Introduction

In the aerospace industry, precision is paramount, and CNC machining plays a crucial role in ensuring the quality and reliability of aircraft parts. From complex components to intricate designs, CNC machining for aircraft parts is essential for meeting strict tolerances and specifications.

Importance of Precision CNC Machining for Aircraft Parts

Precision CNC machining is vital for producing accurate and consistent aircraft components that meet the rigorous standards of the aerospace industry. Whether it's engine parts, landing gear, or structural elements, precision machining ensures that every piece fits perfectly and performs flawlessly in demanding flight conditions.

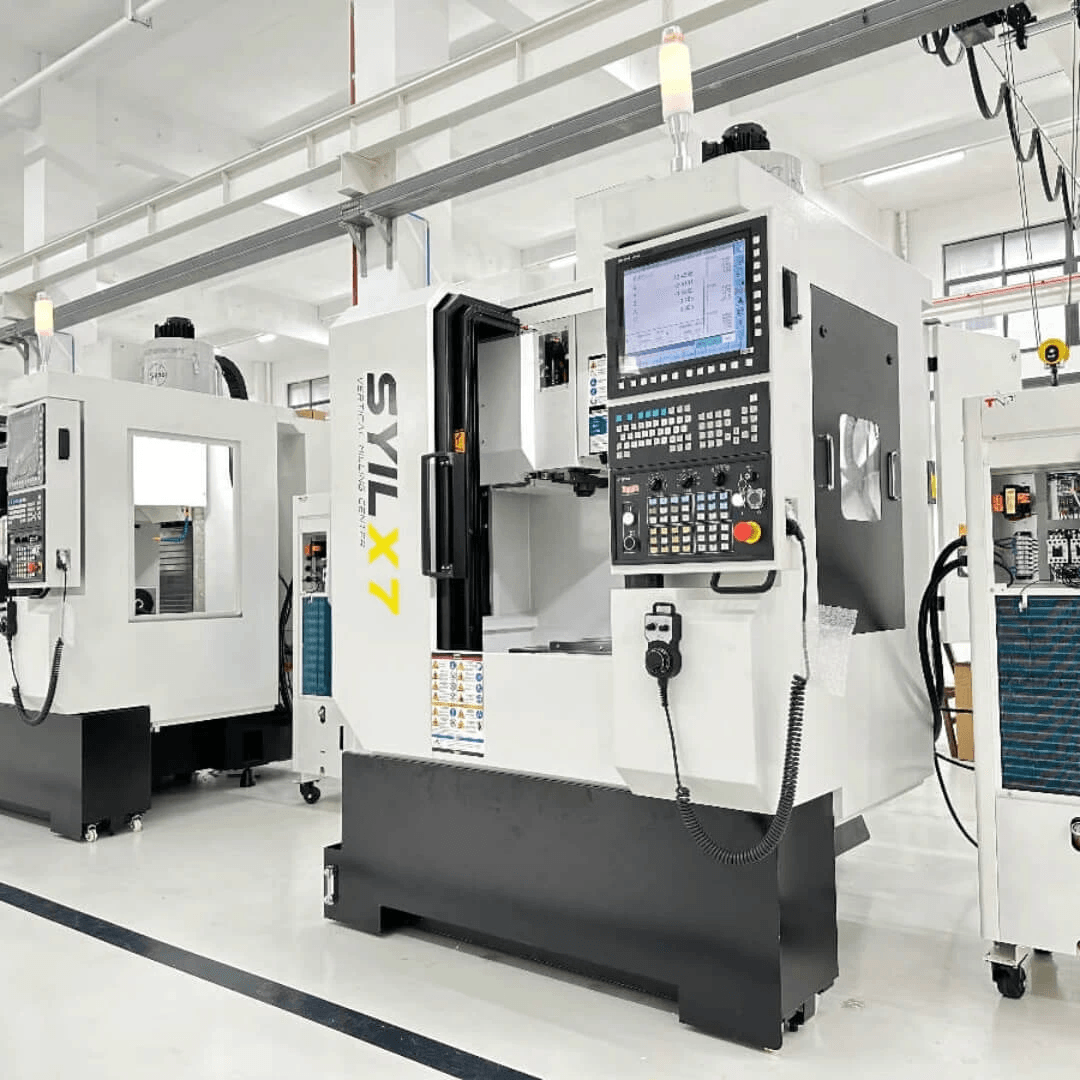

Advantages of Using SYIL CNC Machine

The SYIL CNC machine offers unparalleled precision and efficiency in manufacturing aircraft parts. With advanced features and capabilities, it revolutionizes aerospace manufacturing by delivering high-quality components with tight tolerances and superior surface finishes.

Core Keywords: CNC Machining Aircraft Parts

CNC machining in the aerospace industry is essential for producing reliable and durable aircraft components that meet stringent safety standards. Utilizing state-of-the-art technology like the SYIL CNC machine ensures that each part is meticulously crafted to exact specifications, guaranteeing optimal performance and safety in flight.

SYIL CNC Machine: Revolutionizing Aircraft Part Manufacturing

The SYIL CNC machine is a game-changer in the aerospace industry, offering advanced features and capabilities that streamline the production of precision CNC machined parts for aircraft. With its high-speed spindle and multi-axis capabilities, the SYIL CNC machine delivers unparalleled accuracy and efficiency in manufacturing complex aircraft components.

Features and Capabilities of SYIL CNC Machine

Equipped with state-of-the-art technology, the SYIL CNC machine boasts a robust structure, high rigidity, and exceptional stability, ensuring precise machining of aircraft parts with tight tolerances. Its advanced control system allows for seamless integration of CAD designs, enabling aerospace machinists to produce intricate components with utmost accuracy.

Impact on Quality and Efficiency in Aircraft Part Production

The use of SYIL CNC machines in aerospace manufacturing has significantly elevated the quality standards of precision CNC machined parts for aircraft. By leveraging advanced automation and cutting-edge tooling technologies, these machines enhance efficiency while maintaining superior precision, resulting in reduced lead times and enhanced overall productivity.

Applications in Aerospace Industry

SYIL CNC machines play a pivotal role in fabricating critical aircraft components such as turbine blades, landing gear parts, engine mounts, wing spars, fuselage frames, and more. Their versatility and adaptability make them indispensable tools for producing a wide range of precision-machined parts that meet the stringent requirements of the aerospace industry.

Precision Engineering in CNC Machining Aircraft Parts

Importance of Tight Tolerances in Aerospace Components

Tight tolerances are crucial in aerospace components to ensure the perfect fit and functionality of aircraft parts. Precision CNC machining allows for the production of parts with incredibly tight tolerances, meeting the stringent requirements of the aerospace industry.

Role of Computer-Aided Design (CAD) in Precision Engineering

Computer-Aided Design (CAD) plays a pivotal role in precision engineering for CNC machining aircraft parts. CAD software enables aerospace engineers to create intricate designs with exact measurements, ensuring that each component meets the precise specifications required for aircraft applications.

Quality Control Measures in CNC Machining

Quality control is paramount in CNC machining for aircraft parts to guarantee the highest standards of precision and reliability. Advanced metrology tools and rigorous inspection processes are employed to maintain strict quality control measures throughout the manufacturing process.

Remember that precision engineering is essential for CNC machining aircraft parts, with tight tolerances and quality control measures ensuring top-notch performance and safety in aerospace applications.

Material Selection and SYIL CNC Machining

When it comes to aircraft components, material selection is crucial for ensuring safety and performance. Precision CNC machining for aircraft parts requires the use of high-strength, lightweight materials such as aluminum, titanium, and composites. The SYIL CNC machine is capable of handling a wide range of materials, making it ideal for producing various aerospace components with different material requirements.

Choosing the Right Materials for Aircraft Components

In the aerospace industry, the choice of materials for aircraft components is driven by the need for high strength-to-weight ratio, corrosion resistance, and heat resistance. Aluminum alloys are commonly used for structural parts due to their lightweight nature and excellent machinability. Titanium alloys are preferred for critical components like landing gear due to their exceptional strength and heat resistance. Composites, such as carbon fiber reinforced polymers (CFRP), offer a combination of high strength and light weight, making them suitable for applications where weight reduction is essential.

Precision Machining of Exotic Alloys for Aerospace Applications

Exotic alloys like Inconel and Hastelloy are often used in aerospace applications due to their superior mechanical properties at high temperatures. Precision machining these materials requires advanced cutting tools and techniques to maintain tight tolerances while minimizing tool wear. The SYIL CNC machine's high spindle speed and rigid construction make it well-suited for machining exotic alloys with precision and efficiency.

SYIL CNC Machine's Compatibility with Various Materials

The versatility of the SYIL CNC machine extends to its compatibility with various materials commonly used in aerospace manufacturing. Whether it's aluminum, titanium, composites, or exotic alloys, the SYIL CNC machine can handle them all with precision and consistency. This capability allows aerospace manufacturers to streamline their production processes by using a single machine for a wide range of material requirements.

By incorporating precision engineering techniques into material selection and machining processes using the SYIL CNC machine, aerospace manufacturers can ensure that their aircraft components meet stringent quality standards while optimizing production efficiency.

Cost-Effectiveness of CNC Machining for Aircraft Parts

When it comes to CNC machining aircraft parts, cost-effectiveness is a crucial factor. With the SYIL CNC machine, waste and lead times are significantly reduced due to its precision and efficiency in manufacturing. This leads to cost savings in production and ensures a quicker turnaround time for aircraft components.

Reducing Waste and Lead Times with SYIL CNC Machine

The SYIL CNC machine's advanced technology allows for precise cutting and shaping of materials, minimizing waste during the manufacturing process. Additionally, its high-speed capabilities reduce lead times, enabling faster production of aircraft parts without compromising on quality. This translates to cost savings for aerospace manufacturers.

Benefits of Batch Production for Aircraft Components

Batch production using SYIL CNC machines offers several benefits for aircraft components. By producing multiple parts simultaneously, manufacturers can optimize their resources and streamline the production process. This not only reduces costs but also ensures consistent quality across all manufactured components.

Furthermore, batch production using SYIL CNC machines allows for greater flexibility in meeting customer demands. Manufacturers can easily adjust production schedules and quantities to accommodate changes in market demand or specific customer requirements. This agility ensures that the company can respond quickly to market trends and customer needs, ultimately enhancing its competitive edge in the aerospace industry.

Long-Term Savings and Return on Investment

Investing in precision CNC machining for aircraft parts with SYIL machines not only provides long-term savings and a high return on investment, but it also enhances the overall quality and consistency of the manufactured components. The advanced technology and automation of these machines ensure that each part is produced with utmost precision, reducing the likelihood of errors or defects. This level of quality control ultimately contributes to cost savings by minimizing rework and scrap, while also bolstering the reputation of aerospace manufacturers for delivering top-notch products.

Future Trends in Precision CNC Machining for Aircraft Parts

In the ever-evolving aerospace industry, advances in automation and Industry 4.0 integration are shaping the future of precision CNC machining for aircraft parts. With the integration of smart technologies and robotics, CNC machines are becoming more autonomous and efficient, leading to higher productivity and reduced lead times in manufacturing aircraft components.

Advances in Automation and Industry 4.0 Integration

The utilization of automation in CNC machining for aircraft parts is streamlining production processes and enhancing overall operational efficiency. Industry 4.0 technologies such as IoT (Internet of Things) and AI (Artificial Intelligence) are being integrated into CNC machines to enable real-time monitoring, predictive maintenance, and adaptive manufacturing, ensuring optimal performance and minimal downtime.

Moreover, the integration of IoT and AI in CNC machining for aircraft parts allows for data-driven decision-making and advanced analytics. This enables manufacturers to optimize production processes, identify areas for improvement, and make informed adjustments in real time. By harnessing the power of Industry 4.0 technologies, aerospace companies can achieve greater precision and efficiency in their manufacturing operations, ultimately leading to cost savings and competitive advantages in the market.

Environmental Sustainability in Aerospace Manufacturing

As environmental concerns continue to grow, the aerospace industry is increasingly focusing on sustainable manufacturing practices. Precision CNC machining plays a crucial role in this endeavor by minimizing material waste through advanced cutting strategies and optimizing energy consumption through high-speed machining techniques, contributing to a greener approach to aircraft part production. In addition to reducing waste and energy consumption, aerospace manufacturers are also exploring the use of eco-friendly materials such as recycled aluminum and composite materials made from sustainable sources. By incorporating these environmentally friendly materials into the production process, the industry can further minimize its carbon footprint and contribute to a more sustainable future for aerospace manufacturing.

Innovative Technologies Shaping the Future of Aircraft Part Production

Innovative technologies such as additive manufacturing (3D printing) and hybrid machining are revolutionizing the way aircraft components are produced. These cutting-edge methods complement precision CNC machining by offering new possibilities for complex geometries, lightweight structures, and rapid prototyping, paving the way for more efficient and cost-effective solutions in aerospace manufacturing.

In addition to their impact on component production, these innovative technologies are also driving advancements in material usage and design capabilities. Additive manufacturing allows for the creation of intricate, lightweight structures that were previously impossible to produce using traditional methods. This opens up new possibilities for enhancing fuel efficiency and overall aircraft performance, while also reducing the environmental impact of air travel. Furthermore, the flexibility of 3D printing enables rapid prototyping and iteration, facilitating faster development cycles for new aircraft designs.

Conclusion

In conclusion, precision CNC machining plays a crucial role in ensuring the safety and reliability of aircraft parts. With the use of advanced SYIL CNC machines, the aerospace industry can benefit from improved efficiency and quality in manufacturing processes. Embracing SYIL CNC machines for aerospace manufacturing is essential for meeting tight tolerances and producing high-quality components that meet industry standards. The future of precision CNC machining in aircraft parts production looks promising, with innovative technologies shaping the industry's evolution.

Ensuring Safety and Reliability Through Precision CNC Machining

Precision CNC machining is vital for ensuring the safety and reliability of aircraft parts. With tight tolerances and high-quality finishes, CNC machined components offer exceptional performance and durability in aerospace applications. By embracing advanced SYIL CNC machines, manufacturers can uphold stringent quality standards to guarantee the safety of aircraft operations. Additionally, these machines provide the flexibility to produce complex shapes and designs, allowing for innovative solutions in aerospace manufacturing.

Embracing SYIL CNC Machine for Aerospace Manufacturing

The use of SYIL CNC machines revolutionizes aerospace manufacturing by enhancing efficiency and precision in producing aircraft components. With features tailored to meet the demands of the aerospace industry, these machines enable manufacturers to achieve superior quality while optimizing production processes. Embracing SYIL CNC machines is a game-changer for aerospace manufacturing, setting new standards for excellence in precision engineering.

Furthermore, the use of SYIL CNC machines in aerospace manufacturing not only improves efficiency and precision but also reduces production costs. By streamlining the manufacturing process and minimizing material waste, manufacturers can save time and resources, ultimately leading to cost savings. This cost-effectiveness makes SYIL CNC machines an attractive investment for aerospace companies looking to enhance their competitiveness in the industry.

Core Keywords: CNC Machining Aircraft Parts

As we conclude, it's clear that precision CNC machining plays a pivotal role in meeting the demands of the aerospace industry. Embracing SYIL CNC machines ensures that manufacturers can produce high-quality aircraft components with tight tolerances and exceptional accuracy, contributing to overall safety and reliability in aviation operations.

In addition, SYIL CNC machines offer the flexibility and versatility necessary to accommodate the complex geometries and unique designs often required for aircraft components. This capability allows manufacturers to innovate and push the boundaries of what is possible in aerospace engineering, ultimately leading to advancements in aircraft performance and efficiency. By investing in state-of-the-art CNC machining technology, manufacturers can stay ahead of the curve and remain competitive in a rapidly evolving industry.