Introduction

In the world of jewelry making, innovation is key, and one of the most exciting advancements has been the rise of CNC technology. For jewelers looking to enhance their craftsmanship, investing in a jewelers CNC lathe can revolutionize their production process. As we delve into this topic, it’s essential to understand not just what a CNC jewelry machine is, but also how it can transform traditional methods into modern masterpieces.

The Rise of CNC in Jewelry Making

The emergence of CNC (Computer Numerical Control) machines has marked a significant turning point in jewelry making. These advanced tools allow artisans to create intricate designs with unparalleled precision and speed, something that manual techniques often struggle to achieve. With the growing demand for customizable pieces and complex designs, it's no wonder that many jewelers are asking themselves: Can I make jewelry with a CNC machine? The answer is a resounding yes!

Why Jewelers Should Consider CNC Technology

CNC technology offers numerous advantages that can help jewelers stay competitive in an ever-evolving market. By incorporating a jewelry lathe machine into their workflow, artisans can produce high-quality pieces more efficiently, reducing both time and labor costs. Moreover, the versatility of these machines means they can cater to various styles—from classic elegance to contemporary flair—making them an essential tool for any serious jeweler.

Understanding CNC Machines for Jewelers

Understanding how these machines work is crucial for any jeweler considering this investment. A typical jewelers cnc lathe operates by translating digital designs into physical objects through precise movements controlled by computer software. This level of control not only enhances accuracy but also allows for repeatability—ensuring that each piece is consistent with its predecessor without sacrificing quality or creativity.

Overview of CNC Jewelry Machines

In the world of jewelry making, CNC machines have revolutionized traditional craftsmanship into a realm of precision and efficiency. These advanced tools allow jewelers to create intricate designs that were once only possible by hand, significantly enhancing the production process. Understanding how these machines work and their applications can help jewelers maximize their potential.

What is a CNC Jewelry Machine?

A CNC jewelry machine is a computer-controlled device specifically designed for creating detailed jewelry pieces with incredible accuracy. Unlike manual methods, these machines use digital designs to guide their movements, ensuring that every cut and engraving is executed flawlessly. With various models available, including the popular jewelers CNC lathe, artisans can choose machines tailored to their specific needs in jewelry production.

How Does a Jewelry Lathe Machine Function?

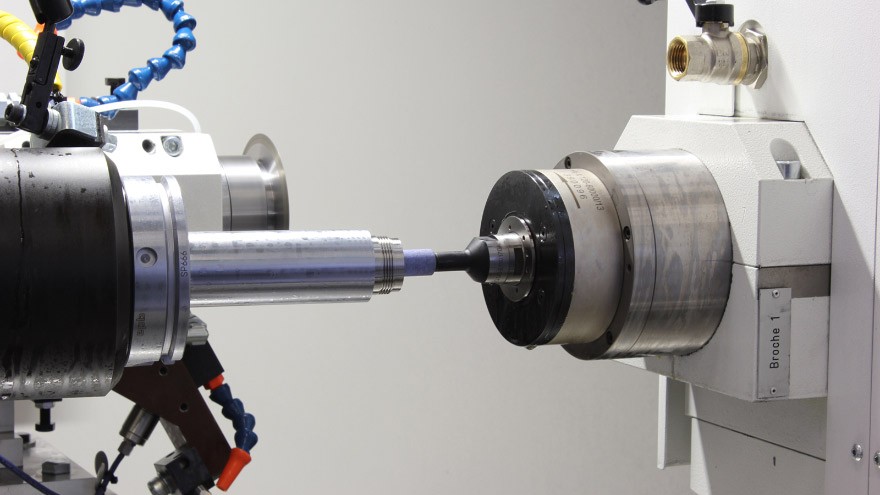

The jewelry lathe machine operates by rotating the material while cutting tools shape it into desired forms. This process allows for smooth finishes and precise details on rings, pendants, and other pieces of jewelry. For those asking, Can I make jewelry with a CNC machine?, the answer is an enthusiastic yes; using a jewelry lathe machine simplifies complex designs that would otherwise take hours or days to complete manually.

Applications in Jewelry Design and Creation

CNC technology has opened up numerous possibilities in the realm of jewelry design and creation. From crafting custom engagement rings to producing intricate watch components using a watchmaker lathe, the applications are vast and varied. Jewelers can explore endless creative avenues while enjoying increased productivity; this versatility makes choosing the best CNC machine for jewelry an essential decision for any serious craftsman.

Benefits of Using a Jewelers CNC Lathe

In the realm of modern jewelry making, the jewelers CNC lathe stands out as a game changer. It offers benefits that traditional methods simply can't match, from precision crafting to unparalleled efficiency. If you're still pondering, Can I make jewelry with a CNC machine? rest assured, this technology opens up exciting new possibilities for both seasoned artisans and budding designers.

Precision and Accuracy in Crafting

One of the most significant advantages of using a jewelry lathe machine is its remarkable precision and accuracy in crafting intricate designs. These machines operate on computer-controlled programs, allowing jewelers to create detailed patterns with millimeter-level accuracy. Whether you're designing delicate rings or elaborate pendants, the jewelers CNC lathe ensures that every piece is crafted to perfection, reducing human error and enhancing overall quality.

Moreover, this level of precision means that even complex designs can be reproduced consistently without sacrificing detail or craftsmanship. Imagine being able to produce identical pieces for your clients or collections without the hassle! The ability to maintain such high standards elevates your work and boosts customer satisfaction.

Efficiency and Speed in Production

Traditional methods can be time-consuming; however, with CNC technology, you can drastically reduce production times while maintaining quality. This means you can take on more projects simultaneously or fulfill larger orders without compromising on craftsmanship.

Additionally, automated processes mean less manual labor is required for repetitive tasks—allowing you to focus your creative energies on design rather than labor-intensive work. As a result, many jewelers are discovering that investing in the best CNC machine for jewelry not only increases their output but also enhances their profitability over time.

Versatility for Various Jewelry Styles

The versatility provided by a jewelers CNC lathe is another compelling reason why more artisans are adopting this technology into their workshops. Whether you're creating classic gold rings or innovative modern pieces using unconventional materials like resin or titanium, these machines adapt effortlessly to various styles and techniques.

Furthermore, different attachments and tools available for jewelry lathe machines enable users to experiment with unique textures and finishes—making it easier than ever to bring imaginative designs to life! With such flexibility at your fingertips, you'll find yourself inspired by new ideas rather than limited by traditional constraints.

Comparing CNC Machines for Jewelry

When it comes to choosing the right CNC technology for jewelry making, jewelers are met with a plethora of options that can make decision-making a bit overwhelming. Understanding the best CNC machine for jewelry involves evaluating several critical factors, including functionality, precision, and overall value. This section breaks down the top contenders in the market, ensuring you find the perfect fit for your creative endeavors.

Best CNC Machine for Jewelry Reviewed

The market offers several standout models when considering a jewelers CNC lathe or a jewelry lathe machine. One of the top-rated options is the SYIL X5 CNC machine, which combines user-friendly software with robust construction, making it ideal for both beginners and seasoned professionals alike. Another notable mention is the Tormach PCNC 440; its versatility allows it to handle everything from intricate ring designs to watchmaker lathe applications seamlessly.

For those seeking an entry-level option without compromising quality, consider the Genmitsu JFT-3040; it's compact yet powerful enough to create detailed pieces efficiently. Each of these machines comes equipped with features tailored specifically for jewelry design, ensuring that you can produce high-quality results every time you use them.

Features to Look for in a Jewelry CNC Machine

When searching for your ideal jewelry lathe machine or jewelers CNC lathe, there are several key features that should be on your checklist. First and foremost is precision; look for machines with high-resolution capabilities that can achieve intricate detailing required in fine jewelry making. Additionally, consider ease of use; machines equipped with intuitive software will save you time and frustration as you navigate through your designs.

Another vital feature is versatility—select a model that can accommodate various materials like metals and plastics while supporting multiple styles of jewelry production. Lastly, ensure that customer support is readily available; having access to resources or troubleshooting assistance can make all the difference when you're first learning how to operate your new equipment.

Cost Analysis: What is the Average Price of a CNC Lathe?

Understanding what is the average price of a CNC lathe varies widely based on brand and capabilities but generally falls within an accessible range for most jewelers looking to invest in this technology. Entry-level models may start around $2,000-$5,000 while more advanced systems equipped with premium features can reach upwards of $20,000 or more depending on their specifications and functionalities.

It's essential not only to consider upfront costs but also long-term value—machines that require less maintenance or offer greater durability may save money over time despite higher initial investments. Additionally, keep an eye out for warranties or financing options provided by manufacturers which could ease some financial burdens as you embark on your journey into automated jewelry creation.

Exploring the SYIL CNC Machine

When it comes to CNC technology in jewelry production, the SYIL CNC machine stands out as a favorite among jewelers. Known for its reliability and precision, this machine is designed to cater specifically to the needs of jewelry makers. Whether you're crafting delicate rings or intricate pendants, the SYIL offers features that enhance creativity and efficiency.

Why Choose SYIL for Jewelry Production?

Choosing the SYIL CNC machine means investing in quality craftsmanship tailored for jewelers. This machine excels in producing high-precision parts, making it an excellent choice for both amateur and professional artisans alike. With its user-friendly interface and robust construction, it's no wonder many jewelers are asking themselves, Can I make jewelry with a CNC machine?—the answer is a resounding yes!

SYIL machines are particularly beneficial for those who work with various materials like gold, silver, and even modern composites. Their versatility allows jewelers to experiment with different styles while maintaining top-notch quality. Plus, with competitive pricing options available, understanding What is the average price of a CNC lathe? becomes easier as SYIL offers great value without sacrificing performance.

Key Features of the SYIL CNC Machine

The SYIL CNC machine boasts several key features that make it stand out in the crowded market of jewelry lathe machines. First off, its high-speed spindle allows for quick material removal while ensuring precision—perfect for those detailed designs that require finesse. Additionally, it supports various tooling options which can accommodate different cutting techniques essential for creating unique pieces.

Another notable feature is its advanced software integration that simplifies design processes from concept to completion. This makes it one of the best CNC machines for jewelry production today! Jewelers can easily upload their designs and watch them come to life with minimal manual intervention.

Moreover, durability is at the forefront of SYIL’s design philosophy; these machines are built to withstand continuous use without compromising on accuracy or performance over time. If you're serious about elevating your craft through technology, investing in a jewelers CNC lathe like this could be transformative.

User Experiences and Testimonials

User experiences often speak volumes about a product's reliability and effectiveness; many have praised their journey with the SYIL CNC machine as nothing short of revolutionary! Feedback highlights not only how easy it is to operate but also how quickly new users adapt—ideal if you’re just starting out on your journey into CNC technology.

Testimonials frequently mention improved production times and enhanced creative possibilities thanks to this powerful tool's capabilities. Jewelers report that they can now tackle complex designs they previously thought impossible using traditional methods alone! The versatility offered by this jewelry lathe machine has empowered many artisans to expand their portfolios significantly.

Overall satisfaction ratings remain high among users who appreciate both performance and customer support provided by SYIL representatives when questions arise about operation or maintenance routines. This commitment reinforces why so many consider investing in a SYIL machine essential for any serious jeweler looking to thrive in today's competitive landscape.

Can I Make Jewelry with a CNC Machine?

The world of jewelry making has evolved dramatically with the introduction of technology, and many jewelers are now asking, Can I make jewelry with a CNC machine? The answer is a resounding yes! With the right tools, particularly a jewelers CNC lathe or a jewelry lathe machine, you can create intricate designs that were once only possible by hand.

Step-by-Step Guide to Jewelry Creation

Creating jewelry using a CNC machine involves several key steps that blend creativity with technical skills. First, you need to design your piece using CAD (Computer-Aided Design) software; this digital blueprint will guide your jewelry lathe machine during production. Once your design is ready, you'll set up the jewelers CNC lathe by selecting appropriate materials and tooling before finally running the program to produce your masterpiece.

After machining, it’s essential to perform post-processing tasks like polishing and finishing touches to ensure your piece shines as intended. The versatility of these machines allows you to craft everything from elegant rings to complex watch components using techniques typically reserved for skilled artisans. So whether you're creating custom pieces or mass-producing designs, mastering these steps will lead you towards success in modern jewelry making.

Tips for Beginners Using CNC Technology

For beginners venturing into the world of CNC technology in jewelry making, starting small is key. Familiarize yourself with the functions of your chosen machinery—whether it's a jewelers CNC lathe or another type—before diving into complex projects. Online tutorials and community forums can offer invaluable support as you learn about operating procedures and best practices tailored specifically for your jewelry lathe machine.

Additionally, patience is crucial; mistakes are part of the learning curve when working with precision machinery like a watchmaker lathe or any other CNC jewellery machine. Don’t hesitate to experiment with different materials and settings until you find what works best for your style and capabilities. Remember that practice makes perfect—the more time spent at the controls of your best CNC machine for jewelry will yield better results over time.

Common Mistakes to Avoid

As exciting as working with a jewelers CNC lathe can be, there are common pitfalls that every beginner should strive to avoid. One major mistake is neglecting proper calibration; failing to ensure that your machinery is correctly aligned can lead to disastrous results in terms of precision and accuracy in crafting pieces. Always double-check settings before commencing work on any project.

Another frequent error involves rushing through the design process; take time when creating CAD models since minor oversights can translate into significant issues during production on your jewelry lathe machine. Lastly, don't underestimate maintenance—keeping your equipment clean and well-maintained will prolong its lifespan while ensuring optimal performance every time you create new pieces.

Conclusion

In the ever-evolving world of jewelry making, CNC technology stands as a transformative force, enabling jewelers to push the boundaries of design and craftsmanship. With the precision offered by a jewelers CNC lathe, artisans can create intricate designs that were once thought impossible. This shift not only enhances creativity but also streamlines production processes, allowing for greater innovation in jewelry design.

Transforming Jewelry Design with CNC Technology

The introduction of the jewelry lathe machine has revolutionized how jewelers approach their craft. By integrating advanced CNC machinery into their workshops, artisans can achieve levels of detail and accuracy that manual methods simply cannot match. As designers experiment with new materials and techniques, they find that CNC technology elevates their work to new heights, transforming traditional pieces into modern masterpieces.

Investing in a CNC Jewelry Machine

When considering whether to invest in a CNC jewelry machine, it’s essential to weigh the benefits against the initial costs. While some may wonder about What is the average price of a CNC lathe?, it’s crucial to recognize this investment as one that pays dividends through increased efficiency and quality output over time. A well-chosen jewelers CNC lathe can become an invaluable tool in your workshop, enhancing both productivity and creative potential.

Future Trends in CNC Jewelry Production

As technology advances, we can expect even more exciting developments in CNC jewelry production. The rise of customizable designs made possible by user-friendly software will allow consumers to engage more directly with makers — think bespoke pieces crafted on demand! Additionally, watchmaker lathes are likely to see innovations that cater specifically to intricate watch components, further expanding the possibilities within this niche market.