Introduction

In the competitive world of jewelry making, efficiency is key. That's where a CNC machine for jewelry comes in. By harnessing the power of advanced technology, businesses can now revolutionize their production processes and stay ahead of the game. But why exactly does your business need a CNC machine for jewelry? Let's explore the impact and benefits in more detail.

The Impact of Efficient CNC Machine for Jewelry

When it comes to creating intricate designs and precise cuts, a CNC machine for jewelry is a game-changer. By automating the manufacturing process, businesses can achieve unparalleled levels of accuracy and consistency in their products, setting them apart from traditional methods.

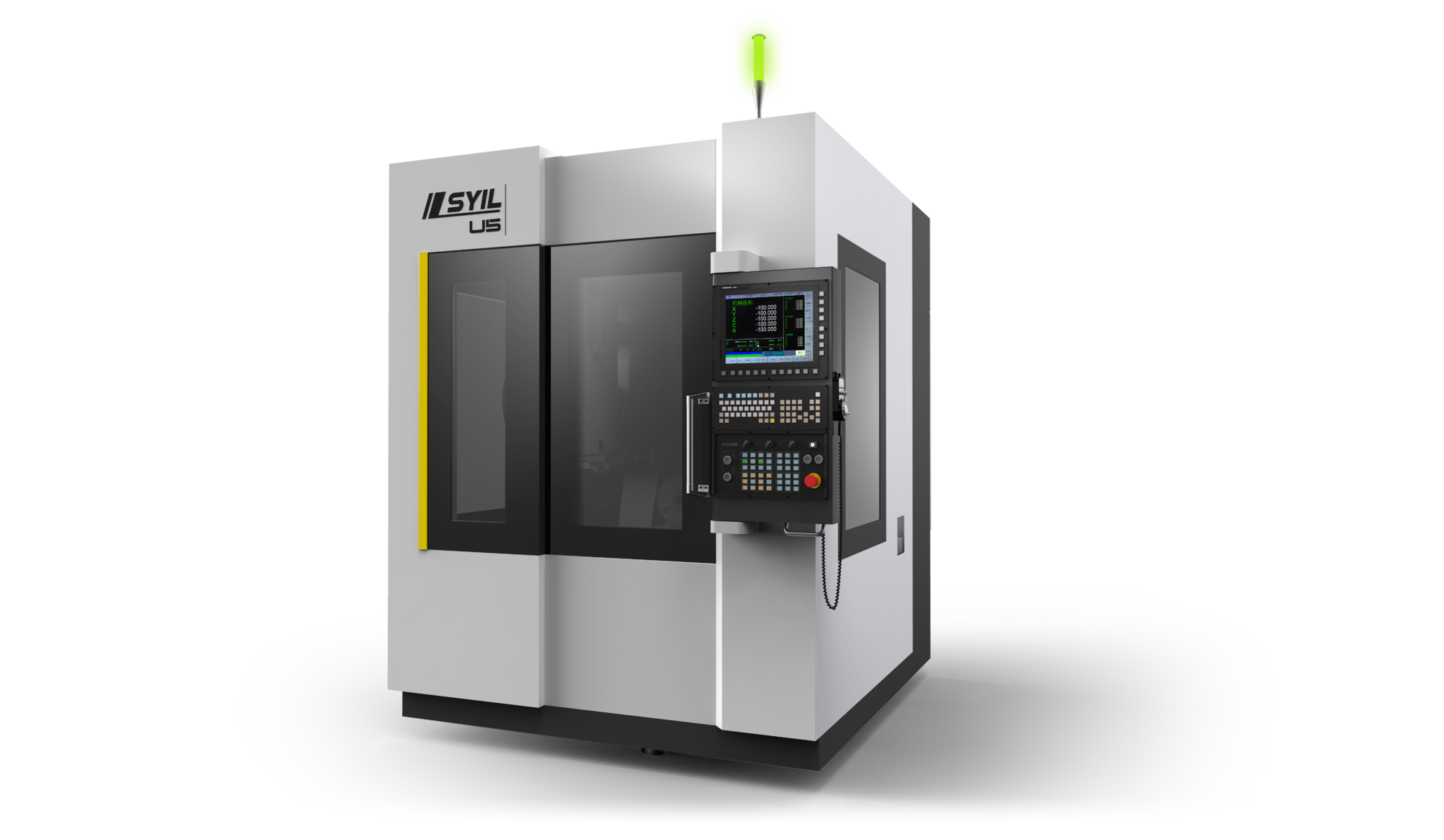

SYIL CNC Machine: Revolutionizing Jewelry Production

Enter SYIL CNC machine - the ultimate solution for jewelry making machines. With its cutting-edge technology and user-friendly interface, SYIL has redefined the way jewelry is made. From intricate patterns to complex shapes, this innovative machine offers unmatched precision and quality.

Why Your Business Needs a CNC Machine for Jewelry

In today's fast-paced world, time is money. A CNC machine for jewelry making not only speeds up production but also reduces costs significantly. With superior quality output and increased efficiency, it's clear that integrating a CNC machine into your workflow is essential for staying competitive in the industry.

Understanding the Benefits

When it comes to jewelry making, precision is key. With the SYIL CNC machine for jewelry, you can achieve unparalleled accuracy in crafting intricate designs and patterns. This means that your jewelry pieces will have flawless symmetry and perfect detailing, giving your customers the quality they deserve.

Increased Precision with SYIL CNC Machine

The SYIL CNC machine for jewelry is equipped with advanced technology that allows for incredibly precise cutting and shaping of metals and gemstones. This level of accuracy ensures that every piece of jewelry you create is consistent in its design and finish, setting you apart from competitors who rely on traditional methods.

Time and Cost Efficiency in Jewelry Manufacturing

By investing in a CNC machine for jewelry making, you can streamline your production processes and significantly reduce the time it takes to manufacture each piece. This not only increases your overall output but also cuts down on labor costs, ultimately leading to higher profitability for your business.

Superior Quality Output with CNC Machine

The use of a CNC machine guarantees a level of quality that is unmatched by traditional jewelry-making techniques. The precision and efficiency of the machine result in flawlessly crafted pieces that are free from human error, ensuring that every item you produce meets the highest standards of excellence.

Choosing the Right CNC Machine

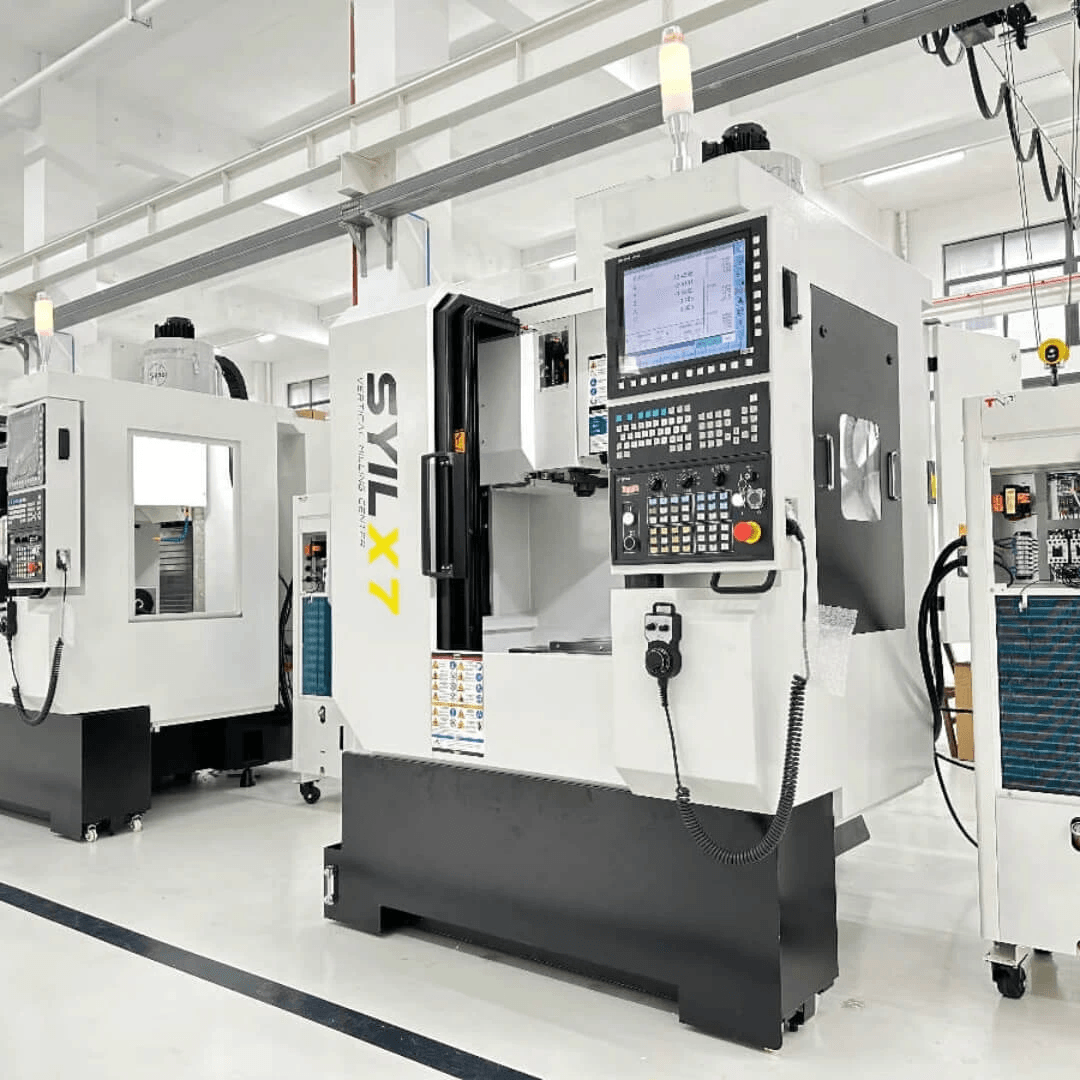

When it comes to choosing the right CNC machine for jewelry making, the SYIL X7 stands out as the ultimate choice. This state-of-the-art machine is specifically designed to meet the unique demands of jewelry production, offering unparalleled precision and efficiency. With its advanced features and capabilities, the SYIL X7 is a game-changer for businesses looking to elevate their jewelry manufacturing processes.

SYIL X7: The Ultimate CNC Machine for Jewelry

The SYIL X7 is tailor-made for jewelry making with its high-speed spindle and multi-axis capabilities, allowing for intricate and precise cuts on various materials such as gold, silver, and platinum. Its user-friendly interface and intuitive controls make it easy to operate, making it an ideal choice for both experienced craftsmen and beginners in the jewelry industry. With its compact size and versatile functionality, the SYIL X7 is a perfect fit for any jewelry workshop looking to enhance their production capabilities.

Key Features to Look for in a CNC Machine

When considering a CNC machine for jewelry making, it's essential to look for key features such as high spindle speed, multi-axis capability, automatic tool changers, and compatibility with CAD/CAM software. These features are crucial in ensuring precise cuts, efficient production processes, and seamless integration with existing design workflows. The SYIL X7 ticks all these boxes and more, making it an ideal investment for businesses seeking to elevate their jewelry manufacturing operations.

Maximizing Efficiency with the Right CNC Machine

By choosing the right CNC machine like the SYIL X7, businesses can maximize efficiency in their jewelry manufacturing processes. The advanced technology integrated into this machine allows for faster production cycles without compromising on quality or precision. This translates to reduced lead times, lower production costs, and ultimately higher profitability for jewelry businesses. With its superior performance and reliability, the SYIL X7 empowers businesses to take their craftsmanship to new heights while staying ahead of industry competition.

Integrating CNC Machine into Your Workflow

Now that you have decided to invest in a CNC machine for jewelry making, it's crucial to seamlessly integrate it into your existing workflow. The SYIL CNC machine for jewelry offers the perfect solution for streamlining production processes. With its precision and efficiency, you can significantly reduce lead times and increase output without compromising on quality.

Streamlining Production Processes with SYIL CNC Machine

The SYIL CNC machine for jewelry is designed to optimize your production processes, allowing you to create intricate designs with ease and accuracy. By automating repetitive tasks, this machine eliminates the margin of error and ensures consistent quality across all your jewelry pieces. This means you can meet customer demands faster and more efficiently than ever before.

Training and Skills Development for CNC Machine Operations

To fully leverage the capabilities of a CNC machine for jewelry making, it's essential to invest in training and skills development for your team. Understanding how to operate the machine effectively will not only enhance productivity but also empower your workforce with valuable skills that are relevant in today's manufacturing landscape.

Adapting Your Business for a CNC Machine-Driven Approach

Adapting your business operations to embrace a CNC machine-driven approach may require some adjustments, but the long-term benefits are well worth it. By incorporating this advanced technology into your workflow, you can position your business as an industry leader in jewelry manufacturing, offering superior quality and precision that sets you apart from traditional methods.

Challenges and Solutions

Overcoming Initial Investment Concerns

One of the main challenges in adopting a CNC machine for jewelry making is the initial investment required. However, the long-term benefits far outweigh the initial costs. By leveraging the precision and efficiency of a CNC machine, your business can significantly reduce material wastage and labor costs, ultimately leading to increased profitability.

In addition to the cost-saving benefits, investing in a CNC machine for jewelry making can also enhance the quality and precision of your products. With the ability to create intricate designs and patterns, you can set your jewelry apart from competitors and attract a wider customer base. This unique selling point can help justify the initial investment and position your business as a leader in the industry.

Addressing Maintenance and Support Needs for CNC Machine

Another challenge is ensuring proper maintenance and support for your jewelry CNC machine. To address this, it's essential to partner with a reputable supplier like SYIL who offers comprehensive training, technical support, and regular maintenance services. This ensures that your CNC machine operates at peak performance, minimizing downtime and maximizing productivity.

In addition to partnering with a reputable supplier for maintenance and support, it's important to stay updated on regulatory and compliance issues that may affect your jewelry CNC machine. This includes understanding industry standards, safety regulations, and any specific guidelines for jewelry manufacturing. By staying informed and proactive in addressing these issues, you can ensure that your CNC machine meets all necessary requirements and operates within legal boundaries.

Navigating Regulatory and Compliance Issues with CNC Machine

When integrating a CNC machine into your jewelry manufacturing process, it's crucial to navigate regulatory and compliance issues effectively. This includes adhering to safety standards, environmental regulations, and intellectual property rights. Working closely with industry experts and staying updated on relevant regulations will help ensure that your business operates within legal boundaries while harnessing the power of CNC technology.

In addition to safety standards, environmental regulations, and intellectual property rights, it's important to consider the impact of CNC machine use on labor laws and employee safety. Ensuring that your workers are properly trained in operating CNC equipment and that their working conditions adhere to industry standards will help mitigate potential legal issues. By proactively addressing these concerns, you can create a work environment that prioritizes both compliance and employee well-being.

Scaling Your Business with CNC Machine

In today's competitive jewelry market, meeting growing demand is crucial for business success. With the SYIL CNC machine for jewelry, you can effortlessly scale your production to keep up with increasing orders. This advanced technology allows you to efficiently produce high-quality jewelry pieces at a faster pace, ensuring that you can meet the needs of your expanding customer base.

Meeting Growing Demand with SYIL CNC Machine

The SYIL CNC machine for jewelry offers unmatched efficiency and precision, making it the perfect solution for handling a surge in demand. By leveraging this cutting-edge technology, you can significantly increase your production capacity without compromising on quality. Whether it's intricate designs or mass-produced items, the CNC machine empowers you to fulfill orders promptly and maintain customer satisfaction even during peak seasons.

Furthermore, the SYIL CNC machine for jewelry allows for an expanded product line and customization options. With its precise and efficient technology, you can easily create new designs and tailor existing ones to meet the specific needs of your customers. This flexibility not only helps you stay ahead of market trends but also enables you to offer unique pieces that set your brand apart from the competition.

Expanding Product Line and Customization Options

With a CNC machine for jewelry making, you have the flexibility to expand your product line and offer a wider range of customization options to your customers. This means that you can cater to diverse preferences and trends in the market, setting your business apart from competitors. Whether it's experimenting with new designs or fulfilling personalized requests, the CNC machine enables you to diversify your offerings while maintaining exceptional craftsmanship.

Future-Proofing Your Jewelry Business with CNC Machine

Investing in a CNC machine not only improves the efficiency and quality of your production process but also sets the stage for embracing new design trends and techniques. With the ability to create intricate and complex designs with precision, a CNC machine allows your jewelry business to explore new creative possibilities and cater to changing consumer tastes. By staying at the forefront of innovation, you can attract a wider customer base and establish your brand as a go-to destination for unique, cutting-edge jewelry pieces.

Conclusion

The SYIL X7 CNC machine for jewelry is the key to sustainable growth in the industry. With its precision, efficiency, and superior quality output, it's a game-changer for jewelry manufacturing. Embrace innovation and revolutionize your jewelry business with the SYIL X7 CNC machine.

Harnessing the Power of SYIL CNC Machine for Sustainable Growth

Investing in a CNC machine for jewelry is the smartest move you can make to ensure sustainable growth for your business. The precision and efficiency of the SYIL X7 will streamline your production processes, reduce costs, and increase productivity, setting you up for long-term success in the industry.

SYIL X7: Your Partner in Jewelry Manufacturing Success

Make jewelry with a CNC machine like the SYIL X7 and experience unparalleled success in jewelry manufacturing. This cutting-edge technology will elevate your production capabilities, allowing you to meet growing demand, expand your product line, and offer customization options that set you apart from competitors.

Embracing Innovation with CNC Machine for Jewelry

What is CNC machining for jewelry making? It's a game-changing innovation that will take your business to new heights. Embrace this technology and stay ahead of the curve in the jewelry industry. The SYIL X7 CNC machine is your partner in embracing innovation and staying at the forefront of jewelry manufacturing.