Introduction

Choosing the right metal CNC machine is crucial for achieving precision and efficiency in machining processes. Whether you are a hobbyist or a professional, selecting the right CNC machine can greatly impact the quality of your work. Factors such as machine type, size, software compatibility, and manufacturer support all play a significant role in making an informed decision.

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. SYIL's range includes desktop CNC machines that are perfect for small-scale operations or enthusiasts looking to bring their ideas to life.

By partnering with SYIL Machine Tools, you gain access to their expertise in delivering reliable machines that meet industry standards while providing excellent customer support throughout your journey with their products.

Machine Types and Their Applications

Metal CNC machines come in various types, each with its own unique applications and benefits. Let's explore the different types of metal CNC machines and understand their uses.

Exploring Different Types of Metal CNC Machines

Metal CNC machines are the backbone of modern manufacturing, offering precise and automated machining for various applications. Here's a look at some of the most common types:

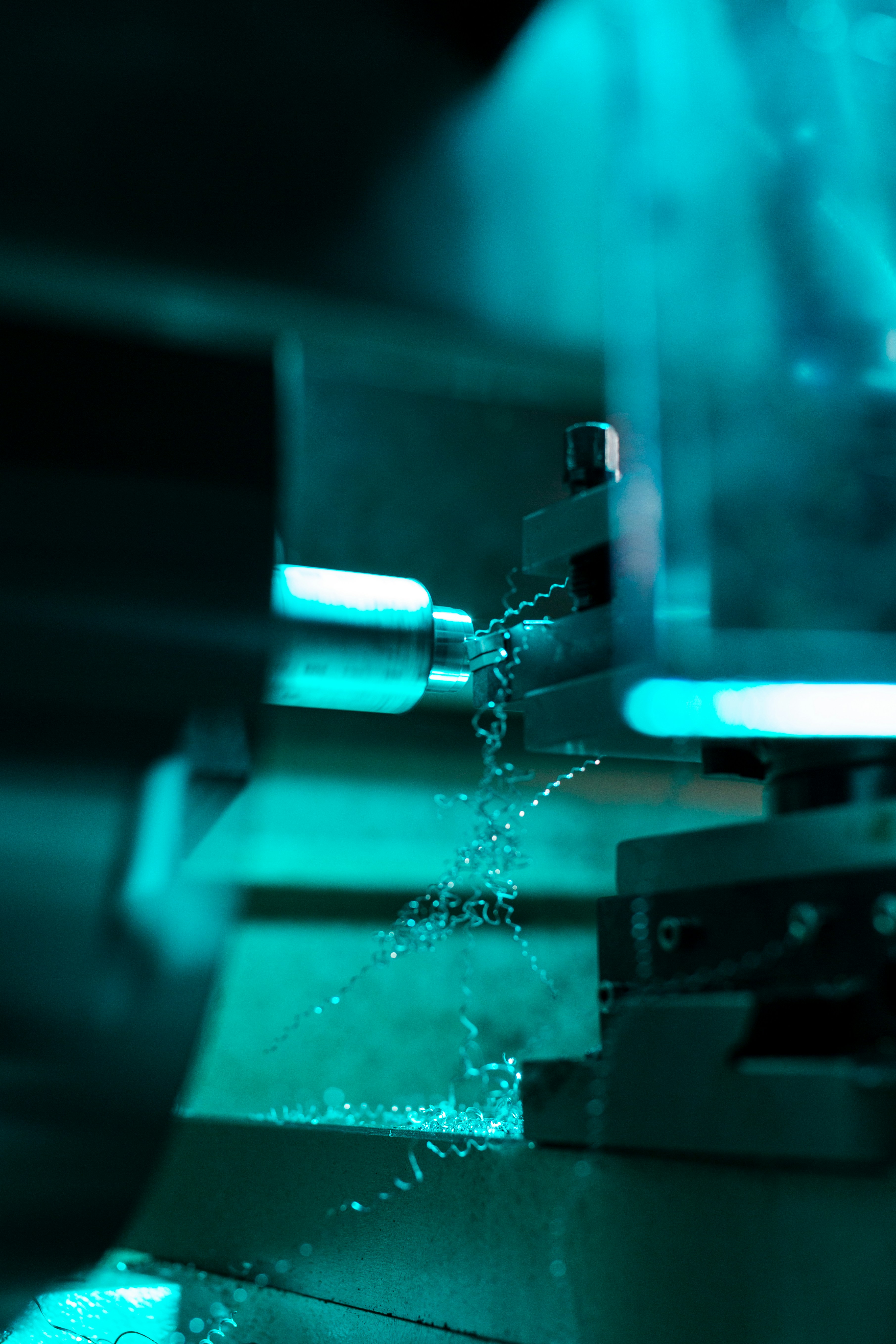

- CNC Milling Machines: Workhorses of the metalworking industry, CNC milling machines utilize rotating cutting tools to sculpt and shape metal parts. They excel at intricate tasks like drilling, tapping, and contouring with high accuracy.

- CNC Lathes: Designed for turning operations, CNC lathes spin the workpiece while a cutting tool carves its form. Think cylindrical shapes, threads, and other rotationally symmetrical parts – a mainstay in automotive and aerospace production.

- CNC Routers: Versatility is the name of the game for CNC routers. Employing computer-controlled movements and rotating cutting tools, they tackle a wide range of materials, including metal. From intricate woodworking and signage to rapid prototyping, CNC routers offer flexibility across various industries.

Understanding each machine's capabilities allows manufacturers to select the right tool for the job, ensuring efficient and precise metal fabrication.

Understanding the Applications of CNC Milling Machines

CNC milling machines stand out amongst other metalworking technologies for their versatility and precision. This versatility translates into a wide range of applications across numerous sectors.

- Precise Part Production: CNC mills craft intricate shapes with exceptional accuracy, making them ideal for prototyping, molds, and complex components. These machines deliver intricate details, from delicate medical instruments to intricate aerospace parts.

- Industry Leaders in Manufacturing: The automotive, aerospace, electronics, and medical equipment industries all rely heavily on CNC milling for their production processes. These machines produce consistent, high-quality parts that meet demanding specifications.

- Multi-Dimensional Machining: With capabilities like 3-axis or 5-axis machining, CNC mills tackle intricate designs and multi-sided machining operations. Advanced software integration allows them to handle complex geometries and produce parts with tight tolerances.

CNC milling machines are a cornerstone of modern manufacturing. They shape intricate parts and drive innovation across various industries.

Benefits of Using a Desktop CNC Machine

Desktop CNC machines offer a powerful and precise solution for small-scale manufacturing and hobbyists. Here are some of the key advantages they provide:

- Space-Saving Design: Unlike their larger counterparts, desktop CNC machines are built to fit on a standard workbench or desktop. This makes them ideal for workshops with limited space or even home use.

- Precision and Capability: Don't be fooled by their size. Desktop CNC machines deliver the same precision and functionality as larger machines on a smaller scale.

- Affordable Entry Point: Desktop CNC machines offer a cost-effective way to get started with CNC machining. This allows individuals and small businesses to explore their design ideas and produce custom parts without a huge investment.

- Prototyping and Production: Desktop CNC machines are perfect for creating prototypes, customizing designs, and completing small-batch production runs.

SYIL Machine Tools offers a range of high-quality desktop CNC machines that combine precision machining with a compact footprint. Built to focus on sustainability, these machines ensure long-lasting performance and reliable operation.

Whether you're a hobbyist or a small business owner, a desktop CNC machine can be a valuable tool for bringing your ideas to life.

Key Features to Look for in a Metal CNC Machine

Precision and Accuracy: Why it Matters in CNC Machining

In the world of metal CNC machining, precision and accuracy are paramount. A metal CNC machine with precise movements ensures that every cut and shape is executed accurately. This is especially crucial when working on intricate designs or complex parts that require tight tolerances. The ability to achieve precise measurements consistently guarantees the quality of the final product, preventing costly errors and rework.

The Importance of Machine Rigidity in CNC Milling

In CNC milling, achieving precise results relies on several factors, and machine rigidity is crucial. Here's why:

- Minimized Vibrations: A rigid machine frame absorbs cutting forces, preventing excessive vibration. This translates to smoother surface finishes on your milled parts.

- Improved Dimensional Accuracy: Reduced vibration leads to more precise cutting, ensuring your parts meet exact dimensional specifications.

- Enhanced Tool Life: Deflection during cutting can damage tools. Minimizing deflection with a rigid machine extends tool life and reduces replacement costs.

By prioritizing machine rigidity, you achieve higher quality parts, tighter tolerances, and a more efficient and cost-effective CNC milling process.

Spindle Speed and Power: Finding the Right Balance for Efficiency

A metal CNC machine's spindle speed and power play vital roles in determining its efficiency. Spindle speed refers to how fast the cutting tool rotates, while power relates to the force applied during cutting. Finding the right balance between these two factors is crucial for achieving efficient machining processes. Higher spindle speeds allow for faster material removal rates, while increased power ensures smooth cutting through tough materials. SYIL's CNC machines offer a range of options to meet various machining requirements.

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Their machines are engineered with advanced features such as high-precision movements, rigid structures, and adjustable spindle speeds to ensure optimal performance. SYIL's commitment to excellence makes it a trusted partner in metal CNC machining.

Choosing the Right Size and Capacity

When selecting a metal CNC machine, it is crucial to consider the size and capacity that will best suit your needs. Evaluating the workspace and material size requirements is essential to ensuring that the machine can effectively accommodate your projects.

Evaluating the Workspace and Material Size Requirements

Before investing in a metal CNC machine, it is important to assess your workspace limitations and determine the maximum dimensions of the materials you will be working with. Consider factors such as ceiling height, floor space, and door width to ensure that the machine can be easily installed and operated without any hindrances.

Additionally, consider the size of the materials you will be machining. Whether you are working with small or large pieces, make sure that the CNC machine's worktable or bed can comfortably accommodate them. This evaluation will help prevent any constraints or limitations during production.

Understanding the Importance of Machine Weight and Stability

Machine weight and stability are critical factors for successful CNC machining. Here's how they contribute to a smooth and accurate operation:

- Enhanced Stability: A heavier machine base offers a wider footprint, lowering its center of gravity. This reduces tipping and vibrations during operation, which is especially important for high-speed machining or heavy-duty tasks.

- Improved Precision: Reduced vibrations translate to more precise tool movement. This leads to cleaner cuts, tighter tolerances, and a better overall surface finish on your machined parts.

- Smoother Operation: A stable machine base absorbs cutting forces more effectively. This minimizes chatter and deflection, resulting in a smoother machining process and potentially longer tool life.

By prioritizing machine weight and stability when choosing a CNC machine, you ensure consistent performance and high-quality results for all your machining projects.

Balancing Cost and Capability: Matching Machine Size to Production Needs

When choosing a metal CNC machine, balancing cost-effectiveness and capability based on your production needs is essential. Investing in a larger machine may seem tempting for future expansion; however, it may not be cost-efficient if you do not require its full capacity.

On the other hand, opting for a smaller machine may initially save costs but could limit production capabilities as demand grows over time. Therefore, it is crucial to assess your current and projected production needs to determine the ideal machine size that aligns with your budget and long-term goals.

SYIL Machine Tools is a trusted provider of precision CNC machines. It offers a wide range of sizes and capacities to cater to various production requirements. Its machines are designed with durability and performance in mind, ensuring that you can achieve optimal results without compromising on quality or efficiency.

Software and Control Systems

Software and control systems play crucial roles in ensuring precision and efficiency in metal CNC machines. Let's explore the significance of CAD/CAM software, different control systems, and the importance of compatibility and user-friendliness in machine software.

The Role of CAD/CAM Software in CNC Machining

CAD/CAM software stands for Computer-Aided Design/Computer-Aided Manufacturing. It is an essential tool in CNC machining, allowing engineers to design intricate 3D models with utmost precision. This software enables them to create detailed blueprints directly translated into machine instructions.

Using CAD/CAM software, operators can easily visualize their designs and make necessary adjustments before sending them to the metal CNC machine for production. This ensures accuracy and minimizes errors during the manufacturing process.

With SYIL's metal CNC machines, their proprietary CAD/CAM software provides a user-friendly interface that simplifies the design process. It offers many features and tools to optimize efficiency while maintaining high-quality results.

Exploring Different Control Systems for Metal CNC Machines

Control systems are responsible for executing the instructions generated by CAD/CAM software on the metal CNC machine. Various types of control systems are available, each with its own set of features and capabilities.

One commonly used control system is numerical control (NC), which uses pre-programmed codes to guide the machine's movements. Another popular option is computer numerical control (CNC), which utilizes computerized controls for enhanced precision and flexibility.

SYIL Machine Tools offers state-of-the-art control systems specifically designed for its metal CNC machines. These systems ensure smooth operation, accurate positioning, and efficient production processes.

Ensuring Compatibility and User-Friendliness in Machine Software

When selecting a metal CNC machine, it is crucial to consider the compatibility and user-friendliness of the machine software. The software should seamlessly integrate with the CAD/CAM and control systems to ensure a smooth workflow.

SYIL's metal CNC machines are designed with compatibility in mind, allowing for easy integration with popular CAD/CAM software. This ensures that operators can effortlessly transfer their designs to the machine for production.

Additionally, SYIL prioritizes user-friendliness in their machine software. Their intuitive interfaces and comprehensive user manuals make it easy for operators to navigate different functions and optimize their machining processes.

By investing in a metal CNC machine from SYIL Machine Tools, you can benefit from their cutting-edge CAD/CAM software and control systems. These features enhance precision and efficiency and streamline production processes.

Evaluating the Manufacturer and Support

When investing in a metal CNC machine, it is crucial to evaluate the manufacturer and the support it provides. Choosing a reputable manufacturer has several significant benefits. Firstly, a reputable manufacturer like SYIL Machine Tools has a proven track record of developing and manufacturing precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability.

A reputable manufacturer ensures that their CNC machines are built to high standards, using top-quality materials and advanced technology. This guarantees that the machine will perform consistently and reliably, delivering accurate results every time. By choosing a reliable manufacturer, you can have peace of mind knowing that your investment is backed by years of expertise and experience in the industry.

Another important aspect to consider is local support and after-sales service availability. When you encounter issues or need assistance with your CNC machine, local support ensures quick response times and efficient solutions. It also means that technicians are familiar with your region's specific requirements, regulations, and operating conditions.

After-sales service plays a crucial role in maximizing the lifespan of your metal CNC machine. Regular maintenance, software updates, and technical support are essential for running your machine smoothly. Reputable manufacturers like SYIL Machine Tools offer comprehensive after-sales service packages to ensure that you can rely on their expertise throughout the machine's lifespan.

SYIL Machine Tools stands out as a trusted provider of precision CNC machines due to its commitment to customer satisfaction. Its machines are known for their durability, accuracy, and efficiency in various applications such as milling, drilling, and more. With SYIL as your partner in precision CNC machining, you can trust that its machines will meet your production needs while delivering exceptional quality.

SYIL Machine Tools: Your Partner in Precision CNC Machining

Making an Informed Decision for Your Metal CNC Machine Investment

When it comes to investing in a metal CNC machine, it is crucial to make an informed decision. Understanding the importance of choosing the right machine that meets your needs can save you time and money in the long run. Consider factors such as machine types, key features, size and capacity, software, control systems, and evaluate the manufacturer and support.

When it comes to precision CNC machining, SYIL Machine Tools is your trusted partner. They have established themselves as a reputable manufacturer with their expertise and experience in developing and manufacturing quality CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability.

Maximizing Efficiency and Quality with the Right Metal CNC Machine

Investing in the right metal CNC machine can greatly impact your efficiency and quality of work. SYIL's CNC machines offer precision, accuracy, rigidity, spindle speed, and power balance for optimal efficiency. Their machines are designed to match your production needs while providing stability and durability.