Introduction

In the ever-evolving world of technology, understanding the various tools available for fabrication is essential. Two prominent players in this arena are 3D printing and CNC machining, each boasting unique capabilities and applications. As we delve into these technologies, a common question arises: is a 3D printer a CNC machine? The answer is nuanced and requires us to explore their fundamental differences and similarities.

Understanding the Technology Landscape

The landscape of manufacturing technology has transformed dramatically over the past few decades, leading to innovative methods of production that cater to diverse needs. Among these advancements, 3D printing has emerged as a groundbreaking technique that allows for rapid prototyping and intricate designs with relative ease. On the other hand, CNC machining has established itself as a reliable method for producing high-precision components in various industries—a contrast that highlights the ongoing debate of 3D Printing vs. CNC Machining.

The Rise of 3D Printing

The rise of 3D printing can be attributed to its ability to revolutionize how products are designed and manufactured. From creating prototypes swiftly to producing complex geometries that traditional methods struggle with, this technology has captured the imagination of engineers and hobbyists alike. However, it often leads people to question: Is 3D printing the same as CNC? While both technologies serve similar purposes in fabrication, they operate on fundamentally different principles.

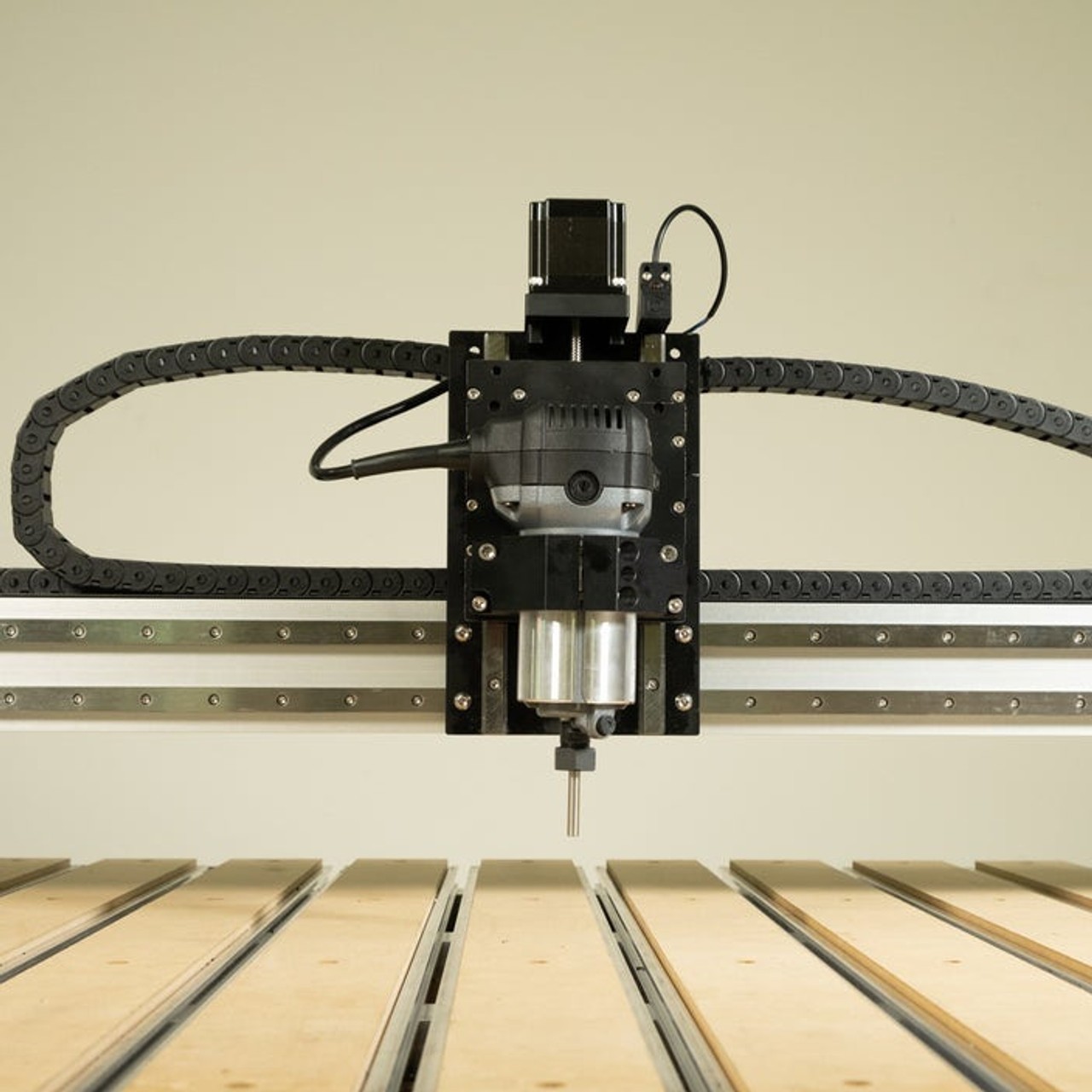

CNC Machines: A Brief Overview

CNC machines have long been staples in manufacturing environments where precision is paramount. These computer-controlled devices utilize subtractive techniques to carve out parts from solid materials like metal or wood, ensuring accuracy across multiple iterations. This brings us back to our earlier inquiry—CNC vs. 3D Printing—where understanding these distinct processes can guide us in choosing which technology best fits our needs.

Defining 3D Printing

In a world where innovation is the name of the game, understanding what 3D printing really is can be quite enlightening. While some might wonder, Is a 3D printer a CNC machine? it's essential to clarify that they are different technologies serving various purposes. So, let’s dive into the fascinating realm of 3D printing!

What is 3D Printing?

At its core, 3D printing is an additive manufacturing process that creates three-dimensional objects from digital files. This technology builds items layer by layer, allowing for intricate designs that would be challenging or impossible to achieve through traditional manufacturing methods. It's not just a passing trend; rather, it's revolutionizing industries from healthcare to aerospace by enabling rapid prototyping and customization.

How Does 3D Printing Work?

The magic of 3D printing begins with a digital model created using computer-aided design (CAD) software or obtained from a 3D scanner. The printer then reads this model and lays down material—often plastic, resin, or metal—in thin layers until the final product emerges. The process is both fascinating and efficient; however, it raises questions like Is 3D printing the same as CNC? While both technologies have their merits, they operate on fundamentally different principles.

Popular 3D Printers on the Market

The market for 3D printers has exploded in recent years, offering options for hobbyists and professionals alike. Some popular models include the Prusa i3 MK3S+, known for its reliability and user-friendly design, and the Ultimaker S5, which boasts high precision and versatility for industrial applications. When comparing CNC vs. 3D Printing, it's important to note that these machines cater to different needs—while one excels at creating complex geometries through additive processes, the other focuses on subtractive methods.

Understanding CNC Machining

CNC machining is a cornerstone of modern manufacturing, providing precision and efficiency that traditional methods often can't match. But what exactly is CNC machining? It's a computer-controlled process that uses pre-programmed software to dictate the movement of factory tools and machinery. This allows for the creation of intricate parts with high accuracy, making it an essential technology in various industries.

What is CNC Machining?

At its core, CNC machining stands for Computer Numerical Control machining. It involves the use of computers to control machine tools such as lathes, mills, routers, and grinders. Unlike manual machining, where human operators guide the tools, CNC machines automate these movements based on coded instructions—allowing for consistent production and minimal human error. This leads to questions like Is 3D printing the same as CNC? since both are pivotal in modern manufacturing but operate on fundamentally different principles.

How Does CNC Machining Operate?

CNC machining operates through a simple yet effective process: design, code generation, and execution. Initially, a part or product design is created using CAD (Computer-Aided Design) software; this design is then converted into G-code—a language that tells the machine how to move. Once programmed, the CNC machine takes over by cutting away material from a solid block (subtractive manufacturing), which contrasts sharply with 3D printing's additive approach. The debate around CNC vs. 3D Printing often highlights these operational differences while showcasing each method's unique advantages.

Notable CNC Machines like the SYIL CNC

Among notable examples of CNC machines is the SYIL CNC series—renowned for their versatility and precision in various applications from prototyping to full-scale production runs. These machines come equipped with advanced features like high-speed spindles and robust control systems that streamline operations across multiple industries—from aerospace to automotive manufacturing. As we explore 3D Printing vs. CNC Machining, it's essential to recognize how machines like SYIL push boundaries in precision engineering while catering to diverse fabrication needs.

Key Differences Between 3D Printing and CNC

When exploring the landscape of modern manufacturing, understanding the key differences between 3D printing and CNC machining is essential. While both technologies are used for creating parts and prototypes, they operate on fundamentally different principles and methodologies. This section will delve into the materials used, fabrication techniques, and precision levels associated with each technology.

Materials Used in 3D Printing vs. CNC

The materials employed in 3D printing and CNC machining vary significantly, influencing their applications and capabilities. 3D printing primarily uses thermoplastics, resins, metals, and ceramics in a form that can be melted or cured layer by layer. On the other hand, CNC machining typically works with solid materials like metals (aluminum, steel), plastics (PVC), wood, and composites that are cut from larger blocks or sheets.

This distinction raises an important question: Is a 3D printer a CNC machine? The answer is no; while both technologies can produce intricate designs, they do so using different material forms—additive versus subtractive processes—which directly affects their respective strengths and limitations. In the ongoing debate of 3D printing vs. CNC machining, understanding material compatibility is crucial for making informed choices based on project needs.

Fabrication Techniques: Additive vs. Subtractive

At the heart of the difference between these two technologies lies their fabrication techniques: additive versus subtractive manufacturing methods. In additive manufacturing (commonly known as 3D printing), objects are built layer by layer from digital models until they reach their final form—a process that allows for complex geometries that would be challenging to achieve through traditional methods.

Conversely, CNC machining employs a subtractive approach where material is removed from a solid block to create desired shapes—think of it as carving a statue out of marble rather than building one with clay! This fundamental difference makes each method suitable for various applications; while some projects may benefit from the flexibility of 3D printing's additive nature, others may require the robustness offered by subtractive processes used in CNC machining.

Precision and Detail Comparison

Precision is another key area where these two technologies diverge significantly in performance capabilities. Generally speaking, CNC machining boasts higher precision due to its ability to work with tight tolerances—often within +/-0.001 inches—making it ideal for industries requiring exact specifications such as aerospace or medical device manufacturing.

In contrast to this level of accuracy found in CNC vs. 3D printing comparisons, most consumer-grade 3D printers tend to have lower resolution limits but have been improving rapidly over time as technology advances; however, achieving similar precision remains challenging with many models still struggling when it comes to fine details or intricate designs compared to their CNC counterparts.

In summary, while both technologies offer unique advantages depending on project requirements—from materials utilized down to fabrication techniques—their inherent differences make them suited for distinct applications within modern manufacturing landscapes.

Advantages of Each Technology

When evaluating the benefits of 3D printing and CNC machining, it's essential to understand their unique strengths. Both technologies have carved out significant niches in manufacturing, each offering distinct advantages depending on the application. Let's dive into what makes each method shine.

Pros of 3D Printing

One of the most attractive features of 3D printing is its ability to create complex geometries that would be nearly impossible with traditional methods. This technology allows for rapid prototyping, enabling designers to iterate quickly without incurring high costs associated with tooling. Additionally, 3D printing is generally more material-efficient, as it uses only the material needed for the part itself, reducing waste significantly.

Another major advantage is customization; with a 3D printer, you can easily modify designs for individual needs without altering production processes. This flexibility makes it ideal for industries like healthcare, where personalized implants or prosthetics are highly sought after. Furthermore, with advancements in materials and techniques, 3D printing has expanded its reach into various sectors including aerospace and automotive.

Lastly, consider that setting up a 3D printer often requires less upfront investment than CNC machines. For small businesses or hobbyists asking themselves Is 3D printing the same as CNC?, the answer leans towards affordability and accessibility when starting out in manufacturing.

Benefits of CNC Machining

CNC machining boasts incredible precision and repeatability that often surpasses what you can achieve with a 3D printer. This level of accuracy is crucial in industries like aerospace or automotive where even minor deviations can lead to catastrophic failures. Moreover, CNC machines can work with a wider range of materials—including metals—that are not typically suitable for 3D printing.

Speed is another key benefit; once programmed correctly, CNC machines can produce parts at a rapid pace without sacrificing quality or detail. Unlike some forms of additive manufacturing that may take hours to print intricate designs layer by layer, CNC machining often completes tasks much faster due to its subtractive nature. If you're comparing CNC vs. 3D Printing, speed may very well tip the scales in favor of CNC for large-scale production runs.

Lastly, durability plays an important role here; components produced via CNC machining are often stronger than their 3D-printed counterparts due to their solid construction methods. This makes them better suited for applications requiring high-stress tolerance and long-term reliability.

When to Choose Which Technology

Choosing between these two powerful technologies hinges on your specific project requirements and constraints—there's no one-size-fits-all answer! If you're looking at low-volume production runs or need highly customized parts quickly—think about using a printer instead; this aligns well with what many ask: Is a 3d printer a cnc machine? The answer is no; they serve different purposes but can complement one another beautifully.

On the other hand, if your project demands high precision and involves working with robust materials like metals or composites—CNC machining should be your go-to option! It shines particularly when producing identical parts in bulk where consistency is paramount—something that’s essential in fields ranging from industrial machinery to electronics.

In summary, understanding whether you need CNC vs. 3D Printing boils down to factors such as material choice, desired precision level, customization needs, and production volume expectations—all critical elements when deciding which technology will best meet your goals!

Real-World Applications

In the realm of manufacturing and prototyping, both 3D printing and CNC machining have carved out their niches, each offering unique advantages depending on the application. Understanding these real-world use cases can help clarify whether you're asking, Is 3D printing the same as CNC? or pondering the differences in capabilities between these two technologies. Here, we’ll explore how each method is utilized across various sectors and what makes them stand out.

3D Printing Use Cases

3D printing has revolutionized several industries by enabling rapid prototyping and customization at a fraction of traditional costs. From medical devices like prosthetics to aerospace components, this technology allows for intricate designs that were previously impossible to achieve with traditional methods. For instance, companies are now using 3D printers to create lightweight yet strong parts that improve fuel efficiency in airplanes—showing just how impactful this technology can be in real-world applications.

Additionally, the fashion industry has begun to embrace 3D printing for producing bespoke accessories and garments tailored to individual preferences. This level of personalization not only enhances customer satisfaction but also reduces waste by allowing for on-demand production. As we continue to explore 3D Printing vs. CNC Machining, it's clear that while both technologies serve vital roles, 3D printing excels in situations where design complexity and customization are paramount.

CNC Machining in Industry

CNC machining has long been a staple in manufacturing due to its precision and reliability when working with metals and hard materials. Industries such as automotive and aerospace rely heavily on CNC machines for producing high-quality components with tight tolerances—something that is essential when safety is at stake. For example, critical engine parts are often machined using CNC technology because it ensures consistency and durability under extreme conditions.

Moreover, many manufacturers utilize CNC machining for bulk production runs where speed without sacrificing quality is crucial. The ability to quickly replicate complex designs while maintaining accuracy makes it an invaluable asset in modern manufacturing environments. When comparing CNC vs. 3D Printing applications, it's evident that while both have their strengths, CNC machining remains unmatched for high-volume production of durable components.

Comparing 3D Printing vs. CNC Machining Applications

When weighing the pros and cons of 3D Printing vs. CNC Machining applications, it’s essential to consider factors like material type, production volume, cost-effectiveness, and design complexity. While a question like Is a 3D printer a CNC machine? might arise from curiosity about their similarities; fundamentally they serve different purposes based on project requirements. For instance, if you need rapid prototyping with intricate geometries or customized products at low volumes—look no further than a 3D printer.

Conversely, if your project demands precision engineering with robust materials over large quantities—CNC machining is likely your best bet due to its efficiency in mass-producing identical items without compromising quality or detail over time. Ultimately understanding these distinctions will guide you toward making informed decisions about which technology best suits your needs as you navigate through the landscape of modern manufacturing.

Conclusion

In the grand debate of 3D Printing vs. CNC Machining, one may wonder, Is 3D printing the same as CNC? The answer is a resounding no; while both technologies serve crucial roles in manufacturing, they operate on fundamentally different principles. Understanding these differences can help you appreciate each method's unique capabilities and applications.

Is 3D Printing the Same as CNC?

To clarify, is a 3D printer a CNC machine? Not quite! While both are used for fabrication, their methods diverge significantly: 3D printing is an additive process that builds objects layer by layer, whereas CNC machining is subtractive, carving away material from a solid block. This distinction leads to varied strengths and weaknesses in each technology.

Choosing Between 3D Printing and CNC

When deciding between CNC vs. 3D Printing for your project, consider factors like material compatibility, design complexity, and budget constraints. If you're working with intricate designs or rapid prototyping needs, you might lean towards 3D printing due to its flexibility and speed. On the other hand, if precision and durability are paramount—especially for industrial applications—CNC machining could be your best bet.

The Future of 3D Printing and CNC Machining

Looking ahead, both technologies are poised for exciting advancements that could redefine manufacturing processes across industries. Innovations in materials for both methods promise more versatile applications; imagine stronger composites in 3D printing or faster speeds in CNC machining! As we explore these paths forward, understanding CNC vs. 3D Printing will be essential for navigating future developments.