Introduction

In the world of CNC (Computer Numerical Control) machining, understanding the fundamentals is crucial for both novices and seasoned professionals. One of the core components of CNC programming involves G code and M code, which serve as the language that tells machines how to perform tasks with precision. By grasping what G-code and M-code are, their significance, and how they function together, operators can enhance their machining processes effectively.

The Basics of CNC Programming

CNC programming is essentially the process of creating a set of instructions for a machine to follow in order to produce a specific part or product. This programming uses various codes, primarily G code and M code, to dictate movements and functions within the machine. Understanding these codes is essential for anyone looking to optimize their CNC operations and ensure quality output.

Importance of G and M Codes

G code and M code are vital because they provide a standardized way for machines to interpret commands across different platforms and manufacturers. Without these codes, communication between programmers and machines would be chaotic at best. Their importance lies not only in facilitating accurate machining but also in enhancing efficiency by reducing errors during production.

How G and M Codes Work

G codes primarily control the movement of CNC machines—think coordinates, speeds, and paths—while M codes manage auxiliary functions like coolant control or tool changes. Together, they create a comprehensive instruction set that guides machinery through intricate tasks with remarkable accuracy. By learning how these codes work together, operators can unlock new levels of productivity in their machining endeavors.

What is G-code and M-code?

When diving into the world of CNC machining, understanding what G-code and M-code are is fundamental. These codes serve as the languages that communicate commands to CNC machines, dictating their movements and actions with precision. Essentially, G-codes are used for geometric functions, while M-codes handle machine-specific operations.

Definition and Purpose

G-code and M-code form the backbone of CNC programming, allowing operators to instruct machines on how to move and perform tasks. G-codes primarily focus on positioning, speed, and tool paths—essentially telling the machine where to go and how fast to get there. On the other hand, M-codes manage auxiliary functions like starting or stopping a spindle or turning coolant on or off; they help ensure that everything runs smoothly during operation.

Commonly Used G Codes

In the realm of CNC programming, several G-codes are frequently utilized due to their importance in controlling machine movements effectively. For instance, G00 is a rapid positioning command that allows for quick movement between points without cutting material—perfect for getting from one location to another swiftly! Similarly, G01 is employed for linear interpolation at a specified feed rate when cutting materials; it’s all about making those clean cuts precisely where you want them.

Other notable mentions include G02 and G03 for circular interpolation in clockwise and counterclockwise directions respectively; these codes help create arcs effortlessly during machining processes. Understanding these commonly used G codes is essential when learning about what is G-code and M code because they set the stage for effective programming.

Commonly Used M Codes

While we’ve touched on some important aspects of what is M code for?, let’s delve deeper into its commonly used commands that keep CNC operations running like clockwork! An example would be M03, which starts the spindle in a clockwise direction—a crucial step before any cutting begins! Conversely, M05 stops the spindle motion when needed—ensuring safety during tool changes or breaks.

Another significant command is M08 which activates coolant flow; this helps maintain temperatures during machining processes while also prolonging tool life by reducing wear from heat friction. By familiarizing oneself with these commonly used M codes alongside their corresponding functions in practical applications, operators can enhance their efficiency on CNC machines significantly.

What is G and M code G28?

When diving into CNC programming, understanding the nuances of G-code and M-code is essential. Among these codes, G28 stands out as a critical command that helps streamline CNC machining processes. This section will explore what G and M code G28 entails, its applications in the industry, and its significance in positioning.

Understanding the G28 Command

G28 is a specific command within the realm of G-code that directs CNC machines to return to a predefined reference point or home position. This command essentially tells the machine to move to its home location, which is crucial for ensuring accurate machining operations. By utilizing this command effectively, operators can ensure that their machines are calibrated correctly before starting any new tasks.

The beauty of using the G28 command lies in its simplicity yet effectiveness in maintaining precision during machining processes. It serves as a reliable method for resetting the machine's position without manual intervention, thereby enhancing efficiency and reducing potential errors. In essence, understanding what is G-code and M code involves recognizing how commands like G28 play a vital role in automating machine operations.

Applications of G28 in CNC Machining

The applications of the G28 command are numerous and vital for efficient CNC machining workflows. For instance, it can be used at the beginning or end of machining cycles to ensure that tools return to their safe positions after completing tasks or when changing tools. This not only protects tools from damage but also ensures safety for operators working around active machinery.

Moreover, industries such as aerospace and automotive heavily rely on precise positioning; thus, incorporating commands like G28 becomes indispensable for maintaining quality standards. These sectors benefit from reduced setup times between jobs since returning to home positions can be automated rather than performed manually each time a new task begins. Thus, understanding what is M code for expands into recognizing how these codes interlink with operational efficiency across various applications.

Importance of G28 in Positioning

Positioning accuracy is paramount in CNC machining; this is where the importance of the G28 command really shines through. By returning machines to their home position accurately every time it's called upon, manufacturers can avoid costly mistakes due to misalignment or incorrect tool placement. This reliability fosters an environment where high-quality production becomes not just an aim but an achievable standard.

Additionally, utilizing this command enhances overall workflow by minimizing downtime caused by manual repositioning efforts—an often tedious task that can lead to human error if not executed correctly every time. With consistent use of commands like what is g and m code—specifically focusing on commands such as G28—manufacturers can maintain tight tolerances while ensuring safety protocols are followed rigorously throughout production processes.

In conclusion, integrating knowledge about what is g code m code into practical applications reveals just how essential commands like G28 are within CNC environments today.

What is M code for?

M codes play a crucial role in the world of CNC programming, serving as command signals that instruct the machine to perform specific functions. While G codes primarily dictate movement and paths, M codes handle ancillary tasks such as tool changes, coolant control, and spindle operations. Understanding what M code is for can significantly enhance machining efficiency and precision.

Overview of M Code Functions

M codes are essentially the behind-the-scenes workers of CNC machines, managing various operational tasks that complement the movement commands given by G codes. They tell the machine when to start or stop certain processes—think of them as the stage director in a play where G codes are the actors performing their lines. For instance, an M code might signal a machine to engage its coolant system or pause for a tool change; without these commands, your CNC operation would be like a theater production without direction—chaotic and likely unsuccessful.

Examples of M Code in Action

To illustrate what M code is for, consider some common examples used in CNC programming:

1) **M03** activates the spindle in a clockwise direction.

2) **M05** stops the spindle.

3) **M08** turns on coolant while **M09** turns it off.

These examples show how M codes work in tandem with G codes to create efficient machining processes. When you issue a G-code command to move along a specific path, you might also use an M code to ensure that cooling fluid is applied during cutting operations—this combination helps maintain tool life and part quality.

Benefits of M Codes in CNC Processes

The benefits of using M codes extend far beyond basic functionality; they enable smoother operations and improved safety protocols within CNC machining environments. By automating essential tasks like coolant control or tool changes through designated M codes, operators can focus more on monitoring processes rather than micromanaging each step manually. Additionally, using standardized M codes across different machines enhances interoperability and reduces training time for new operators—everyone speaks the same language when it comes to what each code does.

In summary, understanding what is G-code and M-code can significantly improve your programming skills while ensuring that your CNC machine operates efficiently and effectively. The seamless integration between G and M codes not only facilitates complex machining tasks but also elevates overall productivity levels.

What is the difference between G-code and CNC?

When diving into the world of CNC machining, understanding the difference between G-code and CNC is crucial for effective programming and operation. G-code refers specifically to the language used to instruct CNC machines on how to move, while CNC (Computer Numerical Control) encompasses the entire process of controlling machine tools using computer systems. Essentially, G-code is a subset of the broader CNC framework, making it an integral part of modern machining techniques.

G-code vs. CNC Explained

To clarify further, think of G-code as a detailed recipe that tells the chef (the CNC machine) exactly how to prepare a dish (perform tasks). Each line of G-code communicates specific instructions such as movement paths, speeds, and tool changes necessary for machining operations. Meanwhile, CNC represents the kitchen itself—the entire setup that allows for automated precision in manufacturing processes.

Understanding What is G-code and M code? becomes essential in this context because both codes work together to ensure smooth operations within a CNC environment. While G-codes dictate motion and positioning, M-codes handle miscellaneous functions like starting or stopping spindle rotation or coolant flow. This collaboration ensures that every aspect of machining runs seamlessly from start to finish.

How G-code Directly Affects CNC Machines

G-code directly influences how efficiently a CNC machine operates by determining its movements and actions with precision. For instance, when you input specific commands like “G01” for linear interpolation or “G28” for returning to home position (which we’ll explore later), you're essentially directing your machine on exactly how it should behave during production runs. The accuracy embedded in these codes translates into high-quality end products with minimal waste.

Moreover, understanding What is M code for? can help operators appreciate how these commands complement their counterparts—G-codes—in optimizing workflows within a manufacturing setting. M-codes manage ancillary functions that are just as vital; they might not control movement but ensure everything else runs smoothly around those movements—including tool changes and coolant management—ultimately enhancing productivity.

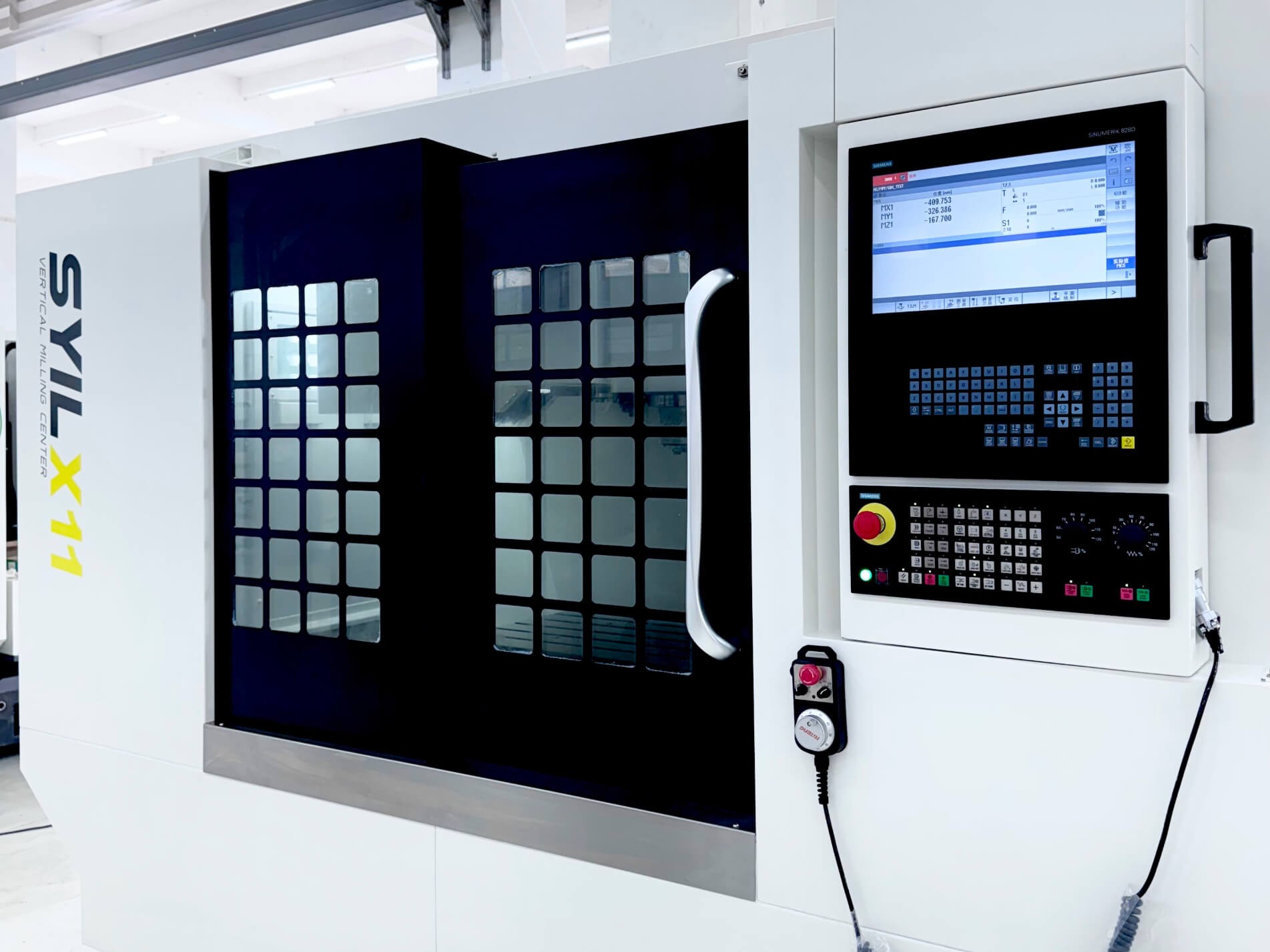

Real-World Applications of G and M Codes in SYIL CNC Machines

In real-world applications involving SYIL CNC machines, both G-codes and M-codes play pivotal roles in achieving optimal performance across various tasks—from milling complex parts to intricate 3D printing projects. For example, when using SYIL’s advanced models equipped with multiple axes capabilities, operators leverage common G-codes like “G02” for circular interpolation alongside M-codes that activate tool changers or coolant systems at precise intervals during machining cycles.

By integrating both types of codes effectively within their programming routines, machinists can maximize efficiency while minimizing errors—a critical factor when answering What is the difference between G-code and CNC? In practice, this means smoother transitions between different phases of production without unnecessary downtime or complications arising from miscommunication between code instructions.

In conclusion, recognizing how these elements interact not only enhances operational understanding but also empowers users to harness their full potential within today's competitive manufacturing landscape.

Best Practices for Using G and M Codes

When it comes to CNC programming, mastering G code and M code can significantly enhance your machining efficiency. Understanding the nuances of these codes is crucial, especially when discussing what is G-code and M code? Effective programming not only ensures precision but also minimizes errors during operation. Let's delve into some best practices that will elevate your CNC game.

Tips for Effective Programming

To start, always comment your code generously. This makes it easier for you or anyone else who may work with the program later to understand what each section does—especially useful when dealing with complex commands like what is G and M code G28? Moreover, structuring your program logically can help in tracking the flow of operations seamlessly. Another tip is to simulate your program before running it on a machine; this way, you can catch potential issues without risking damage to expensive equipment.

Additionally, familiarize yourself with commonly used G codes and M codes specific to your machine's capabilities. Knowing how these codes function will help you troubleshoot problems more effectively and optimize your processes. Remember that even small changes can have significant impacts on machining outcomes; thus, precision in coding is paramount.

Mistakes to Avoid in G and M Coding

One common mistake programmers make is neglecting to check their tool offsets before starting a job. This oversight can lead to catastrophic results—think misaligned cuts or even broken tools! Another pitfall is using outdated or incorrect codes without verifying compatibility with modern machines; just because something worked yesterday doesn’t mean it’ll work today!

Also, be cautious about using absolute positioning versus incremental positioning within your programs; mixing these up can confuse the machine regarding where to move next. Finally, avoid hardcoding values directly into the program unless absolutely necessary—using variables instead allows for greater flexibility should adjustments be needed later.

Resources for Learning More about G and M Codes

To deepen your understanding of what is G-code and M code?, there are numerous resources available online that cater specifically to CNC programming enthusiasts at all levels. Websites like CNC Cookbook offer extensive tutorials on both basic concepts and advanced programming techniques, ensuring you're well-equipped for any machining challenge ahead of you.

Books dedicated to CNC programming often provide comprehensive insights into best practices as well as troubleshooting tips tailored specifically around what is M code for? Additionally, joining forums or online communities focused on CNC machining allows you to share experiences with fellow programmers while learning from their mistakes too!

Lastly, don’t underestimate the value of hands-on practice—nothing beats real-world experience when trying to grasp complex concepts such as what is the difference between G-code and CNC? The more time spent coding in real scenarios will ultimately refine your skills!

Conclusion

In wrapping up our exploration of G and M codes, it’s clear that these programming languages are the backbone of CNC machining. They not only define the movements and functions of machines but also streamline operations, enhancing productivity and precision. Understanding what is G-code and M code, along with their specific applications like G28, equips programmers with the tools necessary for effective CNC operations.

Key Takeaways on G and M Codes

First off, G code m code are essential for controlling CNC machines; they allow for intricate designs to be executed with remarkable accuracy. Knowing what is G-code and M code can significantly improve a machinist's ability to program effectively, reducing errors and increasing efficiency. Additionally, commands like G28 provide crucial positioning information that enhances the overall workflow in machining processes.

The Role of G and M Codes in Precision Machining

G and M codes play a pivotal role in precision machining by ensuring that every movement of the machine is calculated down to the minutest detail. With commands such as those found in what is G-code and M code, operators can achieve high levels of accuracy that are vital in industries requiring tight tolerances. Furthermore, understanding what is M code for helps machinists automate functions such as tool changes or coolant activation, making their work not only more efficient but also safer.

Future Trends in CNC Programming with G and M Codes

Looking ahead, we can expect advancements in technology to further refine how we utilize g code m code in CNC programming. As automation becomes more prevalent, there will be an increased demand for programmers who understand both the fundamentals of what is the difference between G-code and CNC as well as emerging trends like adaptive machining techniques. Moreover, innovations such as artificial intelligence could revolutionize how we approach coding—making it easier than ever to produce complex parts while minimizing human error.