Introduction

In the world of metalworking, efficiency and versatility are paramount. Enter the mill and lathe combo, a powerhouse of functionality that combines two essential tools into one compact unit. This combination mill and lathe not only saves space but also enhances your machining capabilities, making it an indispensable asset for both hobbyists and professionals alike.

Discover the Advantages of Mill and Lathe Combos

The advantages of a combination lathe milling machine are numerous and compelling. With this innovative setup, you can seamlessly switch between turning operations on the lathe machine and milling tasks without needing to change equipment. This versatility allows for more complex projects to be completed in a single setup, significantly reducing downtime.

Why You Need a Combination Machine

If you're serious about your metalworking projects, investing in a lathe with mill functionality is a no-brainer. A combination mill lathe not only conserves valuable workshop space but also streamlines your workflow by enabling you to perform multiple machining processes without interruption. Whether you're crafting intricate parts or tackling larger fabrication tasks, having a mill lathe combo machine at your disposal can elevate your craftsmanship to new heights.

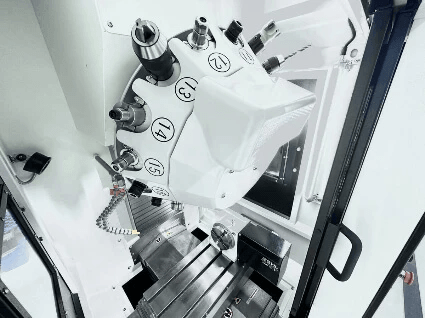

Key Features of Top Lathe Mill Combos

When searching for the best mill and lathe combo on the market, there are several key features to consider that set top models apart from the rest. Look for precision engineering that ensures accuracy in every cut, along with user-friendly controls that make operation smooth even for beginners. Additionally, robust build quality is crucial; after all, you want your combination mill and lathe to withstand years of rigorous use while delivering exceptional performance.

Versatility at Its Best

When it comes to metalworking, versatility is key, and that’s where the mill and lathe combo shines. A combination lathe milling machine combines the best features of both machines, allowing users to perform a variety of tasks without needing separate setups. This multifunctional design makes it easier to switch between operations, saving time and enhancing productivity.

Functionality of a Combination Lathe Milling Machine

The functionality of a combination mill lathe is impressive; it seamlessly integrates turning and milling processes into a single unit. With the ability to switch between operations quickly, this machine can handle everything from detailed shaping to complex drilling tasks with ease. The design allows for precision adjustments, ensuring that every cut is accurate whether you're using the lathe machine or the milling function.

Applications in Various Metalworking Projects

The applications for a combination lathe milling machine are virtually limitless, making it an indispensable tool for hobbyists and professionals alike. From crafting intricate parts for model trains to fabricating components for machinery, this versatile equipment can tackle various projects with finesse. Whether you’re working on automotive repairs or creating custom fittings, having a lathe with mill capabilities opens up new possibilities in your workshop.

Benefits of Having a Lathe with Mill

Investing in a mill lathe combo machine provides numerous benefits that enhance your machining experience. First off, it saves space by combining two powerful machines into one compact unit—perfect for smaller workshops or home garages. Additionally, the convenience of having both functions readily available means you can complete projects faster without compromising on quality—making your work more efficient and enjoyable!

Precision Engineering

In the world of machining, precision is paramount. Whether you're crafting intricate components or simple parts, the accuracy of your work can make or break a project. A mill and lathe combo offers unparalleled precision, ensuring that every cut and detail meets stringent specifications.

Importance of Accuracy in Machining

Accuracy in machining directly influences the quality and functionality of finished products. Even minor deviations can lead to significant issues down the line, such as misalignment or poor fitting parts. For professionals and hobbyists alike, investing in a combination mill and lathe is essential for achieving high standards in their work.

How a Mill Lathe Combo Machine Enhances Precision

A combination lathe milling machine excels at delivering precise results due to its integrated design and advanced features. By combining both milling and turning capabilities into one machine, users can minimize setup times while maintaining tight tolerances. The synergy between the lathe with mill functions allows for intricate designs that would be challenging to achieve with standalone machines.

Real-World Examples of Precise Fabrication

Consider a scenario where an engineer is tasked with creating custom gears for an automotive application; using a mill lathe combo machine allows them to produce highly accurate components efficiently. Another example might involve a jeweler crafting delicate pieces; the ability to switch seamlessly between milling and turning enhances their creative possibilities while ensuring precision throughout the process. These real-world applications highlight how versatile and accurate a combination mill lathe can be in various industries.

Space-Saving Design

In today’s fast-paced world, space is often at a premium, especially in workshops. The combination mill lathe is designed with this in mind, offering a compact solution that combines the functions of both machines into one efficient unit. This clever design not only conserves valuable floor space but also simplifies your workflow, allowing you to switch between milling and turning without the hassle of moving equipment around.

Compact Nature of Combination Mill Lathe

The compact nature of a combination mill and lathe means you can enjoy the best of both worlds without needing an expansive workshop. This ingenious design integrates the lathe machine and milling capabilities into a single framework, which significantly reduces the footprint compared to traditional standalone machines. With a mill lathe combo machine, you can maximize productivity while minimizing clutter—perfect for those who crave efficiency in tight spaces.

Ideal for Small Workshops and Hobbyists

For small workshops or hobbyists just starting out, investing in a combination lathe milling machine makes perfect sense. These machines provide versatility without overwhelming your workspace with multiple large pieces of equipment. Whether you're crafting intricate parts or tackling DIY projects at home, having a lathe with mill allows you to achieve professional results without sacrificing space or budget.

Comparing Space Requirements of Standalone Machines

When comparing space requirements between standalone machines and a mill and lathe combo, the differences are striking. Standalone lathes and mills often require dedicated areas that can dominate your workshop layout; meanwhile, a combination mill lathe fits snugly into smaller corners or workbenches with ease. By choosing a combination machine over separate units, you'll free up room for additional tools or simply enjoy more breathing space while working on your projects.

Durability and Build Quality

When investing in a mill and lathe combo, durability is paramount. A sturdy frame not only ensures longevity but also enhances the performance of the machine during various machining tasks. In the world of metalworking, where precision is key, a robust combination mill lathe can handle the rigors of daily use without compromising on quality.

Why a Sturdy Frame Matters in a Lathe Machine

The frame of a lathe machine serves as its backbone, providing essential support for both milling and turning operations. A solid structure minimizes vibrations that can lead to inaccuracies in machining, ensuring that your projects maintain their intended specifications. When you opt for a combination lathe milling machine with a durable frame, you're investing in consistent results and extended machine life.

Materials Used in Leading Models

Leading models of combination mill lathes are often constructed from high-quality materials designed to withstand heavy use while providing optimal performance. Cast iron is commonly used due to its excellent vibration dampening properties and rigidity, making it ideal for precision machining tasks. Additionally, some manufacturers incorporate advanced alloys or reinforced steel components to further enhance the durability of their mill lathe combo machines.

Overview of SYIL CNC Machine Durability

The SYIL CNC machines are renowned for their exceptional build quality and durability within the realm of combination machines. Designed with heavy-duty frames and high-grade materials, these machines can endure demanding applications while maintaining accuracy over time. Users often praise the SYIL CNC for its reliability in various metalworking projects, proving that this mill and lathe combo stands up well against competition in terms of durability.

User-Friendly Features

When it comes to the world of machining, user-friendly features can make all the difference in ensuring a smooth and efficient workflow. Modern mill and lathe combos are designed with intuitive controls that cater to both seasoned machinists and newcomers alike. The combination lathe milling machine is not just about functionality; it’s also about creating an enjoyable user experience.

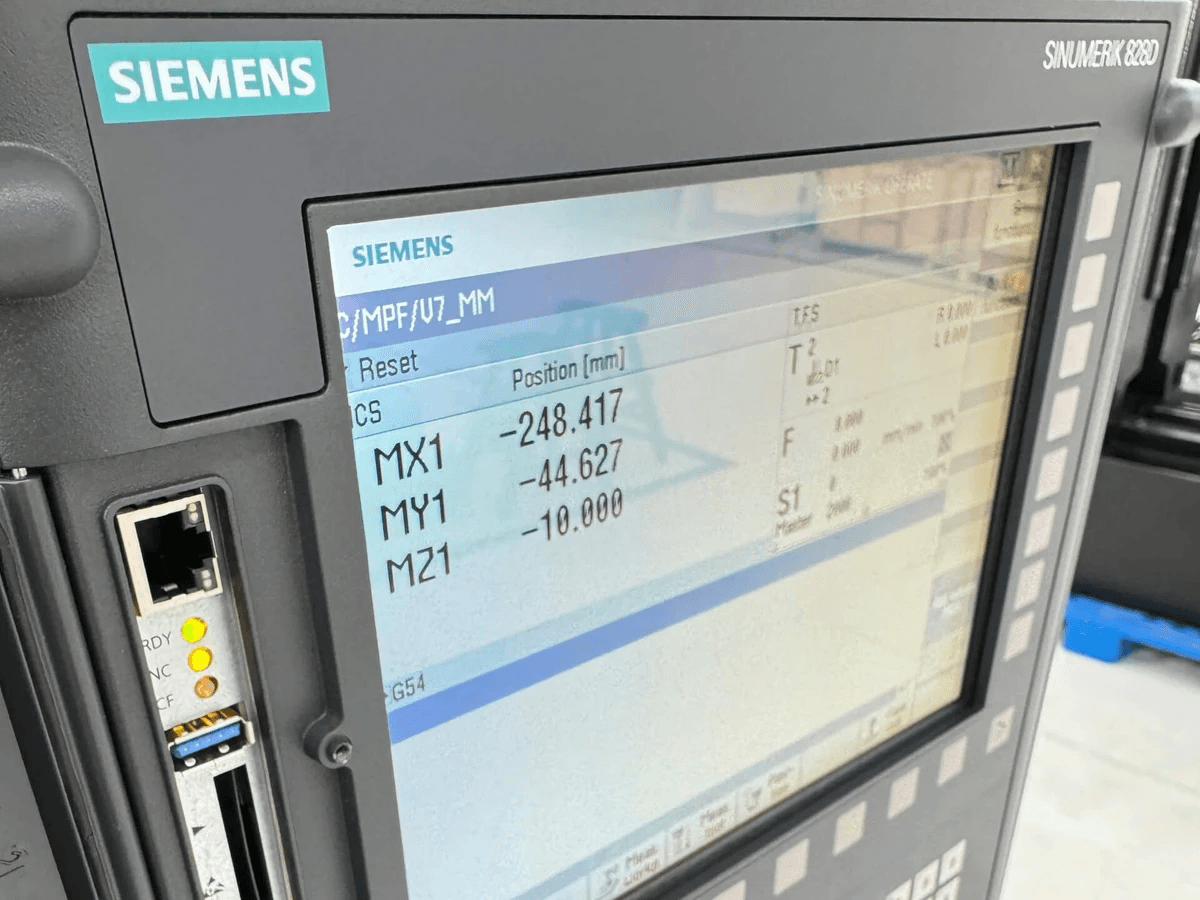

Control Systems in Modern Mill and Lathe Combos

The control systems in today’s mill lathe combo machines have evolved significantly, integrating advanced technology for precision and ease of use. Many models now feature digital readouts (DRO) that provide real-time feedback on measurements, making it easier to achieve accurate cuts and settings. Whether you’re operating a lathe machine or transitioning between milling tasks, these sophisticated controls streamline the process, allowing for quick adjustments without sacrificing quality.

Moreover, some combination mill lathes offer programmable features that enable users to save specific settings for repeated tasks, enhancing productivity in busy workshops. These control systems often include user-friendly interfaces that simplify navigation through various functions—perfect for those who might be intimidated by traditional machinery setups. The result? A seamless transition from novice to expert as you explore the capabilities of your combination mill and lathe.

Ergonomic Designs for Comfort and Efficiency

Ergonomics play a crucial role in the design of modern combination lathe milling machines, ensuring that users can work comfortably without straining their bodies over extended periods. Features such as adjustable heights, strategically placed controls, and cushioned grips help reduce fatigue during long machining sessions—an essential consideration for hobbyists or professionals alike who spend hours at their workstations. This thoughtful design philosophy allows operators to focus on their craft rather than discomfort.

Additionally, many mill and lathe combos incorporate noise-reducing materials which contribute to a quieter working environment—a significant benefit when working in smaller spaces or shared workshops where sound levels can become disruptive. With an ergonomic approach combined with noise reduction features, these machines enhance both comfort and efficiency while maintaining high-quality output in various metalworking projects.

Training Resources for New Users

For those new to machining or unfamiliar with operating a combination mill lathe, ample training resources are available to help bridge the knowledge gap effectively. Manufacturers often provide comprehensive manuals detailing operation guidelines as well as maintenance tips tailored specifically for each model of their mill lathe combo machines. Furthermore, many brands now offer video tutorials online that visually guide users through setup processes and common operations—perfect for visual learners who benefit from seeing techniques demonstrated firsthand.

Community forums dedicated to metalworking enthusiasts also serve as valuable platforms where new users can ask questions or seek advice from experienced machinists regarding best practices with their combination mill lathes. Accessing these resources not only builds confidence but also fosters a sense of belonging within the metalworking community—making it easier than ever to dive into this rewarding craft.

Conclusion

In the ever-evolving world of metalworking, the combination mill and lathe machines stand out as a game-changer. These versatile tools not only maximize your machining capabilities but also streamline your workflow by combining essential functions into one powerful unit. By investing in a mill and lathe combo, you can achieve higher precision, save space, and enhance productivity in your workshop.

Maximizing Your Machining Capabilities

With a combination lathe milling machine, you can tackle a wider range of projects than you could with standalone machines. The seamless integration of lathe and mill functions allows for intricate designs that require both turning and milling operations without needing to switch equipment constantly. This capability not only boosts efficiency but also enables you to produce complex parts with enhanced accuracy using just one machine.

Making an Informed Choice for Your Workshop

When selecting a lathe machine or a combination mill lathe, consider factors such as durability, user-friendliness, and the specific applications you'll be tackling. Research various models that meet your needs while also fitting within your budget; this is crucial for making an informed choice that will serve you well in the long run. Remember that investing in a quality mill lathe combo machine today means equipping yourself for future projects with greater confidence and capability.

The Future of Metalworking with Combination Machines

The future of metalworking lies in the continued advancement of combination machines like the lathe with mill setups we see today. As technology progresses, we can expect even more innovative features that enhance precision engineering while maintaining user-friendly designs. Embracing these advancements will position you at the forefront of machining excellence—ready to take on any challenge that comes your way.