Introduction

In the world of manufacturing and prototyping, the CNC machine for steel has become a game changer. With its precision and versatility, CNC milling opens up a realm of possibilities for both hobbyists and professionals alike. Whether you're asking yourself, Can you CNC machine steel? or wondering about the best practices in metalworking, understanding the power of CNC milling is essential.

Discover the Power of CNC Milling

CNC, or Computer Numerical Control, revolutionizes how we approach machining tasks by automating processes that were once manual and time-consuming. This technology allows for intricate designs and consistent quality that would be difficult to achieve otherwise. With a small CNC machine for steel at your disposal, you can create everything from custom parts to artistic sculptures with remarkable accuracy.

Why Choose CNC Machines for Steel?

Steel is one of the most widely used materials in manufacturing due to its strength and durability; thus, it's vital to have a reliable metal CNC machine for home use or shop environments. The ability to work with this tough material requires specialized machines designed specifically for steel processing. So when considering what is CNC in steel, it's clear that having a robust setup can lead to better outcomes in your projects.

Key Features to Look For

When selecting the best CNC machine for metal work, there are several key features you should consider: spindle speed and power are critical factors that influence cutting efficiency; build quality ensures stability during operation; and software compatibility allows seamless integration with design programs you may already use. Additionally, knowing what is the best steel for CNC machines can guide your choice towards models that excel at handling specific types of metals efficiently. Understanding these elements will empower you to make an informed decision tailored to your unique needs.

Types of Desktop CNC Milling Machines

When diving into the world of CNC milling, understanding the different types available is crucial, especially if you're focusing on a cnc machine for steel. Each type has its unique features and capabilities that cater to various needs, whether you’re a hobbyist or running a small shop. This section will explore high-precision models, compact options, and how entry-level machines compare to their advanced counterparts.

High-Precision Models Explained

High-precision CNC machines are specifically designed for intricate tasks where accuracy is paramount. When asking Can you CNC machine steel? the answer is a resounding yes—especially with these models that can handle tough materials like steel with ease. These machines often feature advanced spindle speeds and robust build quality that ensure consistent results in metal CNC machine applications.

In the realm of high-precision milling, you'll find machines equipped with top-notch software compatibility that allows seamless integration with design programs. This makes them ideal for users who demand perfection in their projects, whether they are creating prototypes or custom parts. If you're searching for what is the best steel for CNC machine work, these models can tackle various grades of steel without compromising on quality.

Benefits of Compact CNC Machines

Compact CNC machines offer an enticing option for those limited by space but still eager to engage in metalwork at home or in small shops. These small CNC machines for steel provide versatility without sacrificing performance; they can manage everything from simple cuts to complex designs efficiently. Their size makes them perfect for hobbyists who may not have access to larger industrial equipment yet still want to explore what is CNC in steel processing.

Another advantage lies in their affordability; compact models often come at lower price points compared to larger counterparts while still delivering impressive results. Many users find that these machines are not only space-efficient but also energy-efficient, making them suitable for home workshops where power consumption matters. With advancements in technology, compact units have become increasingly capable—proving that good things indeed come in small packages.

Comparing Entry-Level and Advanced Options

In contrast, advanced options provide enhanced capabilities such as higher spindle speeds and greater rigidity—essential factors when working with harder metals like stainless or tool steels. As you weigh your choices among the five common types of CNC machines available today, consider how each aligns with your goals and intended use cases within metalworking projects at home or professionally.

Ultimately, whether you're leaning towards a compact model or an advanced powerhouse depends on your specific requirements and budget constraints as you embark on this exciting journey into the world of desktop milling!

Top Desktop CNC Milling Machines for Steel

When it comes to choosing a CNC machine for steel, the options can be overwhelming. Fortunately, several standout models cater specifically to metalworking enthusiasts and professionals alike. Here, we’ll explore some of the top choices that combine versatility, power, and precision in the realm of CNC milling.

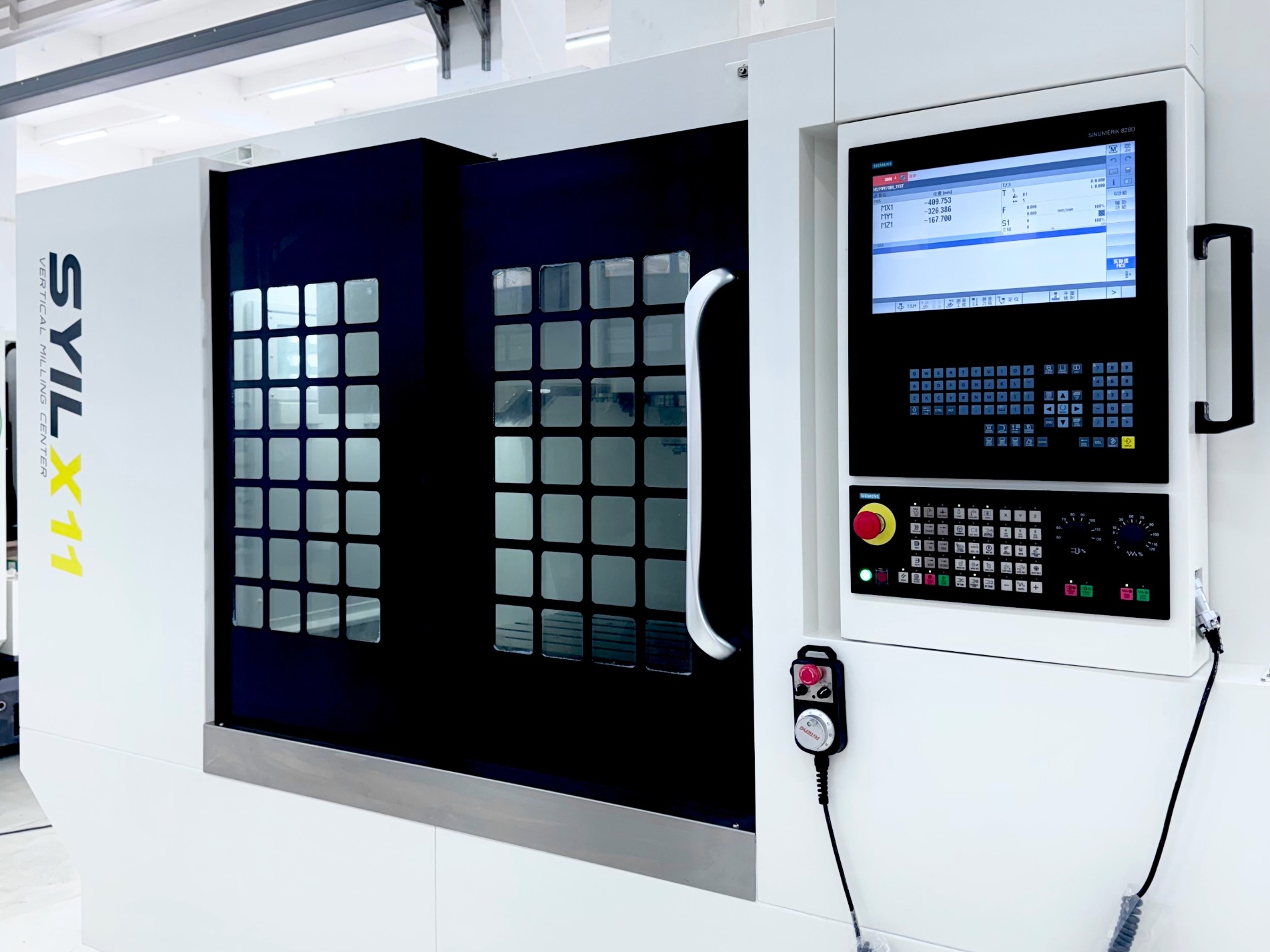

SYIL X5: Versatile and Reliable

The SYIL X5 is a compact yet powerful small CNC machine for steel that has garnered attention for its versatility. With a robust build quality and high spindle speeds, this machine can tackle various steel types effortlessly. Whether you're asking yourself, Can you CNC machine steel? or looking to create intricate designs, the SYIL X5 delivers reliable performance every time.

This model features an intuitive interface that makes it easy to operate even for beginners while still offering advanced capabilities for seasoned machinists. The SYIL X5 is designed with rigidity in mind, ensuring minimal vibrations during operation—a crucial aspect when working with tougher materials like steel. For those wondering what is CNC in steel machining, this machine exemplifies efficiency and precision in every cut.

Tormach 440: Perfect for Small Shops

If you're operating from a small workshop but still want the best CNC machine for metal work, look no further than the Tormach 440. This desktop powerhouse offers an impressive balance of size and capability tailored specifically to home-based machinists or small businesses focusing on metal projects. Its ability to handle various metals makes it an ideal choice if you’re exploring what are the 5 common types of CNC machines.

The Tormach 440 boasts user-friendly software compatibility that allows you to design and execute complex projects with ease—perfectly suited for those who need a reliable metal CNC machine for home use. Plus, its compact design means it won't take up too much space while still providing ample work area for your projects involving steel materials. With this model in your arsenal, you'll find yourself asking less about what is the best steel for CNC machines because it can handle them all!

R8 Spindle Machines: A Game Changer

R8 spindle machines have revolutionized how we approach milling tasks involving metals like steel; these machines offer exceptional versatility without sacrificing performance or quality. Known as one of the best options available today, they excel at both precision work and heavy-duty tasks alike—making them a favorite among professionals seeking a dependable cnc machine for steel applications.

One key advantage of R8 spindle machines is their compatibility with various tooling options; whether you're working on detailed engravings or hefty cuts through thick plates of steel, these machines adapt seamlessly to your needs. If you're contemplating investing in a small CNC machine for steel projects at home or in your shop environment, look no further than R8 spindles—they're truly game changers in modern machining practices!

Essential Features for CNC Machines in Steel

When venturing into the world of CNC machining, especially for steel, understanding essential features can make all the difference. The right CNC machine for steel will not only enhance your productivity but also ensure precision and quality in your projects. Let’s delve into three critical aspects: spindle speed and power, build quality and rigidity, and software compatibility.

Spindle Speed and Power

One of the first questions that arise is, Can you CNC machine steel? The answer lies significantly in the spindle speed and power of your chosen machine. A high spindle speed allows for faster cutting rates while maintaining precision, which is crucial when working with tougher materials like steel. Typically, a powerful spindle can handle various operations from milling to drilling with ease, making it an essential feature in any metal CNC machine for home use.

Moreover, when considering what is the best steel for a CNC machine, remember that different types require different speeds and feed rates to achieve optimal results. For instance, harder steels might necessitate slower speeds but higher torque to prevent tool wear. Thus, selecting a small CNC machine for steel with adjustable spindle settings can provide versatility across various project needs.

Build Quality and Rigidity

The build quality of a CNC machine directly impacts its performance when machining steel. A robust frame ensures stability during operation; any vibrations can lead to inaccuracies or poor finishes on your workpiece—something no one wants after spending hours on a project! Therefore, look for machines made from high-quality materials that offer excellent rigidity.

When we talk about rigidity in relation to What are the 5 common types of CNC machines?, it's evident that milling machines benefit immensely from solid construction. This feature helps maintain precision even under heavy loads or during prolonged use—essential factors when dealing with metal workpieces that require meticulous attention to detail. Investing in a well-built metal CNC machine means fewer headaches down the line.

Software Compatibility

In today's digital age, software compatibility cannot be overlooked when selecting your ideal CNC machine for steel processing. The right software not only streamlines operations but also enhances functionality by allowing you to customize settings according to material characteristics—an absolute must-have feature!

Understanding what is CNC in steel involves recognizing how integrated software solutions can optimize cutting paths and reduce cycle times significantly—this is where advanced control systems come into play! When searching for the best CNC machine for metal work or even a small CNC machine for steel projects at home, ensure it supports popular CAD/CAM programs that suit your workflow preferences.

CNC Machine for Steel: Safety Considerations

When it comes to operating a CNC machine for steel, safety should always be the top priority. Understanding safety standards is crucial to ensure that both the operator and the workspace remain safe during milling operations. With the right knowledge and practices, you can confidently ask, Can you CNC machine steel? and get to work without worry.

Understanding Safety Standards

Safety standards for CNC machines are designed to protect operators from potential hazards associated with working with metal. These standards include guidelines on machine operation, maintenance, and emergency procedures that help mitigate risks. Familiarizing yourself with these regulations not only ensures compliance but also promotes a safer working environment when using a small CNC machine for steel.

Moreover, it's essential to stay updated on any changes in safety regulations related to CNC operations in your area or industry. This might involve attending workshops or training sessions that focus on the latest safety protocols specific to what is CNC in steel processing. Remember, ignorance of these standards can lead to accidents that could have otherwise been prevented.

Best Practices for Safe Operation

To operate your metal CNC machine for home use safely, adopting best practices is vital. Always ensure that your workstation is organized and free of clutter; this minimizes distractions and hazards while you're focused on precision milling tasks. Before starting any project, double-check all settings on your CNC machine for steel and confirm they align with your intended operation parameters.

Another key practice is conducting regular maintenance checks on your equipment; this helps identify any wear or malfunction before they become serious issues during operation. Additionally, always keep an emergency stop button within reach so you can quickly halt operations if something goes awry—because when you're dealing with high-speed machinery cutting through tough materials like steel, every second counts!

Lastly, communicating openly about safety protocols with anyone who may be present while you operate the best CNC machine for metal work ensures everyone knows what to do in case of an emergency.

Importance of Personal Protective Equipment

Personal protective equipment (PPE) plays a pivotal role in ensuring safety when using a CNC machine for steel projects. Essential items like safety goggles protect your eyes from flying debris while ear protection shields against noise generated by powerful milling operations—after all, nobody wants ringing ears after a long day at the workshop!

Wearing gloves may seem intuitive; however, it’s crucial to choose appropriate types that allow dexterity without compromising grip or exposing yourself to entanglement risks with moving parts of the small CNC machine for steel. Also consider wearing sturdy footwear designed specifically for industrial environments—steel-toed boots can save toes from heavy falling objects!

In short, investing time and resources into understanding safety standards alongside practicing safe operation techniques will enhance not just individual well-being but also overall productivity when utilizing advanced technology like metal CNC machines at home.

Tips for Choosing Your CNC Machine

Choosing the right CNC machine for steel can feel like navigating a maze, but with the right tips, you can find your way to the perfect fit. From assessing your project needs to budgeting wisely and finding reliable suppliers, these steps will help you make an informed decision. Let’s dive into the essentials!

Assessing Your Project Needs

Before you invest in a CNC machine for steel, it's crucial to assess what exactly you need it for. Are you planning on doing intricate designs or heavy-duty machining? Understanding your project's specific requirements will guide you in selecting features that align with your goals—whether you're asking yourself, Can you CNC machine steel? or pondering what is CNC in steel.

Different projects may call for different types of machines; for example, if you're working on smaller components, a small CNC machine for steel might be ideal. On the other hand, larger projects may require more robust options with higher spindle speeds and power. Take time to evaluate whether you'll be primarily focused on prototyping or production runs as this could influence which model suits your needs best.

Budgeting for Your CNC Investment

Budgeting is a critical step when choosing the best CNC machine for metal work. Prices can vary widely depending on features such as size, precision capabilities, and brand reputation—so it’s essential to set a realistic budget before diving into options. Remember that while entry-level machines are tempting due to their lower price tags, investing in quality often pays off in terms of durability and performance.

Don’t forget about additional costs such as software licenses and maintenance fees when calculating your overall investment! This is particularly important if you're considering a metal CNC machine for home use; hidden costs can add up quickly if not factored into your budget from the start. Ultimately, being financially prepared will ensure that you choose not just any machine but one that fits both your needs and wallet comfortably.

Finding Local Suppliers and Support

Once you've assessed your project needs and established a budget, it's time to find local suppliers who can provide support tailored specifically to CNC machines for steel. Having access to knowledgeable support staff can make all the difference when navigating setup or troubleshooting issues down the line—especially if you're new to using these machines!

Look out for suppliers who offer demonstrations or training sessions; this hands-on experience can be invaluable as you familiarize yourself with what is often complex machinery. Additionally, consider joining local maker groups or forums where users share insights about their experiences with various models—this community-driven knowledge base could help answer questions like “What are the 5 common types of CNC machines?”

Finding reliable local support ensures that when questions arise about operating procedures or maintenance practices (like how best to care for your chosen small CNC machine), you'll have someone nearby who understands both machinery and material—making your journey smoother.

Conclusion

In wrapping up our exploration of desktop CNC milling machines, it's clear that the future of this technology is bright. With advancements in precision and accessibility, these machines are becoming increasingly vital for both hobbyists and professionals alike. As we look forward, the question remains: can you CNC machine steel? The answer is a resounding yes!

The Future of Desktop CNC Milling

The landscape of desktop CNC milling is evolving rapidly, with innovations that cater to various needs in metal processing. As more manufacturers recognize the benefits of compact yet powerful machines, the market for small CNC machines for steel is expanding significantly. This shift not only democratizes access to high-quality machining but also encourages creativity and innovation among users.

As we move forward, expect to see even more specialized options tailored for specific materials. For instance, what is the best steel for CNC machine applications? Generally, it depends on your project requirements; however, popular choices include mild steel and aluminum due to their machinability and strength. In addition to material advancements, software compatibility will continue to improve, ensuring that users can maximize their machine's capabilities.

Maximizing Efficiency with the Right Machine

Choosing the right CNC machine for steel can make all the difference in achieving optimal results while minimizing downtime. Factors such as spindle speed and build quality play crucial roles in determining how efficiently a machine operates. When considering a metal CNC machine for home use or a professional setting, it's essential to evaluate your specific needs against available options.

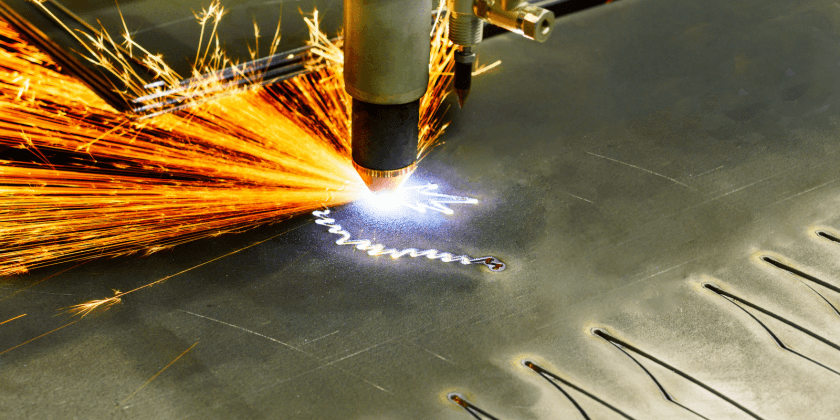

Investing in a high-quality machine ensures that you can tackle various projects without compromising on performance or safety standards. For those wondering about what are the 5 common types of CNC machines available today—milling machines, lathes, plasma cutters, laser cutters, and routers—each serves distinct purposes depending on your project requirements. By understanding these differences and selecting accordingly, you can streamline your workflow effectively.

Final Thoughts on CNC and Steel Processing

In conclusion, embracing desktop CNC milling technology opens up endless possibilities for metal work enthusiasts everywhere. Whether you're operating a small shop or working from home with a small CNC machine for steel projects, having the right equipment at your disposal can elevate your craft significantly. Remember that investing time into understanding what is CNC in steel processing will pay off when it comes time to execute complex designs.

As you consider diving into this fascinating world of machining metals like never before—whether you're asking yourself what is the best steel for CNC machine? or exploring safety measures—know that knowledge truly empowers success in every endeavor you undertake with these remarkable tools.