Introduction

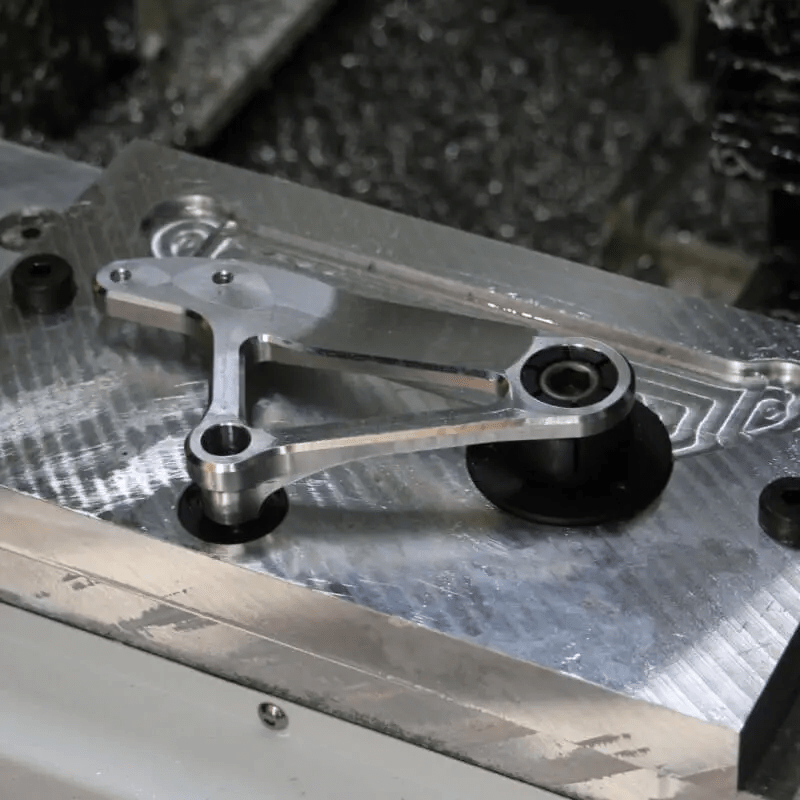

Metal CNC machines have revolutionized the manufacturing industry, offering precision and efficiency like never before. As the demand for high-quality metal products continues to grow, the rise of metal CNC machines has become inevitable. Understanding the basics of CNC (Computer Numerical Control) is crucial to fully appreciate these machines' capabilities. With their ability to create intricate designs and precisely shape metal, metal CNC machines have become indispensable in various industries.

The Rise of Metal CNC Machines

The rise of metal CNC machines can be attributed to their unparalleled accuracy and versatility in machining processes. These machines have transformed traditional manufacturing methods by incorporating computer-controlled automation, resulting in faster production times and improved product quality. With technological advancements, metal CNC machines have become more accessible, allowing businesses of all sizes to benefit from their capabilities.

The Basics: What is CNC?

CNC stands for Computer Numerical Control, which refers to using computer software and hardware to control machine tools with precision and accuracy. In the case of metal CNC machines, this technology enables operators to program-specific instructions into the machine's computer system, guiding it through various machining operations such as milling, turning, and routing. This level of automation eliminates human error and ensures consistent results.

Benefits of Metal CNC Machines: Precision and Efficiency

Metal CNC machines are revolutionizing metalworking with their ability to produce high-quality parts with unmatched precision and efficiency. Here are some of the key benefits they offer:

- Unmatched Precision: CNC machines can achieve tolerances in the thousandths of an inch, allowing for intricate designs and tight-fitting parts that would be impossible to create manually.

- Consistent Quality: CNC machines follow programmed instructions exactly, ensuring every part is identical to the last. This repeatability guarantees consistent quality throughout production runs.

- Increased Efficiency: CNC machines significantly reduce production times by automating tasks that traditionally require manual labor. This allows for faster turnaround times and increased output.

Metal CNC machines are valuable for any machine shop or manufacturing facility. Their ability to produce high-quality parts with precision and efficiency makes them an essential tool for the modern metalworking industry.

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability.

Types of Metal CNC Machines

Metal CNC machines come in various types, each designed for specific machining tasks. Let's explore three common types: milling machines, turning machines, and routing machines.

1. Milling Machines: Versatile and Accurate

Milling machines are the workhorses of metal CNC machining. They use rotary cutters to remove material from a workpiece, resulting in precise and complex shapes. With their versatility, milling machines can handle various materials, from aluminum to steel.

One popular option is the SYIL X5 Plus CNC Milling Machine. This desktop CNC mill offers exceptional accuracy and reliability, making it perfect for small-scale manufacturing projects or hobbyists who want to create intricate designs easily.

2. Turning Machines: Shaping Metal with Precision

Turning machines are ideal for cylindrical parts and often used in automotive and aerospace industries. These machines rotate the workpiece while cutting tools shape it into the desired form. Turning machines excel at creating symmetrical components such as shafts or rings.

For high-quality turning capabilities, consider the SYIL C3 Compact CNC Lathe. This compact machine is designed for precision turning applications and offers excellent stability and accuracy.

3. Routing Machines: Creating Intricate Designs

Routing machines specialize in engraving or carving intricate designs on metal surfaces. These machines use rotating cutting tools to remove material from a workpiece, allowing for detailed patterns or custom designs.

If you want to unleash your creativity with metal routing, check out the SYIL X7 Desktop CNC Router Machine. With its user-friendly interface and robust construction, this machine lets you easily bring your artistic visions to life.

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability.

Key Factors to Consider When Choosing a Metal CNC Machine

When selecting a metal CNC machine, there are several key factors that you need to take into consideration to ensure you find the perfect fit for your needs.

1. Machine Size: Finding the Right Fit for Your Workspace

One crucial factor to consider is the size of the machine. Depending on the available space in your workshop or facility, you'll need to choose a metal CNC machine that fits comfortably without causing any hindrances. SYIL's range of desktop CNC machines provides compact options perfect for small workspaces while still delivering exceptional performance and precision.

2. Spindle Power: Determining Speed and Capability

The spindle power of a metal CNC machine determines its speed and capability when cutting through different materials. Choosing a machine with sufficient spindle power to handle your specific machining requirements is essential. SYIL's CNC milling machines offer varying spindle power options, allowing you to select one that matches your desired speed and cutting capacity.

3. Control System: User-Friendly Interface for Efficient Operation

The control system of a metal CNC machine plays a crucial role in its overall efficiency and ease of operation. A user-friendly interface ensures operators can quickly learn how to navigate the controls and program the machine effectively, resulting in improved productivity. SYIL Machine Tools prioritizes intuitive control systems, making CNC machines accessible even for those new to CNC machining.

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability.

Applications of Metal CNC Machines

Metal CNC machines have revolutionized various industries, including the automotive, aerospace, and medical sectors. These machines offer enhanced efficiency and accuracy in manufacturing processes, making them indispensable in today's competitive market.

1. Automotive Industry: Enhancing Efficiency and Accuracy in Manufacturing

In the automotive industry, metal CNC machines are crucial in streamlining production and ensuring precision. From prototyping to mass production, CNC milling machines create complex parts with high accuracy. The ability to program these machines allows for consistent results, reducing human error and increasing productivity.

One key advantage of metal CNC machines in the automotive industry is their versatility. They can handle a wide range of materials, such as aluminum, steel, and titanium, making them ideal for manufacturing engine parts, chassis components, and intricate interior details.

With SYIL's CNC machines at the forefront of innovation, automotive manufacturers can achieve higher levels of efficiency while maintaining exceptional quality standards. By investing in SYIL's precision CNC milling machines specifically designed for metalworking applications, companies can optimize their production processes and stay ahead of the competition.

2. Aerospace Industry: Precision Machining for Critical Components

The aerospace industry demands utmost precision when manufacturing critical components that ensure safety and performance. Metal CNC machines excel in this field by providing the accurate machining capabilities required for intricate aerospace parts.

CNC milling machines are extensively used to create complex shapes with tight tolerances necessary for aircraft engines, landing gear components, turbine blades, and structural elements. The ability to produce high-quality parts consistently makes metal CNC machines indispensable in this industry.

SYIL's advanced technology ensures that aerospace manufacturers can achieve the highest precision required for their components. With SYIL's CNC machines, aerospace companies can streamline production processes, reduce lead times, and maintain the highest quality standards.

3. Medical Industry: Creating Complex Implants and Prosthetics

The medical industry uses metal CNC machines to create intricate implants and prosthetics precisely. These machines offer the accuracy required for complex medical devices, from hip replacements to dental implants.

CNC milling machines manufacture custom-made implants that perfectly fit a patient's unique anatomy. The ability to work with various biocompatible materials like titanium and stainless steel ensures that the final products meet strict medical standards.

SYIL's CNC machines provide medical manufacturers with the tools to produce high-quality implants and prosthetics. By investing in SYIL's precision CNC milling machines, manufacturers can enhance patient outcomes while maintaining efficiency and reliability.

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Embrace the future of metal CNC machining with SYIL's cutting-edge technology.

Advancements in Metal CNC Technology

Advancements in metal CNC technology have revolutionized the manufacturing industry, offering new possibilities and improved efficiency. Three key advancements include the development of hybrid CNC machines, the integration of artificial intelligence, and the implementation of robotics and automation.

Hybrid CNC Machines: Combining Milling and 3D Printing

Hybrid CNC machines have emerged as a game-changer in metal machining by combining the capabilities of traditional milling machines with 3D printing technology. This innovative approach allows for creating complex metal parts with intricate designs that were previously difficult to achieve. By seamlessly transitioning between milling and 3D printing, these machines offer increased flexibility and precision in manufacturing processes.

One example is SYIL's hybrid CNC machine, seamlessly integrating milling and 3D printing functionalities. With this machine, manufacturers can effortlessly switch between subtractive and additive manufacturing methods, optimizing productivity while maintaining high-quality output. This cutting-edge technology opens new possibilities for rapid prototyping, customization, and small-batch production.

Artificial Intelligence Integration: Optimizing Manufacturing Processes

Artificial intelligence (AI) integration has significantly enhanced metal CNC machining by optimizing manufacturing processes. AI algorithms can analyze vast amounts of data in real time to identify patterns, predict errors or malfunctions, optimize tool paths, and automate decision-making processes. This integration improves efficiency, reduces material waste, enhances accuracy, and minimizes downtime.

SYIL's advanced metal CNC machines leverage AI integration to streamline operations effectively. The AI-powered control systems enable intelligent monitoring of machining parameters such as speed, feed rate optimization, tool selection, and adaptive control strategies. These machines can make real-time adjustments by continuously learning from data inputs during operations, ensuring optimal performance and maximizing productivity.

Robotics and Automation: Increasing Productivity and Reducing Human Error

Integrating robotics and automation in metal CNC machines has revolutionized the manufacturing industry. By automating repetitive tasks and reducing human intervention, these machines significantly increase productivity while minimizing errors. Robotic arms can handle material loading and unloading, tool changes, part manipulation, and complex machining operations.

SYIL's CNC machines incorporate robotics and automation features to streamline workflows. Manufacturers can achieve uninterrupted production cycles with automated tool changers, pallet changers, and robotic material handling systems with minimal downtime. This integration increases efficiency and ensures consistent quality by eliminating human error.

Training and Maintenance for Metal CNC Machines

Mastering the skills required for efficient machining is crucial when operating metal CNC machines. Operator training plays a vital role in ensuring optimal performance and productivity. At SYIL Machine Tools, we understand the importance of comprehensive training programs that cover all aspects of using our metal CNC machines.

Our operator training includes hands-on experience with different types of metal CNC machines, such as CNC milling machines and turning machines. Trainees learn how to set up the machine, load and unload tools, program the machine, and troubleshoot common issues that may arise during operation. With our expert guidance, operators gain confidence in handling complex machining tasks.

Maintenance is another key aspect of keeping metal CNC machines in top condition. Regular maintenance ensures longevity and enhances performance. SYIL Machine Tools provides maintenance best practices that cover routine tasks such as cleaning and lubrication as well as more advanced procedures like inspecting and replacing worn-out parts.

By following these best practices, operators can prevent breakdowns and minimize downtime. We also offer guidance on scheduling preventive maintenance to avoid unexpected production disruptions. Our team of experts is always available to provide support and answer any questions about maintenance procedures.

Despite regular maintenance, occasional issues may still occur during operation. Troubleshooting common issues is essential for minimizing downtime and keeping production running smoothly. SYIL Machine Tools offers comprehensive troubleshooting guides that address common problems operators face.

These guides provide step-by-step instructions on identifying the root cause of an issue and implementing appropriate solutions. Our troubleshooting guides cover various scenarios, from software glitches to mechanical malfunctions, to ensure quick resolution.

Invest in Metal CNC Machines: A Game-Changer for Manufacturing

Metal CNC machines have revolutionized the manufacturing industry, offering unparalleled precision and efficiency. Because they can produce complex designs and shapes, CNC milling machines have become a staple in many workshops. Whether it's a desktop CNC or a larger industrial-grade machine, the benefits of using metal CNC machines are undeniable.

SYIL CNC Machines: Quality and Sustainability at the Core

Quality and sustainability should be top priorities when choosing a metal CNC machine. SYIL Machine Tools understands this importance and develops precision CNC machines for milling and drilling. With over 12k machines supplied globally, SYIL prioritizes delivering reliable and durable equipment that meets the needs of various industries.

Embrace the Future of Metal CNC Machining

As technology advances, so does metal CNC machining. The future holds exciting possibilities for this industry, with advancements like hybrid CNC machines combining milling and 3D printing capabilities. Artificial intelligence integration optimizes manufacturing processes, while robotics and automation increase productivity and reduce human error.