Introduction

Gun milling machines are essential tools in the firearms manufacturing industry, enabling precision and efficiency in the production of various gun parts. Understanding the capabilities and importance of these machines is crucial for anyone involved in gun making. Additionally, choosing the right CNC machine for gun making can make a significant difference in the quality and speed of production.

Understanding Gun Milling Machines

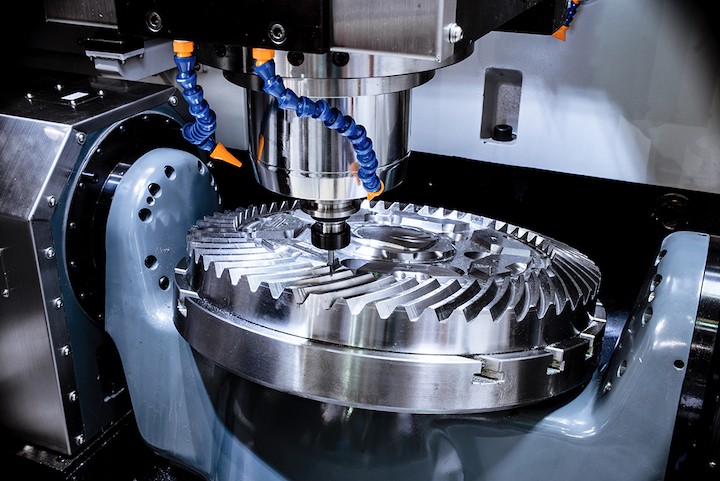

Gun milling machines are specialized equipment designed to shape and cut metal components to create firearms. These machines utilize computer numerical control (CNC) technology to ensure accuracy and consistency in the manufacturing process. With the ability to work with different materials and produce complex parts, gun milling machines have become indispensable in the industry.

Gun milling machines are essential for producing firearms with precision and accuracy. The CNC technology utilized in these machines ensures that each component is manufactured to exact specifications, resulting in consistent quality across all products. Additionally, the ability to work with a variety of materials allows for greater flexibility in design and production, making gun milling machines a crucial tool for firearm manufacturers.

Importance of Gun Milling Machines

The importance of gun milling machines lies in their ability to produce high-quality, precise gun components with minimal margin for error. These machines enable manufacturers to streamline their production processes, reduce manual labor, and achieve consistent results. As firearm designs become more intricate, the need for advanced milling technology continues to grow.

With the increasing demand for customized firearms, gun milling machines play a crucial role in meeting the specific needs of individual gun enthusiasts. These machines offer the flexibility to produce unique components and intricate designs, allowing manufacturers to cater to a diverse range of preferences. As the market for personalized firearms continues to expand, the versatility of CNC machines becomes increasingly valuable in delivering tailored solutions.

Choosing the Right CNC Machine for Gun Making

Selecting the best CNC machine for gun making involves considering factors such as precision, speed, versatility, and cost-effectiveness. Manufacturers must assess their specific needs and production requirements to determine which machine will best suit their operations. Investing in a reliable CNC machine can significantly impact the overall efficiency and quality of firearm production.

Once manufacturers have identified their specific needs and production requirements, they can begin to explore the various CNC machines available on the market. It's important to consider the level of precision required for gun making, as well as the speed at which the machine can operate without compromising quality. Additionally, versatility is key when it comes to adapting to different firearm designs and production processes. By carefully evaluating these factors, manufacturers can make an informed decision that will ultimately impact the efficiency and cost-effectiveness of their operations.

Now that we have set the stage with an introduction to gun milling machines and their significance let's delve deeper into what exactly these machines are capable of achieving.

What is a Gun Milling Machine?

Definition of Gun Milling

Gun milling is the process of using a rotary cutter to remove material from a workpiece, shaping it into the desired form for gun making. This process requires precision and accuracy to ensure the final product meets the necessary specifications.

Gun milling machines work by utilizing a rotary cutter that is precision-engineered to remove material from the workpiece with utmost accuracy. This process involves carefully shaping the metal into the desired form for gun making, ensuring that every detail meets the necessary specifications. The machines are equipped with advanced technology and cutting-edge tools to guarantee that the final product is of the highest quality and meets industry standards.

How Gun Milling Machines Work

Gun milling machines use rotary cutters to remove material from a workpiece, allowing for intricate and precise shaping of gun components. These machines are equipped with CNC technology, which enables automated and efficient production of gun parts with minimal human intervention.

Advantages of Using a Gun Milling Machine

The use of gun milling machines offers several advantages, including increased productivity, consistent quality, and the ability to produce complex shapes and designs with ease. Additionally, these machines allow for cost-effective production by minimizing material waste and reducing labor costs.

Now you have an understanding of what a gun milling machine is and how it works! Next, we'll explore the best CNC machine for gun making and the three basic types of milling machines.

The Best CNC Machine for Gun Making

When it comes to finding the best CNC machine for gun making, the SYIL CNC Machine is a top choice. This machine offers precision, speed, and reliability, making it perfect for creating high-quality gun parts. With its user-friendly interface and customizable features, the SYIL CNC Machine is a favorite among gun manufacturers.

Exploring SYIL CNC Machine

The SYIL CNC Machine is designed specifically for gun milling and offers a range of features that make it stand out from the competition. Its high-speed spindle, rigid construction, and advanced control system ensure accurate and efficient milling of gun components. With its compact size and easy installation process, the SYIL CNC Machine is ideal for small workshops or large-scale production facilities.

In addition to its impressive milling capabilities, the SYIL CNC Machine also offers a user-friendly interface and intuitive controls, making it easy for operators to set up and run the machine with minimal training. This level of accessibility ensures that even inexperienced users can quickly become proficient in operating the equipment, reducing the need for specialized expertise and streamlining production processes. The machine's user-friendly design is a key factor in its appeal to small workshops and large-scale facilities alike, as it allows for seamless integration into existing operations without requiring significant retraining or operational adjustments.

Features to Look for in a Gun Milling Machine

When choosing a gun milling machine, there are several key features to consider. Look for a machine with high spindle speed and torque to handle various materials used in gun manufacturing. Additionally, consider the machine's rigidity, accuracy, and ease of use to ensure optimal performance and productivity. A reliable control system with advanced software capabilities is also essential for precision milling. Moreover, it is important to consider the size and capacity of the machine, as well as its compatibility with CAD/CAM software for seamless integration into your manufacturing process. This will help streamline production and improve overall efficiency in gun making.

Comparing Different CNC Machines for Gun Making

In addition to the SYIL CNC Machine, there are other options available for gun making purposes. It's important to compare different machines based on their specifications, performance capabilities, and price points. Consider factors such as machine size, cutting capacity, tooling options, and after-sales support when evaluating different CNC machines for gun manufacturing.

By exploring the best CNC machines for gun making and understanding their key features, manufacturers can make informed decisions about investing in equipment that meets their specific needs while enhancing their overall production process.

The Three Basic Types of Milling Machines

Understanding Vertical Milling Machines

Vertical milling machines are equipped with a vertical spindle that holds and rotates the cutting tool against the workpiece. This type of machine is ideal for producing intricate parts and components with complex shapes, making it a popular choice for gun milling. The vertical orientation allows for easy access to the workpiece, enabling precise and accurate cutting, drilling, and shaping.

Horizontal milling machines, on the other hand, are equipped with a horizontal spindle that holds and rotates the cutting tool parallel to the workpiece. This design allows for heavier cutting and more stable machining, making it suitable for larger and heavier workpieces. The horizontal orientation also enables efficient chip removal, reducing the risk of chip buildup and potential damage to the workpiece. Additionally, horizontal milling machines are commonly used for producing slots, grooves, and keyways due to their ability to create wide, shallow cuts.

Exploring Horizontal Milling Machines

Horizontal milling machines feature a horizontal spindle that holds the cutting tool parallel to the ground. This setup allows for heavy-duty cutting and removal of material from the workpiece, making it suitable for manufacturing gun barrels, receivers, and other firearm components. Horizontal milling machines are known for their stability and rigidity, ensuring high precision in gun milling operations.

Horizontal milling machines are also versatile, as they can accommodate a wide range of cutting tools and accessories, allowing for various machining operations to be performed on a single workpiece. This flexibility makes them ideal for producing intricate and complex firearm components with different shapes and sizes. Additionally, horizontal milling machines can be equipped with automated features such as CNC controls, which further enhance their efficiency and accuracy in gun manufacturing processes.

Advantages of Using Universal Milling Machines

Universal milling machines offer versatility by combining features of both vertical and horizontal milling machines. With a swiveling table that can move in multiple directions, universal machines provide flexibility in machining various angles and shapes required in gun making. This type of machine is highly efficient for producing different types of firearms with minimal setup time.

By understanding the three basic types of milling machines - vertical, horizontal, and universal - gun manufacturers can make informed decisions when selecting equipment for their operations. Each type offers unique advantages suited to specific requirements in gun making processes such as precision engineering or heavy-duty material removal.

Now let's delve into exploring SYIL CNC Machine as one of the best options for gun making operations.

Conclusion

Investing in the Right Gun Milling Machine

When it comes to investing in the right gun milling machine, it's crucial to consider factors such as precision, speed, and versatility. Look for a CNC machine that offers high-quality milling capabilities and can handle a variety of materials used in gun making. By choosing the right machine, you can ensure efficient and accurate production of gun components.

Mastering Gun Milling Techniques

Mastering gun milling techniques is essential for producing high-quality firearms. It's important to understand the intricacies of gun milling, including the various cutting processes and tool paths involved. With proper training and practice, machinists can hone their skills to create precise and durable gun parts using CNC technology.

With the advancement of CNC technology, gun milling has become more efficient and precise than ever before. CNC machines allow for complex designs and intricate patterns to be milled with incredible accuracy, resulting in firearms of exceptional quality. Machinists who have mastered the art of gun milling can leverage CNC technology to push the boundaries of what is possible in firearm design, creating innovative and unique products that stand out in the market.

Enhancing Gun Making with CNC Technology

CNC technology has revolutionized the way firearms are manufactured, offering unmatched precision and efficiency. By harnessing the power of CNC machines for gun making, manufacturers can streamline production processes and achieve consistent results. With advanced features such as multi-axis machining and automatic tool changers, CNC technology enhances the overall quality of firearms.

By investing in the right gun milling machine, mastering advanced techniques, and leveraging CNC technology, manufacturers can elevate their gun making capabilities to new heights. Whether it's producing custom firearms or mass-producing components, the combination of skilled craftsmanship and cutting-edge machinery is essential for success in the industry.