Introduction

In the realm of modern manufacturing, CNC machining milling stands out as a game-changer that has revolutionized how we create precise components. But what exactly is CNC machining milling? It’s a sophisticated process that combines computer numerical control with traditional milling techniques, allowing for unparalleled accuracy and efficiency in production.

Demystifying CNC Machining Milling

To truly understand CNC machining milling, it's important to break down the terminology. Is CNC machining milling simply a fancy way of saying “cutting metal”? Not quite! This advanced method involves using pre-programmed software to dictate the movement of machinery, which ultimately transforms raw materials into intricate designs with minimal human intervention.

The Importance of CNC Technology

CNC technology is crucial in today's fast-paced industrial environment; it enhances productivity while minimizing errors. The precision offered by CNC machining milling means that manufacturers can produce complex parts on a large scale without compromising quality. As industries evolve and demand for customized solutions grows, the significance of this technology continues to soar.

Tools Driving the CNC Milling Revolution

At the heart of this transformation are the tools that make it all possible—CNC machines equipped with cutting-edge technology designed for maximum efficiency. These tools not only automate processes but also improve safety and reduce waste, making them essential in any manufacturing setup. From understanding what is the process of CNC milling to exploring what is a CNC mill machinist's role, it's clear that these tools are pivotal in driving innovation forward.

What is CNC Machining Milling?

CNC machining milling is a sophisticated manufacturing process that utilizes computer numerical control (CNC) to automate the movement of cutting tools. This technology allows for precise and efficient milling of materials, transforming raw stock into intricate parts with impeccable accuracy. But, is CNC machining milling merely a buzzword? Let's dive deeper into its definition, differences from traditional methods, and the industries that reap its benefits.

Defining CNC Machining and Milling

At its core, CNC machining refers to the automated control of machine tools through computer programming. In the context of milling, it specifically involves rotating cutting tools to remove material from a workpiece along multiple axes. So, what is the process of CNC milling? It encompasses everything from designing parts in CAD software to executing complex cuts with high precision—making it an essential technique in modern manufacturing.

Differences Between CNC and Traditional Milling

The primary distinction between CNC machining milling and traditional milling lies in automation and precision. Traditional methods rely heavily on human operators who manually control the machines, which can lead to inconsistencies in quality and efficiency. In contrast, CNC machining milling employs advanced technology that ensures repeatable accuracy—eliminating human error while enhancing production speed significantly.

Industries Benefiting from CNC Milling

Numerous industries have embraced CNC machining milling due to its remarkable advantages. The aerospace sector leverages this technology for crafting lightweight yet durable components critical for flight safety and performance. Similarly, automotive manufacturers utilize CNC milling for producing intricate engine parts; thus ensuring reliability in their vehicles—showcasing just how vital this process has become across various fields.

The CNC Milling Process Explained

CNC machining milling is a fascinating blend of precision engineering and advanced technology. Understanding the CNC milling process is crucial for anyone looking to delve into this field, whether you're a curious novice or an aspiring CNC mill machinist. Let's take a closer look at how this intricate process works and why it’s so vital in various industries.

Step-by-Step Breakdown

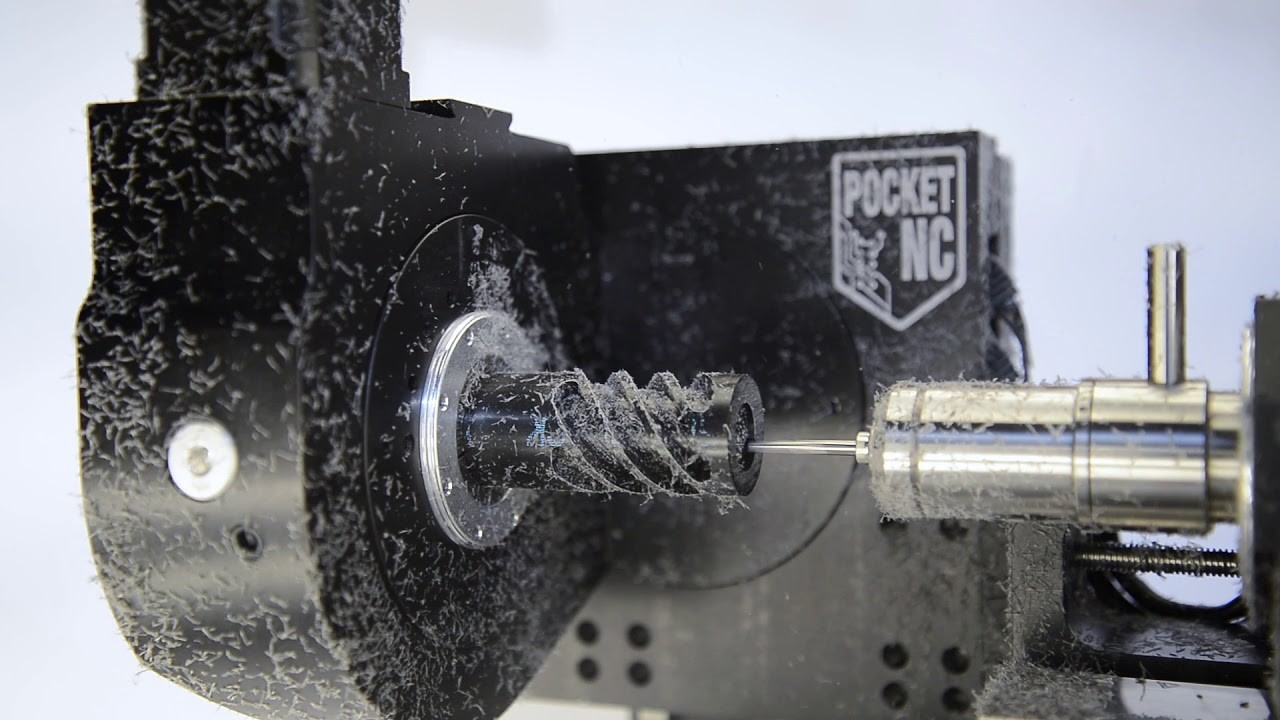

The process of CNC milling begins with designing a part using CAD (Computer-Aided Design) software, which allows engineers to create precise digital models. Once the design is finalized, it's converted into a format that the CNC machine can understand, usually through G-code programming. Next, the CNC mill machinist sets up the machine by securing the material and selecting appropriate tools before starting the machining operation.

During the actual milling process, the machine follows programmed instructions to cut and shape the material with incredible accuracy. The cutting tool moves along multiple axes to achieve complex geometries that would be nearly impossible with traditional methods. Finally, after all operations are complete, quality control checks ensure that each piece meets required specifications before it’s sent out for use in various applications.

How CAD Software Plays a Role

CAD software is pivotal in answering What is the process of CNC milling? It simplifies design creation by allowing users to visualize and modify components in 3D space before any physical work begins. This not only enhances creativity but also minimizes errors that could arise during manual drafting or traditional machining processes.

Moreover, CAD systems can generate G-code automatically based on user-defined parameters, streamlining communication between designers and machinists. This automation reduces setup time significantly while increasing efficiency and precision—key factors in high-quality cnc machining milling operations. In essence, CAD software acts as both an artist's canvas and a conductor's baton for orchestrating seamless manufacturing processes.

Precision and Accuracy in CNC Machining

In cnc machining milling, precision and accuracy are non-negotiable qualities that define successful outcomes. The advanced technology behind these machines allows them to operate within tolerances as tight as one thousandth of an inch! This level of detail ensures that parts fit together perfectly when assembled—crucial for industries like aerospace or automotive where safety depends on flawless components.

Furthermore, modern CNC machines are equipped with sensors and feedback systems that continuously monitor performance during operations. This real-time data helps operators make adjustments on-the-fly if needed, ensuring consistent results across production runs. Thus, understanding what is a CNC mill machinist entails recognizing their role not just as operators but also as quality assurance guardians who maintain these high standards throughout every project.

Tools Used in CNC Milling

Overview of Essential CNC Tools

CNC machining milling relies on a variety of tools that work together seamlessly to create high-quality components. At the heart of this operation are cutting tools, such as end mills and drill bits, which are responsible for shaping materials into desired forms. Additionally, tool holders and fixtures play a vital role in securing workpieces during machining processes, ensuring stability and accuracy throughout what is the process of CNC milling?

Beyond physical tools, software also plays an integral part in CNC operations. Computer-Aided Design (CAD) programs enable machinists to create detailed designs before they even touch a machine. By utilizing these advanced technologies, operators can streamline their workflow and enhance productivity while maintaining high standards in quality.

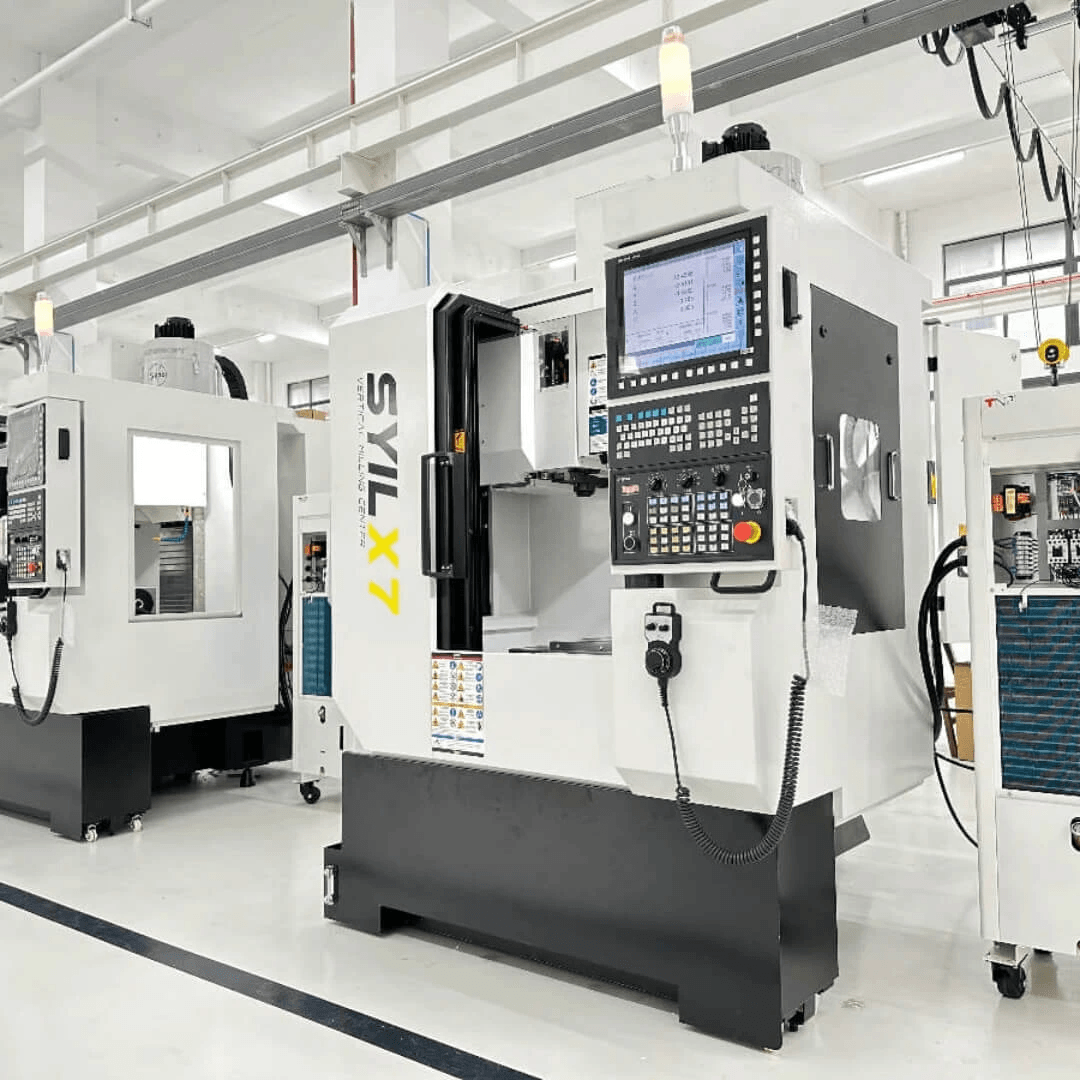

Spotlight on the SYIL CNC Machine

One notable player in the realm of CNC machining milling is the SYIL CNC machine lineup. Known for its versatility and user-friendly interface, SYIL machines cater to both beginners and seasoned professionals alike. With options ranging from compact desktop models to robust industrial machines, they offer solutions tailored for various applications.

The SYIL series stands out due to its impressive precision capabilities combined with affordability—a winning combination for small businesses looking to enter or expand within the market. Moreover, these machines often come equipped with advanced features such as automatic tool changers that significantly reduce downtime during production runs—something every operator appreciates! What is a CNC mill machinist without reliable equipment?

Tool Maintenance for Optimal Performance

To ensure longevity and optimal performance from your CNC tools, regular maintenance is non-negotiable. Just like any sophisticated machinery used in basic CNC milling operations requires attention; so too do your cutting tools! Regularly checking for wear and tear not only prolongs their lifespan but also maintains quality output.

Furthermore, proper cleaning routines should be established after each use; this helps prevent debris buildup that could impact performance over time. It’s equally important to follow manufacturer guidelines regarding lubrication—keeping moving parts well-greased ensures smooth operation during those intricate cuts that define quality in cnc machining milling projects.

In conclusion, understanding the essential tools used in CNC milling—from cutting instruments like end mills to state-of-the-art machines like those from SYIL—is key for anyone delving into this field. By prioritizing maintenance practices alongside utilizing advanced technology effectively ensures success within this ever-evolving industry.

The Role of a CNC Mill Machinist

CNC mill machinists are the backbone of modern manufacturing, ensuring that the intricate process of CNC machining milling runs smoothly and efficiently. But what exactly does it take to excel in this role? Let’s dive into the skills, responsibilities, and overall impact these professionals have on production.

Skills Required for CNC Machinists

To thrive in the world of CNC machining milling, a machinist must possess a unique blend of technical and soft skills. Proficiency in reading blueprints and understanding CAD software is essential; these tools are crucial for interpreting designs accurately. Additionally, a strong grasp of mathematics helps machinists calculate dimensions and tolerances with precision, ensuring quality results every time.

Moreover, problem-solving skills are vital when issues arise during the CNC milling process. A skilled machinist must be able to troubleshoot machinery malfunctions quickly to minimize downtime. Finally, attention to detail is paramount; even minor errors can lead to significant production setbacks or costly waste.

Daily Responsibilities of CNC Operators

The daily responsibilities of a CNC operator encompass various tasks that ensure efficient operation within the workspace. First and foremost, they set up machines by installing tooling and fixtures according to specifications—this is where knowing what is the process of CNC milling? becomes critical. Once set up, operators monitor machines during production runs to maintain quality standards while making adjustments as needed.

Operators also conduct routine maintenance checks on their equipment to ensure everything is functioning optimally; this proactive approach helps prevent unexpected breakdowns that could disrupt operations. Furthermore, they document their work processes meticulously—keeping track of production metrics helps improve future efficiency and serves as a reference for potential troubleshooting.

The Impact of CNC Machinists on Production

CNC machinists play an indispensable role in enhancing productivity across various industries utilizing CNC machining milling techniques. Their expertise directly influences product quality; skilled machinists can produce highly precise components that meet stringent specifications consistently. This level of accuracy not only improves customer satisfaction but also reduces material waste—a win-win for both manufacturers and clients alike.

Additionally, effective communication between machinists and design engineers fosters innovation within manufacturing processes. By providing feedback on machine capabilities or suggesting improvements based on hands-on experience, machinists help refine designs for better manufacturability—essentially bridging the gap between theoretical concepts and practical application in what is often complex machinery.

In summary, understanding “what is a CNC mill machinist?” reveals just how vital these professionals are in driving efficiency and quality within the realm of modern manufacturing techniques like basic CNC milling operations.

Basic Operations in CNC Milling

CNC machining milling is a fascinating process that combines advanced technology with precision engineering. Understanding the basic operations involved can demystify the complexities of this field. So, what is the process of CNC milling? Let’s break it down into its essential components.

Types of Basic Milling Operations

In CNC machining milling, there are several fundamental operations that machinists frequently employ to shape materials into desired forms. These include face milling, where the cutting tool removes material from the surface; peripheral milling, which focuses on cutting along the edge of a workpiece; and slotting, where narrow grooves are created. Each operation serves a specific purpose and contributes to the overall versatility of CNC milling techniques.

What is a CNC mill machinist? Simply put, they are skilled professionals who operate these machines to execute various milling operations efficiently. Their expertise ensures that each type of basic operation is performed with precision and accuracy, making them indispensable in industries relying on CNC machining milling.

CNC Programming Essentials

At the heart of effective CNC machining milling lies programming—a critical skill for any machinist. Understanding G-code and M-code is essential for creating precise instructions that guide the machine through its operations. These codes dictate everything from tool movements to spindle speeds, allowing for intricate designs and complex shapes.

The question Is CNC machining milling? often arises because programming plays such a vital role in differentiating it from traditional methods. In fact, mastering basic CNC programming essentials can significantly enhance production efficiency and reduce errors during manufacturing processes.

Safety Practices in CNC Machining

Safety practices in CNC machining are paramount due to the powerful machinery involved and potential hazards associated with operating such equipment. Proper training on machine operation, understanding safety protocols, and wearing appropriate personal protective equipment (PPE) are crucial steps every operator must take seriously.

Furthermore, regular maintenance checks help ensure that machines function correctly while minimizing risks during operations—making safety an integral part of any basic CNC milling operation routine. By prioritizing safety practices alongside technical skills, machinists can create a safer work environment while maximizing productivity in their projects.

Conclusion

CNC machining milling stands at the forefront of modern manufacturing, revolutionizing how products are created. This advanced technology offers unparalleled precision and efficiency compared to traditional methods, making it a game-changer across various industries. As we wrap up our exploration, let’s highlight some key takeaways about CNC machining milling that can help clarify its significance.

Key Takeaways on CNC Machining Milling

First and foremost, understanding what is CNC machining milling is crucial for anyone interested in the field. It combines computer numerical control with traditional milling techniques to produce intricate designs with incredible accuracy. Additionally, the benefits of CNC machining extend beyond mere efficiency; they include reduced waste and enhanced flexibility in production runs.

When considering what is the process of CNC milling, one must appreciate its systematic approach—from design to execution—ensuring each part meets stringent quality standards. The integration of CAD software into this process allows for seamless transitions from concept to physical product, further emphasizing why industries are increasingly adopting this technology. Ultimately, mastering CNC machining milling can lead to significant advancements in production capabilities and innovation.

Future Trends in CNC Technology

The future of CNC technology promises even more exciting developments that will shape manufacturing landscapes globally. With advancements in automation and artificial intelligence, we can expect smarter machines that not only enhance productivity but also learn from their environments to optimize operations continuously. Moreover, the rise of additive manufacturing alongside traditional CNC machining milling techniques opens new avenues for creating complex geometries that were previously unattainable.

Sustainability is another trend gaining traction within the industry as companies aim to reduce their environmental footprints through efficient resource management practices associated with CNC processes. By embracing eco-friendly materials and energy-efficient machines, manufacturers can align themselves with global sustainability goals while still reaping the benefits of advanced technology. Therefore, staying informed about these trends will be essential for anyone involved or interested in the world of CNC machining milling.

Exploring Career Paths in CNC Machining

For those curious about what is a CNC mill machinist or how one might embark on a career within this dynamic field, there are numerous opportunities available today! A career as a machinist involves not only operating sophisticated machinery but also requires a solid understanding of programming languages like G-code used for basic CNC milling operations. The demand for skilled professionals continues to grow as industries increasingly rely on precision engineering.

Furthermore, pursuing a career as a machinist can lead you down various paths—from working directly on production floors to engaging in roles focused on design or quality assurance within manufacturing settings. Continuous learning through certifications and training programs can enhance your skill set and open doors to leadership positions within organizations invested in cutting-edge technologies like CNC machining milling. So if you're ready to dive into this exciting world filled with innovation and opportunity, now's your chance!