towards more complex designs requiring higher levels of precision than ever before; it's clear why understanding what a CNC swiss machine offers can be vital in choosing suitable solutions tailored specifically around project needs!

What is CNC Precision Machining?

CNC precision machining is a transformative technology that utilizes computer numerical control to create highly accurate parts and components. This method encompasses a variety of machining processes, including milling, turning, and drilling, all executed with remarkable precision. As industries demand tighter tolerances and more complex geometries, understanding what CNC precision machining entails becomes crucial for manufacturers aiming to stay competitive.

Overview of Traditional CNC Machining

Traditional CNC machining involves the use of computer-controlled machines to automate the manufacturing process. These machines can work with various materials such as metals, plastics, and composites to produce intricate parts with high repeatability. While traditional methods have been around for decades and have evolved significantly, they often lack the specialized capabilities found in modern innovations like CNC Swiss precision machining.

Comparing Operating Methods: CNC vs. Swiss

When comparing operating methods between traditional CNC and Swiss machines, the main distinction lies in their design and functionality. Traditional CNC machines typically operate on a fixed workpiece while moving multiple cutting tools around it; however, Swiss machines utilize a sliding headstock that allows for continuous feeding of material through rotating tools. This unique approach enables Swiss precision turning to achieve higher accuracy and efficiency than conventional methods can offer.

Benefits of CNC Precision Machining

The benefits of CNC precision machining are manifold and cater to various industrial needs. First off, it delivers unparalleled accuracy—crucial for sectors where even minor deviations can lead to significant issues down the line. Additionally, when considering options like the cnc swiss precision machine versus traditional alternatives, users often find that they can achieve faster production times while also reducing waste—making it not only efficient but also cost-effective in the long run.

Swiss Precision Turning: A Closer Look

Swiss precision turning is a game-changer in the world of CNC machining, offering unparalleled accuracy and efficiency. This innovative method utilizes a sliding headstock to feed material into the cutting tool, allowing for intricate designs and tight tolerances that traditional methods often struggle to achieve. As we dive deeper into how Swiss turning works, it becomes clear why it’s a preferred choice for many manufacturers.

How Swiss Turning Works

Swiss turning operates on a unique principle that sets it apart from conventional CNC precision machining techniques. The process begins with a bar of material being held in place while the cutting tool moves along multiple axes to create the desired shape. This simultaneous movement enables the machine to produce complex geometries with minimal waste, making it an efficient option for high-volume production runs.

In essence, what is a CNC Swiss machine? It’s designed to excel in producing small, precise parts quickly and accurately. By leveraging advanced technology and sophisticated programming capabilities, Swiss machines can handle everything from simple components to highly complex assemblies without sacrificing quality or speed.

Advantages Over Traditional Turning Methods

One of the standout advantages of Swiss precision turning over traditional methods is its ability to maintain tight tolerances consistently. While standard CNC lathes may struggle with intricate designs, CNC Swiss precision machining can produce parts with remarkable accuracy due to its unique design features and operational techniques. Additionally, because these machines work efficiently with shorter lengths of material, they reduce waste and maximize productivity.

Another benefit lies in their versatility; these machines can perform multiple operations simultaneously—such as drilling and milling—without needing to change setups frequently. This streamlining not only saves time but also reduces labor costs associated with manual setups or transfers between different machines. Therefore, investing in a Cnc swiss precision machine can lead to significant long-term savings while enhancing overall production capabilities.

Industries That Benefit from Swiss Precision

Swiss precision turning finds applications across various industries where high-quality components are essential. For instance, sectors like aerospace rely on this technology for producing lightweight yet durable parts that meet stringent safety standards—a task traditional methods often find challenging due to their limitations in complexity and size constraints. Similarly, the medical industry benefits greatly from this type of machining when creating intricate surgical instruments or implants that require absolute precision.

Moreover, automotive manufacturing has also embraced CNC swiss precision machining due to its ability to produce small parts used in engines or transmission systems efficiently and accurately. These industries demand not only speed but also reliability; hence choosing Swiss turning aligns perfectly with their operational goals while ensuring product integrity remains uncompromised.

In conclusion, understanding how Swiss Precision Turning works opens doors for manufacturers looking for innovative solutions tailored towards efficiency and quality assurance across various applications—from aerospace components down through automotive intricacies—all thanks to the prowess of modern Cnc swiss precision machines.

Cost Analysis: Swiss CNC Machine Price

Evaluating Investment in Swiss Technology

Investing in a CNC Swiss machine requires careful consideration of both upfront costs and potential return on investment. These machines are designed for high precision and efficiency, which can lead to reduced cycle times and lower labor costs over time. When evaluating the investment, consider not only the purchase price but also how much you can save on materials due to reduced waste—an often-overlooked factor in overall cost analysis.

In addition, think about the versatility that a CNC Swiss machine brings to your operations. With its ability to handle complex geometries and tight tolerances, it opens up new avenues for production that traditional methods simply can't match. This adaptability could lead to increased revenue through new contracts or improved product offerings, making it an attractive option for manufacturers looking to stay competitive.

Comparing Costs with Traditional CNC Machines

When comparing the costs of a CNC Swiss machine with traditional CNC machines, it's important to look beyond just purchase prices. While traditional machines may have lower upfront costs, they often require more extensive setups and longer machining times for complex parts—ultimately driving up operational expenses. In contrast, CNC Swiss precision machining allows for quicker setups and faster production cycles due to its unique design features.

Moreover, maintenance costs should also be factored into your comparison. Traditional CNC machines may incur higher maintenance expenses due to their complexity and wear-and-tear on components over time compared to a well-maintained Swiss machine that often boasts superior durability and reliability. Thus, while initial investments might seem steep for a Cnc swiss precision machine, their efficiency may offer significant savings in both time and money over traditional alternatives.

Long-Term Savings with CNC Swiss Precision Machining

The long-term savings associated with investing in a CNC Swiss machine can be substantial when you consider factors such as increased productivity and decreased waste rates. By minimizing material waste through precise cuts and efficient use of resources during production processes like Swiss Precision Turning, manufacturers can see their profit margins widen significantly over time.

Additionally, the operational efficiency gained from using advanced technology leads not only to faster turnaround times but also enhanced product quality—resulting in fewer returns or reworks that could eat into profits down the line. As businesses increasingly prioritize sustainability alongside profitability, opting for modern solutions like cnc swiss precision machining becomes an even more compelling choice.

Ultimately, while the initial outlay may raise eyebrows among budget-conscious managers or owners considering What is a CNC Swiss machine?, understanding these long-term benefits helps paint a clearer picture of why this technology is worth every penny spent upfront.

The Best in the Business: SYIL CNC Machines

When it comes to CNC Swiss precision machining, SYIL stands out as a top contender in the market. Their machines are engineered with cutting-edge technology that enhances productivity and precision, making them a favorite among manufacturers. With a focus on quality and innovation, SYIL has carved a niche for itself in the world of Swiss CNC machines.

Features of SYIL CNC Machines

SYIL CNC machines boast an array of features designed to optimize performance in Swiss precision turning. Equipped with high-speed spindles and advanced tooling systems, these machines can handle complex geometries with ease. Additionally, their user-friendly interface allows operators to maximize efficiency without extensive training, making them an ideal choice for both seasoned professionals and newcomers alike.

One standout feature is the multi-axis capability that enables simultaneous movements, which is crucial for achieving intricate designs typical in CNC precision machining. The robust construction ensures stability during operation, reducing vibrations that can affect accuracy. Furthermore, SYIL offers customization options so businesses can tailor machines to meet specific production needs.

Why Choose SYIL for Swiss Machining?

Choosing SYIL for your Swiss machining needs means investing in reliability and performance tailored to modern manufacturing demands. Their commitment to quality assurance ensures that each machine meets rigorous standards before it reaches customers’ hands. This dedication translates into fewer breakdowns and maintenance issues over time—a critical factor when evaluating the long-term costs associated with Swiss CNC machine price.

Moreover, SYIL integrates smart technology into its machines, allowing for real-time monitoring and data analysis which aids in optimizing production processes. This level of integration not only boosts efficiency but also provides valuable insights into operational performance—something traditional methods struggle to match. By opting for SYIL’s innovative solutions, manufacturers can stay ahead of industry trends while benefiting from enhanced productivity.

Customer Testimonials and Use Cases

The success stories surrounding SYIL's CNC Swiss precision machining are numerous and compelling. Customers frequently highlight how switching to a SYIL machine has significantly improved their production rates while maintaining exceptional quality standards—essentially transforming their operational capabilities overnight! One manufacturer reported a 30% increase in output after integrating a SYIL machine into their workflow.

Various industries have successfully adopted these machines for applications ranging from medical device manufacturing to aerospace components where precision is non-negotiable. Users rave about the seamless transition from traditional methods to advanced Swiss Precision Turning using SYIL’s technology—evidencing its adaptability across sectors with diverse requirements. These testimonials not only underscore customer satisfaction but also illustrate how investing in a Cnc swiss precision machine pays off through enhanced competitiveness.

Conclusion

As we wrap up our exploration of CNC Swiss precision machining, it's clear that this technology offers unique advantages that make it a standout choice for modern manufacturing. From its intricate mechanics to its ability to produce high-quality components with exceptional accuracy, understanding what a CNC Swiss machine can do is essential for any business looking to enhance production efficiency. The versatility of Swiss precision turning further solidifies its position as a game-changer in the industry, appealing to various sectors.

Key Takeaways on CNC Swiss Machining

CNC Swiss precision machining stands out due to its ability to handle complex geometries and tight tolerances effectively. When pondering what is CNC precision machining, one must recognize that it encompasses not just the machines themselves but also the advanced techniques and applications that set them apart from traditional methods. In summary, investing in a CNC Swiss machine means embracing innovation and ensuring your projects meet both quality and efficiency standards.

Final Thoughts on Traditional CNC Options

While traditional CNC options have their merits, they often fall short when compared directly with the capabilities of a CNC Swiss machine. The difference lies in how each technology handles materials; traditional methods may struggle with intricate designs or longer production runs where precision is paramount. Ultimately, businesses need to weigh the benefits of each approach carefully—while classic CNC machining has been around for decades, the evolution brought about by Swiss precision turning cannot be overlooked.

Making the Right Choice for Your Project

Choosing between traditional CNC options and cutting-edge technologies like CNC Swiss precision machining hinges on your specific project needs and budget constraints. Consider factors such as complexity, volume requirements, and desired tolerance levels when evaluating what is a CNC Swiss machine versus other alternatives available today. With insights into costs like Swiss CNC machine price alongside long-term savings potential, you’re better equipped to make an informed decision that aligns with your operational goals.