Introduction

In the world of manufacturing, CNC milling techniques have revolutionized how we approach metalworking tasks. The advent of CNC (Computer Numerical Control) milling machines has enabled precision and efficiency that were once thought impossible, allowing for intricate designs and high-quality finishes in various industries. As the demand for accuracy continues to rise, understanding the nuances of CNC milling machine metal becomes essential for both hobbyists and professionals alike.

The Rise of CNC Milling Techniques

CNC milling techniques have surged in popularity over recent years, transforming traditional machining processes into automated marvels. With advancements in technology, these machines now offer unparalleled precision and speed, making them indispensable tools in modern workshops. From small CNC milling machines designed for hobbyists to robust industrial models, the versatility of CNC machines has paved the way for innovative applications across multiple sectors.

Understanding CNC Milling Machine Metal

At its core, a CNC milling machine operates by removing material from a solid block of metal using rotating cutting tools. This process allows for the creation of complex shapes and parts with exceptional accuracy—qualities that are critical when working with materials like steel or aluminum on a desktop CNC mill steel. Understanding how these machines interact with different types of metal is crucial for achieving optimal results and ensuring longevity in your projects.

Benefits of Precision Metal Machining

The benefits of precision metal machining using CNC technology are manifold; they include reduced waste, enhanced production speed, and improved consistency across batches. For those utilizing hobby CNC milling machines or professional setups alike, achieving tight tolerances can lead to better product performance and customer satisfaction. Ultimately, investing time into mastering these techniques can significantly elevate one’s craftsmanship while minimizing errors associated with manual machining methods.

What is CNC Milling?

CNC milling is a highly sophisticated manufacturing process that utilizes computer numerical control to operate and manage machine tools. This method allows for the precise shaping of metal and other materials, making it a staple in various industries, from aerospace to automotive. With the rise of hobbyists and small businesses, understanding CNC milling machines has never been more essential.

Components of CNC Machines

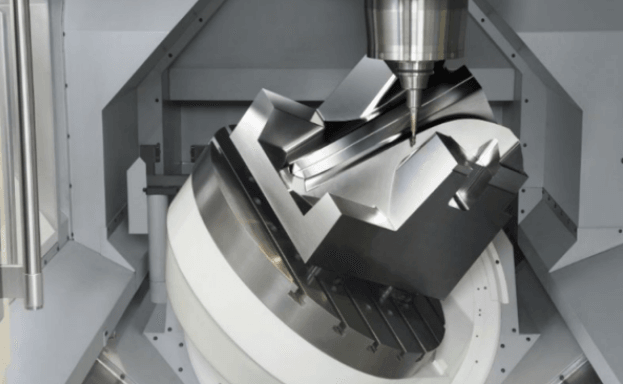

At the heart of every CNC milling machine are several key components that work harmoniously to create intricate designs. The most critical parts include the spindle, which holds the cutting tool; the worktable, where the material sits; and the control panel, which allows operators to input commands. Additionally, motors and drives ensure precise movements along multiple axes—typically three or five—making these machines incredibly versatile for both Desktop CNC milling machines and larger models.

How CNC Milling Works

CNC milling operates by translating a digital design into physical movements through a series of programmed instructions. Initially, a computer-aided design (CAD) file is created or sourced, detailing every aspect of the part to be produced. This file is then converted into G-code—a language that tells the CNC machine how to move its tools and workpieces—allowing even complex shapes to be fabricated with precision typically associated with industrial-grade equipment.

Applications in Various Industries

The applications for CNC milling are as diverse as they are impressive, spanning industries such as automotive, aerospace, medical devices, and even art installations. In automotive manufacturing, for instance, precision parts like engine blocks can be produced using specialized CNC machines tailored for metalwork. Similarly, hobbyists often turn to small CNC milling machines for personal projects ranging from custom hardware pieces to artistic sculptures—showing just how adaptable this technology can be across different fields.

Choosing the Right CNC Milling Machine

Selecting the right CNC milling machine can feel like navigating a maze, especially with so many options available. Understanding the various types of machines and their specific applications is crucial for anyone looking to dive into precision metal machining. Whether you're a hobbyist or a professional, choosing the right CNC milling machine metal can significantly impact your projects.

Overview of Different Types

CNC milling machines come in a variety of shapes and sizes, each tailored for specific tasks. You have your traditional vertical and horizontal CNC machines, which are great for large-scale production, but then there are also Desktop CNC milling machines designed for smaller projects and limited spaces. For those who need something more portable yet powerful, Small CNC milling machines offer flexibility without sacrificing performance.

Comparing Desktop vs. Small CNC Milling Machines

When it comes to choosing between Desktop CNC milling machines and Small CNC milling machines, the decision often hinges on your workspace and project requirements. Desktop models are compact and perfect for hobbyists who may be limited on space but still want to work with materials like steel or aluminum efficiently. On the other hand, Small CNC milling machines provide a bit more power and versatility while still being manageable enough for home workshops.

Factors to Consider for Hobby CNC Milling Machines

For hobbyists diving into the world of precision machining, several factors should guide your choice of Hobby CNC milling machine. First off, consider the materials you'll be working with; some desktop models may struggle with tougher metals like steel while others handle them effortlessly. Additionally, think about software compatibility; good programming tools can make all the difference in achieving high-quality results with your chosen cnc milling machine metal.

Precision Metal Techniques in CNC Milling

In the world of manufacturing, precision metal techniques are essential for producing high-quality components. CNC milling machines have revolutionized the way we work with metal by offering unparalleled accuracy and efficiency. Whether you're using a small CNC milling machine or a desktop CNC mill steel, these machines ensure consistent results that meet demanding specifications.

Benefits of Using CNC Machines for Metal

One of the most significant benefits of using CNC machines for metal is their ability to produce intricate designs with high precision. Unlike traditional machining methods, which can be prone to human error, a CNC milling machine operates based on programmed instructions, ensuring every cut is executed flawlessly. This level of accuracy not only enhances product quality but also reduces material waste, making it an economical choice for both hobbyists and professionals alike.

Moreover, the versatility of CNC milling machines allows for processing various types of metals efficiently. From aluminum to stainless steel, these machines can handle different materials without compromising on quality or finish. For those working with a hobby CNC milling machine, this means you can experiment with multiple metals without needing separate equipment.

Common Materials Processed with CNC Milling

CNC milling machines are designed to work with a diverse range of materials, each offering unique properties suited for different applications. Commonly processed materials include aluminum, which is favored for its lightweight yet durable characteristics; stainless steel, known for its corrosion resistance; and brass, appreciated for its machinability and aesthetic appeal. Additionally, advanced desktop CNC mills can even handle harder metals like titanium when equipped with the right tools.

Another popular material among hobbyists using small CNC milling machines is plastic; it’s easier to mill and often used in prototyping before moving to metal production. The adaptability of these machines makes them ideal not just in industrial settings but also in home workshops where creativity meets engineering prowess. Each material presents its own challenges during machining processes; however, understanding how your chosen material interacts with your cnc milling machine metal will lead to better outcomes.

How Precision Affects Final Output

The precision achieved through modern CNC technology directly influences the final output quality in metal machining projects. When utilizing a desktop CNC mill steel or any other type of cnc milling machine metal, even minute discrepancies can lead to significant differences in fit and function—especially critical when parts must align perfectly within assemblies or systems. Thus, investing time into understanding how precision affects your projects will pay dividends down the line.

Furthermore, precise machining enables manufacturers to achieve tighter tolerances that are increasingly demanded across industries such as aerospace and automotive engineering. The ability to replicate exact measurements consistently means less rework and higher customer satisfaction rates—a win-win scenario! As you explore options like small or hobby CNC milling machines at home or professionally scaled models in factories, remember that precision isn't just about numbers; it's about delivering quality every time.

SYIL CNC Machines: A Case Study

When it comes to CNC milling machine metal, SYIL has carved out a niche that combines innovation with practicality. Known for their robust design and versatility, SYIL CNC machines cater to both hobbyists and professionals alike. With a range of models including desktop CNC milling machines and small CNC milling machines, they provide solutions that fit various machining needs.

Features of SYIL CNC Machines

One standout feature of SYIL CNC machines is their precision engineering, which ensures high accuracy in metal machining. These machines are equipped with powerful spindles and advanced control systems that allow for intricate designs and complex geometries in materials like steel and aluminum. Additionally, the user-friendly interface makes it easier for both seasoned machinists and newcomers using hobby CNC milling machines to operate effectively.

Another notable aspect is their adaptability; whether you’re working on a desktop CNC mill steel project or larger industrial tasks, SYIL provides customizable options tailored to specific requirements. This flexibility extends to the software compatibility as well, allowing users to integrate various CAD/CAM programs seamlessly into their workflow. Moreover, the durability of these machines means they can withstand rigorous use without compromising performance.

Applications and Success Stories

SYIL CNC machines have found applications across diverse industries such as aerospace, automotive, and even art fabrication. For instance, one success story involves an automotive company that utilized a small CNC milling machine from SYIL to produce custom engine components with remarkable precision—reducing production time significantly while maintaining quality standards. Such achievements highlight how effectively these machines can handle demanding tasks in professional settings.

Hobbyists have also embraced SYIL’s offerings; many creators have turned their passion projects into successful businesses using desktop CNC milling machines from this brand. From crafting intricate jewelry pieces to designing custom furniture elements, the possibilities are virtually limitless with the right tools at hand. These success stories not only showcase the versatility of SYIL’s equipment but also inspire others in the maker community.

Comparison with Other CNC Milling Machines

When comparing SYIL CNC machines with other brands in the market, it's clear they hold a competitive edge regarding features and usability for both hobbyist and professional applications. While many manufacturers focus solely on industrial-grade models, SYIL strikes a balance by offering robust desktop and small CNC milling machine options without sacrificing performance or precision in cnc milling machine metal projects.

In contrast to other brands that may offer limited customization or less intuitive software interfaces, SYIL's commitment to user experience sets them apart significantly. Users often report higher satisfaction rates due to ease of setup and operation across different skill levels—something particularly beneficial for those exploring hobby-level machining with smaller units like desktop mills or entry-level small mills designed for beginners.

Ultimately, whether you're delving into cnc milling machine metal work as a passionate hobbyist or managing large-scale production runs professionally, understanding how different models stack up against each other can help you make informed decisions about your investment in technology like those offered by SYIL.

Optimizing Your CNC Milling Process

Optimizing your CNC milling process is crucial for achieving high-quality results while maximizing efficiency. Whether you're working with a Desktop CNC milling machine or a more robust Small CNC milling machine, there are several strategies you can employ to ensure that your operations run smoothly. By focusing on these key areas, you can enhance the performance of your CNC machines and produce superior metal components.

Tips for Efficient Metal Machining

To make the most of your CNC milling machine metal capabilities, start by selecting the right cutting tools and materials for your specific project. High-quality tools not only improve precision but also extend the lifespan of your equipment. Additionally, maintaining optimal feed rates and spindle speeds can significantly reduce machining time while ensuring a clean finish on parts produced by both Desktop CNC mills and Hobby CNC milling machines.

Another essential tip is to regularly inspect and calibrate your machines to maintain their accuracy over time. Even small deviations can lead to subpar results or wasted materials, which is particularly important when working with expensive metals like steel or aluminum. Lastly, consider implementing advanced techniques such as adaptive machining or tool path optimization to further enhance productivity without compromising quality.

Software and Tools for CNC Programming

The right software tools can make all the difference in optimizing your CNC milling process. Popular options include CAD/CAM programs that allow users to design parts digitally before translating them into machine-readable code for their Small CNC milling machines or Hobby CNC milling machines. These programs often come equipped with features that help streamline programming tasks, making it easier than ever to achieve precision in metal machining.

Moreover, utilizing simulation software can help you visualize the entire machining process before actual execution, allowing you to identify potential issues early on. This proactive approach minimizes errors that could arise during operation and ensures smoother workflows across various projects involving Desktop CNC mills or larger industrial setups. Don't forget about regular updates; keeping your software current will provide access to new features that could revolutionize how you work with your CNC machines.

Maintaining Your CNC Milling Machine

Proper maintenance is vital for prolonging the life of any machinery, including those used in precision metal machining like a cnc milling machine metal setup. Regular cleaning of components such as spindles and tool holders prevents dust buildup from interfering with operations and affecting output quality over time. Additionally, lubricating moving parts ensures smooth functionality while reducing wear and tear on critical components of both Desktop and Small CNC milling machines.

It’s also wise to keep an eye on electrical connections and sensors within your Hobby CNC milling machine; any malfunction here could lead to significant downtime or costly repairs down the line. Establishing a routine maintenance schedule tailored specifically for each type of machine will keep them running at peak performance levels—allowing you more time to focus on producing high-quality outputs rather than dealing with unexpected breakdowns.

Conclusion

As we wrap up our exploration of CNC milling, it’s clear that this technology has transformed the landscape of metal machining. The advancements in CNC milling machines have made precision and efficiency more accessible than ever before. Whether you're a hobbyist or a seasoned professional, understanding these changes can enhance your projects and boost productivity.

Advancements in CNC Milling Technology

The evolution of CNC milling technology has led to significant enhancements in performance and capabilities. Modern CNC milling machines now feature advanced software integration, allowing for greater automation and precision when working with metals like steel. Additionally, innovations such as real-time monitoring systems ensure that every cut is executed flawlessly, minimizing waste and maximizing output.

Future Trends in CNC Machining

Looking ahead, the future of CNC machining is bright with trends like increased automation through AI and machine learning on the horizon. Small CNC milling machines are becoming more sophisticated, making them ideal for both industrial applications and hobbyists who demand high-quality results from their desktop setups. Moreover, sustainability is gaining traction; expect to see eco-friendly materials and processes becoming standard in the industry.

Insights for Hobbyists and Professionals

For hobbyists venturing into the world of metal machining with a hobby CNC milling machine, start small but think big! A desktop CNC mill steel can be an excellent entry point without breaking the bank while still delivering impressive results on various projects. Professionals should continuously explore new technologies and techniques to stay ahead; investing time in learning about different types of CNC machines will pay off significantly in terms of efficiency and quality.