Introduction

Defining CNC Machining for Titanium and Steel

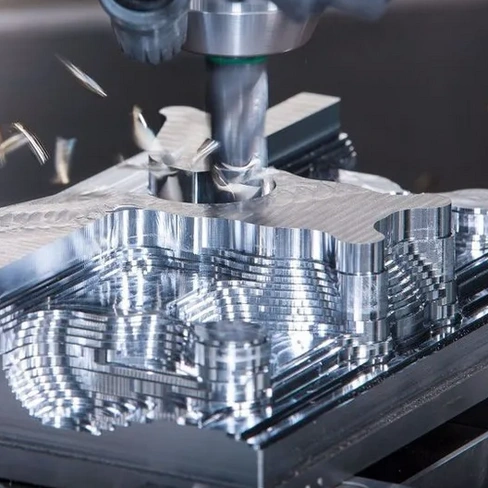

CNC machining refers to the use of computer numerical control technology to automate the operation of machine tools, allowing for highly precise cuts and shapes in materials like titanium and steel. The process involves programming a computer to dictate the movements of tools, which can create intricate designs with minimal human intervention. When we talk about CNC machining titanium, we're diving into a realm where material properties significantly influence the techniques employed.

Why Choose Titanium Over Steel?

Choosing titanium over steel often boils down to its superior strength-to-weight ratio and exceptional corrosion resistance. While steel is widely used due to its durability and cost-effectiveness, titanium offers distinct advantages in specific applications where weight savings are critical—such as aerospace or medical devices. So, why choose titanium? Because sometimes you need a lightweight champion that can withstand harsh environments without breaking a sweat!

The Applications of CNC Machining

CNC machining finds its place across various industries, each with unique demands for precision and material properties. From aerospace components that require lightweight yet durable materials like titanium to automotive parts made from robust steel, the applications are vast and varied. Whether you're asking Can titanium be CNC machined? or pondering What materials cannot be CNC machined?, understanding these applications helps clarify why certain choices are made in manufacturing processes.

Material Composition and Properties

Comparing Titanium and Steel Densities

One of the first things to consider when evaluating titanium versus steel is density. Titanium has a lower density than most steels, which means that for the same volume, titanium components will weigh significantly less. This lightweight nature makes titanium an excellent choice in applications where reducing weight is essential without compromising strength—think aerospace or high-performance automotive parts.

Moreover, while titanium's lower density offers significant benefits in terms of weight savings, it also presents challenges during CNC machining for titanium. The lighter material can sometimes lead to vibrations during machining if not properly secured or if the tooling isn’t optimized. Thus, understanding how do you machine titanium effectively becomes critical to achieving optimal results.

Strength and Durability of Each Metal

When it comes to strength and durability, both titanium and steel have their merits but serve different purposes depending on the application at hand. Titanium is known for its exceptional strength-to-weight ratio; it can withstand high levels of stress while remaining lightweight—a feature that makes it particularly appealing in industries like aerospace where performance is paramount. On the other hand, certain types of steel exhibit higher tensile strength than most grades of titanium.

In terms of durability under extreme conditions—like temperature fluctuations or heavy loads—steel often takes the lead due to its toughness. However, what is the machinability of titanium? Despite being strong and durable, titanium can be trickier to machine than steel due to its tendency to work-harden quickly when subjected to cutting forces during CNC machining processes.

Resistance to Corrosion and Wear

Resistance to corrosion is another key factor that differentiates these two materials; here’s where titanium shines brightly! Titanium naturally forms a protective oxide layer that shields it from corrosive environments such as saltwater or acidic substances—making it a top choice for marine applications or medical implants exposed to bodily fluids. On the flip side, while some steels are treated with coatings or alloys for improved corrosion resistance (like stainless steel), they generally don’t match up against pure titanium in this regard.

Wear resistance also plays a significant role in determining which metal might be best suited for your project needs; both materials offer good wear resistance but differ based on specific applications used in CNC machining processes. For instance: Can Titanium be CNC machined effectively? Yes! But it's essential to use appropriate tools designed specifically for working with this resilient metal; otherwise you risk accelerated tool wear which can lead you down a costly path!

In summary, understanding these material properties helps streamline your decision-making process when selecting between CNC machining titanium versus steel components tailored towards your project requirements.

Machinability and Techniques

What is the Machinability of Titanium?

The machinability of titanium refers to how easily the material can be cut or shaped using CNC machining processes. Unlike steel, which can be machined relatively quickly with standard tools, titanium tends to work-harden during machining, making it more resistant to cutting forces. This characteristic raises the question: What is the machinability of titanium? Generally speaking, titanium has a lower machinability rating than many metals; however, with the right tools and techniques in place, successful CNC machining for titanium projects can still be achieved.

How Do You Machine Titanium Effectively?

To effectively machine titanium, one must consider several factors that influence performance and efficiency during the process. First off, utilizing sharp cutting tools made from high-speed steel or carbide is essential because dull tools can lead to increased heat generation and tool wear—two things that are not friends with titanium! Additionally, controlling cutting speeds and feeds becomes critical; slower speeds combined with higher feed rates often yield better results when machining this resilient metal. So when you ponder How do you machine titanium?, remember that precision and technique are your best allies.

Tips for CNC Machining Titanium Successfully

When diving into CNC machining titanium successfully, there are some tried-and-true tips worth keeping in mind. First up: always use plenty of coolant during machining operations! Coolant helps dissipate heat generated by friction while also reducing tool wear—two key factors in maintaining efficiency during your project. Another tip is to avoid excessive tool engagement; instead of trying to remove large amounts of material in one go (which can lead to disaster), take lighter cuts over multiple passes for a smoother finish overall. Lastly, remember that certain materials simply cannot be CNC machined effectively—so ensure you're working within your machine's capabilities before starting your project.

Cost Considerations

When evaluating the financial implications of CNC machining titanium, several factors come into play. While titanium is often more expensive than steel, its unique properties can justify the cost in certain applications. Therefore, understanding whether CNC machining titanium is worth the price hinges on your project's specific needs and long-term benefits.

Is CNC Machining Titanium Worth the Price?

CNC machining titanium can initially seem like a costly endeavor due to higher raw material prices and specialized tooling requirements. However, when you consider its strength-to-weight ratio and resistance to corrosion, titanium often proves to be a more economical choice over time. Investing in CNC machining for titanium may lead to lower maintenance costs and longer-lasting components, making it a smart financial decision for many industries.

Cost Comparison: Titanium vs. Steel Projects

When comparing project costs between titanium and steel, several variables must be taken into account, including material prices, labor costs, and the complexity of machining processes. While steel generally has a lower upfront cost, projects requiring lightweight or corrosion-resistant materials may benefit from using CNC machining titanium despite its higher initial investment. Ultimately, weighing these factors will help determine whether choosing titanium is financially viable for your specific project.

Budgeting for CNC Machining for Titanium

Budgeting for CNC machining for titanium requires careful planning due to its unique characteristics and processing challenges. Start by estimating material costs based on current market prices while factoring in potential waste during cutting or shaping—after all, what materials cannot be CNC machined? Additionally, consider investing in high-quality tools specifically designed for machining titanium; this upfront expense can pay off by improving efficiency and reducing production times.

Applications and Industries

CNC machining has revolutionized various industries, particularly in the aerospace, medical, and automotive sectors. The choice between titanium and steel often depends on specific application requirements, such as weight, strength, and corrosion resistance. Understanding how CNC machining titanium plays a role in these industries can help businesses make informed decisions.

Aerospace Applications of Titanium and Steel

In the aerospace industry, both titanium and steel are crucial for producing lightweight yet strong components. Titanium is favored for its high strength-to-weight ratio, making it ideal for aircraft frames and engine parts where reducing weight is essential. Conversely, steel's durability makes it suitable for landing gears and structural elements that require superior toughness.

When considering CNC machining for titanium in aerospace applications, it's vital to understand what materials cannot be CNC machined effectively due to their hardness or brittleness. The machinability of titanium can be challenging; however, advancements in cutting tools have made it easier to achieve precision parts without compromising quality. As a result, many aerospace manufacturers are increasingly adopting titanium CNC machining techniques to enhance performance while maintaining safety standards.

Medical Uses of CNC Machined Titanium

The medical field has embraced CNC machining titanium due to its biocompatibility and resistance to corrosion. Titanium implants—such as dental fixtures or orthopedic devices—benefit from the material's ability to integrate with bone tissue while resisting wear over time. This unique property ensures that medical professionals can rely on titanium components for long-lasting solutions.

How do you machine titanium effectively in a medical context? Precision is key; thus, specialized tools designed for CNC machining titanium are essential to ensure optimal results without damaging the material’s integrity. Furthermore, the ability to create complex shapes through advanced CNC techniques allows manufacturers to produce tailored solutions that meet stringent regulatory requirements in healthcare.

Automotive Industry Trends and Material Choice

In recent years, the automotive industry has witnessed a shift towards lightweight materials like aluminum and titanium for improved fuel efficiency without sacrificing performance. While traditional steel remains popular due to its cost-effectiveness and strength, many manufacturers are exploring how do you machine titanium into critical components such as engine mounts or suspension systems that require both durability and reduced weight.

One question frequently asked is: Can titanium be CNC machined alongside other materials? The answer lies in understanding each material's properties; while some metals may not be suitable for certain applications due to their machinability challenges or costs involved with precision work on them. However, with proper techniques tailored specifically for CNC machining titanium projects—like optimizing feed rates—manufacturers can effectively utilize this versatile metal across various automotive applications.

Equipment and Tools

Best Machines for Titanium Machining: SYIL CNC

When considering CNC machining for titanium, SYIL CNC machines stand out as some of the best options available. These machines are engineered with robust construction and advanced features that cater specifically to the demands of titanium machining. With their precision control systems and powerful spindles, SYIL CNC machines ensure optimal performance when tackling tough materials like titanium.

Moreover, these machines often come equipped with specialized cooling systems that help manage heat build-up during the machining process—a critical factor when learning how do you machine titanium effectively. In addition to their durability, SYIL's user-friendly interfaces make them accessible even for those new to titanium CNC machining.

Tools Required for CNC Machining Titanium

To successfully engage in titanium CNC machining, specific tools are necessary to handle this challenging material effectively. High-speed steel (HSS) or carbide cutting tools are commonly used because they can withstand the high temperatures generated while cutting titanium. It's also essential to have sharp tools since dull edges can lead to increased friction and premature tool wear.

Additionally, using coated tools—such as those with a TiAlN coating—can significantly enhance performance by reducing friction and improving tool life during CNC machining titanium processes. Remember that proper tool selection not only affects productivity but also ensures your finished product meets quality standards.

Can Titanium Be CNC Machined on Mini CNC Machines?

A common question arises: can titanium be CNC machined on mini CNC machines? While it's technically possible, it may not be advisable due to several factors such as power limitations and rigidity concerns inherent in smaller machines. Mini CNC machines typically lack the necessary torque required for effective cutting of tougher materials like titanium.

Furthermore, mini machines may struggle with maintaining precision over extended runs when working with such demanding materials—leading you back to pondering what is the machinability of titanium? For optimal results in your projects involving this metal, investing in a dedicated machine designed specifically for larger-scale operations is recommended rather than relying on mini options.

Conclusion

In summary, the choice between titanium and steel in CNC machining is not just a matter of preference but hinges on specific project requirements. Titanium offers unique advantages such as lower density, higher corrosion resistance, and superior strength-to-weight ratios compared to steel. However, these benefits come with challenges in machinability and cost that must be carefully considered.

Key Differences Between Titanium and Steel

When comparing titanium and steel, one cannot overlook the significant differences in their properties that impact CNC machining outcomes. For instance, while titanium is lighter and more resistant to corrosion, it poses challenges regarding its machinability; many operators wonder, “What is the machinability of titanium?” In contrast, steel is generally easier to machine but may not provide the same level of performance in demanding environments.

Understanding these key differences can guide you toward the right material for your specific application. If you're asking yourself “Can titanium be CNC machined?”, rest assured it can be done effectively with the right techniques and tools. Ultimately, knowing when to choose titanium over steel can significantly influence your project's success.

Making an Informed Decision for Your Project

Making an informed decision about whether to use CNC machining for titanium or steel involves evaluating several factors including application requirements, budget constraints, and desired performance characteristics. Considerations like weight reduction in aerospace applications or enhanced durability in medical devices often favor titanium despite its higher costs. If you're still pondering How do you machine titanium?—researching techniques tailored specifically for this metal will empower you to optimize your project outcomes.

Additionally, understanding what materials cannot be CNC machined helps narrow down your options further—titanium has its challenges but remains a viable choice when approached correctly. As you weigh your options between materials like titanium vs. steel projects, remember that knowledge is power; make sure you're armed with all necessary insights before diving into production.

Future Trends in CNC Machining Technology

Looking ahead to future trends in CNC machining technology reveals exciting advancements that could enhance how we work with both titanium and steel materials alike. Innovations such as improved cutting tools specifically designed for better performance with tough metals like titanium are on the horizon—making questions like Can Titanium Be CNC Machined? even more relevant as technology evolves.

Moreover, developments in automation and AI-driven machining processes promise greater efficiency while reducing costs associated with complex materials like titanium through optimized workflows—making it increasingly feasible for projects previously deemed too expensive or challenging. As these trends unfold within the realm of Titanium CNC Machining, staying informed will ensure you remain at the forefront of industry advancements.