Introduction

In the world of metal fabrication, brass and copper machining is undergoing a remarkable transformation. The advent of precision CNC machines has redefined how these materials are shaped, allowing for intricate designs and tighter tolerances than ever before. This innovation raises an important question: Can a CNC machine cut brass? The answer is a resounding yes, and it opens up a realm of possibilities for manufacturers seeking to enhance their production capabilities.

Revolutionizing Brass and Copper Machining

Brass machining has always been an art form, but with modern CNC technology, it has evolved into a science. Traditional methods often fell short in precision and efficiency, leading to wasted materials and time-consuming processes. Today’s CNC machines for brass parts are designed to tackle these challenges head-on, offering unmatched accuracy that keeps production lines humming smoothly.

The Rise of Precision CNC Machines

Precision CNC machines have surged in popularity due to their ability to deliver consistent results across multiple runs. These machines not only cut brass with incredible accuracy but also allow for complex geometries that would be nearly impossible with manual machining techniques. As more industries recognize the benefits of automation, the question arises: What is the best way to machine brass? Understanding this will help businesses leverage the full potential of their equipment.

Why Precision Matters in Metal Fabrication

In metal fabrication, precision is not just a luxury; it's a necessity. Poorly machined parts can lead to costly errors and project delays, making it crucial to choose the right tools and techniques from the get-go. When contemplating what materials cannot be CNC machined or exploring what is the best machinable brass for your projects, keep in mind that investing in high-quality equipment will pay off in both performance and reliability.

Understanding CNC Machines

What Makes a CNC Machine Ideal for Brass

A CNC machine designed specifically for brass parts must possess several key attributes that enhance its performance. First off, the ability to handle high-speed machining is crucial; brass is softer than many metals, allowing for faster cutting speeds without compromising surface finish quality. Moreover, a good CNC machine should also feature robust tooling options that can withstand the unique challenges posed by machining brass.

Another significant factor is versatility; an ideal CNC machine can accommodate various types of brass alloys, making it adaptable to different project requirements. This flexibility ensures that whether you're working with free-cutting brass or harder alloys, your CNC machine can deliver consistent results. Lastly, precision matters immensely; even minor deviations can lead to major discrepancies in fit and function when crafting components from this material.

Types of CNC Machines for Brass Parts

When considering what machine can cut brass effectively, several types of CNC machines come into play. Vertical machining centers (VMCs) are popular choices due to their ability to perform complex milling operations on various brass shapes and sizes. Additionally, lathes are commonly used in turning operations where cylindrical forms are required—a staple in many industries relying on machined brass components.

Another option includes multi-axis machines which allow for more intricate designs and tighter tolerances—ideal if your project demands sophisticated geometries or detailed engravings on your brass parts. Each type has its own strengths and weaknesses depending on the specific application you have in mind; understanding these nuances will help you select the right tool for your needs.

Key Features for Effective Brass Machining

To achieve optimal results when using a CNC machine for brass parts, certain features become indispensable during the machining process. First up is spindle speed: higher RPMs are often necessary when cutting softer materials like brass to maintain efficiency while achieving smooth finishes—so look out for machines with adjustable spindle settings!

Next on the list is coolant systems; effective cooling not only extends tool life but also prevents thermal distortion during machining processes—essential when working with materials like brass which can be sensitive to heat buildup. Finally, consider automation features such as tool changers or probing systems; these enhancements streamline production runs while ensuring consistent quality across all machined parts.

Can a CNC Machine Cut Brass?

The Process of Machining Brass

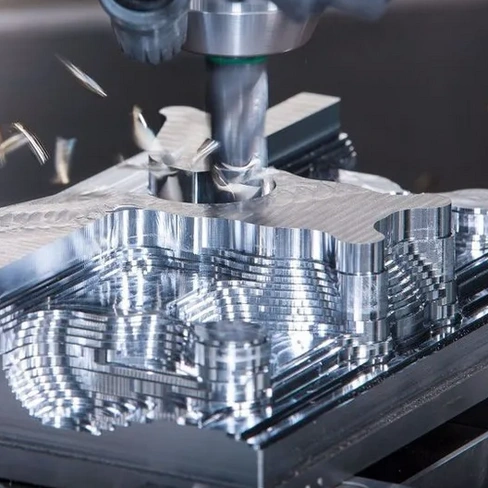

Machining brass involves several steps that highlight the capabilities of a CNC machine for brass parts. Initially, the raw material is secured in place, ensuring stability during the cutting process. The CNC machine then follows programmed instructions to carve out shapes and features from the brass stock, utilizing various cutting tools designed specifically for this metal. This automated process allows for consistent results across multiple pieces, significantly reducing human error and increasing productivity.

Benefits of CNC Machining for Brass Parts

CNC machining offers numerous advantages when it comes to working with brass materials. First off, precision is paramount; these machines can achieve tolerances that manual methods simply cannot match. Additionally, using a CNC machine for brass parts streamlines production by allowing complex designs to be executed quickly and accurately. Another benefit is material efficiency; CNC machining minimizes waste by optimizing tool paths and reducing excess scrap material.

Real-World Applications of CNC Brass Machining

The versatility of machining brass with a CNC machine has led to its widespread use across various industries. From automotive components like fittings and connectors to intricate decorative elements in jewelry making, the applications are nearly limitless! Furthermore, many electronics rely on machined brass parts for connectors and housings due to their excellent conductivity properties. In essence, wherever precision meets functionality in metalwork, you’re likely to find a CNC machine at play—especially when dealing with materials like brass.

What is the Best Way to Machine Brass?

Recommended Techniques for Brass Machining

To get the most out of your CNC machine for brass parts, it's crucial to adopt recommended techniques tailored for this material. Start by ensuring that your cutting speed and feed rate are optimized; brass typically requires higher speeds than many other metals due to its favorable machining properties. Additionally, using a climb milling technique can help improve surface finish and extend tool life while reducing the risk of chatter.

Another effective method is to utilize flood coolant during machining. This not only helps dissipate heat but also minimizes chip buildup, which can be detrimental in maintaining precision when working on intricate designs. When asking yourself, Can a CNC machine cut brass? remember that employing these techniques will significantly enhance your chances of success.

Tools and Settings for Optimal Results

Selecting the right tools and settings is vital when determining what is the best way to machine brass. High-speed steel (HSS) or carbide tools are often preferred due to their ability to withstand higher speeds without dulling quickly. For optimal results, consider using a tool with a positive rake angle; this design allows for smoother cutting action and less friction against the material.

In terms of settings, adjusting spindle speed based on the diameter of your cutting tool can yield impressive results—generally speaking, larger tools require lower speeds while smaller ones can handle faster rotations. Don't forget about depth of cut; taking shallower cuts may result in better finishes and longer tool life while still allowing you to achieve desired tolerances efficiently.

Common Challenges and How to Overcome Them

While machining brass offers many advantages, there are common challenges one might face along the way—especially when pondering what materials cannot be CNC machined? Issues like chip clogging or excessive tool wear can arise if not addressed properly during machining operations on brass parts. To overcome these hurdles, frequent inspections during production will help catch any problems early before they escalate into costly setbacks.

Another challenge could be managing workpiece movement during machining; securing your workpiece properly will prevent inaccuracies in cuts due to vibrations or shifts in position as you operate your CNC machine for brass parts. Lastly, keeping an eye on cooling methods will mitigate heat-related issues that could lead not only to poor finishes but also potential damage to both tooling and workpieces alike.

Exploring Machinable Brass Alloys

What is the Best Machinable Brass?

When it comes to finding the best machinable brass, C36000 is often at the top of the list. This alloy is known for its excellent machinability, making it a favorite for those using a CNC machine for brass parts. With a high copper content and low lead levels, C36000 offers a good balance of strength and ductility while providing superior surface finish capabilities.

In addition to C36000, other alloys like C37700 and C38500 also offer great machinability but may have slightly different characteristics that could suit specific applications better. For instance, if you're looking for enhanced corrosion resistance alongside ease of machining, consider using C37700 instead. Ultimately, understanding what is the best way to machine brass involves knowing which alloy will yield optimal results for your project requirements.

Comparing Different Brass Alloys for CNC Projects

Each brass alloy has unique properties that can affect its performance during machining processes with a CNC machine designed for cutting brass parts. Comparing these alloys based on factors such as machinability ratings, tensile strength, and corrosion resistance will help you make an informed decision. For example, while C36000 excels in machining speed and surface finish quality, other alloys might provide better durability or resistance to wear.

Understanding these differences allows you to tailor your choice based on whether you prioritize speed or durability in your CNC projects. Remember that not every material can be CNC machined effectively; materials with high hardness or brittleness typically fall into this category.

Selecting the Right Alloy for Your Application

Selecting the right alloy requires careful consideration of both mechanical properties and intended use cases of your finished products. Start by assessing what materials cannot be CNC machined effectively; this knowledge will help narrow down your options significantly. Once you've eliminated unsuitable choices from consideration based on their machining characteristics or application requirements—like thermal conductivity or resistance to chemicals—you can focus on finding an ideal match among available brass alloys.

Next up is analyzing specific project needs: Are you producing intricate designs requiring tight tolerances? Or perhaps robust components meant to withstand high stress? Answering these questions will guide you toward selecting an appropriate grade that balances workability with performance expectations—ensuring satisfaction at every stage from design through production!

Choosing the Right CNC Machine

What Machine Can Cut Brass?

The question Can a CNC machine cut brass? often arises among those new to metal fabrication. Yes, a variety of CNC machines are capable of cutting brass, including milling machines, lathes, and routers designed specifically for metalwork. When selecting a cnc machine for brass parts, consider factors like spindle speed, tool compatibility, and rigidity to ensure optimal performance.

Brass is a relatively soft metal compared to others like steel or titanium, so it requires precise tools that can handle its unique properties without causing damage or wear. Machines equipped with high-speed spindles and appropriate tooling will yield better results when working with this versatile material. Additionally, choosing a machine with adjustable settings allows you to fine-tune your process based on the specific type of brass you are machining.

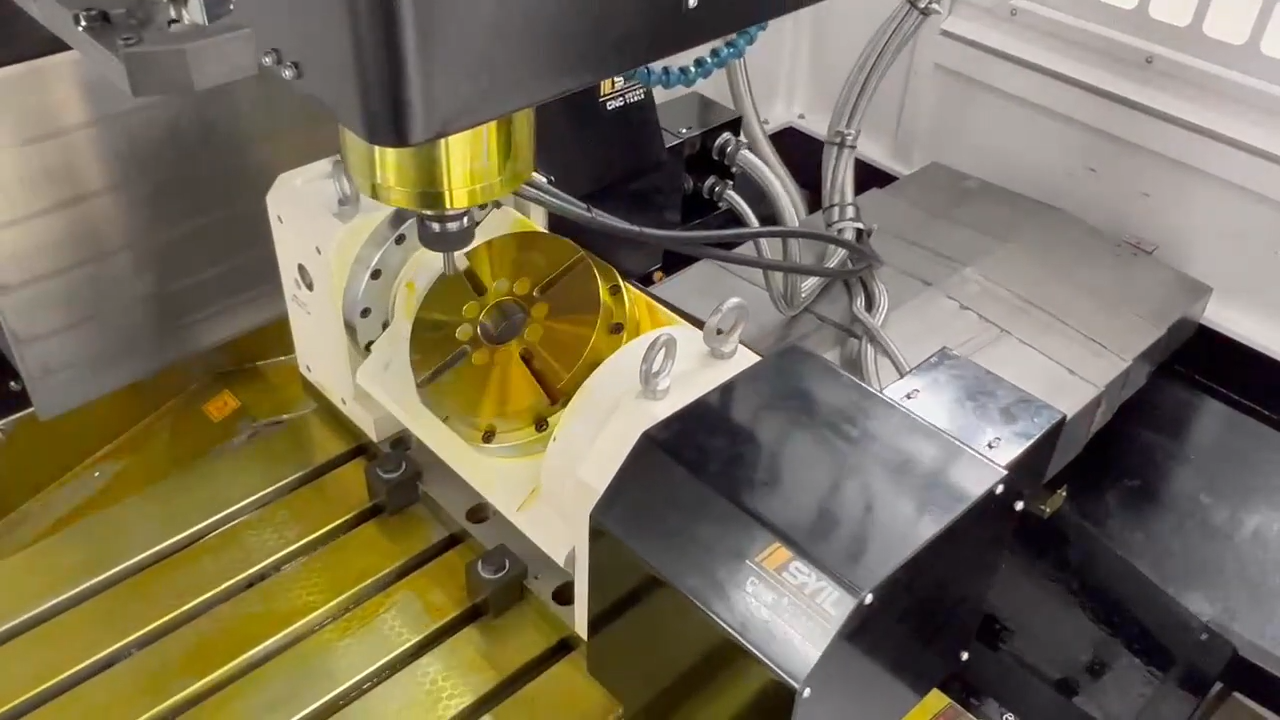

Spotlight on SYIL CNC Machines

When exploring options for a cnc machine for brass parts, SYIL CNC machines stand out as an excellent choice due to their precision engineering and user-friendly features. Known for their robust design and versatility, SYIL machines offer various models that cater specifically to machining non-ferrous metals like brass effectively. Their advanced technology ensures that users can achieve intricate designs while maintaining tight tolerances.

SYIL's commitment to quality means you'll find machines equipped with powerful spindles capable of high RPMs—perfect for cutting through even the toughest machinable brasses available today. Moreover, they come with intuitive software interfaces that simplify programming tasks while allowing for complex operations without requiring extensive training. If you're in search of what is the best machinable brass in conjunction with reliable machinery options, SYIL should definitely be on your radar.

Factors to Consider When Buying a CNC Machine

Choosing the right CNC machine involves more than just knowing what materials can be machined; it also requires careful consideration of several key factors tailored to your specific needs. First off, assess your budget—high-quality cnc machines can range significantly in price based on features and capabilities related directly to machining brass parts efficiently.

Next up is evaluating the size and workspace requirements; ensure you have enough room not only for the machine itself but also for any necessary accessories or tools needed during operation. Lastly—and perhaps most importantly—consider after-sales support from manufacturers like SYIL; reliable customer service can make all the difference when troubleshooting issues related to what materials cannot be CNC machined effectively or optimizing processes.

Conclusion

In wrapping up our exploration of CNC machining for brass, it’s clear that the benefits are manifold. From precision and efficiency to versatility in design, a CNC machine for brass parts is an invaluable asset for any metal fabrication shop. The ability to consistently produce high-quality brass components makes CNC technology a game-changer in the industry.

Benefits of CNC for Brass Fabrication

First and foremost, the accuracy of these machines ensures that every cut is precise, thus minimizing waste and maximizing productivity. Additionally, the automation involved allows for complex designs that would be nearly impossible to achieve manually, making it easier than ever to create intricate components from various brass alloys.

Moreover, CNC machines can handle repetitive tasks with ease, which is essential when producing large quantities of parts. This capability not only speeds up production but also reduces labor costs significantly—who wouldn’t want to spend less on manpower while still achieving top-notch results? Finally, by utilizing advanced tooling and settings tailored specifically for brass, manufacturers can achieve superior finishes that enhance both aesthetics and functionality.

Key Takeaways on Precision Machining

When considering what is the best way to machine brass, precision stands out as a critical factor in achieving quality results. Understanding how different types of CNC machines operate can help determine which machine can cut brass most effectively while accommodating specific project requirements. Furthermore, knowing what materials cannot be CNC machined is equally important; avoiding incompatible materials ensures smooth operations and prevents costly mistakes.

Another key takeaway revolves around the selection of machinable brass alloys—what is the best machinable brass? The answer varies based on application needs; however, some alloys are renowned for their workability and resistance to wear. Lastly, effective troubleshooting skills can help overcome common challenges faced during machining processes so that projects stay on schedule without sacrificing quality.

The Future of CNC Machines in Metalwork

The future looks bright for CNC machines in metalwork—especially regarding their role in cutting brass parts! As technology continues to evolve with advancements like artificial intelligence and machine learning integration into manufacturing processes, we can expect even greater precision and efficiency from these machines. Innovations such as automated tool changing systems will further streamline operations while enhancing capabilities across various industries.

Additionally, as more businesses recognize the advantages offered by a cnc machine for brass parts over traditional methods, we’re likely to see increased adoption rates across sectors ranging from automotive to aerospace manufacturing. This shift will not only boost productivity but also foster creativity within design teams as they explore new possibilities enabled by state-of-the-art machinery.

In conclusion, embracing CNC technology opens doors to unparalleled opportunities in metal fabrication—especially when working with versatile materials like brass!