Introduction

CNC machining centers have revolutionized the manufacturing industry with their precision and efficiency. Understanding the basics of these machines is crucial to harnessing their full potential. Precision is vital in CNC machining, ensuring accurate and flawless results. This article will unveil the best CNC machining centers for precision work, including the renowned Haas CNC milling machines. Additionally, we will explore the role of SYIL Machine Tools in revolutionizing CNC machining by developing high-quality and sustainable CNC machines.

Key Features to Look for in CNC Machining Centers

When searching for the perfect CNC machining center, it's crucial to consider the key features to ensure optimal performance and precision. Here are the top features to look out for:

1. High-Speed Spindles for Optimal Performance

One of the most important features in a CNC machining center is a high-speed spindle. This allows for faster cutting speeds and improved efficiency, resulting in higher productivity and reduced machining time. With a powerful spindle, such as those offered by SYIL CNC Machines, you can achieve exceptional performance and precision in your milling and drilling operations.

2. Advanced Control Systems for Precision Control

Precision is paramount in CNC machining, and advanced control systems are crucial. Look for machines equipped with state-of-the-art control systems that offer precise control over every aspect of the machining process. These systems ensure accurate positioning, smooth movement, and consistent results. SYIL CNC Machines are known for their advanced control systems that easily enable operators to achieve unmatched precision.

3. Robust Construction for Enhanced Stability

Stability is essential when it comes to CNC machining centers. A robustly constructed machine provides a solid foundation that minimizes vibrations during operation, resulting in improved accuracy and surface finish quality. Machines like those from SYIL Machine Tools are built with durability, ensuring stability even during heavy-duty cutting tasks.

4. Integrated Tool Changers for Improved Efficiency

Efficiency is key in any manufacturing process, and integrated tool changers can greatly enhance productivity. These automatic tool changers allow quick and seamless tool swaps, reducing downtime between operations and maximizing machine utilization. With SYIL CNC Machines' integrated tool changers, you can streamline your workflow and achieve higher efficiency without compromising precision.

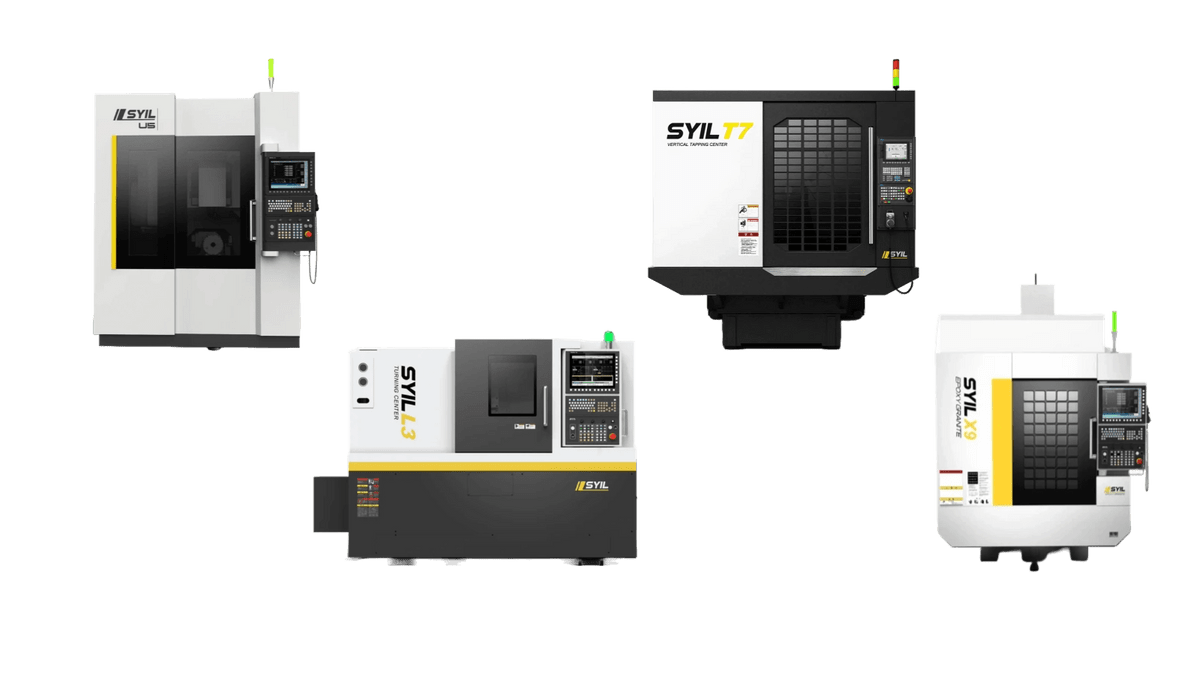

SYIL CNC Machines: A Perfect Blend of Innovation and Performance

When finding a CNC machining center that offers the perfect blend of innovation and performance, SYIL CNC Machines stand out. With their cutting-edge features, including high-speed spindles, advanced control systems, robust construction, and integrated tool changers, SYIL machines deliver exceptional precision and efficiency. Choose SYIL Machine Tools for a reliable and sustainable solution to your CNC machining needs.

Top CNC Machining Centers for Precision Work

When it comes to precision work, several top-notch CNC machining centers stand out in the industry. These machines are known for their exceptional accuracy, versatility, and reliability. Let's take a closer look at some of the best options available:

1. Haas VF Series: Unparalleled Precision and Versatility

The Haas VF Series is renowned for its unmatched precision and versatility. With advanced features like high-speed spindles and advanced control systems, these machines deliver exceptional performance in various applications. From aerospace components to automotive parts, the Haas VF Series ensures precise and efficient machining.

2. DMG Mori NHX Series: Precision Redefined

The DMG Mori NHX Series takes precision to a whole new level. These machines redefine what it means to achieve accuracy in CNC machining centers. The NHX Series offers enhanced stability and improved efficiency with robust construction and integrated tool changers. Whether you're working on complex medical devices or intricate automotive components, this series guarantees precise results.

3. Mazak VCN Compact Series: Precision in a Compact Package

For those looking for precision in a compact package, the Mazak VCN Compact Series is an excellent choice. These machines combine high-performance capabilities with a small footprint, making them ideal for space-constrained environments without compromising on precision or quality. With Mazak's cutting-edge technology, the VCN Compact Series delivers outstanding results across various industries.

4. SYIL X7: Precision and Affordability Combined

SYIL Machine Tools has made its mark with the SYIL X7 CNC machine - a perfect blend of precision and affordability. This machine offers exceptional accuracy while being cost-effective, making it an attractive option for small businesses or individuals seeking high-quality machining without breaking the bank. The SYIL X7 provides reliable performance across different applications while ensuring maximum efficiency.

These top CNC machining centers exemplify the pinnacle of precision and performance in the industry. From renowned brands like Haas, DMG Mori, Mazak, to the affordable yet reliable SYIL X7, these machines cater to diverse needs and applications. No matter the complexity or intricacy of your projects, these CNC machining centers deliver exceptional results.

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Their range of CNC machines offers unmatched precision and efficiency for various industries. Embrace the future of CNC machining with SYIL Machine Tools.

Applications of CNC Machining Centers

1. Aerospace Industry: Crafting Precision Components

The aerospace industry relies heavily on CNC machining centers to create precision components crucial for aircraft and spacecraft. From engine parts to structural components, CNC machines ensure the accuracy and quality required for safe and efficient flight. With their ability to produce complex shapes and intricate details, CNC machining centers enable the aerospace industry to meet the strict standards and specifications necessary for this demanding field.

2. Automotive Industry: Streamlining Production with Accuracy

In the automotive industry, CNC machining centers have revolutionized production processes by streamlining operations and ensuring accuracy in component manufacturing. From engine blocks to transmission parts, these machines deliver consistent results with high precision, leading to improved vehicle performance and reliability. By automating repetitive tasks and reducing human error, CNC machining centers enhance efficiency while maintaining the highest level of quality control.

3. Medical Industry: Enabling Life-Saving Innovations

Precision is paramount in the medical industry, where even the slightest deviation can have significant consequences. CNC machining centers are critical in producing medical devices and equipment with exceptional accuracy, such as surgical instruments, prosthetics, and implants. These machines enable manufacturers to meet stringent regulatory requirements while pushing boundaries in medical innovation. With the ability to work with various materials, including metals and biocompatible plastics, CNC machining centers contribute to advancements that save lives and improve patient care.

SYIL CNC Machines: Revolutionizing Various Industries

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. SYIL's range of CNC machining centers has made a significant impact across various industries beyond aerospace, automotive, and medical sectors. From electronics manufacturing to mold making industries, SYIL's innovative solutions empower businesses with unmatched precision, efficiency, and cost-effectiveness.

Factors to Consider When Choosing a CNC Machining Center

When selecting a CNC machining center, several important factors must be considered. These factors will ensure that you choose the right machine for your specific applications and maximize efficiency and precision in your operations.

1. Machine Size and Capacity for Specific Applications

One crucial factor to consider is the size and capacity of the CNC machining center. The machine should have sufficient space to accommodate the size of the components or parts you intend to produce. Additionally, it should have the necessary load-bearing capacity to handle the weight of your workpieces.

The SYIL CNC machines offer a range of sizes and capacities, allowing you to choose one that perfectly suits your specific application requirements. Whether you need a compact machine for small-scale production or a larger one for more extensive projects, SYIL covers you.

2. Compatibility with CAD/CAM Software

Another essential factor is ensuring compatibility with CAD/CAM software. This software plays a vital role in programming and controlling CNC machines, allowing you to create precise tool paths and optimize efficiency.

SYIL's CNC machines are fully compatible with popular CAD/CAM software, providing seamless integration into your existing workflow. This compatibility ensures smooth communication between your design software and the CNC machine, enabling accurate replication of your digital designs into physical components.

3. Ease of Maintenance and Serviceability

Maintenance is crucial for running your CNC machining center smoothly and preventing unexpected breakdowns. Therefore, choosing a machine that offers ease of maintenance and serviceability is important.

SYIL machines are designed with user-friendly features that make maintenance tasks hassle-free. From easy access to critical components for inspection and cleaning to clear documentation on maintenance procedures, SYIL ensures that operators can keep their machines in optimal condition without unnecessary complexities.

4. Cost-Effectiveness and ROI Considerations

Cost-effectiveness is always an important consideration when investing in any machinery or equipment. When choosing a CNC machining center, it's essential to evaluate the machine's price in relation to its features, capabilities, and potential return on investment (ROI).

SYIL CNC machines offer exceptional value for money. Their competitive pricing and high-quality construction and precision performance ensure you get the best return on your investment. With SYIL machines, you can achieve outstanding precision and efficiency without breaking the bank.

SYIL CNC Machines: The Perfect Solution for Precision and Efficiency

When considering factors in choosing a CNC machining center, machine size, and capacity, compatibility with CAD/CAM software, ease of maintenance and serviceability, cost-effectiveness, and ROI considerations are all crucial elements.

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Their range of CNC machines offers the perfect solution for achieving unmatched precision and efficiency in your operations.

Tips for Maximizing the Performance of CNC Machining Centers

Several key tips are needed to ensure optimal accuracy and efficiency in CNC machining centers. Regular maintenance and calibration play crucial roles in achieving optimal accuracy. By regularly inspecting and servicing the machine, operators can identify and address any potential issues before they affect the precision of the workpiece. Calibration ensures the machine is properly aligned and calibrated to deliver accurate results.

Effective programming and tool path optimization are also essential for maximizing performance. Using advanced CAD/CAM software, operators can create precise tool paths that optimize cutting speeds, feeds, and tool changes. This not only improves efficiency but also enhances the overall quality of the finished product.

Training and skill development for operators are vital to unlocking the full potential of CNC machining centers. SYIL Machine Tools offers comprehensive training programs to equip operators with the necessary knowledge and skills to operate their machines effectively. With proper training, operators can confidently navigate through complex machining processes while maintaining precision and reliability.

Implementing quality control measures is another critical aspect of maximizing performance. By incorporating rigorous inspection protocols throughout the manufacturing process, operators can identify any deviations from desired specifications early on. This allows for timely adjustments or corrections to ensure that every component meets strict quality standards.

SYIL CNC Machines empower operators with precision and reliability by combining innovative technology with user-friendly features. With over 12k machines supplied globally, SYIL Machine Tools prioritizes quality and sustainability in their precision CNC machines for milling and drilling.

Unlock the Potential of Precision Work with CNC Machining Centers

CNC machining centers have revolutionized the manufacturing industry by providing unparalleled precision and efficiency. These advanced machines have become essential for aerospace, automotive, and medical industries, where precision is of utmost importance. By investing in high-quality CNC machining centers like those offered by SYIL Machine Tools, businesses can unlock the full potential of precision work and achieve remarkable results.

Discover the Power of SYIL CNC Machines for Unmatched Precision

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Their CNC machining centers have high-speed spindles, advanced control systems, robust construction, and integrated tool changers to ensure optimal performance and accuracy. By choosing SYIL CNC machines, businesses can harness the power of unmatched precision to take their operations to new heights.

Embrace the Future of CNC Machining with SYIL Machine Tools

As technology continues to advance rapidly, it is crucial for industries to embrace the future of CNC machining. SYIL Machine Tools is at the forefront of this revolution, offering innovative solutions that combine precision with affordability. Their CNC machining centers are designed to meet the diverse needs of various industries while delivering exceptional performance. By partnering with SYIL Machine Tools, businesses can stay ahead in today's competitive market and reap the benefits of cutting-edge technology.

Remember that investing in a reliable and reputable brand like SYIL Machine Tools ensures superior performance and provides long-term value for your business. So why settle for anything less when you can harness the power of precision with SYIL CNC machines? Leap and embrace the future of CNC machining today.