Introduction

When it comes to aerospace manufacturing, precision is key. Aerospace milling is a crucial part of the machining process in aerospace, involving the shaping and cutting of materials to create intricate components for aircraft and spacecraft. The success of aerospace milling is vital for ensuring the safety and performance of aerospace vehicles, making it a critical aspect of the industry.

Understanding Aerospace Milling

Aerospace milling is a specialized machining process that involves using cutting tools to remove material from a workpiece to create complex shapes and components for aerospace applications. It requires high levels of precision, accuracy, and attention to detail in order to meet the stringent requirements of the aerospace industry.

Importance of Aerospace Milling Success

The success of aerospace milling directly impacts the quality, reliability, and safety of aircraft and spacecraft. Any errors or imperfections in the machining process can compromise the structural integrity and performance of critical components, leading to potentially catastrophic consequences.

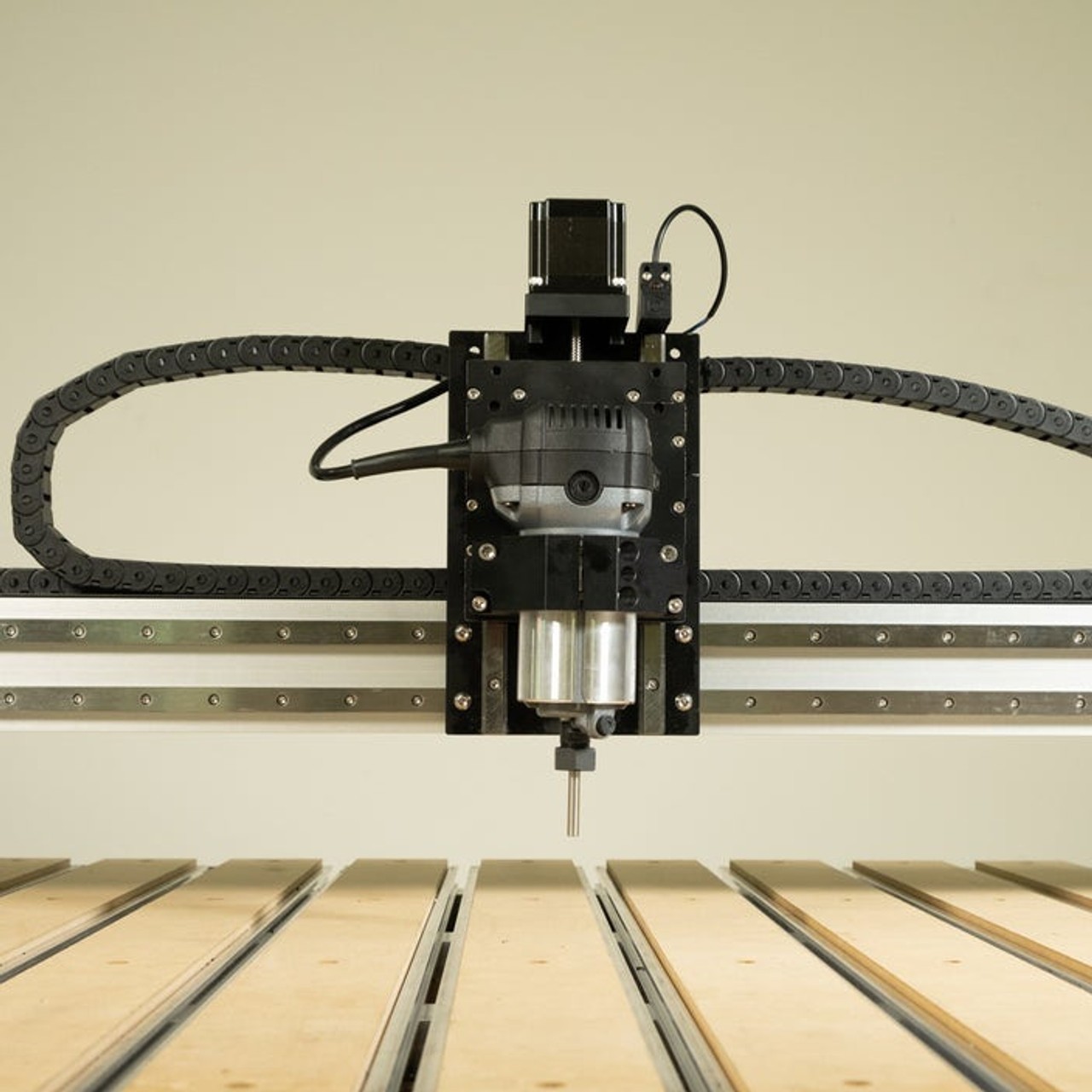

What is Aerospace CNC Machining?

Aerospace CNC (Computer Numerical Control) machining refers to the use of computerized systems to control machine tools in the manufacturing process. This advanced technology allows for precise and consistent machining operations, ensuring that complex aerospace components are produced with high accuracy and efficiency.

The Role of Aerospace Machinists

Aerospace machining is a complex and precise process crucial to the manufacturing of aircraft and spacecraft parts. Aerospace machinists play a vital role in this industry, requiring specialized skills and expertise to operate CNC machines and produce high-quality components for aerospace applications.

Skills and Expertise Required

Aerospace machinists must possess a strong understanding of engineering principles, as well as proficiency in reading blueprints and technical drawings. They need to have a keen eye for detail, excellent problem-solving abilities, and be able to work with various materials such as aluminum, titanium, and composites. Additionally, knowledge of CAD/CAM software is essential for programming CNC machines to create intricate aerospace components.

Precision and Accuracy in Machining

Precision is paramount in aerospace machining due to the strict tolerances required for aircraft parts. Machinists must be capable of producing highly accurate components within microns to ensure safety and reliability in aerospace systems. This demands meticulous attention to detail, advanced measurement techniques, and the ability to maintain consistent quality throughout the manufacturing process.

Utilizing SYIL CNC Machine

The use of state-of-the-art equipment such as the SYIL CNC machine is essential for aerospace machinists to achieve the precision and efficiency needed for complex aerospace milling projects. The SYIL machine offers advanced features including high-speed spindle options, rigid construction, and user-friendly controls that enable machinists to produce intricate components with ease while meeting stringent aerospace industry standards.

Key Factors for Aerospace Milling Success

Material Selection and Compatibility

A crucial aspect of aerospace milling is the careful selection of materials that are compatible with the specific requirements of the aircraft or spacecraft being manufactured. Aerospace milling often involves working with advanced materials such as titanium, aluminum, and composites that require specialized machining techniques to ensure structural integrity and performance. Machinists must have a deep understanding of material properties and behavior to make informed decisions regarding material selection for aerospace components.

Tooling and Cutting Strategies

In aerospace milling, the choice of cutting tools and machining strategies is paramount to achieving precision and efficiency. High-performance tooling, including end mills, drills, and inserts, are utilized to meet the stringent tolerances and surface finish requirements demanded by aerospace applications. Machinists also employ advanced cutting strategies such as high-speed machining and adaptive control to optimize productivity while maintaining quality standards in aerospace manufacturing.

Quality Control and Inspection Processes

Quality control and inspection processes play a vital role in ensuring the reliability and safety of aerospace components produced through milling operations. Rigorous inspection protocols are implemented to verify dimensional accuracy, surface finish, and material integrity, often utilizing advanced metrology equipment such as coordinate measuring machines (CMM) and non-destructive testing methods. Aerospace machinists are responsible for adhering to strict quality standards throughout the manufacturing process to deliver components that meet or exceed industry regulations.

By focusing on material selection, tooling strategies, and quality control processes in aerospace milling operations, machinists can contribute significantly to the success of aerospace manufacturing endeavors while ensuring compliance with stringent industry requirements.

Advanced Techniques in Aerospace Milling

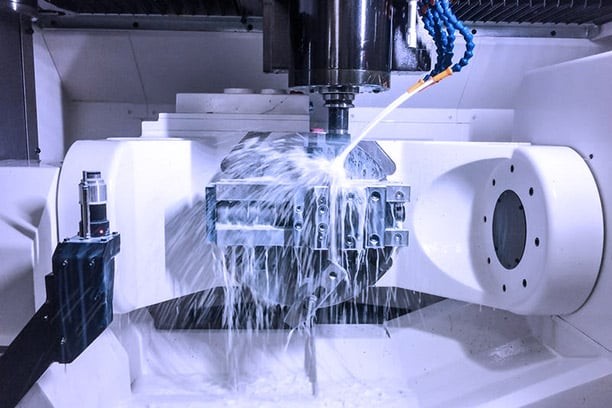

Aerospace milling involves the use of advanced techniques to achieve precision and efficiency in manufacturing components for the aerospace industry. High-speed machining is a key method used to increase productivity and reduce production time, allowing for faster turnaround on critical parts. By utilizing specialized cutting tools and optimizing cutting parameters, aerospace machinists can achieve superior surface finishes and tight tolerances required for aerospace applications.

High-Speed Machining

High-speed machining in aerospace milling involves using cutting tools that rotate at high speeds and feed rates, allowing for rapid material removal while maintaining accuracy. This technique is essential for producing complex components with intricate geometries, such as turbine blades and engine components. By maximizing spindle speeds and tool paths, machinists can achieve superior surface finishes and reduce cycle times, ultimately improving overall productivity in aerospace manufacturing.

Multi-Axis Machining

Multi-axis machining is another advanced technique used in aerospace milling to enhance the complexity of parts that can be produced. By utilizing CNC machines with multiple axes of motion, machinists can efficiently machine complex geometries from various angles without the need for repositioning or manual intervention. This capability allows for the production of highly intricate components with tight tolerances, essential for the demanding requirements of aerospace applications.

Adaptive Control Machining

Adaptive control machining is a cutting-edge technique that leverages real-time feedback to adjust machining parameters based on actual cutting conditions. By continuously monitoring tool wear, material properties, and environmental factors, adaptive control systems optimize cutting processes to maintain consistent quality and prolong tool life. This innovative approach ensures the highest level of precision and reliability in aerospace manufacturing, ultimately leading to improved component performance and longevity.

In addition to enhancing precision and efficiency, adaptive control machining also contributes to cost savings by reducing scrap and rework. With the ability to make real-time adjustments, manufacturers can minimize material waste and improve overall production yield. This proactive approach to machining not only improves the bottom line but also reduces environmental impact, making it a sustainable choice for aerospace manufacturing.

By incorporating these advanced techniques into aerospace milling processes, manufacturers can achieve unparalleled levels of precision and efficiency while meeting the stringent requirements of the industry.

Industry Insights on Aerospace Milling

The aerospace industry is constantly evolving, and emerging technologies play a crucial role in advancing aerospace milling processes. Innovations such as additive manufacturing and composite materials are revolutionizing the way components are produced for aircraft and spacecraft. These new technologies are enhancing the efficiency, precision, and quality of aerospace milling, giving manufacturers a competitive edge in the market.

Emerging Technologies

Additive manufacturing, also known as 3D printing, is transforming the aerospace manufacturing landscape by enabling the production of complex geometries with reduced material waste. This innovative technology allows for greater design flexibility and customization while maintaining high strength-to-weight ratios in aerospace components. Additionally, advancements in composite materials are leading to lighter and more durable parts, contributing to improved fuel efficiency and performance in aerospace applications.

In addition to additive manufacturing and advancements in composite materials, the aerospace industry is also seeing significant developments in automation and robotics. Automation is streamlining production processes, reducing human error, and improving overall efficiency in aerospace manufacturing. Robotics are being used for tasks such as assembly, inspection, and maintenance, further enhancing precision and productivity in the production of aerospace components. These technologies are revolutionizing the way aircraft are built and maintained, leading to increased reliability and safety.

Future Trends in Aerospace Manufacturing

The future of aerospace manufacturing is driven by trends such as automation, digitalization, and sustainability. As technology continues to advance, automation through robotics and artificial intelligence will streamline production processes and reduce lead times for aerospace milling operations. Furthermore, digitalization through data analytics and simulation tools will optimize machining strategies and improve overall productivity in the industry.

As technology continues to advance, the aerospace manufacturing industry is also focusing on sustainability as a key trend for the future. With a growing emphasis on environmental responsibility, manufacturers are seeking ways to reduce waste and energy consumption in their production processes. This includes the development of eco-friendly materials and the implementation of green manufacturing practices to minimize the industry's carbon footprint. By integrating sustainability into aerospace manufacturing, companies can not only meet regulatory requirements but also appeal to environmentally-conscious consumers and investors.

Maximizing Efficiency and Productivity

In order to stay competitive in the global aerospace market, manufacturers are focusing on maximizing efficiency and productivity in their machining operations. This involves implementing advanced manufacturing techniques such as lights-out machining, where CNC machines operate autonomously without human intervention for extended periods of time. By leveraging these cutting-edge methods, companies can achieve higher throughput rates while maintaining exceptional precision in their aerospace milling processes.

In addition to lights-out machining, manufacturers are also investing in state-of-the-art cutting tools and tool holders to further enhance their machining operations. These advanced tools are designed to optimize material removal rates and extend tool life, resulting in significant cost savings and improved overall productivity. By incorporating these high-performance cutting solutions into their processes, aerospace manufacturers can effectively reduce cycle times and increase the efficiency of their milling operations.

Conclusion

Aerospace milling is a critical aspect of aerospace manufacturing, and achieving excellence in this field requires precision, expertise, and advanced techniques. Machinists play a crucial role in ensuring the success of aerospace milling through their skills and attention to detail. Continuous improvement in machining processes is essential to keep up with emerging technologies and future trends in aerospace manufacturing.

Achieving Excellence in Aerospace Milling

To achieve excellence in aerospace milling, machinists must have a deep understanding of the machining process in aerospace and utilize advanced CNC machining technology. The ability to select the right materials, implement effective tooling strategies, and maintain strict quality control are key factors for success in aerospace milling.

To achieve excellence in aerospace milling, machinists must have a deep understanding of the machining process in aerospace and utilize advanced CNC machining technology. The ability to select the right materials, implement effective tooling strategies, and maintain strict quality control are key factors for success in aerospace milling. Additionally, staying updated with the latest advancements in aerospace materials and machining techniques is crucial for producing high-quality components that meet the stringent requirements of the aerospace industry. Continuous training and education on new technologies and processes can help machinists stay ahead of the curve and deliver exceptional results.

Continuous Improvement in Machining Processes

Continuous improvement is vital to stay ahead in the aerospace manufacturing industry. Machinists need to embrace advanced techniques such as high-speed machining, multi-axis machining, and adaptive control machining to enhance productivity and efficiency. Keeping up with emerging technologies and adopting innovative approaches will drive continuous improvement in machining processes.

Machinists must also prioritize ongoing training and skill development to keep up with the latest advancements in machining technology. This may involve attending workshops, completing certification programs, or participating in on-the-job training to ensure they are equipped to operate and maintain cutting-edge machinery. By investing in their knowledge and expertise, machinists can contribute to the continuous improvement of machining processes within the aerospace manufacturing industry.

The Future of Aerospace Manufacturing

The future of aerospace manufacturing holds exciting possibilities with the integration of cutting-edge technologies like automation, artificial intelligence, and additive manufacturing. Maximizing efficiency and productivity will be crucial for meeting the demands of the evolving aerospace industry while maintaining high standards of quality.