Introduction

In the world of metal fabrication, understanding CNC (Computer Numerical Control) metal cutting is crucial for businesses aiming to enhance their production capabilities. CNC machines have revolutionized the way we approach tasks like shaping and cutting materials, particularly steel. With the rise of steel cutting CNC machines, manufacturers can achieve levels of precision and efficiency previously deemed unattainable.

Understanding CNC Metal Cutting

What is CNC machine metal cutting? At its core, it refers to the process where a computer-controlled machine cuts and shapes metal with remarkable accuracy. This technology allows operators to create intricate designs while minimizing human error, making it an invaluable tool in modern fabrication settings.

The Rise of Steel Cutting CNC Machines

Can a CNC machine cut steel? Absolutely! The evolution of steel cutting CNC machines has made it possible to handle tougher materials that require more robust solutions. As industries continue to demand higher quality and faster production times, these machines have become essential for meeting those needs.

Efficiency in Modern Fabrication

Efficiency is key in any manufacturing process, especially when considering factors such as cost-effectiveness and time management. How much does CNC cutting cost per hour? While costs can vary based on several factors, investing in a steel cutting CNC machine often results in lower material wastage and increased output speed compared to traditional methods. By embracing this technology, companies can stay competitive while optimizing their operations.

What is a Steel Cutting CNC Machine?

A steel cutting CNC machine is an advanced tool designed specifically for precision cutting of steel materials. By leveraging computer numerical control (CNC) technology, these machines automate the cutting process, ensuring high levels of accuracy and efficiency. This innovation has revolutionized how industries approach metal fabrication, making it possible to achieve intricate designs with minimal human intervention.

Definition and Functionality

At its core, a steel cutting CNC machine utilizes programmed commands to control the movement of tools that cut through steel. This means that operators can input specific measurements and designs into the system, allowing the machine to execute complex cuts with remarkable precision. Essentially, what is CNC machine metal cutting? It's a method that combines technology with craftsmanship to produce high-quality components from steel sheets or blocks.

How CNC Machines Cut Steel

So, how do these machines actually cut steel? They employ various methods such as plasma cutting, laser cutting, and waterjet cutting to slice through metal with ease. The choice of method often depends on the thickness of the material and the desired finish; for example, a sheet metal CNC machine might use laser technology for clean edges on thinner sheets while heavier materials may require plasma cutting.

Comparison with Traditional Cutting Methods

When comparing a steel cutting CNC machine with traditional methods like manual sawing or torch cutting, it's clear that CNC machines offer significant advantages. Traditional methods often involve more labor-intensive processes leading to inconsistent results and higher waste levels. In contrast, CNCs for metal fabrication provide consistent quality across multiple pieces while reducing material costs due to their precise cuts—what’s not to love about that?

Advantages of Using Steel Cutting CNC Machines

Steel cutting CNC machines have revolutionized the metal fabrication industry, offering numerous benefits that traditional cutting methods simply cannot match. These advanced machines enhance productivity and quality, making them indispensable in modern manufacturing. From precision to cost savings, let's delve into the advantages that make steel cutting CNC machines a top choice for metalworkers everywhere.

Precision and Accuracy in Cutting

One of the standout features of a steel cutting CNC machine is its ability to deliver unparalleled precision and accuracy in cutting. Unlike manual methods, which can be prone to human error, these machines operate based on programmed designs, ensuring consistent results every time. This level of accuracy is crucial when fabricating components that require tight tolerances; after all, who wants to deal with misaligned parts?

When asking Can a CNC machine cut steel? the answer is a resounding yes! These machines are engineered specifically for such tasks, utilizing advanced technology like laser or plasma cutting to achieve clean edges and precise dimensions. As a result, manufacturers can produce high-quality products that meet strict specifications without compromising on quality.

Reduced Waste and Material Costs

Another significant advantage of using steel cutting CNC machines is their ability to minimize waste and lower material costs. Traditional cutting methods often lead to excess scrap material due to inaccuracies or inefficient layouts; however, CNC technology optimizes the use of raw materials by calculating the most efficient way to cut pieces from sheets or blocks. This not only saves money but also contributes positively to environmental sustainability by reducing waste.

In addition, with fewer errors in production comes less need for rework or replacement parts—an added bonus for any business looking at their bottom line! The question What are the 5 common types of CNC machines? highlights that while there are various options available (like routers and mills), those designed for sheet metal CNC machine applications excel at maximizing material efficiency during steel fabrication processes.

Increased Production Speed

The speed at which steel cutting CNC machines operate can significantly boost overall production rates compared to traditional methods. With automated processes taking over tasks that once required skilled laborers' time and effort, manufacturers can quickly turn around projects without sacrificing quality or precision. This increased efficiency means businesses can fulfill orders faster than ever before.

Moreover, as advancements continue in CNC technology—such as improved software algorithms and faster motors—the potential for even greater production speed becomes evident. When considering how much does CNC cutting cost per hour? It's essential to factor in not just labor costs but also how much more product you can produce with these efficient systems at your disposal.

In conclusion, investing in a steel cutting CNC machine offers an array of advantages: enhanced precision, reduced waste leading to lower costs, and increased production speed that keeps you ahead of competitors in today's fast-paced market environment.

Exploring Common Types of CNC Machines

Overview of Five Common CNC Machines

1. **CNC Milling Machines**: These versatile machines use rotary cutters to remove material from a workpiece and can handle complex shapes with precision. They are often used for creating intricate components in steel cutting.

2. **CNC Lathes**: Ideal for cylindrical parts, these machines rotate the workpiece against a stationary cutting tool, allowing for smooth finishes and precise cuts in steel.

3. **CNC Plasma Cutters**: Perfect for cutting through thick sheets of metal, these machines utilize high-velocity plasma to slice through steel quickly and effectively.

4. **CNC Laser Cutters**: Employing focused laser beams, these machines deliver high precision when cutting thin sheets of steel, making them popular in industries requiring detailed designs.

5. **Sheet Metal CNC Machines**: Specifically designed for working with sheet metal, these machines can perform various operations like bending and punching while ensuring clean cuts in steel sheets.

These five common types of CNC machines demonstrate the versatility available in modern fabrication processes, particularly when it comes to steel cutting CNC machines.

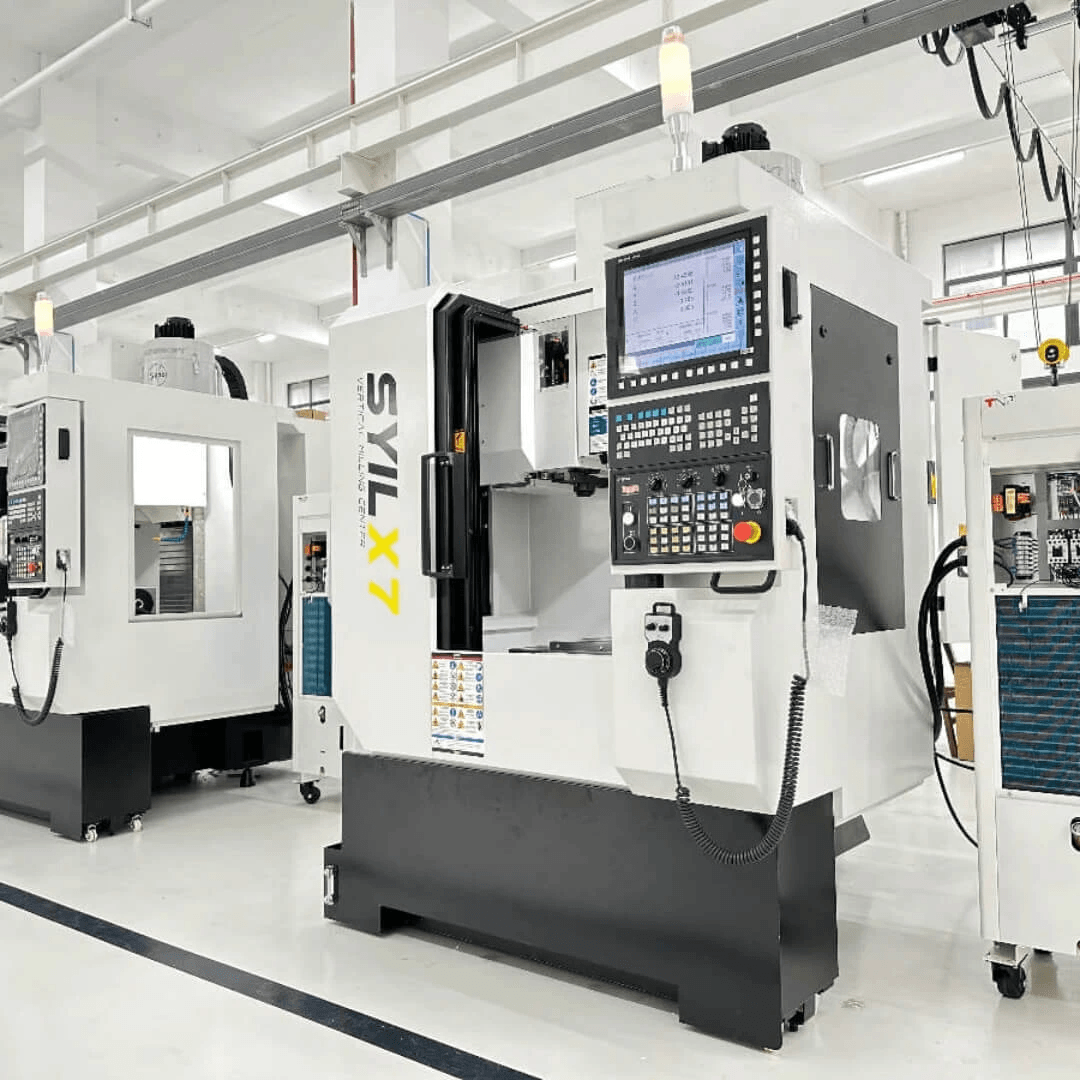

Special Features of a SYIL CNC Machine

The SYIL brand has made waves in the realm of CNC technology due to its exceptional machinery tailored for precision metal work. One standout feature is its user-friendly interface that simplifies programming even for those new to CNC machining—no need to be an engineer! Additionally, SYIL's models often come equipped with advanced features such as high-speed spindles and robust construction that enhance performance during steel cutting operations.

What sets SYIL apart is also its commitment to adaptability; their machines can be configured for different tasks beyond just traditional milling or turning operations—making them perfect candidates if you're asking yourself Can a CNC machine cut steel? The answer is an emphatic yes! With SYIL's innovative designs and capabilities, you can achieve impeccable results whether you're tackling thick plates or delicate components.

Applications in Steel Cutting

Steel cutting applications are vast and varied across many industries—from automotive manufacturing to aerospace engineering—and using a specialized steel cutting CNC machine can significantly improve efficiency and output quality. For instance, automotive manufacturers rely on these machines for producing intricate parts that require tight tolerances and durability; after all, safety on the road depends on it!

In construction projects where structural integrity is paramount, sheet metal CNC machines play an essential role by ensuring accurate cuts that align perfectly with design specifications—no one wants wobbly beams! Moreover, businesses looking into cost considerations often find themselves asking how much does CNC cutting cost per hour? The answer varies based on factors like machine type and complexity but generally leads toward significant savings over manual methods due to reduced waste and faster production times.

Cost Considerations for CNC Cutting

When it comes to CNC cutting, especially with a steel cutting CNC machine, understanding the financial implications is crucial. The costs associated with operating these machines can vary widely based on several factors, including machine type and operational efficiency. So, how much does CNC cutting cost per hour? Let's dive into the specifics.

Understanding Hourly CNC Cutting Costs

Hourly costs for operating a steel cutting CNC machine can range significantly depending on various elements such as the complexity of the job and the type of machine used. Typically, you might find that hourly rates can vary from $75 to over $150 per hour, depending on whether you're utilizing a high-end model or a more basic sheet metal CNC machine. Additionally, maintenance and tooling costs play a significant role in determining overall expenses; keeping your equipment in top shape is essential for consistent performance.

Factors Affecting Costs in Metal Fabrication

Several factors influence costs in metal fabrication beyond just the hourly rate of using a steel cutting CNC machine. These include material types, thicknesses, and quantities required for production; all of which can affect both time and resource allocation during manufacturing. Moreover, labor costs associated with programming and operating these machines must be considered since skilled operators are often necessary to maximize efficiency while minimizing errors.

Cost-Effectiveness of CNC vs. Manual Cutting

When comparing cost-effectiveness between CNCs for metal fabrication and traditional manual methods, it becomes clear that CNC machines tend to offer better long-term savings despite higher initial investments. While manual cutting may seem cheaper upfront, it often results in increased waste and longer lead times due to human error—factors that can significantly inflate overall project costs over time. Ultimately, investing in advanced technology like steel cutting CNC machines not only enhances precision but also boosts productivity—making them an attractive option for modern fabrication needs.

Innovations in CNC Technology

The world of CNC technology is ever-evolving, with innovations that continually enhance the capabilities and efficiency of machines, particularly for steel cutting. Steel cutting CNC machines are at the forefront of this revolution, integrating advanced features that streamline operations and improve precision. These advancements not only address traditional challenges in metal fabrication but also pave the way for future developments.

Recent Advancements in CNC Machines

Recent advancements in CNC machines have transformed how manufacturers approach metal cutting, especially with steel cutting CNC machines. Enhanced software algorithms now allow for more sophisticated programming, enabling operators to execute complex cuts with ease and accuracy. Additionally, the integration of automation technologies has led to increased productivity; machines can now operate continuously with minimal human intervention while maintaining high levels of precision.

Moreover, improvements in laser and plasma cutting technologies have made it possible to cut thicker steel plates efficiently. Many manufacturers are asking, Can a CNC machine cut steel? The answer is a resounding yes—modern machines can handle various thicknesses and types of steel with remarkable finesse. This evolution has significantly reduced time spent on setup and execution compared to traditional methods.

The Future of Steel Cutting Technology

Looking ahead, the future of steel cutting technology appears bright as innovations continue to emerge at a rapid pace. One exciting development is the potential integration of artificial intelligence (AI) into steel cutting CNC machines; AI can optimize cutting paths based on real-time data analysis, leading to even greater efficiency and cost savings. Furthermore, advancements in materials science may lead to lighter yet stronger materials being used in machine construction, enhancing durability while reducing wear over time.

As industries increasingly adopt Industry 4.0 principles—where smart manufacturing meets interconnected systems—the role of CNCs for metal fabrication will expand significantly. With predictive maintenance becoming more common through IoT-enabled devices, businesses can minimize downtime by anticipating failures before they occur. This proactive approach could redefine operational strategies across various sectors reliant on precise metalwork.

CNCs for Metal Fabrication: Trends to Watch

Several key trends are shaping the landscape for CNCs used in metal fabrication today that warrant attention from industry professionals and enthusiasts alike. First among these is the increasing demand for customized solutions; businesses are seeking versatile sheet metal CNC machines capable of producing bespoke parts without extensive retooling or delays. This flexibility not only meets customer needs but also enhances overall competitiveness.

Another trend is sustainability; manufacturers are prioritizing eco-friendly practices by investing in energy-efficient machinery that reduces waste during production processes—an essential consideration when discussing how much does CNC cutting cost per hour? By minimizing material waste alongside energy consumption, companies can achieve both environmental benefits and cost savings simultaneously.

Lastly, there’s a growing emphasis on training programs focused on upskilling operators to keep pace with technological advancements within their facilities—ensuring that workers understand what is needed when operating modern steel cutting CNC machines effectively becomes critical as these tools evolve further.

Conclusion

In conclusion, the evolution of the steel cutting CNC machine has revolutionized production efficiency in various industries. By leveraging advanced technology, manufacturers can achieve unprecedented levels of precision and speed, ultimately leading to better quality products and reduced operational costs. This transformation underscores the importance of embracing CNCs for metal fabrication to remain competitive in today’s fast-paced market.

The Impact of Efficiency on Production

The impact of efficiency on production cannot be overstated; it directly correlates with profitability and market responsiveness. With a steel cutting CNC machine, businesses can streamline their processes, significantly reducing lead times while maintaining high-quality standards. In essence, improved efficiency translates into more output with less waste, making it a game-changer for manufacturers.

Choosing the Right Steel Cutting CNC Machine

Understanding what machine is used to cut steel effectively involves evaluating capabilities like size, power requirements, and software compatibility. Additionally, knowing what are the 5 common types of CNC machines helps businesses make informed decisions that align with their production goals.

Keeping Up with CNC Innovations

Staying current with advancements in technology is crucial for any business relying on steel cutting CNC machines. Innovations in this field promise enhanced features that improve functionality and user experience—think smarter software and more efficient cutting techniques! By keeping up with these trends and understanding how much does CNC cutting cost per hour, companies can better allocate resources and plan future investments wisely.