Introduction

When it comes to aerospace milling, precision and quality are paramount. This machining process in aerospace involves the use of advanced CNC technology to manufacture components for aircraft and spacecraft. Aerospace CNC machining requires skilled professionals known as aerospace machinists who specialize in the intricacies of aerospace manufacturing.

Understanding Aerospace Milling

Aerospace milling is a specialized machining process used to create precise components for the aerospace industry. It involves cutting and shaping materials such as aluminum, titanium, and composites to meet strict industry standards for safety and performance.

Importance of Superior Quality

Superior quality is crucial in aerospace manufacturing as any defects or imperfections could compromise the safety and reliability of aircraft and spacecraft. Achieving tight tolerances and maintaining surface finish are essential in ensuring that every component meets rigorous industry standards.

SYIL CNC Machine for Aerospace Milling

The SYIL CNC machine is a cutting-edge solution specifically designed for aerospace milling applications. With its high-speed capabilities, advanced tooling options, and customizable features, the SYIL CNC machine offers unparalleled precision and efficiency for aerospace manufacturing.

The Role of Precision in Aerospace Milling

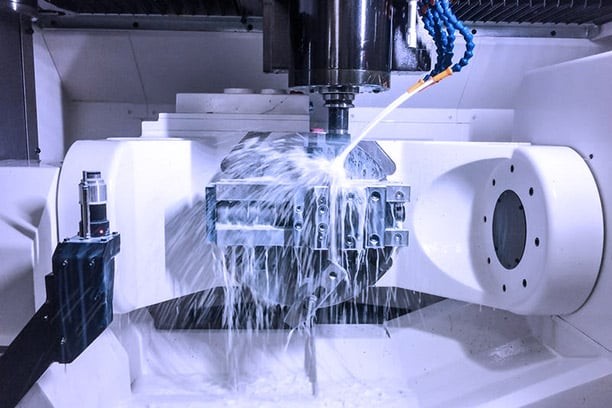

Aerospace milling is a crucial part of the manufacturing process for aircraft and spacecraft components. The machining process in aerospace involves the use of CNC machines to precisely shape and finish metal parts. Achieving tight tolerances is essential in aerospace milling to ensure that components fit together perfectly, minimizing any potential for failure during operation.

Achieving Tight Tolerances

In aerospace manufacturing, achieving tight tolerances is vital for ensuring the safety and reliability of aircraft and spacecraft. CNC machines used in aerospace milling are capable of extremely precise movements, allowing machinists to create parts with minimal deviations from the intended specifications. This level of precision is necessary to guarantee that every component fits together seamlessly, maintaining the structural integrity of the final product.

Maintaining Surface Finish

Surface finish is another critical aspect of aerospace milling, as it directly impacts the performance and longevity of components. Smooth surface finishes are essential for reducing friction and wear, which can significantly affect the efficiency and lifespan of aerospace parts. CNC machines equipped with advanced tooling allow machinists to achieve superior surface finishes, meeting or exceeding industry standards for quality and performance.

Utilizing Advanced Tooling

The use of advanced tooling is a key factor in achieving precision in aerospace milling. High-quality cutting tools designed specifically for aerospace materials enable machinists to produce intricate shapes with exceptional accuracy. These tools are engineered to withstand the demands of aerospace manufacturing, ensuring that each part meets stringent requirements for strength, durability, and performance.

By leveraging advanced CNC technology and specialized tooling, aerospace machinists can achieve unparalleled precision and quality in their work. This level of expertise is crucial for meeting the rigorous demands of aerospace manufacturing while driving innovation within the industr

Benefits of SYIL CNC Machine in Aerospace Milling

When it comes to aerospace milling, precision and efficiency are crucial. The SYIL CNC machine offers high speed and accuracy, allowing for complex parts to be machined with tight tolerances. This ensures that components meet the rigorous standards required for aerospace applications. With the ability to produce intricate details at rapid speeds, the SYIL CNC machine is a game-changer in aerospace manufacturing.

High Speed and Accuracy

The SYIL CNC machine is designed to deliver exceptional speed and accuracy in aerospace milling operations. Its advanced technology allows for rapid material removal while maintaining precise dimensions, resulting in superior quality components for aircraft and spacecraft. This high level of performance ensures that critical parts are manufactured with utmost precision, meeting the stringent requirements of the aerospace industry.

Furthermore, the SYIL CNC machine offers customizable options to meet the specific needs of aerospace milling operations. With a range of tooling, fixturing, and software capabilities, this machine can be tailored to handle a variety of complex components and materials. This flexibility allows for efficient production of unique parts, giving aerospace manufacturers the ability to adapt to changing requirements and stay ahead of the competition.

Customizable Options

A key advantage of the SYIL CNC machine is its customizable options, which cater to the specific needs of aerospace machining projects. From tooling configurations to cutting parameters, operators have the flexibility to tailor the machining process according to unique requirements. This adaptability enables manufacturers to produce a wide range of components with varying complexities, contributing to greater versatility in aerospace manufacturing.

In addition to the customizable options, the SYIL CNC machine also offers advanced automation features that streamline the aerospace machining process. This includes automated tool changes, part loading and unloading, and real-time monitoring of machining parameters. By reducing manual intervention, these automation capabilities improve efficiency and accuracy, ultimately leading to cost savings for manufacturers. The seamless integration of customizable options and automation makes the SYIL CNC machine a cost-effective solution for aerospace machining projects.

Cost-Efficiency

In addition to its exceptional performance capabilities, the SYIL CNC machine offers cost-efficiency in aerospace milling operations. By optimizing material usage and reducing waste through precise machining processes, this innovative technology helps minimize production costs without compromising on quality. As a result, manufacturers can achieve higher productivity and profitability while delivering top-notch components for aerospace applications.

Furthermore, the SYIL CNC machine's cost-efficiency extends beyond material optimization and waste reduction. Its advanced automation capabilities allow for reduced labor costs and increased production efficiency. This means that manufacturers can save on operational expenses while maintaining high precision and quality in their aerospace milling processes. The overall cost-effectiveness of this technology positions businesses to stay competitive in the industry and meet the demands of their clients

Expertise in Aerospace Machining

When it comes to aerospace milling, skilled operators play a crucial role in ensuring the precision and accuracy of the machining process. These professionals are highly trained in the use of advanced CNC machines and have a deep understanding of the specific requirements for aerospace components. Their expertise allows them to interpret complex engineering drawings and execute intricate machining operations with utmost precision.

Skilled Operators

Aerospace machinists are highly skilled individuals who specialize in the manufacturing of components for aircraft and spacecraft. They undergo extensive training to operate CNC machines and are well-versed in the intricacies of aerospace materials such as aluminum, titanium, and composites. Their expertise enables them to produce high-quality parts that meet stringent industry standards for safety and performance.

Aerospace machinists are also responsible for adhering to strict quality control measures throughout the manufacturing process. They meticulously inspect each component to ensure that it meets precise specifications and tolerances, utilizing advanced measuring equipment and techniques. Their attention to detail and commitment to excellence play a critical role in upholding the safety and reliability of aerospace vehicles.

Quality Control Measures

In aerospace manufacturing, quality control measures are paramount to ensure that each component meets exacting specifications. Skilled operators meticulously inspect every part throughout the machining process, utilizing advanced metrology equipment to verify dimensional accuracy and surface finish. This rigorous quality assurance process guarantees that all components adhere to the strict tolerances required for aerospace applications.

Skilled operators in aerospace manufacturing also employ specialized techniques such as non-destructive testing to ensure the integrity of critical components. This includes using methods like ultrasonic, radiographic, and eddy current testing to detect any flaws or defects that may compromise the performance and safety of the parts. By incorporating these advanced techniques into the quality control process, manufacturers can identify and rectify any issues before the components are integrated into larger assemblies.

Specialized Techniques

Aerospace machinists employ specialized techniques tailored specifically for the unique challenges posed by aerospace milling. From multi-axis machining to adaptive toolpaths, these professionals leverage cutting-edge methods to achieve intricate geometries while maintaining superior surface finishes. Their expertise allows them to optimize tooling strategies, minimize material waste, and maximize production efficiency.

Aerospace machinists also utilize advanced programming software to create complex toolpaths that can adapt to changing conditions in real-time. This dynamic approach allows for greater precision and efficiency, as the machines can adjust their movements based on feedback from sensors and other monitoring systems. By integrating adaptive toolpaths into their operations, aerospace machinists can ensure that each component is manufactured with the highest level of accuracy and consistency.

Innovation in Aerospace Manufacturing

In the ever-evolving world of aerospace manufacturing, advanced materials play a crucial role in enhancing performance and durability. Aerospace milling involves working with materials such as titanium, aluminum, and composites, all of which require precision machining to meet stringent industry standards. These advanced materials are known for their lightweight properties and high strength, making them ideal for aerospace applications.

Advanced Materials

Aerospace milling often involves working with advanced materials such as titanium, which is known for its exceptional strength-to-weight ratio. The machining process in aerospace requires specialized techniques to work with these materials, ensuring that tight tolerances are achieved without compromising structural integrity. From engine components to airframe structures, aerospace CNC machining is essential for shaping and finishing these advanced materials to exact specifications.

Industry Standards

In the aerospace industry, strict adherence to industry standards is paramount to ensure the safety and reliability of aircraft components. Aerospace machinists play a vital role in upholding these standards by utilizing state-of-the-art CNC machines to produce precision parts that meet or exceed regulatory requirements. From dimensional accuracy to surface finish quality, aerospace milling must adhere to rigorous industry standards to guarantee optimal performance under demanding conditions.

Future Trends in Aerospace Milling

As technology continues to advance, future trends in aerospace milling point towards even greater precision and efficiency. With the integration of automation and smart manufacturing processes, aerospace CNC machining is poised to become more streamlined and adaptable than ever before. Additionally, advancements in tooling and cutting technologies are expected to further enhance the capabilities of CNC machines for aerospace milling, allowing for faster production rates without sacrificing quality.

Remember that innovation is at the heart of aerospace manufacturing – from cutting-edge materials to industry standards and future trends – all contributing towards pushing the boundaries of what's possible in this dynamic field.

Conclusion

In conclusion, aerospace milling plays a crucial role in the manufacturing of aircraft components, requiring precision and high-quality standards. The machining process in aerospace involves shaping and cutting materials to create intricate parts for aircraft. Aerospace CNC machining utilizes computer-controlled machines to achieve the necessary precision and accuracy required for aerospace components. An aerospace machinist is a skilled professional responsible for operating CNC machines and producing complex parts for the aerospace industry. Aerospace manufacturing involves the production of aircraft and spacecraft components, utilizing advanced technologies and materials to meet industry demands.

Ensuring Safety and Reliability

The safety and reliability of aerospace components are paramount in the aviation industry, making precision machining a critical aspect of ensuring quality and performance. With tight tolerances and advanced tooling, aerospace milling guarantees that parts meet rigorous safety standards, providing peace of mind for manufacturers and end-users alike.

Meeting Industry Demands

As the demand for air travel continues to grow, the aerospace industry faces increasing pressure to produce high-quality components efficiently. Aerospace CNC machining allows manufacturers to meet these demands by offering high-speed production, customizable options, and cost-efficiency, ensuring that supply can keep up with demand without sacrificing quality.

The Future of Aerospace Milling Technology

The future of aerospace milling technology looks promising with advancements in materials, processes, and automation on the horizon. As new materials are developed to improve performance while reducing weight, innovative machining techniques will be needed to work with these advanced materials effectively. Additionally, automation in CNC machines will further enhance efficiency and productivity in aerospace manufacturing.