Introduction

In the world of jewelry making, precision and creativity go hand in hand, and at the heart of this intricate craft lies the jewelry lathe machine. This remarkable tool is essential for jewelers looking to transform raw materials into stunning pieces of art. But what exactly is a jeweler's lathe? Understanding its functionality and applications can open up new horizons for both aspiring artisans and seasoned professionals alike.

Discovering the Jewelry Lathe Machine

The journey into the realm of jewelry begins with discovering the jewelry lathe machine, a device that revolutionizes how artisans create and manipulate metal. This machine allows jewelers to achieve an unparalleled level of detail and precision, turning ordinary materials into extraordinary works of art. With its ability to shape, cut, and polish various metals, the jewelry lathe has become an indispensable tool in modern workshops.

Understanding What Is A Jewelers Lathe?

So, what is a jeweler's lathe? Simply put, it is a specialized tool designed for crafting intricate designs in metal and other materials used in jewelry making. Unlike standard lathes found in other industries, a jeweler’s lathe is typically more compact and tailored specifically for delicate tasks such as turning rings or shaping pendants. By utilizing features like variable speed control and precision tooling, this machine empowers jewelers to achieve remarkable results with ease.

Applications of the Jeweler's Lathe

The applications of the jeweler’s lathe are as diverse as they are fascinating. From creating custom pieces that reflect personal stories to repairing cherished heirlooms with impeccable accuracy, this machine serves multiple purposes in any jeweler’s toolkit. Whether you're leveraging a desktop Swiss lathe for small-scale projects or innovating unique designs with advanced technology, understanding how to effectively use a jeweler’s lathe can elevate your craft significantly.

The Basics of Jewelry Lathe Machines

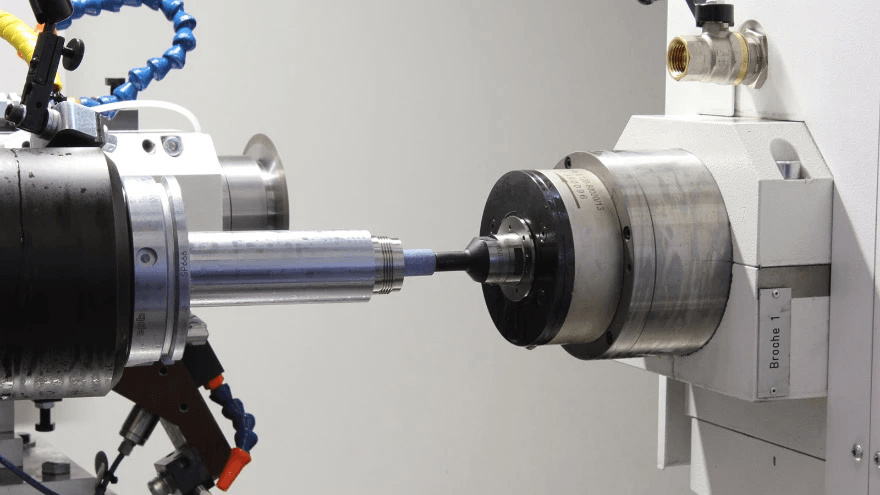

Understanding Jewelers Lathe Functionality

A jeweler's lathe operates by rotating a workpiece against cutting tools, enabling the creation of intricate designs and shapes. This functionality is crucial for tasks such as turning metal, polishing surfaces, and drilling holes with remarkable accuracy. By mastering how to use a jewelry lathe machine, jewelers can transform their creative visions into reality while maintaining high standards of craftsmanship.

The versatility of jewelers lathes means they can be used for various applications, from creating rings to detailing pendants. With adjustable speeds and tool settings, these machines allow for fine-tuning based on the material being worked on—whether it's gold, silver, or other precious metals. Ultimately, understanding how a jeweler's lathe functions empowers artisans to push their boundaries in design and innovation.

Key Features of Desktop Swiss Lathes

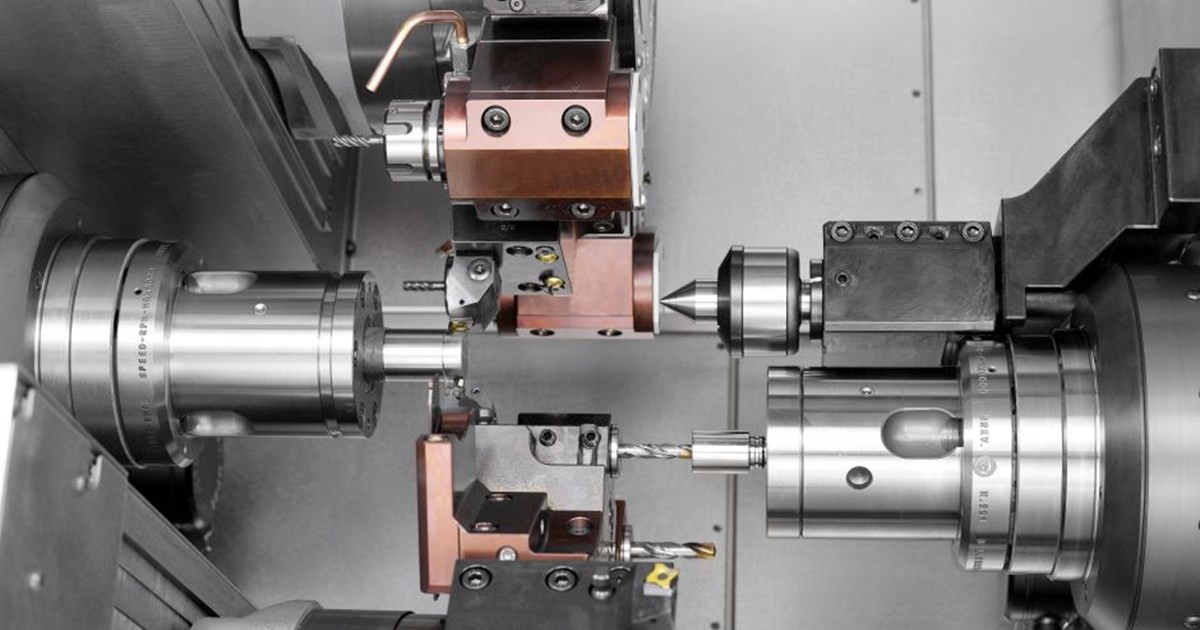

Desktop Swiss lathes have become increasingly popular among jewelers due to their compact size and impressive capabilities. These machines often feature high-precision spindles that provide excellent rotational speed control for delicate operations—ideal for working on small components typical in jewelry making. With user-friendly interfaces and programmable settings, desktop Swiss lathes make it easier than ever for jewelers to achieve consistent results.

Another standout feature is their ability to perform multiple tasks without needing extensive setup changes; this efficiency saves time while ensuring quality craftsmanship remains intact. Additionally, many models are equipped with advanced technology such as CNC (Computer Numerical Control), which allows for intricate designs that would be difficult or impossible with manual techniques alone. This blend of precision and convenience makes desktop Swiss lathes an essential asset in any modern jeweler's toolkit.

Different Types of Jewelry Lathe Machines

Jewelry lathe machines come in several varieties tailored to specific needs within the crafting process. From traditional manual models to more advanced CNC versions—each type offers unique advantages suited for various applications in jewelry making. For instance, while manual lathes provide hands-on control favored by some artisans, CNC machines offer unparalleled precision through automation.

In addition to these primary categories, there are specialized lathes designed specifically for tasks like engraving or stone setting that further enhance a jeweler's capabilities. Each type serves distinct purposes depending on what kind of work is being done; thus understanding these differences is key when selecting the right equipment for your workshop needs. Whether you're looking at basic tools or high-tech options like desktop Swiss lathes, knowing your choices will help you elevate your craft significantly.

Precision Crafting with Jewelry Lathes

Precision is the name of the game when it comes to crafting exquisite jewelry, and a jewelry lathe machine is your best ally in achieving that level of detail. These machines allow jewelers to work with an unparalleled accuracy that enhances both design and function. With high-precision lathes, even the most intricate designs can come to life, making them essential tools in any jeweler's workshop.

Benefits of High-Precision Lathes

High-precision lathes offer a plethora of benefits for jewelers looking to elevate their craft. One significant advantage is the ability to create components that fit together perfectly, minimizing the need for time-consuming adjustments later on. Additionally, these machines reduce material waste by ensuring that every cut is intentional and precise, allowing jewelers to maximize their resources while creating stunning pieces.

The consistency offered by a high-precision lathe also means that jewelers can replicate designs accurately across multiple pieces. This capability is particularly useful for custom orders or limited edition collections where uniformity is key. Ultimately, investing in a jewelry lathe machine with high precision not only streamlines production but also enhances overall craftsmanship.

How Lathes Enhance Design Accuracy

When you ask yourself, What Is A Jewelers Lathe? you'll quickly realize it's more than just a tool; it’s a game-changer for design accuracy. By utilizing advanced technology and features found in modern desktop Swiss lathes, jewelers can achieve levels of detail previously thought impossible. These machines enable artisans to carve intricate patterns into metals or gemstones with remarkable ease and precision.

Moreover, lathes allow for real-time adjustments during the crafting process, which means any miscalculations can be corrected on-the-fly without ruining an entire piece. This adaptability ensures that every aspect of the design aligns perfectly with the jeweler's vision—whether it's a delicate ring or an elaborate necklace. In essence, using a jeweler's lathe not only simplifies complex tasks but also empowers artisans to push creative boundaries.

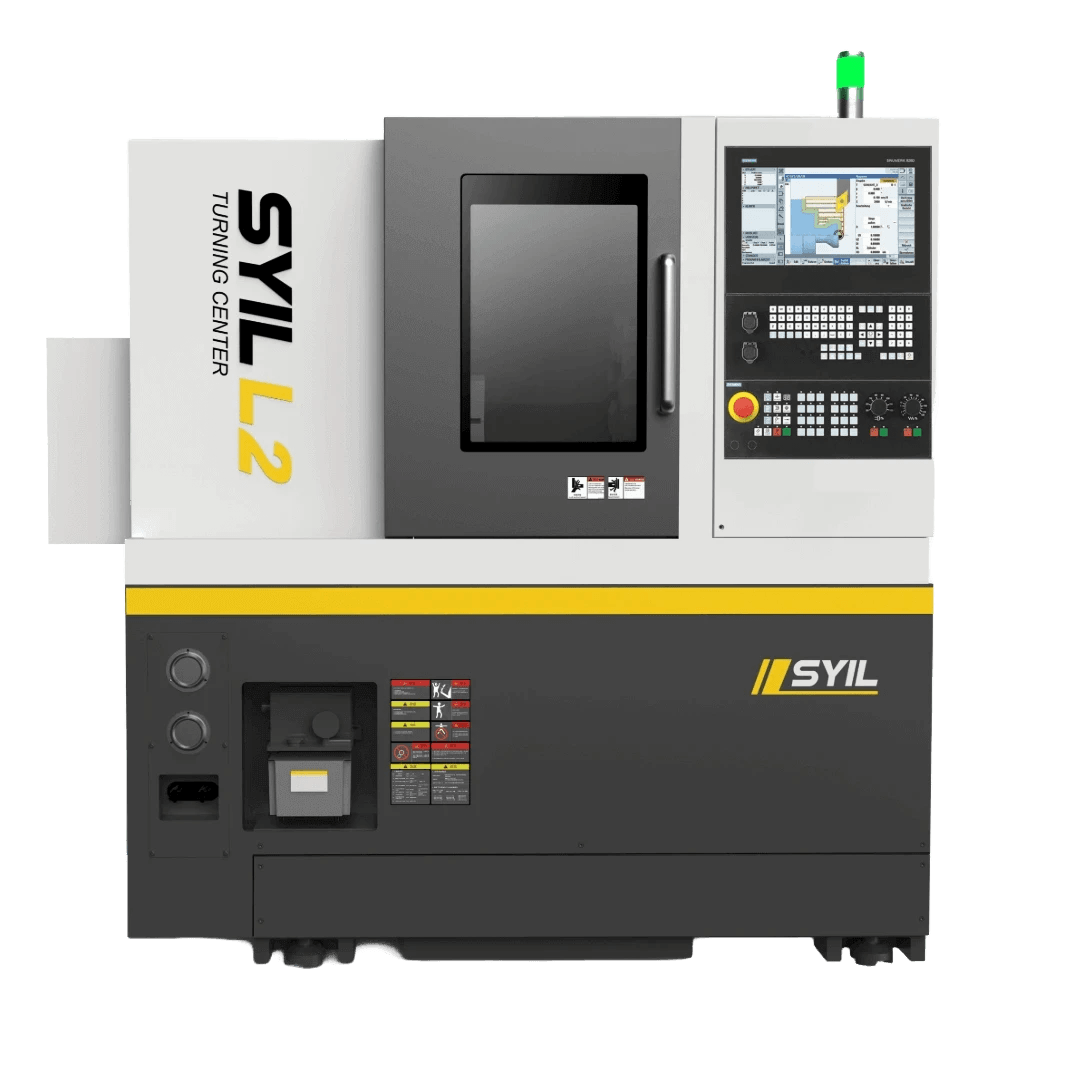

Innovating with the SYIL CNC Machine

The SYIL CNC machine represents the pinnacle of innovation in jewelry crafting technology today—a true marvel among jewelry lathe machines! This state-of-the-art equipment combines speed and precision like no other desktop Swiss lathe available on the market. With its user-friendly interface and advanced programming capabilities, even those new to what does a jeweler do can quickly master its operation.

One standout feature of the SYIL CNC machine is its versatility; it accommodates various materials from precious metals to synthetic gems effortlessly. Jewelers can experiment with different techniques—like engraving or milling—to create one-of-a-kind pieces tailored specifically for their clients’ desires. As technology continues to evolve, incorporating machines like SYIL into your workshop may just be what you need to stay ahead in this competitive industry.

Customization and Unique Designs

In the world of jewelry making, customization is where the magic happens. A skilled jeweler can transform raw materials into stunning, one-of-a-kind pieces that reflect individual tastes and styles. With tools like the jewelry lathe machine, artisans can push the boundaries of creativity, crafting unique designs that stand out in a crowded market.

How Does a Jeweler Create One-of-a-Kind Pieces?

Creating one-of-a-kind pieces involves a mix of artistry and technical skill. Jewelers often start by sketching their ideas before selecting the appropriate materials for their design, which may include precious metals or gemstones. Using tools such as a jeweler's lathe allows them to shape these materials precisely, ensuring that each piece is not only beautiful but also structurally sound.

The process typically includes multiple stages: designing, machining with a desktop Swiss lathe for intricate details, and finishing touches that bring the piece to life. The combination of traditional craftsmanship and modern technology enables jewelers to innovate while maintaining quality. Ultimately, it’s this blend of creativity and precision that leads to truly unique jewelry.

Leveraging Lathe Machines for Customization

Lathe machines play a pivotal role in customizing jewelry by allowing jewelers to achieve high levels of detail and precision. With features like variable speed control and interchangeable tooling systems, these machines enable artisans to work on various projects efficiently. Whether it's creating custom settings for stones or intricate engravings on bands, using a jeweler's lathe enhances both speed and accuracy.

Desktop Swiss lathes are particularly advantageous for small-scale production runs or bespoke designs since they allow jewelers to fine-tune their creations with ease. This flexibility means that even small adjustments can be made quickly without compromising quality or design integrity. By leveraging these capabilities, jewelers can offer personalized options that cater specifically to their clients’ desires.

Incorporating Personal Touches Using Jewelers Lathes

Personal touches are what make custom jewelry truly special; they tell a story about the wearer or commemorate significant moments in life. Jewelers often incorporate initials, dates, or symbols into their designs using advanced techniques facilitated by jewelry lathe machines. This level of personalization not only adds sentimental value but also differentiates each piece from mass-produced alternatives.

Moreover, incorporating unique textures or finishes through lathing techniques allows artisans to create visually arresting contrasts within their work—think polished surfaces paired with matte finishes or engraved patterns against smooth metal backgrounds! These creative choices elevate ordinary pieces into extraordinary statements of individuality. In essence, using jeweler's lathes empowers artists to infuse personality into every creation they produce.

Making Repairs and Alterations

Jewelry, much like any cherished item, can experience wear and tear over time. When it comes to restoring the beauty and integrity of jewelry pieces, the jewelry lathe machine proves to be an invaluable tool. Whether it's a simple resizing or a complex restoration, understanding how a jeweler utilizes this machine can make all the difference.

Jewelry Lathe Machine in Repair Work

The jewelry lathe machine is essential for any jeweler looking to perform repairs effectively. This versatile tool allows jewelers to work on various materials with precision, making it ideal for tasks such as reshaping rings or polishing intricate designs. By employing a desktop Swiss lathe, jewelers can achieve remarkable results that enhance both functionality and aesthetics in their repair work.

In repair scenarios, what does a jeweler do with a lathe? They often use it to create smooth finishes on damaged pieces or adjust settings for gemstones that may have come loose. The ability to manipulate metal with such accuracy ensures that repairs not only restore but also elevate the original design.

Techniques for Fixing Jewelry Flaws

When faced with flaws in jewelry pieces, there are several techniques that jewelers employ using their jewelers lathe. One common method is turning down excess metal from a ring's band to achieve the perfect fit for the wearer’s finger size. Additionally, lathes are used for smoothing out rough edges after soldering or reshaping items.

Another technique involves using the lathe for engraving or adding intricate details back into designs after damage has occurred. This not only fixes flaws but also adds character and uniqueness back into each piece of jewelry. The versatility of a jewelry lathe machine allows jewelers to adapt their techniques based on the specific needs of each repair job.

Importance of Precision in Alterations

Precision is paramount when making alterations to jewelry; even minor adjustments can have significant impacts on overall design and wearability. A desktop Swiss lathe offers unparalleled accuracy that ensures every cut and polish aligns perfectly with the jeweler's vision. This level of detail is crucial when working on high-value items where imperfections could detract from their worth.

Moreover, what does a jeweler do when they prioritize precision? They meticulously measure before making any changes, ensuring that every alteration enhances rather than compromises the piece's integrity. In an industry where craftsmanship speaks volumes, utilizing tools like the jewelers lathe becomes essential in maintaining high standards of quality throughout every project.

The Future of Jewelry Production

The future of jewelry production is being shaped by cutting-edge technology and innovative techniques. As jewelers explore new avenues for creativity, the role of the jewelry lathe machine becomes even more pivotal. With advancements in design software and materials, the possibilities for unique creations are virtually limitless.

Emerging Trends in Jewelry Lathe Technology

Emerging trends in jewelry lathe technology are revolutionizing how artisans approach their craft. For instance, modern desktop Swiss lathes now come equipped with advanced features such as programmable controls and enhanced precision capabilities. These innovations allow jewelers to create intricate designs that were once thought impossible, pushing the boundaries of what a jeweler's lathe can achieve.

Moreover, with the integration of 3D printing and CNC technology into traditional lathe practices, jewelers can experiment with hybrid designs that merge old-world craftsmanship with modern manufacturing techniques. This not only enhances efficiency but also opens up new creative pathways for crafting one-of-a-kind pieces using a jeweler's lathe. As these technologies continue to evolve, we can expect to see an exciting fusion of tradition and innovation in jewelry making.

How Automation is Shaping the Industry

Automation is reshaping the jewelry industry by streamlining processes that were once labor-intensive. With automated systems integrated into jewelry lathe machines, tasks such as polishing and finishing become quicker and more consistent than ever before. This efficiency allows jewelers to focus on design elements while leaving repetitive tasks to machines.

Furthermore, automation helps reduce human error during production, ensuring that each piece meets high standards of quality consistently—something crucial when working with precious materials. As a result, what does a jeweler do? They evolve from mere craftsmen into designers who can conceptualize elaborate pieces while relying on advanced machinery like desktop Swiss lathes for execution.

What Does a Jeweler Do in Modern Workshops?

In modern workshops equipped with state-of-the-art tools like the jewelry lathe machine, the role of a jeweler has transformed significantly. Jewelers today engage more in design thinking than ever before; they sketch out ideas digitally before bringing them to life using their trusty jeweler's lathes or CNC machines. This shift allows them to explore various styles rapidly and produce prototypes efficiently.

Additionally, contemporary jewelers often collaborate across disciplines—working closely with engineers and designers—to bring innovative concepts into reality using advanced technology such as CAD (Computer-Aided Design) software alongside their lathes. By embracing these changes within their craft, they not only enhance their artistry but also stay competitive in an ever-evolving market where customization is key.

Conclusion

In the world of jewelry making, the jewelry lathe machine stands as a beacon of creativity and precision. Its ability to transform raw materials into intricate designs allows jewelers to push the boundaries of their craft. By understanding what is a jewelers lathe and its applications, artisans can maximize their creative potential and produce stunning pieces that reflect their unique vision.

Maximizing Creativity with Jewelry Lathes

To truly unleash creativity, jewelers must embrace the capabilities of the jewelry lathe machine. These machines enable intricate detailing, allowing for designs that were once deemed impossible. With tools like the desktop swiss lathe, artisans can explore new styles and techniques, turning mere concepts into tangible art.

The versatility of jewlers lathes means that whether you're crafting delicate rings or bold pendants, you have the power to infuse personal touches into each piece. Customization becomes second nature when you harness these machines effectively. Ultimately, maximizing creativity with a jeweler's lathe results in one-of-a-kind masterpieces that tell a story.

The Role of Lathe Machines in Jewelry Making

Lathe machines play a pivotal role in modern jewelry making by providing precision and consistency in every project. Understanding what does a jeweler do goes beyond just design; it includes mastering tools like jewelers lathes to create flawless items efficiently. The ability to manipulate materials with accuracy ensures that each piece meets high standards of quality.

Furthermore, these machines are essential for both crafting new designs and repairing existing ones. With advancements in technology, such as CNC capabilities found in some jewelry lathe machines, jewelers can achieve even greater levels of detail and efficiency than ever before. Thus, lathes not only enhance production but also elevate craftsmanship within the industry.

Your Next Steps with Jewelry Lathes

Now that you've delved into the world of jewelry lathes, it's time to consider your next steps toward mastery! Whether you’re an aspiring jeweler or an experienced artisan looking to refine your skills, investing in a quality jewelry lathe machine is crucial for growth. Explore options like desktop swiss lathes that suit your workspace while providing all necessary functionalities.

Take some time to practice using your jewlers lathe; experimentation is key! Attend workshops or online courses focused on mastering these tools—this hands-on experience will be invaluable as you develop your style and technique further. Remember: every great artist started somewhere; let your journey with lathes lead you toward creating breathtaking jewelry pieces!