Introduction

In the world of manufacturing and design, CNC (Computer Numerical Control) machines have revolutionized the way we create and produce items. With their precision and efficiency, understanding CNC capabilities can open up a realm of possibilities for both hobbyists and professionals alike. But what materials can a CNC machine cut? This question is crucial for anyone looking to leverage CNC technology for their projects.

Understanding CNC Capabilities

CNC machines are not just about cutting; they are versatile tools that can perform various functions such as engraving, milling, and drilling with remarkable accuracy. They operate based on digital designs, allowing users to manipulate materials in ways that manual methods simply cannot match. When considering what materials can CNC cut, it’s essential to grasp the full scope of these machines' capabilities to maximize their potential.

The Versatility of CNC Machines

From intricate designs in wood to robust components in metal, the versatility of CNC machines means they can tackle a wide array of projects across different industries. Whether you're crafting custom furniture or developing prototypes for engineering applications, knowing what you can cut with a CNC is vital for successful project execution. With the right material selection based on your project's needs, you can unlock endless creative possibilities.

Popular Materials for CNC Routing

When diving into the world of CNC machining material selection, it's important to familiarize yourself with popular options like wood, plastics, and metals that are commonly used for routing tasks. Each material has its unique properties that affect how it interacts with the cutting tools—some materials are easier to work with than others. However, understanding what materials cannot be CNC machined is equally important; this knowledge helps avoid costly mistakes and ensures your projects run smoothly.

Common Materials for CNC Machining

Wood Varieties Suitable for CNC

Wood is a classic choice in the world of CNC machining, offering both beauty and versatility. Popular varieties like plywood, MDF (Medium Density Fiberboard), and hardwoods such as oak and maple are perfect candidates for intricate designs and detailed cuts. The question often arises: what materials can CNC cut? Well, wood ranks high on that list due to its ease of handling and ability to produce stunning results.

CNC machines excel at creating custom furniture pieces, decorative items, or even complex sculptures from wood. When selecting wood types for your project, consider factors like grain patterns and density; these will influence the final product's aesthetics and durability. However, while many woods are suitable for CNC machining, it's essential to remember that certain softwoods may not hold up as well under pressure or intricate designs.

Plastics: The CNC Friendly Option

Plastics have become increasingly popular in the realm of CNC machining due to their lightweight nature and versatility in applications. Materials such as acrylic (PMMA), polycarbonate (PC), and nylon are frequently chosen because they can be easily cut into precise shapes without cracking or chipping—definitely what materials can a CNC machine cut! Whether you're crafting signage or components for various products, plastics offer an excellent balance between durability and ease of manipulation.

One significant advantage of using plastics is their ability to be colored or finished post-machining without much hassle. This opens up endless possibilities when considering what products can be made on a CNC machine—from functional parts to artistic creations that stand out visually! Plus, with proper tools and settings adjusted during the process, you’ll find that cutting plastic is generally cleaner than working with some metals.

Metals that CNC Machines Can Cut

These metals are favored in industries ranging from automotive to aerospace due to their strength-to-weight ratios and durability under stress. However, understanding which metals work best requires knowledge about material properties; after all—what materials cannot be CNC machined?

While softer metals like aluminum are easy targets for precision cutting techniques with minimal wear on tools, harder alloys may require specialized equipment or tooling strategies tailored specifically for them. This consideration plays an essential role in your overall **CNC Machining Material Selection** process; choosing the right metal will ensure not only quality output but also efficiency during production runs! So whether you're creating custom brackets or intricate parts for machinery—knowing what you can cut with a CNC will guide your decisions effectively.

Specialty Materials for Creative Projects

Composite Materials and Their Uses

Composite materials are a fantastic choice for CNC machining, combining two or more distinct materials to create something stronger and lighter than its individual components. For instance, fiberglass reinforced plastics or carbon fiber composites are popular in industries ranging from aerospace to automotive due to their high strength-to-weight ratios. When considering CNC Machining Material Selection, these composites stand out because they can be crafted into intricate shapes while maintaining durability.

What can you cut with a CNC machine? The answer includes these versatile composites that enable designers to push boundaries and create products that are both functional and aesthetically pleasing. However, it’s crucial to note that not all composite materials are created equal; some may present challenges during the machining process due to their layered structure or resin content.

Foam and its Applications in CNC Design

Foam is another specialty material that has gained popularity in the realm of CNC design, particularly for prototyping and model-making purposes. With its lightweight nature and ease of cutting, foam allows creators to quickly produce prototypes without extensive resources or time commitments. What products can be made on a CNC machine using foam? From intricate architectural models to custom packaging solutions, foam is an excellent medium for detailed work.

When exploring what materials cannot be CNC machined, it’s essential to consider the density and type of foam being used—while softer foams are easier to cut, denser varieties might require specific tooling or settings on your machine. Additionally, foam's versatility means it can also serve as an effective substrate for other materials in layered designs.

Unconventional Choices: Glass and Stone

For those looking at unconventional choices in material selection, glass and stone provide unique opportunities for creativity with CNC machines. Glass may seem intimidating at first glance; however, when properly configured with diamond-tipped bits and suitable speeds, it can be intricately engraved or cut into stunning designs—adding elegance to any project. Similarly, stone offers durability but requires robust machinery capable of handling hard materials effectively.

Understanding what materials cannot be CNC machined is just as important as knowing what you can work with; both glass and stone demand specific considerations regarding thickness restrictions and tool compatibility when incorporating them into your designs. As you explore what materials can a CNC machine cut beyond traditional choices like wood or metal, remember that pushing these boundaries often leads to extraordinary results!

Limitations of CNC Machining

What Materials Cannot Be CNC Machined?

Not every material is suitable for CNC machining, and knowing what materials cannot be CNC machined will save you time and resources. For instance, very soft materials like rubber or certain types of fabrics may not hold up well during the cutting process, leading to an unsatisfactory finish. Additionally, extremely hard materials such as tempered glass or certain ceramics can be challenging to work with due to their brittleness and tendency to shatter under pressure.

When considering what can you cut with a CNC machine, it's essential to remember that some composites or layered materials may also pose problems due to delamination during cutting. This means that while many metals, plastics, and woods are ideal candidates for CNC routing, others simply aren’t worth the hassle. Ultimately, understanding these limitations helps streamline your project planning by focusing on compatible options.

Considerations for Soft and Hard Materials

When it comes to selecting materials for your projects, both soft and hard options come with unique challenges in terms of CNC machining material selection. Soft materials like foam or light plastics can be easy to cut but might require special tooling or settings to avoid tearing or excessive wear on the bits. Conversely, hard materials such as aluminum or stainless steel demand more robust machinery and specific tooling techniques but yield excellent results when done correctly.

It's also important to consider how the properties of these materials affect the finished product; softer options may provide a lightweight solution but lack durability compared to harder alternatives. Moreover, understanding how different speeds and feeds impact both types of material will enhance your ability to produce high-quality products on a CNC machine. So whether you're crafting intricate designs from wood or machining durable metal parts, knowing your material's characteristics is key.

Understanding Material Thickness Restrictions

Material thickness plays a significant role in determining what products can be made on a CNC machine effectively. Each type of material has its own limitations concerning thickness; for example, while plywood might be easily machined up to 1 inch thick without issue, thicker metals could require specialized tools or even different machines altogether. This means that if you're working with thicker stock than recommended for your chosen method—whether it’s milling or routing—you might end up frustrated by poor results.

Additionally, understanding how thickness influences cutting speed is crucial; thicker pieces generally require slower feed rates which can increase production time significantly if not planned accordingly. Therefore, when deciding on what materials can a CNC machine cut successfully in terms of thickness restrictions becomes paramount in achieving precise outcomes without compromising quality. Keeping these factors in mind will undoubtedly lead you toward more successful projects!

Product Creation with CNC Machines

CNC machines are not just tools; they are gateways to endless creativity and innovation. With the right setup, you can produce a vast array of products ranging from intricate designs to practical components. But what materials can a CNC machine cut? This question is fundamental as it shapes the possibilities of product creation and influences your CNC machining material selection.

What Products Can Be Made on a CNC Machine?

The versatility of CNC machines allows for the creation of numerous products, including furniture, signage, and even custom jewelry. From functional items like brackets and housings to artistic pieces like sculptures, there’s virtually no limit to what can be crafted using these machines. When considering what materials can a CNC machine cut, think beyond traditional wood or metal; plastics and composites also open up new avenues for product innovation.

Understanding what materials can CNC cut is essential for maximizing your creative potential. For instance, if you’re looking to create decorative wall art or detailed engravings, softer woods like pine or MDF might be ideal choices. Meanwhile, if you're venturing into more robust applications like automotive parts or industrial components, metals such as aluminum or steel could be the way to go.

Engraving vs. Cutting: Choosing Your Technique

When it comes to product creation with CNC machines, knowing whether to engrave or cut is crucial in achieving your desired outcome. Engraving typically involves removing a small amount of material from the surface to create designs or text without cutting through entirely—perfect for adding details on signs or personalized items. On the other hand, cutting completely removes sections from your material and is suitable for creating shapes or parts that need precise dimensions.

So what materials cannot be CNC machined? While most common materials are fair game for both engraving and cutting techniques, some harder substances may pose challenges due to tool wear or machine capabilities. Always consider your project requirements when selecting between engraving and cutting—your choice will significantly impact both aesthetics and functionality.

Prototyping and Customization with CNC

One of the standout features of using a CNC machine is its ability to facilitate rapid prototyping and customization—an invaluable asset in today’s fast-paced market! Whether you're developing a new product design or tailoring an existing one based on customer feedback, CNC technology allows you to iterate quickly without sacrificing quality. This adaptability makes it easier than ever to explore different designs while asking yourself: What can you cut with a CNC?

In terms of customization options available through this technology, you’ll find that nearly any material suitable for machining opens up possibilities for unique creations tailored specifically for clients' needs—whether it's custom signage made from acrylics or specialized parts fabricated from metals like titanium. By understanding what materials can a CNC machine cut effectively within your project's scope, you'll ensure successful outcomes every time.

Choosing the Right CNC Machine

Selecting the right CNC machine can be a game-changer for your projects. The capabilities of different machines can significantly influence what materials can a CNC machine cut and how effectively they do so. Whether you're looking to create intricate designs or robust products, understanding your options is key.

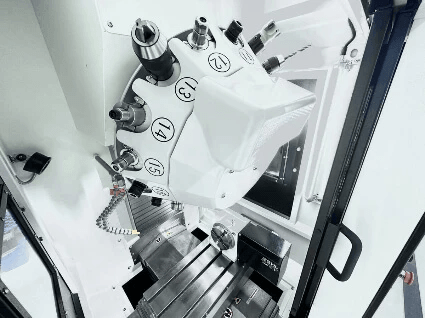

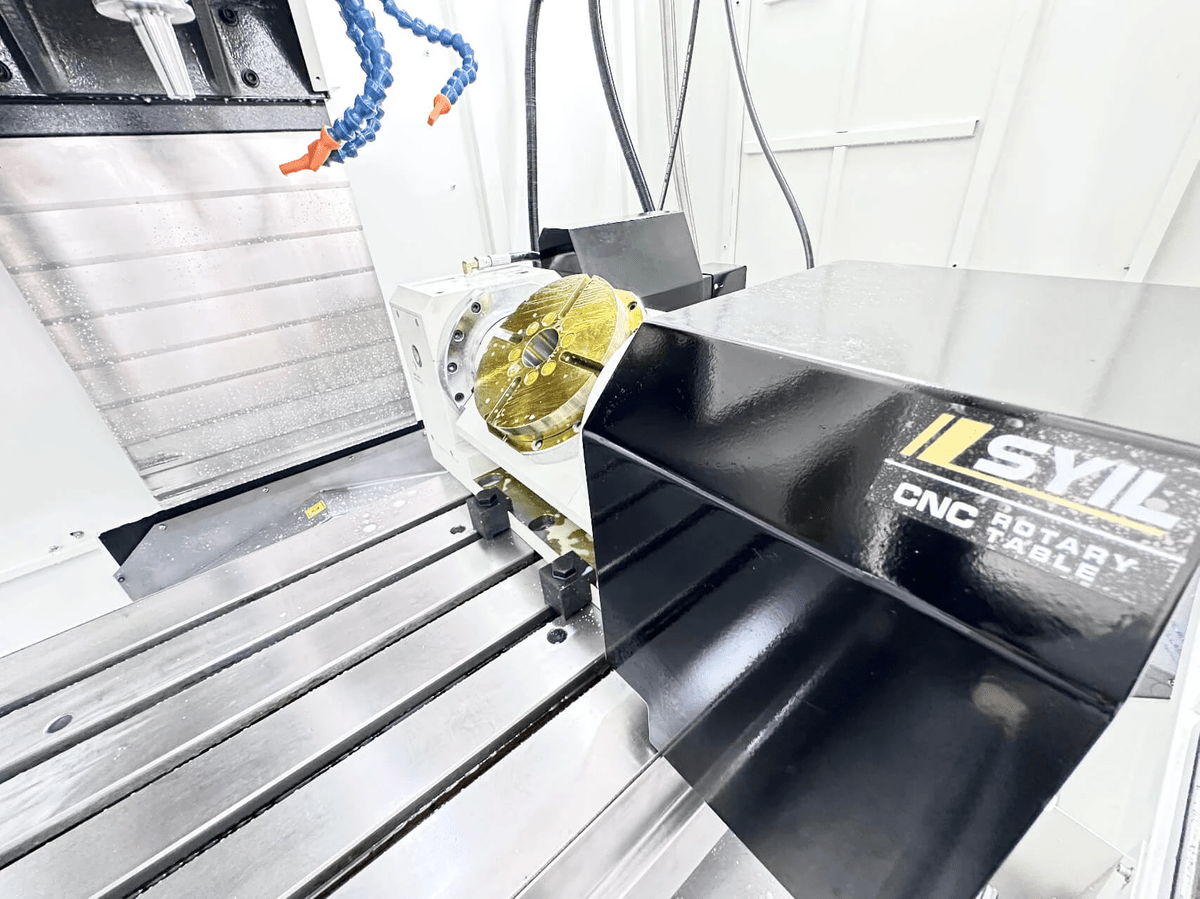

The SYIL X5 Mini CNC Machine

The SYIL X5 Mini CNC Machine is an excellent choice for hobbyists and small businesses alike, offering versatility in material handling. With its compact design, it allows you to explore various materials, from wood to plastics and even metals, making it a great introduction to what materials can CNC cut effectively. This machine is particularly user-friendly, ensuring that even beginners can dive into the world of CNC machining without feeling overwhelmed.

One of the standout features of the SYIL X5 is its precision and reliability when working with different materials. It enables you to experiment with various projects, answering the question: what products can be made on a CNC machine? From custom furniture pieces to intricate signage, this mini machine opens up a world of creative possibilities.

Factors Influencing CNC Machining Material Selection

When considering CNC Machining Material Selection, several factors come into play that will determine your project’s success. First and foremost is understanding material compatibility; not all materials are suited for every type of CNC machine, leading us back to the question: what materials cannot be CNC machined? For instance, extremely hard or brittle materials may pose challenges in cutting or engraving processes.

Another crucial factor is thickness; certain machines have limitations on how thick or dense a material can be while still achieving precise cuts. Knowing these restrictions will save you time and frustration during your project planning phase. Additionally, consider the intricacy of your design—some materials lend themselves better to detailed work than others.

Tips for Ensuring a Smooth CNC Process

To ensure a smooth process when using your chosen machine, preparation is key! Start by thoroughly researching what you plan to cut; knowing what materials can a cnc machine cut will help streamline your workflow significantly. Make sure you've selected appropriate tools and bits designed specifically for those materials—this will enhance both efficiency and quality.

Another tip is to conduct test runs with scrap pieces before diving into your main project; this helps you understand how different settings affect cutting performance and ensures that you're well-prepared to tackle more significant tasks like prototyping or customization with CNC technology. Finally, keep an eye on maintenance; regular checks on your equipment will prevent hiccups that could derail your creative endeavors.

Conclusion

As we wrap up our exploration of CNC machining, it's clear that the potential for creativity and precision is vast. Whether you're curious about what materials can a CNC machine cut or pondering what products can be made on a CNC machine, the possibilities are nearly limitless. From wood and plastics to metals and specialty materials, understanding CNC Machining Material Selection is crucial for achieving your desired results.

Recap of CNC Machining Material Potential

Throughout this guide, we've delved into the diverse range of materials that can be processed by CNC machines. From popular choices like various wood types to innovative options such as composite materials and even stone, the question of What materials can CNC cut? has many answers. However, it's equally important to consider what materials cannot be CNC machined; knowing these limitations helps refine your project choices.

Finding the Right Material for Your Project

When determining what you want to create with a CNC machine, selecting the right material is fundamental to your project's success. Consider factors like durability, aesthetic appeal, and functionality while also asking yourself: What can you cut with a CNC? Each material brings its own unique qualities to the table—whether it’s lightweight foam or sturdy metal—and understanding these attributes aids in making informed decisions during your CNC Machining Material Selection process.

Embracing Creativity with CNC Capabilities

CNC machines are not just tools; they are gateways to creativity that allow you to bring imaginative designs into reality. By experimenting with different materials and techniques—like engraving versus cutting—you will unlock new avenues for product innovation and customization. So don’t hesitate; dive into the world of CNC machining and let your creativity flourish by exploring all that you can achieve!