Introduction

Understanding CNC Machining for Stainless Steel

CNC machining stands for Computer Numerical Control machining, a process that automates the operation of machine tools through computer programming. When it comes to stainless steel, which is known for its strength and corrosion resistance, using the right CNC machine can significantly enhance productivity and accuracy. The question often arises: can you CNC stainless steel? Absolutely! With the right techniques and tools, stainless steel can be machined into precise components.

The Importance of Selecting the Right Machine

Choosing the right CNC machine is paramount in ensuring quality output and operational efficiency. Different machines come equipped with unique capabilities tailored for various applications; thus, knowing what are the 5 common types of CNC machines can help in making an informed decision. For instance, a desktop CNC milling machine may be ideal for small-scale projects while larger industrial applications might require more robust options.

Key Factors in Successful Machining

Successful machining involves several critical factors including material selection, tool choice, and operational parameters like speed and feed rates. Understanding how machinable is 316 stainless steel compared to other grades can influence these decisions significantly. Additionally, being aware of what materials cannot be CNC machined helps prevent costly mistakes during production.

Basics of CNC Machines

When diving into the world of CNC machining, it's crucial to understand the types of machines available and their specific capabilities. A CNC machine for stainless steel is designed to handle the unique challenges posed by this material. By familiarizing yourself with these basics, you can make informed decisions that optimize your machining processes.

What are the 5 common types of CNC machines?

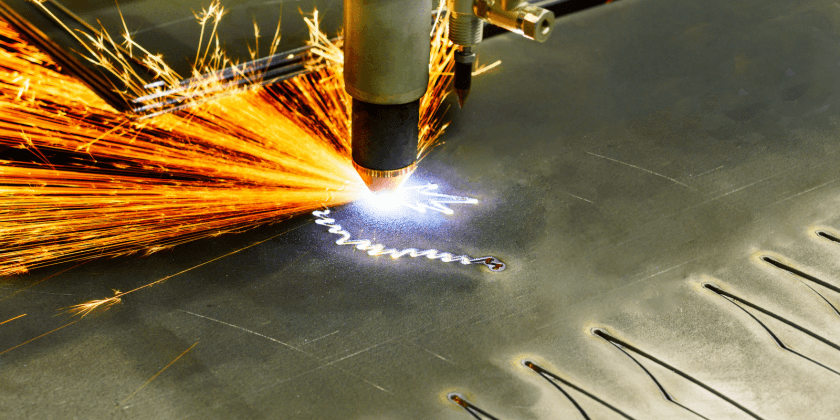

CNC machines come in various shapes and sizes, each tailored for different tasks. The five most common types include CNC milling machines, CNC lathes, CNC plasma cutters, CNC laser cutters, and CNC routers. Each type serves a distinct purpose: milling machines excel at shaping materials; lathes are perfect for cylindrical objects; plasma and laser cutters provide precision cutting; while routers are ideal for intricate designs.

Understanding what each machine does is essential when asking yourself, Can you CNC stainless steel? The answer is a resounding yes! However, not all machines are equally suited for this tough material. Knowing which type of CNC machine for stainless steel to use can significantly impact your project's success.

Exploring the capabilities of the SYIL CNC machine

The SYIL CNC machine stands out in the marketplace due to its versatility and robust features specifically designed for machining stainless steel. It combines high-speed performance with precision engineering, making it an excellent choice for both small-scale operations and larger manufacturing needs. With advanced software integration and user-friendly controls, even beginners can confidently tackle complex projects.

One significant advantage of using a SYIL machine is its ability to handle various stainless steel grades effectively—including 316 stainless steel—known for its toughness. This capability ensures that machinists can achieve high-quality finishes without compromising on efficiency or speed. If you're considering investing in equipment that specializes in machining stainless steel, this could be your go-to option.

How CNC machines operate on stainless steel

Machining stainless steel presents unique challenges due to its hardness and tendency to work-harden during cutting processes. Understanding how a CNC machine operates on this material is critical for achieving optimal results in your projects. Typically, these machines utilize specific cutting tools designed to withstand high temperatures and resist wear while maintaining sharpness.

The operation begins with selecting appropriate tooling—carbide inserts or high-speed steel tools often work best when tackling materials like 316 stainless steel due to their durability under stress. Once set up correctly, the programmed movements allow precise cuts with minimal human intervention—making it easier than ever to produce intricate parts from tough materials like stainless steel without breaking a sweat!

In summary, mastering how these machines function will help you avoid potential pitfalls associated with machining difficult materials while ensuring efficient production runs every time you engage your desktop CNC milling machine or any other type you choose.

Choosing Materials for CNC Machining

Can you CNC stainless steel?

Absolutely, you can CNC stainless steel! In fact, many industries rely on precision parts made from this durable metal. However, machining stainless steel does require specific considerations regarding tooling and techniques; after all, it's not just about having a cnc machine for stainless steel—it's knowing how to use it effectively.

Stainless steel comes in various grades, with 316 being among the most commonly machined types. So, how machinable is 316 stainless steel? While it offers excellent corrosion resistance and strength, it can be challenging to machine due to its toughness and work-hardening properties. Therefore, selecting appropriate cutting tools and speeds is crucial for success when using a desktop CNC milling machine or any other type of CNC equipment.

What materials cannot be CNC machined?

While many materials can be machined with a cnc machine for stainless steel, some simply don’t play well with these machines. For instance, extremely hard materials like ceramics or certain composites may lead to tool wear that outpaces production efficiency. Additionally, soft materials such as rubber or foam can result in poor dimensional accuracy when using traditional machining methods.

Other materials that are problematic include those that are too brittle or have inconsistent grain structures such as some plastics or wood types. These can cause chipping or splintering during machining processes, leading to subpar results that no one wants in their final product. Ultimately, understanding what materials cannot be CNC machined ensures you set realistic expectations before starting your project.

The impact of material selection on machining

Material selection has a profound impact on every phase of the machining process—from tool wear rates to cycle times and even part quality. Choosing an unsuitable material could lead to excessive downtime due to frequent tool changes or even catastrophic failures during production runs with your cnc machine for stainless steel.

Moreover, different materials respond differently under various cutting conditions; thus understanding this relationship helps optimize settings for better performance outcomes—whether you're working with 316 stainless steel or exploring other options available through what are the 5 common types of CNC machines?

In summary, selecting the right material not only enhances productivity but also directly affects costs associated with tooling and waste management during machining operations.

Techniques for Machining Stainless Steel

How machinable is 316 stainless steel?

316 stainless steel is moderately machinable compared to other metals. It presents challenges due to its toughness and work-hardening characteristics; however, with the proper CNC machine for stainless steel, these challenges can be overcome. Generally speaking, if you're using a high-quality CNC machine designed for this material type, you’ll find that 316 can be machined effectively with the right settings.

One important factor to consider when machining 316 stainless steel is cutting speed. Lower speeds are often necessary to avoid excessive heat buildup that can lead to tool wear or even failure. Additionally, using appropriate feed rates will help maintain tool integrity while ensuring precision in your cuts—essentially giving you a better chance at achieving those clean edges we all crave.

Recommended cutting tools for stainless steel

When it comes to selecting cutting tools for machining stainless steel like 316, carbide tools are typically your best bet. These tools offer excellent hardness and wear resistance necessary for tackling tougher materials without compromising performance. Additionally, coatings such as TiN (Titanium Nitride) or TiAlN (Titanium Aluminum Nitride) can significantly enhance tool life by reducing friction during the machining process.

For those considering a desktop CNC milling machine for smaller projects involving stainless steel, specialized end mills designed specifically for this metal are also available. These end mills can help create precise features while minimizing chatter—an issue that could ruin your work if not addressed properly. Remember that having the right tool at hand makes all the difference between a successful project and one that ends up in the scrap pile!

Best practices for achieving precise cuts

Achieving precise cuts when machining stainless steel requires careful attention to several factors: speed, feed rate, coolant use, and setup stability are all critical elements of success. Using flood coolant or misting systems helps dissipate heat generated during cutting—keeping both your material and tooling cool while maximizing efficiency in your operations.

Another best practice involves maintaining sharp tooling; dull blades will not only produce poor finishes but also increase wear on your CNC machine components over time! Regularly inspecting and replacing worn-out tools ensures smooth operation when working with tough materials like 316 stainless steel. Lastly, make sure your setup is stable; any vibration during machining could lead to inaccuracies or even damage parts of your CNC machine designed specifically for processing this resilient metal.

Desktop CNC Milling Machines

Desktop CNC milling machines are becoming increasingly popular for hobbyists and small businesses alike. These compact machines offer impressive capabilities, allowing users to create intricate designs without the need for a large workspace. With advancements in technology, a desktop CNC machine for stainless steel can now deliver precision that rivals traditional models.

Benefits of using a desktop CNC milling machine

One of the primary benefits of using a desktop CNC milling machine is its space efficiency. These machines are designed to fit comfortably in smaller workshops or even home garages, making them accessible to more users than ever before. Furthermore, they often come at a lower price point compared to larger CNC machines, which makes them an attractive option for those just starting out in machining stainless steel.

Another advantage is the ease of use; many desktop CNC machines feature user-friendly interfaces and software that simplify the design-to-production process. This means that even those who ask themselves, Can you CNC stainless steel? can quickly learn how to operate these machines effectively. Additionally, they provide an excellent platform for experimentation with various materials and designs without the significant investment typically required by larger machinery.

Ideal applications for small-scale projects

Desktop CNC milling machines are perfect for small-scale projects such as prototypes, custom parts, and artistic creations. Their ability to handle complex geometries makes them suitable for industries like jewelry design or model making where precision is key. Moreover, they can be used effectively in educational settings where students can gain hands-on experience with machining stainless steel.

Comparison with traditional CNC machines

When comparing desktop CNC milling machines with traditional ones, size and cost often stand out as major differentiators. Traditional CNC machines tend to occupy much larger footprints and come with higher price tags due to their advanced capabilities and robust construction aimed at industrial use. However, this doesn't mean that desktop models lack performance; many are surprisingly powerful when it comes to machining stainless steel.

Another key difference lies in the learning curve associated with each type of machine; while traditional models may require more technical knowledge and experience, desktop versions usually cater more towards beginners or casual users looking for simplicity without sacrificing quality results—especially when asking how machinable is 316 stainless steel? Ultimately, both types serve distinct purposes depending on user needs: from professional manufacturing environments down to home workshops eager for innovation.

Troubleshooting Common CNC Issues

CNC machining can be a precise and efficient way to work with stainless steel, but it’s not without its challenges. Understanding common issues that arise during the machining process is crucial for achieving optimal results. Whether you’re using a desktop CNC milling machine or a more robust industrial model, knowing how to troubleshoot problems can save both time and resources.

Identifying problems with CNC machining

When working with a CNC machine for stainless steel, several issues may arise that can hinder your project’s success. Common problems include tool wear, incorrect feed rates, and misalignment of the workpiece. If you find that your machined parts are not meeting specifications or if you're experiencing excessive vibration during operation, these are clear indicators that something is amiss in your setup.

Another sign of trouble is poor surface finish on the machined stainless steel components. This could stem from dull cutting tools or inappropriate speeds and feeds for the specific material being used. By closely monitoring these factors, you can quickly identify whether you're facing issues related to tooling or machine settings.

Lastly, if you notice unusual noises coming from your CNC machine while machining stainless steel, this could indicate mechanical problems such as loose components or inadequate lubrication. Such sounds should never be ignored; they often signal underlying issues that need immediate attention before they escalate into more significant failures.

Solutions for improving machining success

To enhance the performance of your CNC machine for stainless steel, start by ensuring that you are using the correct cutting tools designed specifically for this material type. High-speed steel (HSS) and carbide tools are commonly recommended due to their durability and ability to withstand high temperatures generated during machining processes like drilling or milling 316 stainless steel.

Adjusting feed rates and spindle speeds based on the specific grade of stainless steel being machined can also significantly impact results. For example, 316 stainless steel is known for its toughness; thus, slower feed rates might be necessary to achieve better precision when cutting through this alloy compared to others like aluminum.

Regular maintenance of your CNC equipment cannot be overstated either; keeping everything well-lubricated and aligned will minimize wear and tear on both the machine itself and your cutting tools. Additionally, investing in quality coolant systems helps manage heat build-up during operation—crucial when working with materials known for their hardness like stainless steel.

When to seek expert assistance

While many troubleshooting techniques can be tackled independently, there comes a time when seeking expert assistance becomes essential in maintaining efficiency in CNC machining processes—especially when dealing with complex projects involving materials like 316 stainless steel. If you've exhausted all troubleshooting methods yet still face persistent issues such as recurring tool breakage or inaccuracies in dimensions after multiple adjustments, it may be time to consult an experienced technician or machinist.

Furthermore, if you're unsure about whether certain materials cannot be CNC machined effectively due to their properties (like titanium alloys), professionals can provide valuable insights based on years of experience working with various grades of metals including those notoriously difficult ones!

Engaging experts not only helps resolve current challenges but also allows you access to advanced techniques and technologies that might elevate your projects beyond basic capabilities offered by standard desktop CNC milling machines alone.

Conclusion

In the world of CNC machining, particularly for stainless steel, the journey from concept to creation is a blend of precision, technology, and art. Maximizing efficiency in CNC machining is not just about having the right tools; it’s about understanding how to leverage these tools effectively. By selecting the appropriate cnc machine for stainless steel and employing best practices, manufacturers can significantly enhance productivity while maintaining high-quality outputs.

Maximizing Efficiency in CNC Machining

To truly maximize efficiency in machining stainless steel, one must consider various factors such as machine selection, tooling options, and operational techniques. Choosing the right cnc machine for stainless steel can lead to faster production times and reduced waste material. Additionally, understanding how machinable is 316 stainless steel compared to other grades can influence your choice of cutting strategies and tool materials.

Efficiency also hinges on proper maintenance and calibration of machines. Regularly checking alignment and tool sharpness ensures that each cut remains precise and reduces downtime due to errors or equipment failure. Ultimately, a well-maintained desktop CNC milling machine or larger industrial unit will contribute significantly to overall efficiency.

Innovations in CNC Technology

The landscape of CNC technology is rapidly evolving with innovations that enhance capabilities across various sectors. New advancements allow for smarter machines equipped with AI-driven analytics that monitor performance metrics in real-time—this means identifying potential issues before they escalate into costly problems. Additionally, innovations such as multi-axis machining have revolutionized how complex parts are fabricated from materials like stainless steel.

These technological strides also extend into software development that aids operators in optimizing designs specifically for machining processes. For instance, simulation software helps predict outcomes based on chosen parameters before any physical work begins—saving both time and resources when determining if you can CNC stainless steel effectively without encountering issues related to material limitations.

Future of CNC Machining for Stainless Steel

Looking ahead, the future of CNC machining for stainless steel appears bright with endless possibilities driven by continuous innovation and demand for precision engineering solutions. As industries increasingly rely on custom components made from durable materials like 316 stainless steel, the need for sophisticated cnc machines will only grow stronger. Moreover, as we explore what materials cannot be CNC machined efficiently or cost-effectively, manufacturers will refine their approaches to prioritize those that offer optimal results.

The integration of sustainable practices within this field will also shape its future trajectory—eco-friendly technologies aimed at reducing waste during production are becoming more prevalent. Furthermore, advancements in additive manufacturing techniques may complement traditional subtractive methods found in desktop CNC milling machines—leading us toward hybrid systems capable of producing intricate designs while minimizing material usage.

In conclusion, embracing these trends will empower businesses to remain competitive while meeting customer demands effectively within an ever-evolving market landscape focused on precision engineering solutions.