Introduction

Are you curious about CNC jewelry engraving? This innovative technology allows you to create stunning custom jewelry designs with precision and efficiency. With the SYIL CNC machine, you can explore endless possibilities for making earrings, necklaces, and more. Discover the benefits of using CNC for jewelry engraving and unlock your creativity like never before.

Understanding CNC Jewelry Engraving

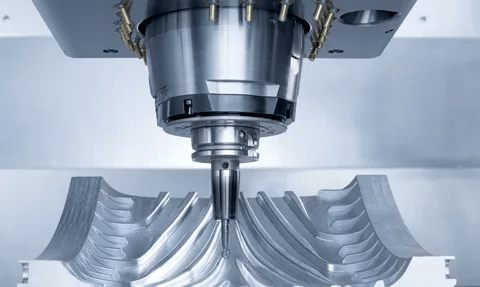

CNC jewelry engraving involves using computer-controlled machines to carve intricate designs onto various metals and materials. This advanced process offers unparalleled accuracy and detail, making it ideal for crafting unique pieces that stand out from the crowd.

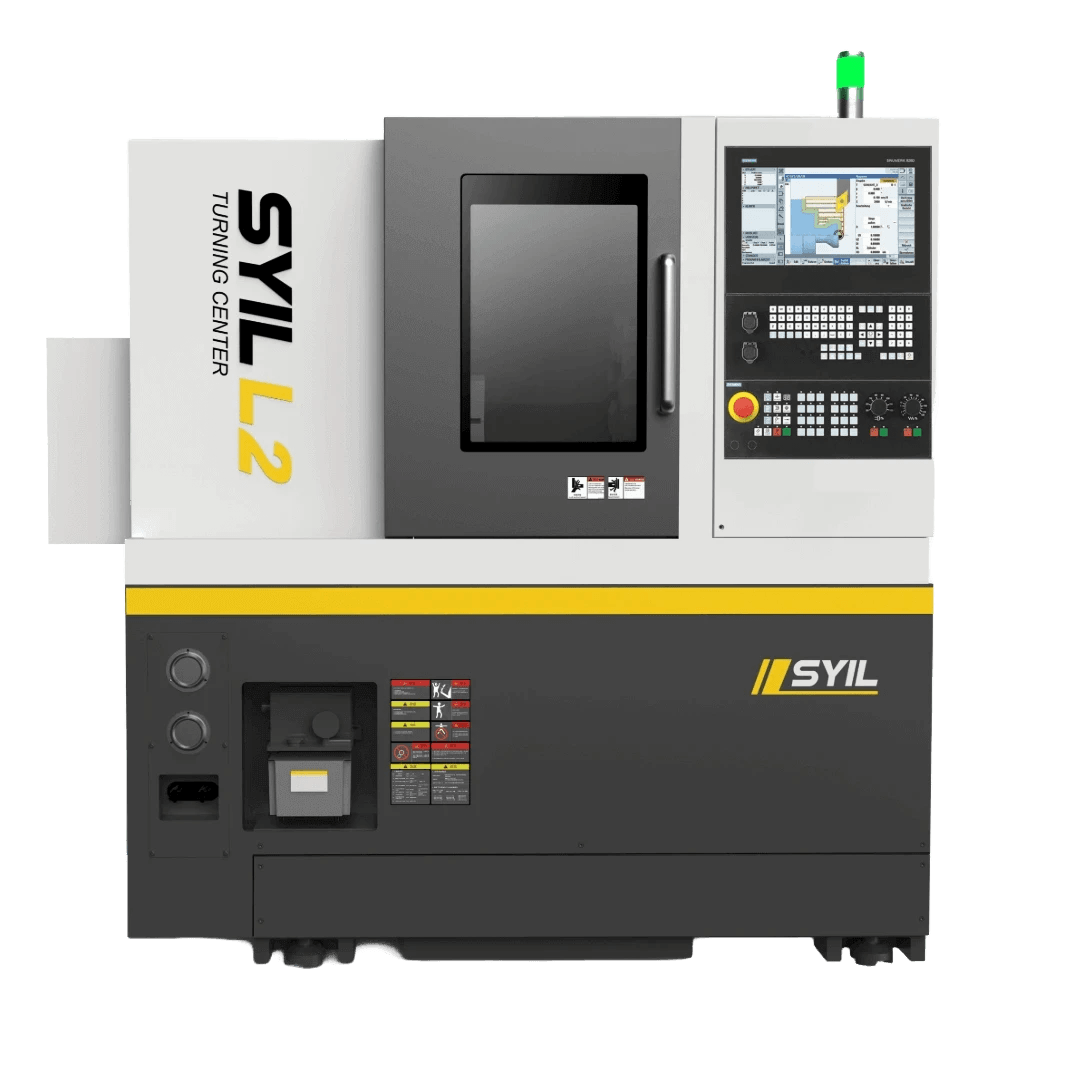

SYIL CNC Machine Overview

The SYIL CNC machine is a game-changer for jewelry makers, providing a reliable and versatile platform for creating custom designs. Its user-friendly interface and precise cutting capabilities make it the perfect tool for bringing your creative visions to life.

Benefits of Using CNC for Jewelry Engraving

By utilizing a CNC machine for jewelry engraving, you can achieve consistent results with minimal effort. This technology streamlines the production process, maximizes efficiency, and reduces material waste, ultimately saving you time and resources while delivering exceptional quality.

Getting Started with CNC Jewelry Engraving

So, you've decided to venture into the world of CNC jewelry engraving. The first step is to choose the right software that will enable you to bring your design ideas to life. Look for user-friendly programs that offer a wide range of design options and compatibility with your SYIL CNC machine.

Choosing the Right Software

When it comes to making earrings on the CNC mill or customizing jewelry designs, having the right software is crucial. Look for programs specifically tailored for jewelry design, with features such as 3D modeling, intricate pattern creation, and toolpath simulation. This will ensure that your designs are accurately translated onto your SYIL CNC machine.

After selecting the right software for jewelry design, the next step is to ensure that your SYIL CNC machine is set up properly. This includes calibrating the machine, installing the necessary tools and fixtures, and testing its functionality. Proper setup will guarantee that your jewelry designs are executed with precision and accuracy, resulting in high-quality finished products. Additionally, familiarizing yourself with the machine's operating system and troubleshooting procedures will help you address any issues that may arise during the manufacturing process.

Setting Up Your SYIL CNC Machine

Now that you have your software in place, it's time to set up your SYIL CNC machine for jewelry engraving. Make sure to follow the manufacturer's instructions carefully, from assembling the machine components to calibrating the settings for precision engraving. Proper setup is essential for achieving high-quality results.

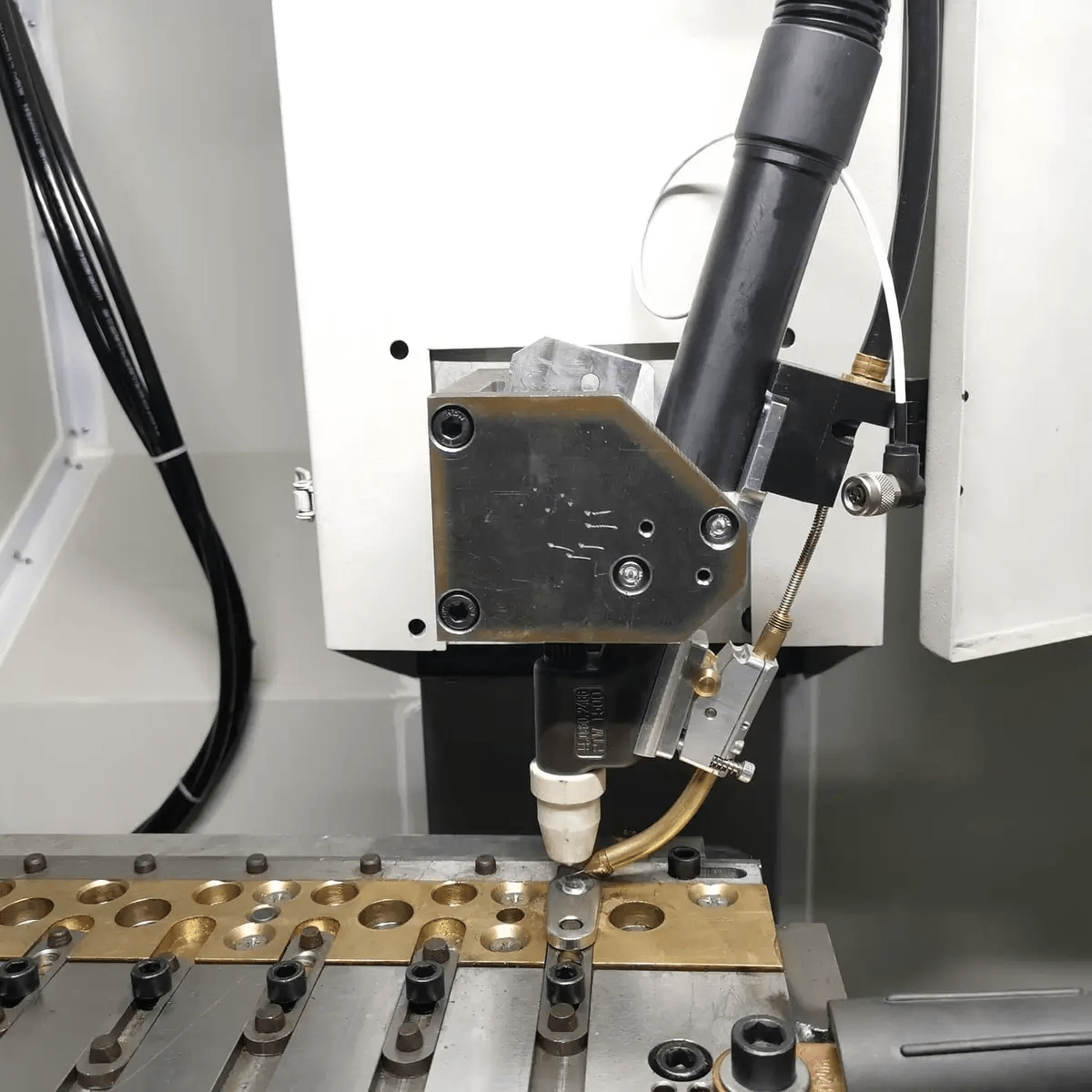

After setting up your SYIL CNC machine, the next step is to select the ideal engraving tools for jewelry engraving. Consider the type of material you will be working with and choose the appropriate cutting tools for the job. Diamond-tipped engraving tools are often recommended for precision and durability when working with precious metals and gemstones. Additionally, make sure to have a variety of tool sizes on hand to accommodate different design details and intricacies.

Selecting the Ideal Engraving Tools

To create stunning custom CNC machine earrings and intricate jewelry designs, selecting the ideal engraving tools is key. Consider factors such as tool material, tip size, and cutting depth when choosing tools for different materials like gold, silver, or precious stones. Investing in high-quality tools will ensure clean and precise engravings on your jewelry pieces.

Remember, getting started with CNC jewelry engraving requires attention to detail and careful planning in choosing software, setting up your machine, and selecting the right tools. With these foundational steps in place, you're ready to embark on an exciting journey of creating unique and personalized jewelry pieces using your SYIL CNC machine!

Mastering Precision Techniques

Tips for Intricate Designs

When it comes to CNC jewelry design, intricate details can truly elevate a piece. Utilize the capabilities of your jewelry machine to create delicate patterns and designs that would be nearly impossible by hand. Experiment with different tool sizes and speeds to achieve the level of detail you desire in your custom CNC machine earrings.

Experiment with different materials to add depth and dimension to your CNC jewelry designs. Consider incorporating mixed metals, gemstones, or even non-traditional materials like wood or acrylic to create unique textures and visual interest. By combining various materials, you can achieve a multi-dimensional look that sets your custom CNC machine earrings apart from the rest.

Achieving Consistent Depth

One of the key advantages of using a CNC machine for jewelry engraving is the ability to achieve consistent depth across your designs. By mastering the settings on your SYIL CNC machine, you can ensure that each piece has uniform depth, resulting in a professional and polished finish for your custom cnc machine earrings.

Another benefit of using a CNC machine for jewelry engraving is the ability to handle delicate materials with care. The precision and accuracy of the machine allow you to work with fragile materials such as gold, silver, and precious stones without causing damage. This opens up a world of possibilities for creating intricate and detailed designs that would be difficult to achieve by hand.

Handling Delicate Materials with Care

CNC jewelry design often involves working with delicate materials such as precious metals and gemstones. It's important to handle these materials with care when using a jewelry machine, ensuring that they are securely fastened and protected during the engraving process. Take the time to understand the best practices for working with different materials on your SYIL CNC machine to avoid any damage or mishaps.

Remember, mastering precision techniques with your SYIL CNC machine is essential for creating high-quality custom jewelry pieces that stand out in the market. With attention to detail and careful consideration of material handling, you can take your CNC jewelry engraving skills to new heights.

Customizing Designs with SYIL CNC Machine

When it comes to creating unique earrings, the SYIL CNC machine offers endless possibilities. With its precision and versatility, you can design and produce one-of-a-kind earrings that stand out from the crowd. Whether you prefer intricate patterns or minimalist designs, the CNC machine allows you to bring your vision to life with ease.

Creating Unique Earrings

With a CNC jewelry machine, making earrings is a breeze. You can experiment with different materials such as gold, silver, or even wood to craft stunning pieces that reflect your personal style. The machine's ability to execute complex designs with utmost precision ensures that each pair of earrings is a work of art, ready to adorn the ears of discerning customers. Furthermore, the CNC jewelry machine allows for customization on a whole new level. You can create personalized earrings with initials, birthstones, or other meaningful symbols, offering customers unique and sentimental pieces that they will cherish for years to come. Additionally, the efficiency of the CNC machine means you can produce custom orders quickly and efficiently, catering to individual tastes and preferences without compromising on quality or craftsmanship.

Exploring Custom Jewelry Options

The beauty of using a CNC machine for jewelry design is the freedom to explore custom options. From experimenting with unconventional shapes to incorporating intricate details, the possibilities are endless. Whether you want to create statement pieces or delicate everyday wear, the SYIL CNC machine empowers you to push boundaries and redefine traditional jewelry norms.

With the SYIL CNC machine, you can also offer personalized engraving services for your clients. Whether it's a special date, a meaningful quote, or a loved one's name, the precision of the CNC machine ensures that each engraving is flawlessly executed. This level of customization adds sentimental value to the jewelry pieces and creates a unique selling point for your business. By harnessing the power of technology, you can elevate the client experience and leave a lasting impression with personalized engravings that speak to their individuality.

Personalizing Engraving for Clients

One of the most exciting aspects of using a CNC machine for jewelry engraving is the ability to personalize designs for clients. Whether it's adding initials, dates, or meaningful symbols, the machine allows you to create bespoke pieces that hold sentimental value for your customers. This level of customization sets your jewelry apart and establishes a deeper connection with those who wear it.

The ability to offer personalized engraving for clients also opens up new opportunities for collaboration and creativity. Clients can work closely with you to co-create unique designs that reflect their personality and story, making the jewelry even more meaningful. This collaborative process not only strengthens the bond between you and your clients but also allows for a more immersive and engaging experience, setting your jewelry business apart from others in the industry.

Optimizing Workflow and Efficiency

In the world of jewelry making, time is money. By streamlining your production processes with a CNC machine, you can significantly reduce the time it takes to create intricate designs. With the ability to automate repetitive tasks, such as drilling holes or cutting shapes, you can focus on the creative aspects of jewelry design, ultimately increasing your output and profitability.

Streamlining Production Processes

By utilizing a CNC jewelry machine, you can streamline your production processes by eliminating manual labor and reducing human error. With the ability to program complex designs and replicate them with precision, you can produce multiple pieces of jewelry in a fraction of the time it would take using traditional methods. This not only saves time but also allows for consistent quality across all your creations.

Maximizing Output with Automation

Automation is key to maximizing output when working with a CNC jewelry machine. By programming repetitive tasks into your machine's software, you can let it run unattended while producing multiple pieces simultaneously. This not only increases productivity but also frees up your time to focus on other aspects of your business, such as marketing and sales.

In addition to increasing productivity, automation also helps minimize material waste in the jewelry-making process. By precisely controlling the cutting and shaping of materials, CNC machines can reduce the amount of wasted material, ultimately saving you money on supplies. This efficient use of materials not only benefits your bottom line but also contributes to a more sustainable and environmentally friendly approach to jewelry production. With automation, you can optimize your processes to minimize waste and maximize efficiency, giving you a competitive edge in the market.

Minimizing Material Waste

With traditional jewelry-making methods, material waste is often inevitable due to human error or imprecise tools. However, with a CNC machine, you can minimize material waste by accurately cutting and engraving designs with minimal margin for error. This not only saves money on materials but also contributes to a more sustainable approach to jewelry production. Furthermore, the precision of CNC machines allows for intricate and complex designs to be executed with ease, opening up new creative possibilities for jewelry makers. This level of detail and accuracy can result in stunning, high-quality pieces that are sure to impress customers and stand out in the market.

Fine-Tuning Your Craft

As you delve deeper into CNC jewelry engraving, it's important to be equipped to troubleshoot common engraving issues that may arise. Whether it's a misalignment in your design or an issue with the depth of the engraving, knowing how to identify and rectify these problems is crucial for maintaining high-quality output.

Troubleshooting Common Engraving Issues

When working with a CNC jewelry machine, it's not uncommon to encounter issues such as tool breakage, incorrect tool paths, or spindle speed discrepancies. By familiarizing yourself with these common problems and their solutions, you'll be better prepared to address them swiftly and efficiently, ensuring minimal disruption to your production process.

Refining Finishing Touches

The beauty of creating jewelry with a CNC machine lies in the precision and intricacy of the designs you can achieve. To truly elevate your pieces, focus on refining the finishing touches of each engraving. Pay attention to detail, experiment with different cutting tools and techniques, and aim for flawless execution that sets your custom CNC machine earrings apart from the rest.

Maintaining Your SYIL CNC Machine

To keep your SYIL CNC machine operating at its best, regular maintenance is key. From cleaning and lubricating components to calibrating settings for optimal performance, taking care of your machine ensures longevity and consistent results in your jewelry design endeavors.

With these fine-tuning techniques in mind, you're well on your way to mastering the art of jewelry engraving with a CNC machine. Keep pushing boundaries in custom cnc machine earrings design while maintaining top-notch quality through troubleshooting issues, perfecting finishing touches, and prioritizing proper maintenance for your equipment.

Conclusion

In conclusion, CNC technology has revolutionized jewelry engraving, making it easier and more efficient than ever before. With the SYIL CNC machine, artisans can unleash their creativity and innovate custom jewelry designs with precision and consistency. The ability to make unique earrings on the CNC mill opens up endless possibilities for personalized and one-of-a-kind pieces.

Elevating Jewelry Engraving with CNC Technology

The use of CNC technology has elevated the art of jewelry engraving to new heights, allowing for intricate and precise designs that were once difficult to achieve by hand. With the right software and tools, artisans can now create stunning custom cnc machine earrings with ease, bringing their visions to life in a way that was previously unimaginable.

Unleashing Creativity with SYIL CNC

SYIL CNC machines have empowered jewelry designers to unleash their creativity like never before, offering a level of precision and control that traditional methods simply cannot match. The ability to customize jewelry designs with ease allows for endless possibilities in creating unique and personalized pieces that truly stand out in the market.

Innovating Custom Jewelry Design

The use of CNC technology in jewelry design has sparked a wave of innovation, opening doors for artists to explore new techniques and push the boundaries of what is possible in jewelry making. From intricate patterns to delicate engravings, the SYIL CNC machine has given artisans the tools they need to innovate custom jewelry design in ways that were once thought impossible.