Introduction

In the ever-evolving landscape of medicine, titanium has emerged as a vital material, especially in the realm of medical implants. Its unique properties make it an ideal choice for various applications, leading to a surge in demand for CNC titanium machined parts. As healthcare professionals seek innovative solutions for patient care, understanding the intersection of titanium and CNC machining becomes crucial.

The Importance of Titanium in Medicine

Titanium's biocompatibility is one of its most significant advantages in medical applications. This means that when used in implants, it integrates seamlessly with the human body without causing adverse reactions. Additionally, its lightweight yet strong properties ensure that patients experience comfort while benefiting from durable and reliable medical devices.

Understanding CNC Machining for Implants

CNC machining has revolutionized the way medical implants are manufactured, allowing for precision and consistency that traditional methods simply cannot match. With a CNC machine for titanium, manufacturers can create intricate designs tailored to individual patient needs. As more healthcare providers turn to these advanced technologies, knowing how to CNC machine titanium effectively is becoming increasingly important.

Why Choose Titanium Milling?

When it comes to creating custom implants, choosing a titanium CNC milling machine offers numerous benefits over other materials and methods. Not only does titanium resist corrosion better than many alternatives, but its ability to withstand stress ensures long-lasting performance in demanding environments like the human body. Moreover, understanding what materials cannot be CNC machined helps highlight why titanium stands out as a preferred choice in this field.

What is CNC Titanium Machining?

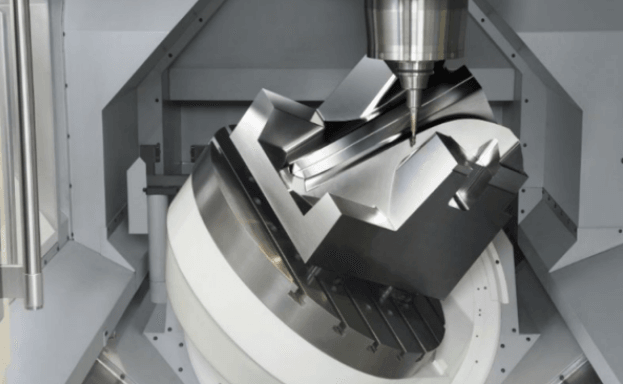

CNC Titanium Machining is a specialized process that utilizes Computer Numerical Control (CNC) technology to create precision parts from titanium. This method is crucial in industries where high-performance materials are required, particularly in medical applications. By leveraging advanced CNC machines, manufacturers can produce intricate titanium components with remarkable accuracy and efficiency.

Overview of CNC Technology

CNC technology revolutionizes the manufacturing landscape by automating the machining process through computer programming. This allows for increased precision and repeatability compared to traditional manual machining methods. With CNC machines for titanium, operators can input complex designs that the machine executes flawlessly, producing high-quality titanium CNC machined parts that meet stringent specifications.

The integration of CAD/CAM software enhances this process further by allowing designers to visualize and simulate their creations before production begins. This not only reduces errors but also minimizes waste, making it a cost-effective solution for manufacturers. Overall, CNC technology has become indispensable in creating intricate geometries from tough materials like titanium.

Key Benefits of CNC Titanium Machining

One major advantage of using a Titanium CNC milling machine is its ability to produce highly detailed parts with minimal human intervention. This automation leads to faster production cycles while maintaining exceptional quality standards—an essential factor in the medical industry where reliability is paramount. Moreover, titanium's unique properties combined with advanced machining techniques ensure that components are both lightweight and durable.

Another benefit lies in the versatility of CNC machines for titanium; they can handle various shapes and sizes without requiring extensive retooling or setup changes. This adaptability makes it easier to respond to specific client needs or design modifications quickly and efficiently. Additionally, the precise nature of this machining method significantly reduces material waste compared to traditional methods.

Lastly, when asking Is titanium easy to CNC?, it's important to note that while it may present challenges due to its hardness and toughness, modern tooling technologies have made it increasingly manageable for skilled machinists. The right tools and techniques can yield outstanding results even from this demanding material.

Applications in Medical Implant Manufacturing

CNC Titanium Machining finds extensive application in medical implant manufacturing due to the unique characteristics of titanium itself—biocompatibility being at the forefront. From orthopedic implants like hip replacements to dental fixtures such as crowns and bridges, precision-engineered titanium components are often preferred because they integrate seamlessly with human tissue without causing adverse reactions.

Furthermore, as healthcare continues evolving towards personalized medicine solutions, custom-fit implants are becoming more prevalent; here’s where CNC machined parts truly shine! The ability to create tailor-made solutions through advanced milling techniques ensures that each patient receives an implant designed specifically for their anatomy and needs.

In summary, whether you’re pondering What materials cannot be CNC machined? or exploring how best to implement these technologies into your operations, understanding the role of Titanium CNC Machining becomes increasingly vital within modern medicine's landscape—paving pathways toward innovative healthcare solutions.

Advantages of Titanium in Medical Devices

Titanium has become a cornerstone in the realm of medical devices, and for good reason. Its unique properties make it an ideal choice for CNC titanium machined parts, ensuring they meet the rigorous demands of healthcare applications. From implants to surgical instruments, titanium's advantages are both numerous and significant.

Biocompatibility of Titanium

One of the standout features of titanium is its remarkable biocompatibility. This means that when titanium comes into contact with human tissue, it does not provoke an adverse reaction, making it a preferred material for medical implants. In fact, many surgeons opt for titanium CNC machining because it leads to fewer complications post-surgery compared to other materials.

The ability of titanium to integrate with bone—often referred to as osseointegration—is vital for implants like dental fixtures or orthopedic devices. This property allows for stronger and more stable connections within the body, which is essential for patient recovery and long-term success. As healthcare continues to evolve, understanding how to CNC machine titanium effectively will be crucial in maximizing these benefits.

Lightweight yet Strong Properties

Despite being lightweight, titanium boasts an impressive strength-to-weight ratio that outperforms many other metals used in medical applications. This characteristic makes CNC machine parts from titanium easier to handle during procedures without compromising on durability or performance.

Surgeons appreciate that lighter implants can lead to less strain on patients' bodies during recovery while maintaining high structural integrity under stress. The combination of lightweight design with robust performance is why many manufacturers are turning towards Titanium CNC machining techniques when creating innovative solutions in healthcare technology.

Resistance to Corrosion

Another compelling advantage of using titanium in medical devices is its exceptional resistance to corrosion and wear over time. Unlike some metals that can degrade when exposed to bodily fluids or harsh sterilization processes, a Titanium CNC milling machine produces components that maintain their integrity long-term. This resistance not only extends the lifespan of implants but also reduces the risk of complications arising from material degradation.

Furthermore, this corrosion resistance means that patients can have peace of mind knowing their implants won't react adversely over time—an essential factor when considering what materials cannot be CNC machined effectively due to susceptibility issues like rust or wear-and-tear damage. As we explore new frontiers in healthcare technology, understanding how to CNC machine titanium becomes increasingly important in leveraging its unique properties against potential challenges.

How to CNC Machine Titanium?

CNC machining titanium can seem daunting, but with the right approach and understanding, it becomes a manageable process. This section will guide you through selecting the appropriate CNC machine for titanium, best practices for milling, and the tools and techniques that ensure precision in creating high-quality CNC titanium machined parts. Whether you're asking yourself What CNC machine can cut titanium? or pondering Is titanium easy to CNC?, we've got you covered.

Selecting the Right CNC Machine for Titanium

Choosing the right CNC machine for titanium is crucial for achieving optimal results in your projects. Not all machines are created equal; therefore, it’s essential to look for a Titanium CNC milling machine specifically designed to handle this tough material. A robust machine with high rigidity and a powerful spindle is necessary to efficiently cut through titanium without compromising on accuracy.

When considering what features matter most in a CNC machine for titanium, pay attention to factors like speed settings, torque capabilities, and tool compatibility. A well-suited machine will allow you to produce intricate designs while minimizing wear on both the tools and the workpiece itself. Ultimately, investing in a quality CNC machine can significantly enhance your ability to create precise cnc titanium machined parts.

Best Practices for Milling Titanium

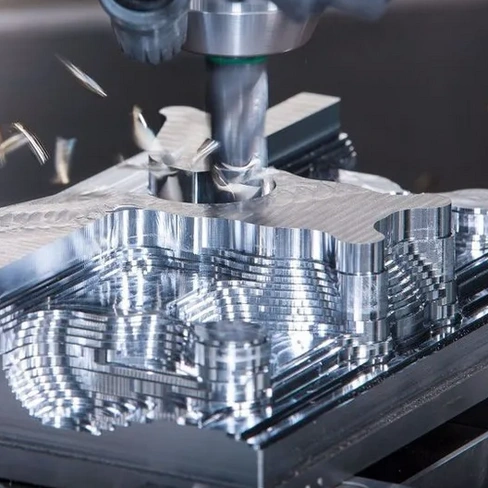

Milling titanium requires specific techniques that differ from working with softer materials; otherwise, you risk damaging both your tools and your workpiece. One of the best practices is to maintain optimal cutting speeds while using appropriate feeds—keeping them low helps prevent overheating and tool wear during machining processes. Additionally, it's advisable to use flood coolant or mist systems during milling operations since they help manage heat build-up effectively.

Another key practice is ensuring proper tool geometry when working with titanium; using sharp tools with appropriate coatings can significantly improve performance by reducing friction during cuts. Regularly checking tool condition also plays a vital role in maintaining quality output—after all, dull tools lead to subpar finishes! By adhering to these best practices, you'll find that machining titanium becomes less of a chore and more of an art form.

Tools and Techniques for Precision

Precision is paramount when it comes to creating high-quality cnc titanium machined parts; therefore, selecting the right tools is essential. End mills designed specifically for hard materials should be at the top of your list—they often feature unique geometries that promote efficient chip removal while maintaining cutting stability throughout operations. Carbide tooling is also recommended due to its durability against wear when working with tough metals like titanium.

In addition to choosing proper tooling, employing advanced techniques such as trochoidal milling can enhance efficiency significantly by allowing deeper cuts at higher speeds without sacrificing precision or leading edge integrity. Furthermore, utilizing simulation software before actual machining operations aids in anticipating potential issues—this proactive approach allows you to optimize cutting parameters effectively before hitting “start.” With these tools and techniques in hand, you're well-equipped to tackle any challenges associated with how to CNC machine titanium successfully!

Exploring the SYIL CNC Machine

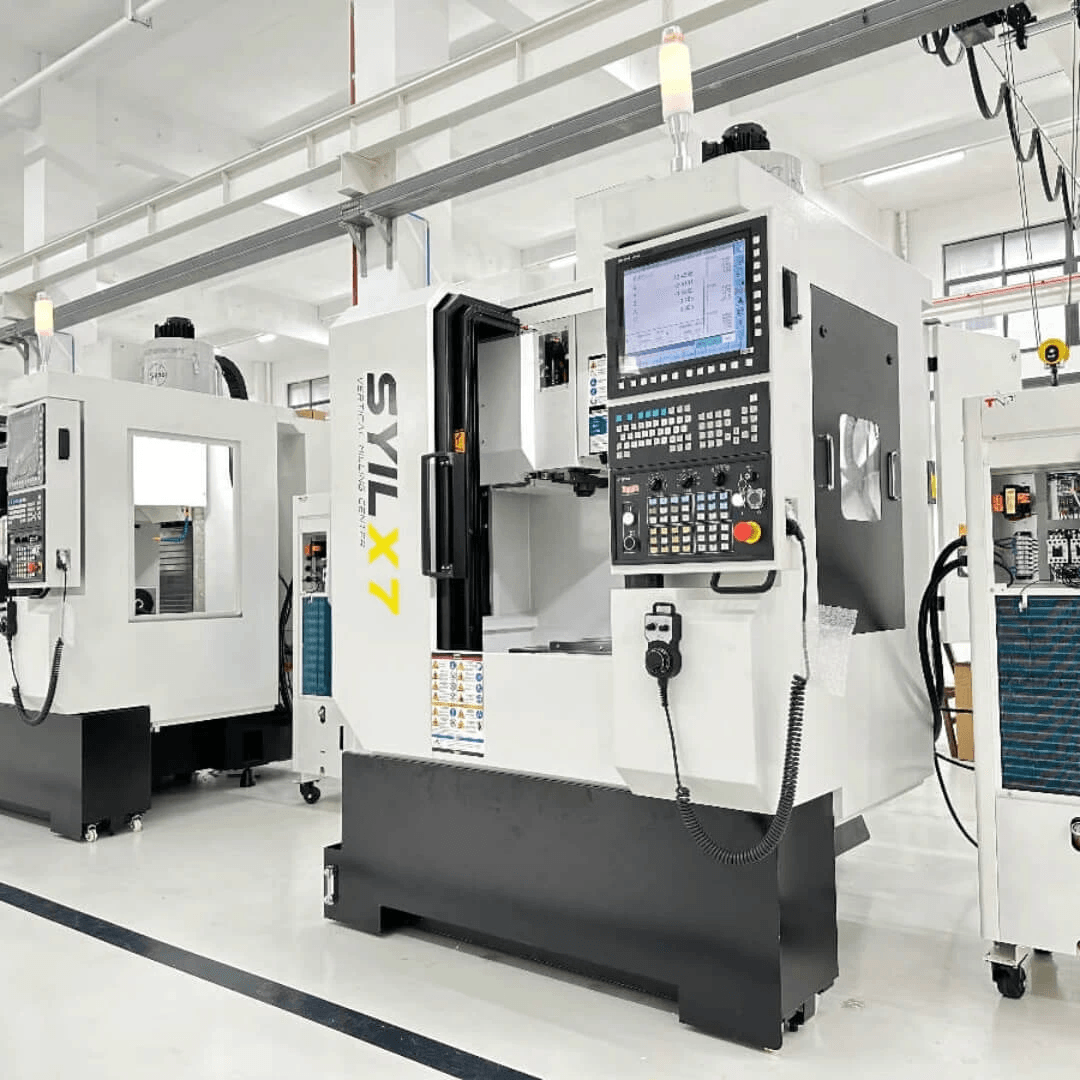

Features of the SYIL X5 Mini CNC Machine

The SYIL X5 Mini CNC Machine boasts a robust build and precision engineering that make it ideal for machining titanium parts. Equipped with advanced spindle technology, this Titanium CNC milling machine ensures optimal cutting speeds and enhanced tool life when working with tough materials like titanium. Its user-friendly interface allows even those new to how to CNC machine titanium? to navigate operations smoothly while achieving exceptional results.

Moreover, the SYIL X5 features a compact design without compromising on performance, making it suitable for small workshops or labs focused on producing cnc titanium machined parts. Its versatility allows users to switch between different materials easily, although one might ponder: is titanium easy to CNC? The answer lies in using the right tools and techniques—both of which are supported by this impressive machine.

Benefits for Small Scale Medical Projects

For small scale medical projects requiring precision and reliability, the SYIL X5 offers distinct advantages in Titanium CNC Machining. First off, its affordability makes it accessible for startups and smaller companies aiming to produce high-quality implants without breaking the bank. Additionally, its ability to create intricate designs means that even complex shapes can be achieved efficiently.

Another benefit is its minimal footprint; you can fit this compact machine into tight spaces while still producing top-notch cnc titanium machined parts at scale. This flexibility allows teams working on limited budgets or space constraints to explore advanced manufacturing options without sacrificing quality or performance.

Case Studies in Titanium Milling

To illustrate the effectiveness of the SYIL X5 in real-world applications, let’s delve into some case studies showcasing successful Titanium CNC Machining projects. One notable example involved a medical device manufacturer that utilized this milling machine to produce custom orthopedic implants tailored specifically for patients’ needs—an endeavor that required both precision and biocompatibility.

Another case highlighted how a dental lab improved its workflow by integrating the SYIL X5 into their process for crafting dental crowns from titanium alloys. By enabling them to achieve higher accuracy while reducing turnaround times significantly, they were able not only to meet but exceed patient expectations consistently.

Through these examples, we see how effective this Titanium CNC milling machine can be in addressing specific challenges faced within healthcare manufacturing—proving once again why so many professionals are turning towards innovative solutions like these when asking what materials cannot be CNC machined?

Limitations in CNC Machining Materials

What Materials Cannot be CNC Machined?

When considering what materials cannot be CNC machined, it's essential to identify those that are either too brittle or too soft. For instance, materials like glass and certain types of plastics can shatter or deform under machining conditions. Additionally, highly abrasive materials such as carbide can wear down tools quickly, making them less than ideal for traditional CNC processes.

Conversely, titanium is often favored because it offers a balance of strength and machinability that many other materials lack. It’s important to note that while titanium can be challenging to machine due to its toughness and tendency to work-harden, it is still a viable option compared to other more problematic substances. Thus, when asking What CNC machine can cut titanium?, you’ll find specialized machines designed specifically for this purpose.

Challenges with Difficult Materials

Difficult materials present several challenges during the machining process. For example, they may require specialized tools or altered cutting speeds and feeds to avoid tool wear or breakage—issues not commonly encountered with more straightforward metals like aluminum or steel. Furthermore, some materials might generate excessive heat during milling operations which could lead to thermal deformation or even damage the part being produced.

In contrast, titanium's unique properties mean that while it may not be easy to CNC machine at first glance—prompting questions like Is titanium easy to CNC?—the right setup and techniques make all the difference in achieving precision components. Manufacturers often need advanced cooling systems and tailored tool paths when working with titanium; however, the results are worth the extra effort as they lead to high-quality cnc titanium machined parts that meet strict medical standards.

The Role of Titanium as a Preferred Choice

Given its unique properties and performance characteristics, titanium stands out as a preferred choice in various applications within medical device manufacturing. Its biocompatibility ensures minimal rejection by the human body while offering lightweight yet strong attributes necessary for implants and surgical instruments alike. When considering options for a Titanium CNC milling machine capable of producing intricate designs without compromising quality or performance, few materials rival titanium's versatility.

Moreover, while there are certainly challenges associated with how to CNC machine titanium effectively—such as managing tool wear rates—the benefits far outweigh these hurdles in most cases. As manufacturers continue exploring advancements in Titanium CNC Machining technologies and techniques tailored specifically for this metal's demands, we can expect even greater innovations on the horizon.

Conclusion

In summary, titanium has carved out a crucial niche in the healthcare sector, particularly in the realm of medical implants. Its unique properties, such as biocompatibility and resistance to corrosion, make it an ideal choice for various applications. Moreover, the advancements in CNC titanium machining have only enhanced its usability in producing high-quality, precise implants that meet stringent medical standards.

Summary of Titanium's Role in Healthcare

Titanium's role in healthcare cannot be overstated; it is the backbone of many modern medical devices and implants. From orthopedic screws to dental implants, titanium CNC machined parts are integral for ensuring patient safety and longevity of devices. The combination of strength and lightweight characteristics allows for innovative designs that improve patient outcomes without compromising on performance.

The Future of CNC Machining for Implants

Looking ahead, the future of CNC machining for implants appears bright as technology continues to evolve rapidly. With advancements in CNC machines specifically designed for titanium—such as those capable of cutting intricate designs—manufacturers can create increasingly complex geometries that enhance implant functionality. As more healthcare providers recognize the benefits of titanium CNC machining, we can expect a surge in demand for customized solutions tailored to individual patient needs.

Innovations in Titanium Milling Technology

Innovations in titanium milling technology are set to revolutionize how we approach manufacturing medical devices. Newer CNC milling machines designed exclusively for titanium allow for greater precision and efficiency while minimizing waste material—a significant factor when considering what materials cannot be CNC machined effectively. As research continues into optimizing these processes, we may soon see even more effective ways to produce high-quality titanium components that push the boundaries of current medical practices.