Introduction

In the world of electronics, precision is key, and a PCB drill machine plays a pivotal role in achieving that precision. Whether you're a hobbyist or a professional, understanding how to effectively use drilling routing machines can elevate your PCB fabrication process. However, even the most advanced equipment can lead to errors if not used properly; hence, recognizing common mistakes is crucial for successful operation.

Key Benefits of a PCB Drill Machine

A PCB drill machine offers several advantages that make it indispensable for circuit board production. First and foremost, it allows for highly accurate drilling of holes needed for components on the PCB board. Additionally, these machines enhance efficiency by enabling faster production times compared to manual methods—so you can say goodbye to tedious hand-drilling!

Importance of Proper Usage

Knowing how to make a PCB drill work effectively is essential for maximizing its benefits. Improper usage not only compromises the quality of your boards but can also lead to costly repairs or replacements down the line. By adhering to best practices and understanding what is a PCB drill in depth, you ensure that your projects run smoothly and yield impressive results.

Overview of Common Mistakes

While using a PCB drilling machine might seem straightforward, there are several pitfalls that users often encounter. For instance, many overlook the importance of selecting appropriate materials or fail to calibrate their machines correctly before starting the drilling process. By familiarizing yourself with these common mistakes—like asking Can you drill through a PCB board? without proper knowledge—you'll be better equipped to avoid them and achieve optimal performance from your equipment.

Understanding What is a PCB Drill?

When diving into the world of electronics, one often encounters the term PCB drill machine. But what exactly is it? A PCB drill is a specialized tool designed for creating precise holes in printed circuit boards (PCBs), which are essential for connecting electronic components. It’s not just any drilling device; it’s engineered to handle the unique materials and thicknesses found in PCBs, making it a vital asset for manufacturers and hobbyists alike.

The Basics of PCB Drilling

At its core, PCB drilling involves using a drill bit to create holes in the substrate material of a PCB. This process facilitates the placement of electronic components and allows for electrical connections between different layers of the board. So, how to make a PCB drill? You start with designing your circuit layout, then use the appropriate settings on your PCB drill machine to ensure accuracy and precision during drilling.

Understanding how to operate these machines effectively can significantly impact your project’s success. The right choice of speed, feed rate, and bit type can enhance hole quality while minimizing damage to the board itself. This makes mastering the basics of PCB drilling crucial whether you're an amateur tinkerer or a seasoned professional.

How it Differs from Other Machines

While there are various types of drilling routing machines available on the market, not all are suited for PCBs. Traditional drills may lack the precision required for intricate circuit designs or may not accommodate the fine materials used in PCBs without causing damage. What is a PCB machine if not one that excels in delivering high accuracy while ensuring minimal wear on both bits and boards?

Moreover, unlike general-purpose drills that might handle wood or metal with ease, PCB drill machines come equipped with features tailored specifically for electronic applications—like adjustable speeds and specialized bits designed for composite materials. This distinction makes them indispensable when working with complex layouts that demand attention to detail.

Common Misconceptions

Despite their importance, several common misconceptions about PCB drills persist among newcomers in electronics manufacturing. One such myth is that you can use any standard drill on PCBs; however, this can lead to poor results or even ruin your project entirely! Can you drill through a PCB board using traditional tools? Technically yes—but expect uneven holes and potential damage.

Another misconception revolves around maintenance; many believe that once you have set up your pcb drill machine, little else needs attention until something breaks down. In reality, regular checks are essential to ensure optimal performance over time—after all, prevention is better than cure! By debunking these myths, users can approach their projects with greater confidence and knowledge.

Choosing the Right PCB Drill Machine

Selecting the right PCB drill machine can make or break your PCB manufacturing process. With a myriad of options available, understanding what features and specifications matter most is crucial for achieving optimal results. Whether you’re a hobbyist or a professional, knowing how to make a PCB drill that suits your needs will enhance your productivity and precision.

Factors to Consider

When choosing a PCB drill machine, several factors come into play that can significantly affect your drilling efficiency. First and foremost is the type of materials you'll be working with; different machines excel with various substrates, so ensure compatibility with your chosen PCB material. Additionally, consider the drilling speed and accuracy; high-speed operations can save time but might compromise quality if not managed properly.

Another essential factor is the machine's capacity—how many layers can it handle? If you're planning to work on multilayer boards, investing in a more advanced model may be necessary. Finally, don't overlook customer support and warranty options from PCB drilling machine manufacturers; having reliable assistance can save you from future headaches.

Popular Models and Brands

The market offers an array of popular models and brands when it comes to drilling routing machines. Some notable names include the Excellon series known for its precision and reliability in high-volume production environments, as well as the LPKF ProtoMat series which caters specifically to prototyping needs. Each brand has unique features tailored for different applications, making it vital to assess which aligns best with your requirements.

For those looking for budget-friendly options without sacrificing quality, brands like SainSmart provide decent entry-level machines perfect for hobbyists or small-scale operations. On the other hand, if you're after industrial-grade performance, consider brands like Panasonic or Mitsubishi that are renowned for their robust designs suitable for heavy-duty tasks.

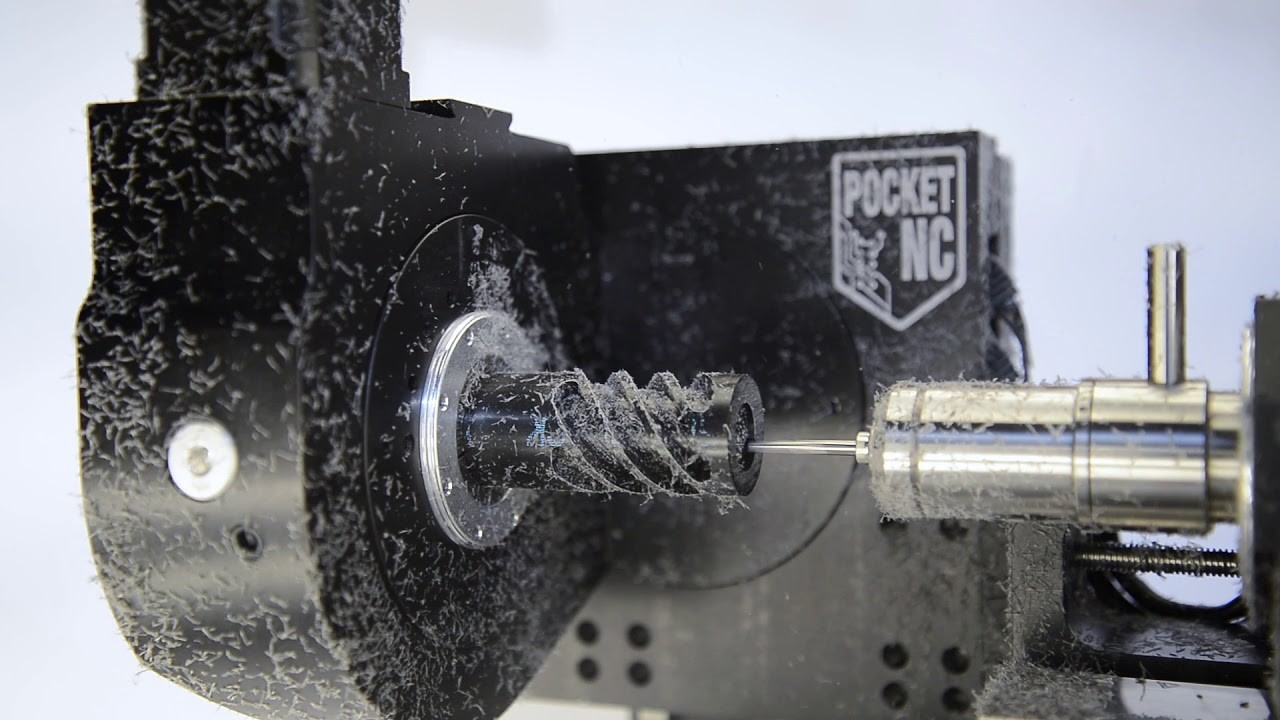

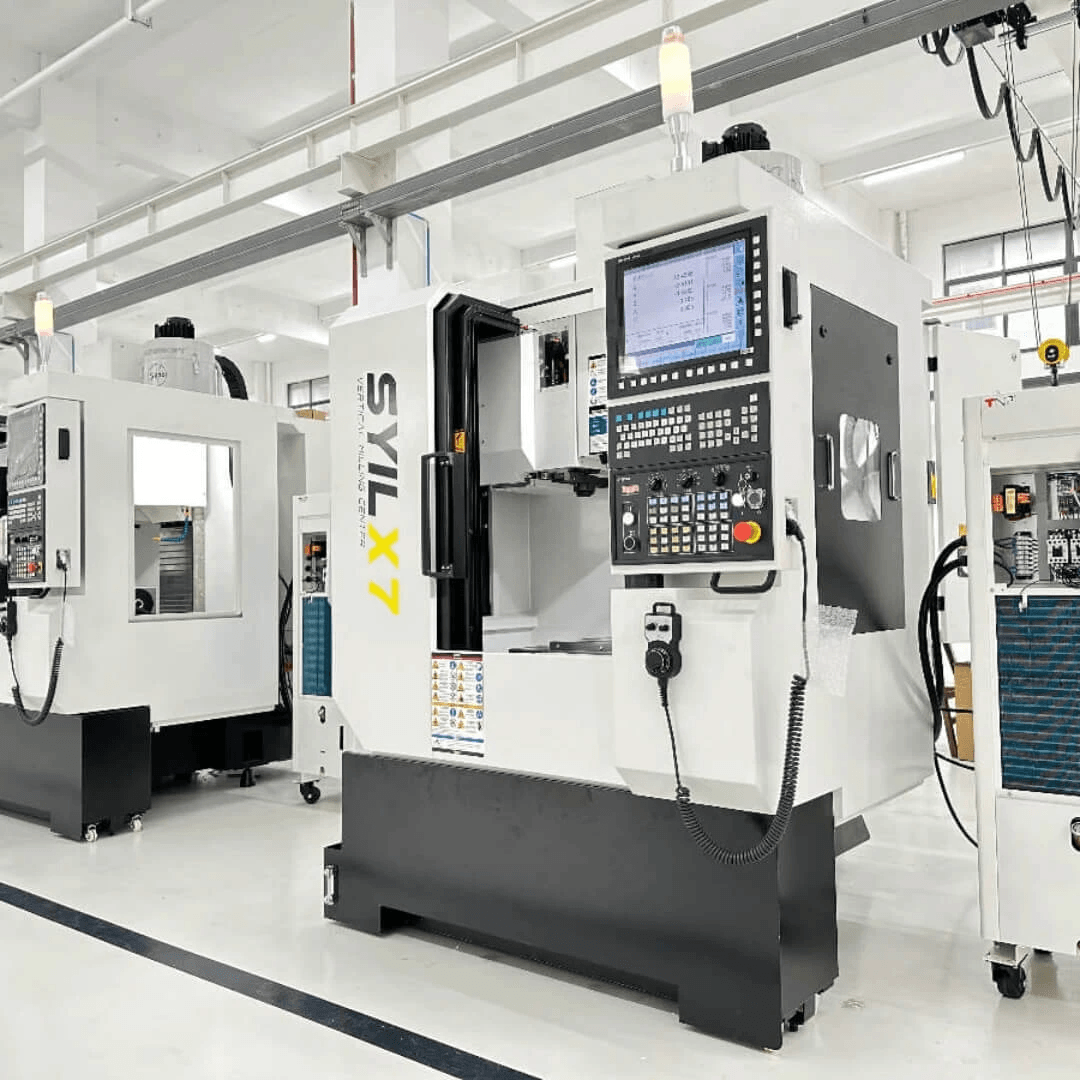

Overview of SYIL CNC Machines

SYIL CNC machines have carved out a niche in the realm of PCB drill machines due to their exceptional performance and user-friendly design. Known primarily for their versatility in both milling and drilling applications, SYIL offers models that cater specifically to various PCB manufacturing needs—be it single-layer boards or intricate multilayer designs. Their commitment to innovation ensures that users benefit from cutting-edge technology while maintaining ease of operation.

One standout feature of SYIL machines is their software integration capabilities which streamline the process of translating design files into actual PCBs. This not only reduces setup time but also minimizes errors during production—a common concern among those asking Can you drill through a PCB board? The combination of reliability and advanced functionality makes SYIL CNC machines an excellent choice for anyone serious about enhancing their PCB fabrication process.

Preparing the PCB for Drilling

Getting your PCB ready for drilling is a crucial step that can significantly impact the final product's quality. Proper preparation ensures that the drilling process runs smoothly and efficiently, reducing the likelihood of errors and wasted materials. So, before you fire up that PCB drill machine, let’s dive into what you need to do.

Essential Steps Before Drilling

First things first: make sure your design files are accurate and compatible with your PCB drill machine. You’ll want to double-check dimensions, hole sizes, and layer alignments to avoid any nasty surprises later on. Once you've confirmed everything is in order, it's time to securely mount your PCB onto the drilling platform—this prevents any movement during operation.

Next, clean the surface of your PCB thoroughly to eliminate dust or debris that could interfere with drilling accuracy. A clean workspace is essential because even a tiny speck can lead to misalignment or damage when you're using those precision drilling routing machines. Finally, ensure all necessary settings on your machine are correctly configured according to your specific project requirements before hitting that power button.

Importance of Material Selection

Choosing the right material for your PCB is paramount; it directly affects both performance and durability. Different materials have varying properties that can influence how well they handle heat during drilling or how easily they allow for precise hole placements. For instance, FR-4 is a popular choice due to its excellent electrical insulation properties and mechanical strength—ideal for most applications.

But wait! Not all PCBs are created equal; some might require specialized materials depending on their intended use or environmental conditions they'll face later on. By selecting high-quality materials tailored for your specific needs, you not only enhance performance but also extend the lifespan of both your PCB and the drill itself—saving you time and money down the line.

Tools Required for Preparation

Before diving into drilling with your trusty PCB drill machine, gather all necessary tools for an efficient setup process. You'll need clamps or fixtures to secure the board firmly in place—no one wants a runaway board while you're trying to make precision holes! Additionally, having measuring tools like calipers handy will help ensure everything aligns perfectly before starting.

Don't forget about cleaning supplies such as lint-free cloths or brushes; these will keep surfaces pristine and free from contaminants that could jeopardize results during drilling operations. Lastly, having a reliable software program at hand can assist in verifying designs against specifications—making sure you know exactly what needs doing before you start asking yourself What is a PCB drill?

Operating the PCB Drilling Machine Safely

Operating a PCB drill machine requires attention and care to ensure both safety and efficiency. The precision involved in drilling through a PCB board can lead to accidents if proper protocols are not followed. Understanding how to make a PCB drill safely can significantly enhance your experience with drilling routing machines.

Safety Protocols to Follow

When working with a PCB drilling machine, it's crucial to wear appropriate personal protective equipment (PPE), such as safety goggles and gloves, to safeguard against flying debris and sharp tools. Additionally, ensure that the workspace is well-ventilated and free of clutter, minimizing the risk of accidents or damage to the equipment. Always consult the user manual for specific safety guidelines related to your particular model, as different manufacturers may have unique recommendations.

Common Operational Errors

One of the most common operational errors when using a PCB drill machine is incorrect setup of the drilling parameters, which can lead to improper hole sizes or misalignment on the board. Another frequent mistake is neglecting to check tool wear; dull bits can cause excessive heat buildup, damaging both the board and the drill itself. Additionally, failing to secure the PCB properly during drilling can result in shifting or movement, which compromises accuracy—definitely not what you want when you're asking yourself: Can you drill through a PCB board?

How to Avoid Damage

To avoid damage while operating your PCB drilling machine, start by double-checking all settings before beginning your work; this includes speed settings and depth adjustments tailored for your specific material type. Regular maintenance checks on both your machine and tools will help identify any wear that could lead to mishaps during operation—after all, prevention is better than cure! Lastly, always handle PCBs gently; they are delicate components that require careful treatment throughout their lifecycle from preparation through drilling.

Maintenance Tips for PCB Drill Machines

Maintaining your PCB drill machine is crucial for ensuring its longevity and optimal performance. Just like any other piece of machinery, regular upkeep can prevent costly repairs and downtime. In this section, we’ll explore routine checks, signs that your machine might need repair, and what manufacturers recommend to keep your equipment in top shape.

Routine Checks and Maintenance

Routine checks are essential to keep your PCB drilling machine running smoothly. Start by inspecting the drill bits regularly; dull or damaged bits can lead to poor drilling quality and even damage the PCB board itself. Additionally, it’s important to clean the machine after each use to remove debris and dust that can interfere with its operation.

Lubrication is another critical aspect of maintenance for Drilling Routing machines. Ensure that moving parts are adequately lubricated according to the manufacturer’s specifications, which helps reduce friction and wear over time. Finally, make a habit of checking electrical connections periodically; loose wires can cause operational issues or even pose safety risks.

Signs Your Machine Needs Repair

Recognizing when your PCB drill machine needs repair is vital in preventing further damage or inefficiency. One clear sign is unusual noises during operation—grinding or rattling sounds often indicate mechanical issues that require immediate attention. Another red flag is inconsistent drilling results; if you notice variations in hole sizes or depths, it may be time for a thorough inspection.

Additionally, monitor the performance of your drilling process closely; if you find yourself having to adjust settings frequently for optimal results, this could signal underlying problems with the machine's calibration or components. Lastly, take note of any error messages displayed on digital interfaces—these alerts often provide crucial information about what might be malfunctioning within the system.

Manufacturer Recommendations

When it comes to maintaining your PCB drill machine effectively, following manufacturer recommendations can save you a lot of headaches down the line. Most manufacturers provide detailed guidelines on routine maintenance schedules tailored specifically for their machines—be sure to consult these documents regularly. They may also suggest specific cleaning agents or lubricants that are compatible with your equipment.

Furthermore, many PCB Drilling Machine manufacturers recommend scheduling professional servicing at least once a year if you’re using the equipment heavily—this ensures that any potential issues are caught early before they escalate into major repairs. Lastly, don't overlook software updates; many modern machines rely on firmware that requires periodic updates for optimal performance.

Conclusion

In wrapping up our exploration of PCB drill machines, it's clear that understanding their operation and maintenance is crucial for achieving optimal results. By avoiding common mistakes and implementing effective techniques, you can significantly enhance your PCB drilling experience. Armed with the right knowledge, you’ll be well on your way to mastering the art of PCB drilling.

Avoiding Common PCB Drilling Mistakes

One of the most prevalent errors when using a PCB drill machine is neglecting proper setup and calibration. Without taking the time to ensure that all settings are accurate, you risk damaging both the machine and your workpiece. Additionally, many users overlook the importance of selecting appropriate drill bits for their specific needs, which can lead to frustrating outcomes and wasted materials.

Another mistake often made is rushing through the drilling process without adequate preparation or safety measures in place. This not only compromises the quality of your work but also poses risks to personal safety. By being mindful of these pitfalls—such as improper material selection or inadequate maintenance—you can avoid setbacks and keep your projects on track.

Maximizing Efficiency with Proper Techniques

To truly harness the capabilities of a PCB drill machine, employing proper techniques is essential. For instance, understanding how to make a PCB drill involves more than just pressing buttons; it requires knowledge about feed rates, spindle speeds, and tool selection tailored to specific materials. These factors play a significant role in ensuring that you achieve clean holes without unnecessary wear on your equipment.

Additionally, familiarizing yourself with various types of drilling routing machines can help optimize your workflow by allowing you to choose tools best suited for different tasks. Implementing systematic approaches—like organizing your workspace and maintaining an efficient schedule—can further enhance productivity while minimizing errors during operations like “Can you drill through a PCB board?” Yes! But only if done correctly!

Resources for Continuous Learning

Continuous learning is vital in keeping up with advancements in technology related to PCB drilling machines and methods. Engaging with reputable resources such as industry publications or online forums can provide insights into best practices from seasoned professionals in this field. Furthermore, exploring content from leading PCB drilling machine manufacturers will enable you to stay informed about new products or techniques that could elevate your projects.

Don’t forget about hands-on workshops or webinars offered by experts who specialize in what is a PCB drill? They often share invaluable tips on how to make a PCB drill effectively while addressing common challenges faced by users today. Embrace every opportunity for growth; after all, mastering this craft not only enhances efficiency but also opens doors for innovative designs!