Introduction

In recent years, the healthcare industry has witnessed a significant transformation with the rise of custom medical machining. This evolution is largely driven by advancements in technology, particularly Computer Numerical Control (CNC) machining, which has revolutionized how medical devices are designed and manufactured. With an emphasis on precision and customization, healthcare providers are increasingly turning to custom CNC machining to enhance patient care and improve outcomes.

The Rise of Custom Medical Machining

Custom medical machining has emerged as a vital component in the production of specialized medical devices tailored to meet specific patient needs. This shift towards bespoke solutions allows for greater flexibility in design and functionality, which is essential in a field where every detail can impact patient safety and effectiveness. As healthcare demands evolve, custom medical machining manufacturers are stepping up to create innovative instruments that cater to these unique requirements.

How CNC Shaped the Medical Device Industry

CNC technology has played a pivotal role in shaping the modern medical device industry by enabling precise manufacturing processes that were previously unimaginable. By automating complex tasks, CNC in medical terms allows for consistent quality and repeatability across large production runs while also accommodating smaller batches of custom devices. The result? An impressive array of options that can be tailored specifically for individual patients or surgical procedures.

Benefits of Precision in Healthcare

The benefits of precision offered by custom CNC machining extend beyond mere aesthetics; they directly influence patient outcomes and operational efficiency within healthcare settings. For instance, what is an example of a custom made medical device? Consider orthopedic implants designed with exact specifications based on 3D imaging data—this level of customization enhances fit and functionality while reducing recovery times for patients. Ultimately, embracing precision through custom medical machining not only improves surgical success rates but also elevates overall patient care standards across the board.

Understanding CNC in Medical Terms

In the realm of healthcare, custom medical machining has revolutionized the way medical devices are designed and manufactured. At the heart of this transformation lies CNC (Computer Numerical Control) machining, a technology that has made precision and customization more accessible than ever. By understanding what CNC machining is and its role in medical devices, we can appreciate its significance in enhancing patient care.

What is CNC Machining?

CNC machining refers to a manufacturing process where pre-programmed computer software dictates the movement of machinery and tools. This technology allows for high precision and repeatability, making it ideal for custom CNC machining applications in the medical field.

The Role of CNC in Medical Devices

CNC plays a pivotal role in producing various medical devices by ensuring that each component meets stringent quality standards while maintaining tight tolerances. For instance, what is an example of a custom-made medical device? Think about orthopedic implants tailored specifically to fit an individual’s anatomy—these are often crafted using advanced CNC techniques. The ability to produce such customized solutions not only enhances device performance but also significantly improves patient outcomes.

Key Features of Medical CNC Machining

Medical CNC machining is characterized by several key features that distinguish it from traditional manufacturing processes. First and foremost, it offers unparalleled precision, which is critical when dealing with life-saving equipment or delicate instruments. Additionally, custom medical machining companies often utilize biocompatible materials to ensure safety and compliance with regulatory standards—a crucial aspect when developing products intended for human use.

Custom Machining for Medical Instruments

In the ever-evolving landscape of healthcare, custom medical machining has become a cornerstone for creating tailored medical instruments that meet specific patient needs. Unlike off-the-shelf solutions, custom CNC machining allows for precise adjustments in dimensions and features, ensuring that each device is optimized for its intended use. This level of customization not only enhances performance but also significantly improves patient outcomes, making it an essential aspect of modern medicine.

Importance of Custom Medical Machining

Custom medical machining is crucial in developing instruments that cater to the unique requirements of various medical procedures. With advancements in technology, healthcare providers are increasingly relying on custom CNC machining to produce specialized devices that enhance surgical precision and efficacy. The ability to create bespoke tools means that healthcare professionals can tackle complex cases more effectively, ultimately leading to improved patient care.

Moreover, the importance of custom medical machining extends beyond just functionality; it also encompasses regulatory compliance and safety standards. Each custom-made device must adhere to stringent guidelines set by health authorities, ensuring they are both safe and effective for use in clinical settings. By choosing reputable custom medical machining companies, manufacturers can guarantee their products meet these high standards while still delivering exceptional quality.

Examples of Custom Made Medical Devices

When considering what is an example of a custom made medical device, one might think of surgical instruments like scalpels or forceps designed specifically for particular procedures or anatomical considerations. Additionally, prosthetics tailored to fit individual patients perfectly illustrate the significance of custom CNC machining in enhancing quality of life through personalized solutions. Other examples include orthopedic implants designed using advanced imaging techniques to match a patient's unique bone structure.

In the realm of diagnostics, custom medical devices such as specialized catheters or endoscopes demonstrate how precision engineering can lead to better diagnostic capabilities and reduced procedural risks. These devices are often crafted with specific materials and geometries that improve their functionality while minimizing discomfort for patients during use. The breadth and diversity in examples highlight just how integral custom CNC machining is across various fields within medicine.

Case Studies: Successful Custom Instrument Projects

To truly appreciate the impact of custom medical machining, let’s delve into some case studies showcasing successful projects undertaken by leading manufacturers in this field. One notable instance involved a company specializing in orthopedic implants that collaborated with surgeons to develop a range of fixation devices tailored specifically for complex joint surgeries. By utilizing advanced CAD software and CNC technology, they created instruments that not only improved surgical outcomes but also reduced operation times significantly.

Another compelling case study involved a manufacturer producing customized robotic surgical tools designed for minimally invasive procedures. By engaging directly with surgeons during the design phase, they ensured these tools met real-world demands while adhering strictly to safety regulations—demonstrating how effective communication between healthcare providers and custom medical machining companies can lead to groundbreaking results.

These examples underscore the transformative potential inherent in embracing tailored solutions through medical CNC machining—showing us all just how far innovation can take us when precision meets personalization.

The Cost Factor in Custom Machining

When it comes to custom medical machining, understanding the cost factor is crucial for healthcare providers and manufacturers alike. The intricacies involved in creating precision instruments mean that pricing can vary significantly based on a multitude of factors. Knowing how much custom machining costs can help stakeholders make informed decisions, ensuring they receive quality products without breaking the bank.

How Much Does Custom Machining Cost?

So, how much does custom machining cost? Generally, prices can range from a few hundred to several thousand dollars per piece, depending on complexity and materials used. For instance, a simple component may be relatively inexpensive, while intricate designs requiring advanced techniques could drive costs higher—think of those bespoke surgical instruments tailored specifically for unique procedures.

Additionally, the scale of production plays a significant role; larger orders often benefit from economies of scale that reduce the per-unit cost. Custom CNC machining also incurs setup fees which can add to initial expenses but are generally offset by high-quality outputs and longer-lasting devices. Ultimately, understanding these variables helps healthcare providers budget effectively for their needs while ensuring they don’t compromise on quality.

Factors Influencing Custom CNC Machining Pricing

Several factors influence the pricing of custom CNC machining services in the medical field. First and foremost is material selection; high-grade materials such as titanium or specialized polymers tend to be more expensive than standard metals or plastics due to their superior properties and biocompatibility. Additionally, the complexity of the design impacts labor time and machine usage—more intricate designs require advanced programming and longer processing times.

Another key factor is tolerances; tighter tolerances often necessitate more precise machinery and skilled operators, increasing overall costs. Moreover, lead times play a role; quicker turnaround requests may incur rush fees due to prioritization in production schedules. Understanding these influences enables healthcare providers to select appropriate vendors among various custom medical machining companies based on budgetary constraints without sacrificing quality.

Cost-Effective Solutions for Healthcare Providers

Finding cost-effective solutions in custom medical machining doesn't have to feel like searching for a needle in a haystack! One approach is collaborating with experienced custom medical machining manufacturers who offer flexible pricing models or bulk discounts for larger orders. These companies often leverage advanced technologies like automation or efficient supply chain management, ultimately passing savings onto clients.

Another option is exploring alternative materials that still meet regulatory standards but offer lower costs than premium options without compromising functionality—think about innovative composites instead of traditional metals when feasible! Lastly, investing in long-term partnerships with reliable custom CNC machining companies can lead to better pricing structures over time as trust builds between parties involved—after all, good relationships are priceless!

Selecting the Right Custom Medical Machining Company

Choosing the right custom medical machining company is crucial for ensuring that your medical devices meet stringent quality standards and patient needs. With the rising demand for precision and customization in healthcare, understanding what to look for in a manufacturer can save time, money, and headaches down the line. This section will guide you through some of the top custom medical machining manufacturers, how to evaluate their capabilities, and why SYIL CNC machines stand out in this competitive landscape.

Top Custom Medical Machining Manufacturers

The market is brimming with custom medical machining manufacturers who specialize in producing high-quality components tailored for various medical applications. Companies like Medtronic, Stryker, and Zimmer Biomet have established themselves as leaders by consistently delivering innovative solutions that comply with regulatory requirements. Additionally, smaller niche players are emerging, focusing on specialized areas such as orthopedic implants or surgical instruments—offering unique advantages in terms of flexibility and customization.

When considering custom CNC machining options, it’s essential to review each manufacturer’s portfolio to see examples of their work in action. This not only showcases their expertise but also gives insight into what is an example of a custom made medical device they’ve successfully produced. A well-rounded manufacturer should demonstrate experience across a range of products while maintaining rigorous quality control measures.

Lastly, don’t forget to check customer testimonials and case studies highlighting successful collaborations between healthcare providers and custom medical machining companies. These insights provide valuable context on reliability, responsiveness, and overall satisfaction—key factors when selecting a partner for your next project.

Evaluating Custom Medical Machining Companies

Evaluating potential custom medical machining companies requires careful consideration of several factors that impact both cost and quality outcomes. Start by assessing their certifications; ISO 13485 certification indicates compliance with international standards specific to the medical device industry—an essential marker of credibility in this field. Furthermore, inquire about their machinery capabilities: modern CNC machines equipped with advanced technology can significantly enhance precision during production.

Another critical aspect involves understanding how much does custom machining cost? Pricing can vary widely based on complexity, materials used, volume requirements, and lead times; hence transparency regarding pricing structures is vital for budgeting effectively. It’s advisable to request detailed quotes from multiple vendors while ensuring they break down costs associated with design iterations or prototyping phases.

Finally, consider the company’s ability to provide ongoing support throughout the lifecycle of your product—from prototype development through post-production service offerings like maintenance or repairs. A responsive partner will ensure that any issues are swiftly addressed without disrupting your operations or patient care processes.

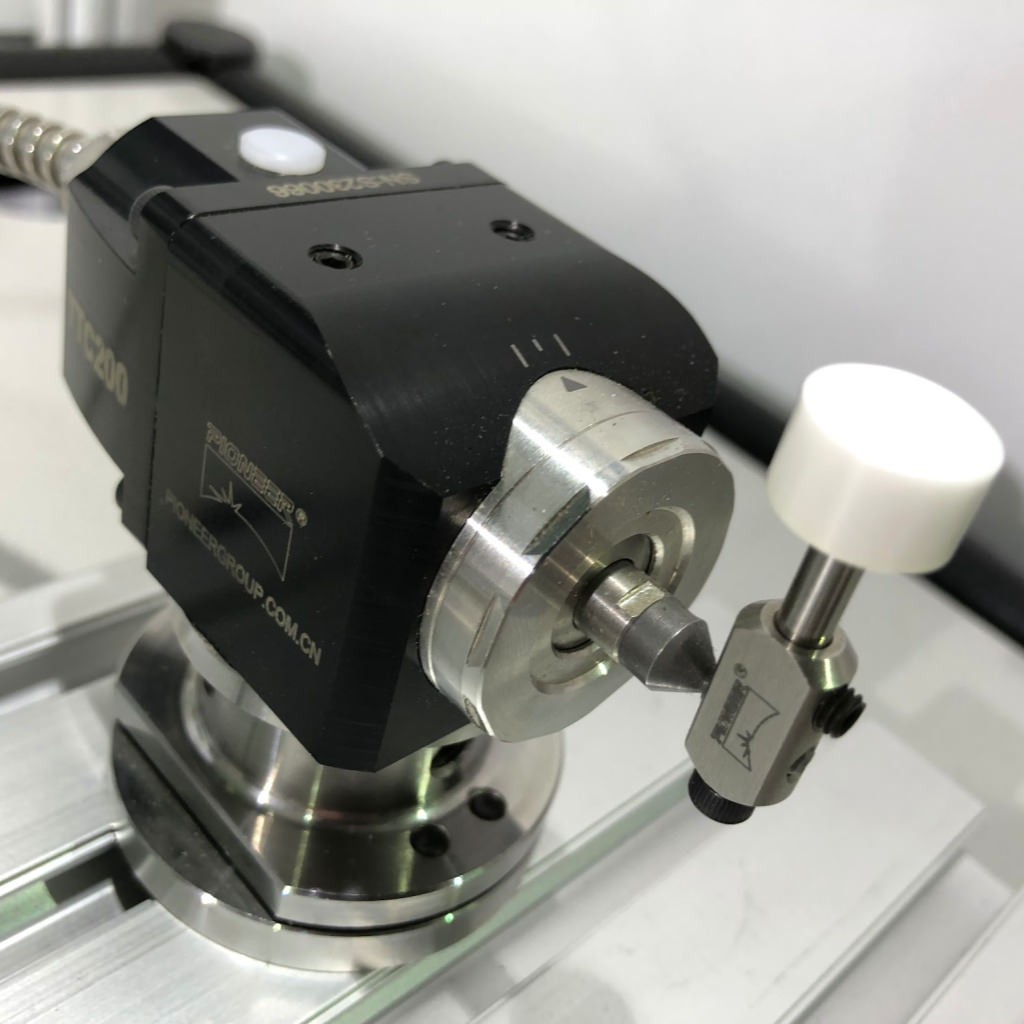

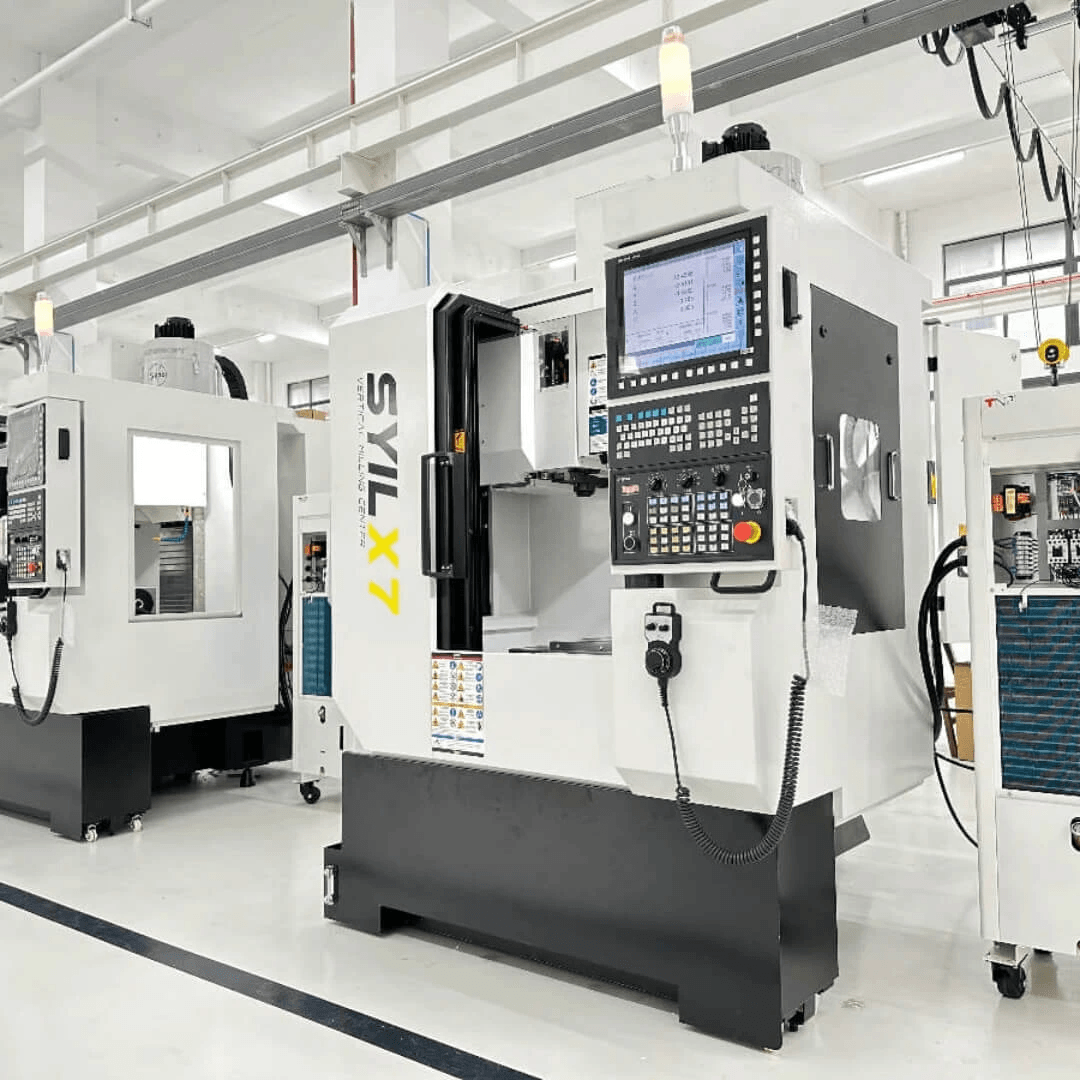

Why Choose SYIL CNC Machines for Precision

When it comes to precision in custom medical machining projects, SYIL CNC machines have garnered attention as a reliable choice among manufacturers seeking high-quality output without breaking the bank. Known for their user-friendly interface combined with robust performance capabilities—SYIL machines facilitate efficient production processes while maintaining tight tolerances required in healthcare applications like surgical instruments or implantable devices.

One standout feature is SYIL's commitment to innovation; they continuously integrate cutting-edge technology into their equipment which enhances productivity while reducing waste—a significant advantage when considering cost-effective solutions for healthcare providers navigating budget constraints related to manufacturing expenses associated with custom CNC machining projects.

Moreover, SYIL’s reputation within the industry speaks volumes; satisfied clients rave about improved turnaround times coupled with exceptional customer service support throughout every stage of production—from initial inquiry through final delivery—making them an ideal partner if you're looking at investing in high-quality custom medical machining solutions tailored specifically toward enhancing patient care outcomes.

Future Trends in Medical CNC Machining

The landscape of medical CNC machining is evolving rapidly, driven by technological advancements and the growing demand for precision in healthcare. As we look ahead, several trends are shaping the future of custom medical machining, ensuring that the industry continues to meet the needs of both patients and providers. From innovative manufacturing techniques to the integration of 3D printing, these trends promise to revolutionize how medical devices are designed and produced.

Innovations in Custom Medical Machining

Innovations in custom medical machining are transforming how medical instruments are crafted, providing unmatched precision and efficiency. One significant advancement is the use of advanced materials that enhance durability while maintaining biocompatibility—essential for devices used within the human body. Additionally, software improvements enable more sophisticated design simulations, allowing manufacturers to create highly customized solutions tailored to specific patient needs.

As a result, custom CNC machining has become more accessible for healthcare providers seeking unique solutions without sacrificing quality or performance. Moreover, these innovations help streamline production processes, reducing lead times and improving turnaround rates for critical components. Ultimately, this evolution not only enhances patient care but also empowers medical professionals with tools designed specifically for their requirements.

The Impact of 3D Printing on CNC Machining

The rise of 3D printing has significantly impacted CNC machining within the medical sector by enabling rapid prototyping and production of complex geometries that were previously challenging to achieve. This technology allows for a level of customization that traditional methods struggle to match—perfectly aligning with the principles behind custom medical machining. For example, creating intricate implants or surgical tools can now be done swiftly and cost-effectively using a combination of both 3D printing and CNC techniques.

With this synergy between technologies, manufacturers can produce small batches or even one-off items tailored precisely to individual patient anatomies—a feat that enhances surgical outcomes dramatically. Furthermore, as 3D printing technology continues to advance, its integration into custom CNC machining processes will likely lead to even more innovative solutions in device design and manufacturing practices. This collaboration promises a future where personalized medicine becomes increasingly feasible through bespoke instrument development.

Predictions for Medical Instrument Development

Looking ahead at predictions for medical instrument development reveals an exciting horizon filled with opportunities fueled by advancements in custom CNC machining technologies. We can expect a surge in smart devices equipped with sensors capable of monitoring patient conditions in real time—an evolution made possible through precise engineering techniques offered by custom medical machining manufacturers. These innovations will not only improve diagnostic capabilities but also enhance treatment efficacy through data-driven insights.

Moreover, as healthcare systems continue embracing value-based care models, there will be increased pressure on manufacturers to deliver cost-effective solutions without compromising quality—prompting further exploration into how much does custom machining cost? This focus on affordability coupled with customization ensures that healthcare providers have access to instruments uniquely suited to their operational needs while optimizing resource allocation effectively.

In summary, embracing these trends will pave the way for enhanced patient care experiences and improved clinical outcomes across various specialties in medicine—a testament to the vital role played by custom CNC machining companies today.

Conclusion

In the rapidly evolving landscape of healthcare, precision machining has emerged as a cornerstone of medical innovation. The impact of precision machining on healthcare cannot be overstated; it has transformed how medical devices are designed, manufactured, and utilized in clinical settings. With custom medical machining at the forefront, we can expect enhanced patient outcomes and improved operational efficiencies across the board.

The Impact of Precision Machining on Healthcare

Precision machining plays a critical role in ensuring that medical devices meet stringent regulatory standards while also being tailored to specific patient needs. For instance, understanding what is CNC in medical terms allows manufacturers to create components that fit seamlessly into complex systems like surgical robots or diagnostic machines. The result is a higher level of reliability and safety in medical treatments, which ultimately benefits both healthcare providers and patients alike.

Custom Instrumentation's Role in Patient Care

Custom instrumentation is vital for delivering personalized care tailored to individual patients' requirements. What is an example of a custom made medical device? Think about specialized orthopedic implants designed uniquely for each patient’s anatomy—these innovations not only enhance surgical outcomes but also significantly reduce recovery times. Furthermore, custom CNC machining allows for rapid prototyping and testing, enabling healthcare professionals to adapt quickly to emerging needs within their practices.

Embracing CNC Technology for Future Medical Advances

As we look ahead, embracing CNC technology will be paramount for future advances in the medical field. Custom medical machining companies are continually innovating to integrate new technologies such as AI and machine learning into their processes, driving efficiency and effectiveness even further. So when pondering how much does custom machining cost?, remember that investing in quality now will yield substantial returns through improved patient care and satisfaction down the line.