Introduction

In recent years, the medical industry has witnessed a remarkable transformation with the rise of CNC machining. This advanced manufacturing process has become indispensable for producing precision machined medical parts that meet the rigorous demands of healthcare professionals. As the need for accuracy and reliability in medical applications grows, CNC machining is stepping up to provide tailored solutions that enhance patient care and safety.

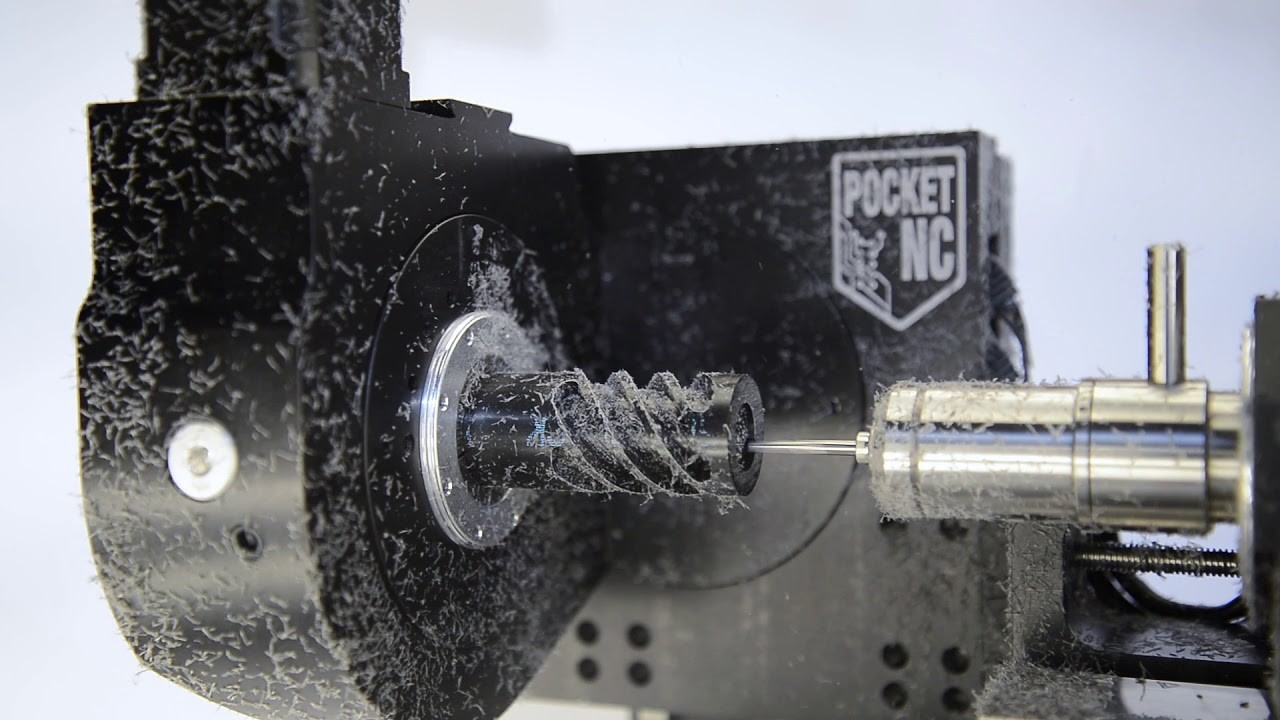

The Rise of CNC Machining in Medicine

CNC machining has gained significant traction in medicine due to its ability to create complex geometries with unparalleled precision. The production of Medical CNC Machined Parts allows for customization that traditional manufacturing methods simply cannot achieve. As a result, healthcare providers are increasingly turning to this technology to develop innovative tools and devices that cater specifically to patient needs.

Precision and Safety: Key Industry Needs

In the high-stakes world of healthcare, precision is not just a luxury; it's a necessity. Medical machined components must adhere to stringent safety standards to ensure optimal performance during critical procedures. With CNC Machining for the Medical Industry, manufacturers can produce parts that minimize risks and enhance patient outcomes by maintaining consistent quality throughout production.

Overview of CNC Machining Medical Parts

CNC machining encompasses a wide range of applications within the medical field, from surgical instruments to diagnostic equipment. A comprehensive Precision cnc machined medical parts list includes everything from orthopedic implants to dental devices, showcasing the versatility of this technology. By leveraging advanced techniques in Medical CNC machining, manufacturers are redefining what’s possible in creating reliable and effective medical solutions.

Surgical Instruments

Surgical instruments are the backbone of modern medical procedures, and CNC machining has revolutionized their production. High precision is not just a luxury; it’s a necessity in creating surgical tools that can withstand the rigors of operating rooms while ensuring patient safety. With the rise of Medical CNC machining, the ability to produce intricate designs with exacting standards has become commonplace, leading to improved outcomes and enhanced trust in medical practices.

High-Precision Surgical Tools

When it comes to high-precision surgical tools, every detail matters. These precision machined medical parts are crafted with meticulous attention to ensure they meet stringent industry standards for safety and effectiveness. From scalpels to forceps, each tool undergoes rigorous testing and quality assurance processes during CNC Machining for the Medical Industry, making them reliable companions in critical surgical scenarios.

Commonly Used CNC Machined Instruments

A variety of commonly used CNC machined instruments have emerged as essential components in surgeries worldwide. Examples include hemostatic clamps, needle holders, and retractors—all of which benefit from precision cnc machined medical parts list that guarantees consistency across multiple units. The use of Medical machined components not only enhances functionality but also minimizes operational risks during complex procedures.

The Role of Quality Control in Manufacturing

Quality control plays a pivotal role in the manufacturing process of surgical instruments made through Medical CNC machining. Each batch of precision machined medical parts undergoes stringent checks to ensure they adhere to predefined specifications before reaching healthcare professionals. This commitment to quality ensures that surgeons can rely on their tools under pressure, ultimately leading to better patient outcomes and greater confidence in surgical interventions.

Orthopedic Implants

Orthopedic implants are a cornerstone of modern medicine, offering solutions for various musculoskeletal issues. With the evolution of technology, CNC machining has become indispensable in producing these implants with unparalleled accuracy. The customization capabilities of CNC machining for the medical industry allow for tailored solutions that significantly improve patient outcomes.

Customization through CNC Machining

One of the most compelling advantages of CNC machining is its ability to create customized orthopedic implants that fit individual patient needs perfectly. This level of personalization is crucial, as every patient's anatomy is unique, and a one-size-fits-all approach simply won't suffice in orthopedic surgery. By utilizing precision machined medical parts, surgeons can ensure better alignment and functionality, ultimately leading to quicker recovery times and enhanced mobility.

Moreover, Medical CNC machining allows for rapid prototyping and iterative design changes, facilitating collaboration between engineers and medical professionals. This adaptability means that patients can receive implants designed specifically for their body structure, minimizing complications associated with ill-fitting devices. As healthcare continues to evolve towards personalized medicine, the role of precision cnc machined medical parts will only grow more significant.

Examples of Precision Machined Medical Parts

The variety of precision machined medical parts used in orthopedic applications is vast and impressive. Common examples include hip joints, knee replacements, and spinal fusion devices—all meticulously crafted to meet stringent quality standards. Each component must be manufactured with extreme precision; even slight deviations can lead to serious complications during surgery or post-operative recovery.

Additionally, manufacturers often maintain a comprehensive precision cnc machined medical parts list that outlines various components tailored for specific procedures or conditions. From screws and plates used in fracture fixation to complex joint prostheses designed through advanced CAD software—each part exemplifies the marriage between technology and medicine facilitated by CNC machining for the medical industry. The consistent quality achieved through Medical CNC Machining ensures these devices perform reliably within the human body.

The Impact of Biocompatibility

Biocompatibility is a critical consideration when designing orthopedic implants using Medical machined components; materials must interact positively with body tissues without causing adverse reactions. Precision machined medical parts made from materials like titanium or certain polymers are favored due to their strength and compatibility with biological systems. Ensuring biocompatibility not only enhances patient safety but also increases the longevity of implants within the body.

Furthermore, advancements in surface treatments and coatings are enhancing biocompatibility further while also promoting osseointegration—the process where bone cells attach directly to an implant's surface—thereby improving stability over time. As research progresses into new materials and methods in Medical CNC machining, we can expect even more innovative solutions that prioritize both performance and safety in orthopedic applications. Ultimately, understanding biocompatibility will continue shaping how precision cnc machined medical parts are developed for future generations.

Dental Devices

In the realm of dentistry, CNC machining has revolutionized the way dental devices are designed and manufactured. The precision and efficiency offered by CNC machining for the medical industry have enabled dentists to provide better care with customized solutions tailored to individual patient needs. From crowns to braces, precision machined medical parts are now a cornerstone of modern dental practices.

CNC Machining in Dentistry

CNC machining in dentistry allows for the creation of intricate designs that were once impossible with traditional methods. The technology ensures that each component is crafted with remarkable accuracy, resulting in enhanced fit and comfort for patients. By utilizing Medical CNC machining techniques, dental professionals can produce high-quality components that meet strict regulatory standards while maximizing patient satisfaction.

Popular Medical CNC Machined Parts

A variety of popular medical CNC machined parts are utilized in dental practices today, showcasing the versatility of this technology. These include crowns, bridges, orthodontic appliances, and implant abutments—all precision cnc machined medical parts that require meticulous attention to detail. Each part plays a vital role in ensuring effective dental treatment and improving overall oral health.

Advancements in Dental Technology

Recent advancements in dental technology have further propelled the use of Medical machined components within the field. Innovations such as 3D printing combined with CNC machining have allowed for even greater customization and efficiency, leading to improved patient outcomes. As these technologies continue to evolve, we can expect an exciting future where precision machined medical parts become even more integral to dentistry.

Prosthetics and Orthotics

Prosthetics and orthotics have experienced a revolution thanks to the advancements in CNC machining for the medical industry. By utilizing precision machined medical parts, manufacturers can create devices that are not only functional but also tailored to meet individual needs. This personalized approach enhances comfort and usability, ultimately improving patients' quality of life.

Tailored Solutions with Medical CNC Machining

CNC machining allows for the creation of custom prosthetic limbs and orthotic devices that fit each patient’s unique anatomy. By employing precision CNC machined medical parts, healthcare providers can ensure that these devices accommodate specific physical requirements, leading to better performance and comfort. This level of customization is particularly important in prosthetics, where even minor adjustments can significantly impact mobility and functionality.

Integration of Technology in Design

The integration of advanced technologies such as 3D scanning and computer-aided design (CAD) has transformed how medical machined components are developed. With Medical CNC machining, designers can create intricate shapes that are both lightweight and strong, optimizing the overall performance of prosthetic devices. These innovations enable seamless collaboration between engineers and clinicians, ensuring that every detail is accounted for in the final product.

Success Stories in Patient Outcomes

Numerous success stories highlight how precision CNC machined medical parts have positively impacted patient outcomes in prosthetics and orthotics. For instance, individuals who received custom-fitted prosthetic limbs reported increased mobility and a greater sense of independence compared to those with standard options. These real-world examples showcase the effectiveness of tailored solutions made possible through cutting-edge Medical CNC machining techniques.

Diagnostic Equipment

In the realm of healthcare, diagnostic equipment plays a pivotal role in ensuring accurate patient assessments and timely interventions. The effectiveness of these tools hinges on the precision machined medical parts that constitute their core components. With advancements in CNC machining for the medical industry, manufacturers are able to produce highly reliable and accurate medical machined components that meet stringent regulatory standards.

Importance of Accurate Medical Machined Components

Accurate medical machined components are crucial for the functionality and reliability of diagnostic equipment. Any deviation in precision can lead to incorrect readings, which may compromise patient safety and treatment outcomes. Therefore, investing in high-quality CNC machining medical parts is essential for maintaining the integrity of diagnostic tools used in hospitals and clinics.

Moreover, precision cnc machined medical parts ensure that devices like MRI machines, ultrasound equipment, and blood analyzers operate seamlessly. These components undergo rigorous testing to guarantee they meet the exact specifications required by healthcare professionals. As such, manufacturers must prioritize accuracy at every stage of production to uphold patient care standards.

Leading Manufacturers in Diagnostic Tools

Several leading manufacturers specialize in creating top-tier diagnostic tools that rely heavily on precision machined medical parts. Companies like Siemens Healthineers and GE Healthcare have established themselves as frontrunners by leveraging advanced CNC machining technologies to enhance their product offerings. Their commitment to quality ensures that every piece of equipment is equipped with reliable medical CNC machined parts designed for optimal performance.

Additionally, many smaller companies are also making waves in this space by focusing on niche markets within diagnostics. These manufacturers often utilize cutting-edge techniques in CNC machining for the medical industry to create specialized devices tailored to specific needs—be it portable ultrasound units or intricate laboratory analyzers. This diversity fosters innovation while ensuring patients receive accurate diagnoses through dependable technology.

How CNC Machining Enhances Performance

CNC machining enhances performance across various facets of diagnostic equipment by allowing for tighter tolerances and improved consistency among medical machined components. The automation involved ensures that each part is produced with exceptional accuracy, reducing human error during manufacturing processes significantly. This results not only in better-performing devices but also contributes to longer lifespans for these critical tools.

Furthermore, advancements in materials used alongside precision cnc machined medical parts have led to lighter yet more durable designs—perfectly suited for modern healthcare demands where mobility is key. The ability to customize components through CNC machining enables manufacturers to innovate continuously while adhering strictly to regulatory requirements governing the healthcare sector.

In summary, as we delve deeper into how CNC machining transforms diagnostic equipment, it becomes clear that this technology is indispensable for achieving high-quality standards necessary for effective patient care.

Conclusion

As we reach the end of our exploration into CNC machining in the medical field, it's clear that innovations are continuously propelling this technology forward. From advanced materials to sophisticated software, the evolution of CNC machining is shaping how precision machined medical parts are designed and manufactured. These innovations not only enhance the capabilities of medical professionals but also significantly improve patient outcomes through better tools and devices.

Innovations Driving CNC Machining Forward

The medical industry is witnessing a surge in innovative techniques that make Medical CNC machining more efficient and effective. Technologies such as 3D printing and artificial intelligence are merging with traditional CNC methods to create highly customized solutions for surgical instruments and implants. This synergy allows for a comprehensive precision cnc machined medical parts list that meets the diverse needs of healthcare providers, ensuring they have access to top-tier medical machined components.

Moreover, advancements in materials science have led to the development of biocompatible substances that can be precision machined for various applications. These materials not only enhance durability but also reduce the risk of adverse reactions in patients, showcasing how innovation directly impacts safety and efficacy in healthcare settings. As these technologies evolve, we can expect even greater efficiencies in production processes and quality control measures for Medical CNC Machined Parts.

The Future of Medical CNC Machined Parts

Looking ahead, the future of Medical CNC machining appears bright with endless possibilities on the horizon. The demand for personalized medicine is driving manufacturers to explore new avenues for customization through precision machining techniques tailored specifically for individual patients' needs. This trend will likely lead to an expanded range of precision machined medical parts designed uniquely for each case, thereby enhancing treatment effectiveness.

Furthermore, as regulatory frameworks adapt to accommodate these technological advancements, we can anticipate a broader acceptance of complex designs within surgical instruments and implants made from advanced materials. This shift will empower healthcare professionals with tools that not only perform better but also integrate seamlessly into existing protocols within hospitals and clinics worldwide. The landscape is set for significant growth in Medical CNC machining across various specialties.

Why Precision Matters in Healthcare

Precision is paramount when it comes to healthcare; after all, lives depend on it! Inaccuracies or flaws in medical machined components could lead to catastrophic consequences during procedures or treatments, making quality assurance non-negotiable in this industry.

Moreover, precise manufacturing processes directly correlate with improved patient outcomes—whether it's through enhanced functionality of surgical tools or better fitting orthopedic implants that promote healing and comfort post-surgery. With continuous investments being made into refining these processes further, there's no doubt that precision machined medical parts will continue to play a crucial role in advancing healthcare practices globally.