Introduction

In a world where precision meets affordability, discovering the right desktop CNC machine for metal can feel like finding a needle in a haystack. With advancements in technology, the market is now flooded with options that cater to both hobbyists and professionals alike. Whether you're looking to craft intricate designs or simply want to explore the capabilities of metal machining, there’s never been a better time to dive into the realm of affordable desktop CNC machines.

Discovering Affordable CNC Machines

The rise of affordable desktop CNC machines has democratized access to high-quality machining tools. No longer do you need an industrial-sized budget or space; compact models are now designed specifically for home workshops and small businesses. This shift has opened doors for many who ask, Can you use a CNC machine for metal? The answer is a resounding yes, as these machines are engineered to handle various metals with precision and efficiency.

Benefits of Metal CNC Machining

Metal CNC machining offers several advantages that traditional methods simply can't match. First and foremost, it allows for unparalleled accuracy—ensuring every cut is exactly where it needs to be. Additionally, using a desktop CNC machine for metal significantly reduces waste material and enhances production speed, making it an ideal choice for those seeking the best desktop CNC milling machines available today.

Why Choose a Desktop Model

Choosing a desktop model comes with its own set of perks that make it an attractive option for both enthusiasts and professionals alike. These machines are not only space-efficient but also provide flexibility in terms of project scale—from small prototypes to larger components without sacrificing quality or precision. Plus, many people wonder if “Can a desktop CNC cut steel?” The answer is yes! With the right setup and materials, these compact powerhouses can handle various types of metals while delivering impressive results.

Overview of Desktop CNC Machines for Metal

Key Features to Consider

When searching for an affordable desktop CNC machine, several key features should be at the forefront of your decision-making process. First and foremost is the machine's cutting capacity; ensure it can handle the thickness and type of metal you plan to work with. Additionally, look for machines with robust construction and high-quality components that ensure durability and accuracy—after all, you want a machine that can withstand rigorous use while maintaining precision.

Another crucial feature is the software compatibility; user-friendly interfaces can significantly enhance your experience when operating a desktop CNC mill. Look for models that support popular CAD/CAM software options so you can easily create designs and execute them flawlessly. Lastly, consider the availability of customer support or community resources—having access to troubleshooting advice or user forums can make all the difference in maximizing your investment in metal desktop CNC machines.

Types of Metal Suitable for CNC Machining

One of the most frequently asked questions is: Can you use a CNC machine for metal? The answer is a resounding yes! Desktop CNC machines are capable of machining various metals, including aluminum, brass, copper, and even mild steel under certain conditions. However, it’s essential to choose an affordable desktop CNC machine specifically designed to handle these materials effectively.

Aluminum is often favored due to its lightweight nature and excellent machinability; it's commonly used in aerospace components or automotive parts. Brass offers great aesthetic appeal along with good machinability and corrosion resistance—perfect for decorative items or intricate fittings. For those wondering if a desktop CNC can cut steel: while some models may handle mild steel with appropriate tooling and settings, it's crucial to assess each machine's specifications before diving into more challenging projects.

Common Uses in Various Industries

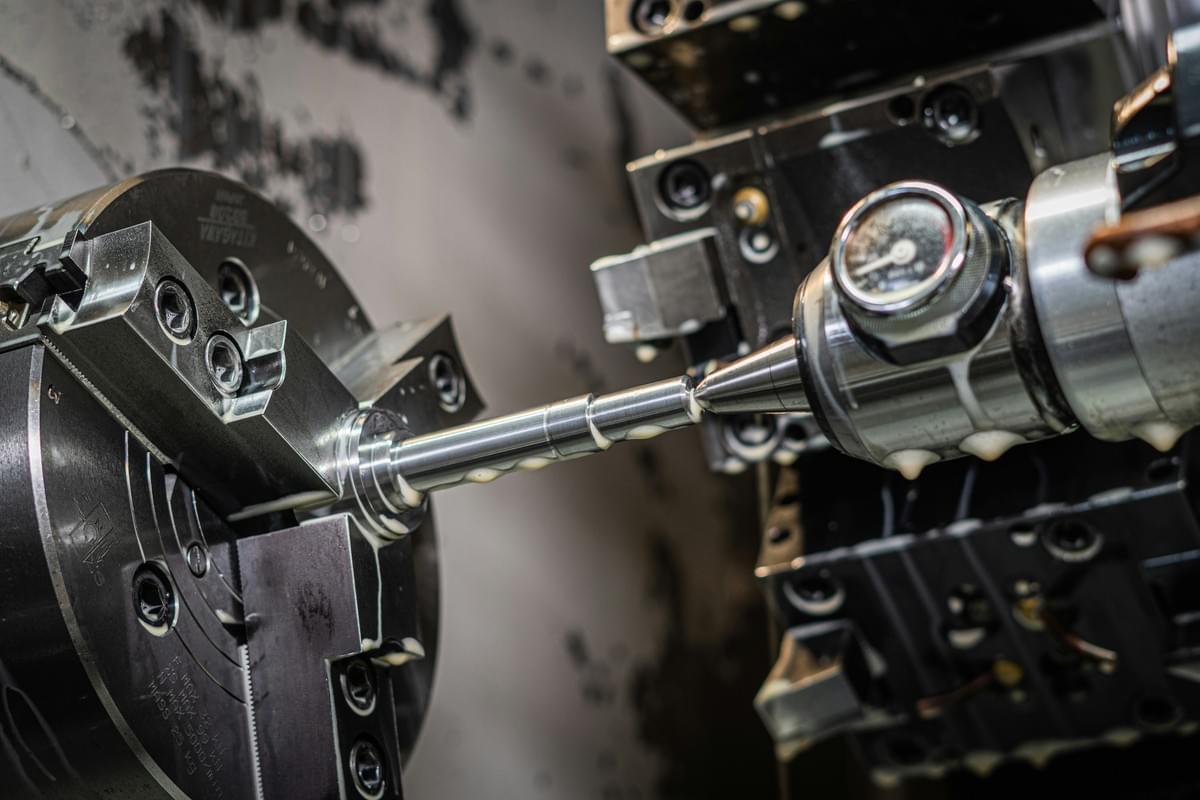

Metal desktop CNC machines have found their niche across several industries due to their versatility and precision capabilities. In manufacturing sectors like aerospace or automotive engineering, these machines are invaluable for creating prototypes or small production runs with exacting tolerances—a must-have when quality matters most!

Additionally, they are widely used in jewelry design where intricate patterns need precise execution; artisans rely on these tools not just for functionality but also as creative extensions of their craft. From hobbyists crafting custom parts at home to professionals producing specialized equipment in workshops—desktop CNC milling machines are transforming how we approach metalworking across diverse fields.

Top Affordable Desktop CNC Machines

When diving into the world of metalworking, finding the right desktop CNC machine for metal can be a game-changer. The market is rich with options that cater to various needs and budgets, making it easier than ever to find an affordable desktop CNC machine that meets your requirements. In this section, we’ll explore three standout models that have gained popularity among hobbyists and professionals alike.

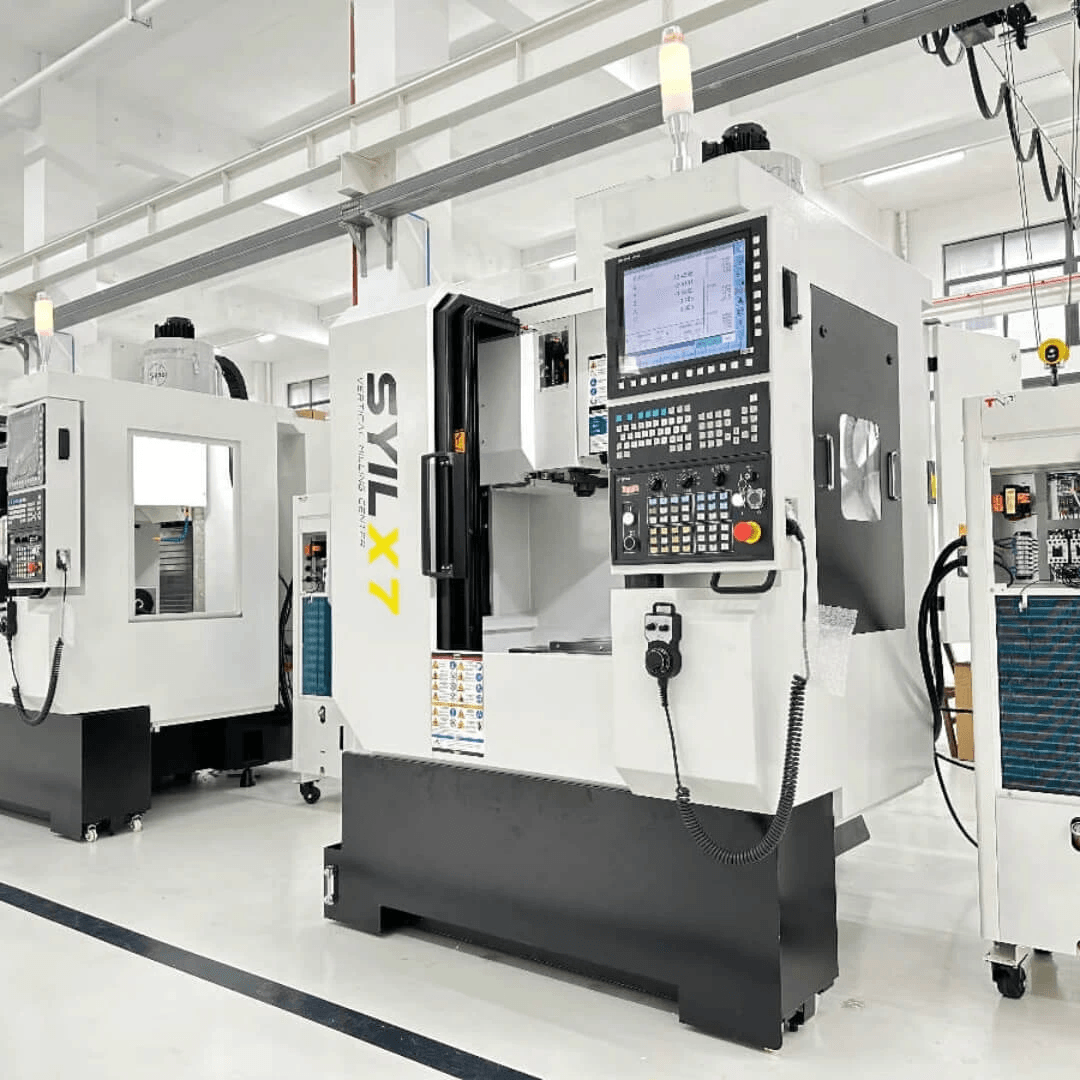

SYIL X5 Desktop CNC Machine

The SYIL X5 is often hailed as one of the best desktop CNC milling machines available today, especially for those looking to work with metal. Its robust construction allows it to handle a variety of materials, including aluminum and even some steel grades, proving that yes, a desktop CNC can cut steel! With its impressive spindle speed and precision capabilities, this machine offers users an excellent balance between affordability and performance.

One of the key features of the SYIL X5 is its compact design paired with powerful functionality. This means you don’t need a massive workshop to accommodate it; it fits comfortably on most workbenches while delivering professional-grade results. Additionally, its user-friendly interface makes it accessible even for those new to using metal desktop CNC machines.

For anyone serious about entering or advancing in the world of metal machining without breaking the bank, investing in the SYIL X5 could be your best bet. It's designed not only for efficiency but also for ease of use—perfect for both seasoned machinists and enthusiastic beginners.

BobsCNC E4 Router

Next up is the BobsCNC E4 Router—a fantastic option if you’re looking at affordable desktop CNC machines that don’t compromise on quality or versatility. While primarily recognized as a woodworking router, many users have successfully adapted this model for light metalwork applications as well. This raises an interesting question: can you use a CNC machine for metal? The answer is yes—with some careful consideration regarding material limitations!

What sets the BobsCNC E4 apart from other models is its unique wooden frame construction combined with high-quality components like NEMA 23 stepper motors. This not only keeps costs low but also ensures durability over time. Users appreciate how easy it is to assemble this machine; many report being up and running in no time at all—perfect for those eager to dive into projects quickly.

Though primarily designed for softer materials like plastics and wood, users have shared their experiences successfully machining aluminum components too! If you're searching for one of the best desktop CNC milling machines on a budget while still having room to explore metal projects later on, consider adding this router to your toolkit.

Carbide 3D Shapeoko 4

Last but certainly not least is the Carbide 3D Shapeoko 4—a powerhouse in the realm of affordable desktop CNC machines tailored specifically toward both beginners and experienced operators alike! Known for its rigidity and precision capabilities, this model shines when working with various metals such as aluminum or brass—making it an excellent choice if you're wondering about cutting capabilities with steel or other tougher materials.

The Shapeoko 4 boasts several enhancements compared to previous versions—including improved structural integrity which translates directly into better performance during high-speed operations! Users frequently rave about how easily they can achieve fine details in their projects without sacrificing speed—something vital when working on intricate designs typical in metalworking applications.

Moreover, Carbide 3D has developed intuitive software solutions that integrate seamlessly with their hardware—allowing users full control over their machining processes right from setup through execution! If you're keen on exploring what modern Metal Desktop CNC Machines can do without emptying your wallet completely—the Shapeoko 4 should definitely be on your radar!

Comparing Performance and Precision

Speed and Efficiency Insights

Speed is often the first thing that comes to mind when evaluating a desktop CNC machine for metal. Machines like the Carbide 3D Shapeoko 4 can achieve high feed rates without compromising accuracy, making them suitable for various projects—from intricate designs to larger components. Additionally, efficiency plays a crucial role; an affordable desktop CNC machine should minimize downtime while maximizing output quality.

The ability of these machines to work continuously with minimal supervision allows users to take on multiple projects simultaneously or tackle larger tasks without constant oversight. This means you can spend more time creating and less time waiting around for your project to finish. Ultimately, investing in a fast and efficient model will significantly enhance your productivity in any metalworking endeavor.

Understanding Tolerances in Metalwork

Tolerances are essential when working with metal; they dictate how closely parts must fit together in final assembly. Desktop CNC milling machines excel at maintaining tight tolerances—often within ±0.005 inches—making them ideal for precision applications such as aerospace or automotive components. Understanding these tolerances helps users select the right tools and settings for their specific needs.

It's important to note that not all desktop CNC machines are created equal; some may struggle with maintaining consistent tolerances over extended periods or with different materials. Therefore, when considering which metal desktop CNC machines are best suited for your projects, it's wise to review performance specifications carefully before making a decision. Remember that even an affordable model can produce outstanding results if it meets your tolerance requirements.

Real-World User Experiences

User experiences often provide valuable insights into how well a desktop CNC machine performs under various conditions. Many hobbyists and professionals alike have reported satisfaction with their choices among the best desktop CNC milling machines available today—especially those designed specifically for metalworking tasks. Reviews frequently highlight aspects such as ease of use, reliability during operation, and overall quality of finished products.

For instance, users have praised models like the SYIL X5 for their robust construction and ability to cut steel effectively—a question many ask: Can a desktop CNC cut steel? The answer is yes! With proper setup and tooling, these machines can handle tougher metals while still delivering precision cuts that meet industry standards.

In summary, real-world feedback underscores the importance of selecting a reliable model tailored for specific applications in metalwork—whether you're asking Can you use a CNC machine for metal? or simply looking for an efficient solution that fits within your budgetary constraints.

Setup and Maintenance Tips

Setting up and maintaining your desktop CNC machine for metal is crucial to ensure optimal performance and longevity. While the process may seem daunting at first, following a few essential steps can make it a breeze. With proper setup and care, your affordable desktop CNC machine can become an indispensable tool in your workshop.

Essential Setup Procedures

Before you can unleash the full potential of your desktop CNC machine for metal, you'll need to follow some essential setup procedures. Start by placing the machine on a sturdy, level surface to prevent any vibrations during operation; this is key for achieving precision in machining. Next, carefully follow the manufacturer's instructions to assemble all components correctly, ensuring that everything from the spindle to the bed is aligned perfectly.

Once assembled, it's time to calibrate your CNC machine properly. This includes setting up limit switches and homing procedures so that your machine knows its boundaries—this step is vital when working with various materials like aluminum or even steel. After calibration, don’t forget to test run with softer materials before diving into more robust metals; this will help you fine-tune settings without risking damage.

Routine Maintenance Best Practices

To keep your best desktop CNC milling machines running smoothly, routine maintenance is essential. Regularly check for any loose bolts or connections that may have come undone during operation; tightening these can prevent larger issues down the line. Additionally, cleaning debris from around the work area and lubricating moving parts will help maintain precision over time.

It's also important to inspect cutting tools frequently; dull bits can lead to poor-quality cuts and increased wear on your affordable desktop CNC machine. Consider investing in a tool holder or organizer so you always have sharp tools ready when needed—this will save time and improve efficiency in your projects. Lastly, maintain a log of maintenance activities; tracking these details helps identify patterns that could indicate underlying issues.

Troubleshooting Common Issues

Even with careful setup and maintenance, you may encounter some common issues while using metal desktop CNC machines. If you're experiencing inconsistent cuts or unexpected errors during operation, start by checking for any misalignment in the axes or worn-out cutting tools—these are often culprits behind poor performance. Remember: if something feels off while operating your CNC machine for metalwork, it’s worth stopping immediately to troubleshoot before proceeding further.

Another frequent issue involves software glitches or connection problems between your computer and the CNC unit itself; ensure all drivers are updated regularly to avoid these headaches. If you're asking yourself Can you use a CNC machine for metal?—the answer is yes! Just make sure you’ve configured everything correctly according to material specifications before diving into more complex projects like cutting steel.

Lastly, don't hesitate to reach out within online communities dedicated to desktop machining; many experienced users are eager to share tips based on their own troubleshooting experiences with similar machines!

Exploring Software Options for CNC Machining

When diving into the world of desktop CNC machines for metal, selecting the right software can enhance your machining experience significantly. The software you choose will not only dictate how effectively you can operate your machine but also determine the complexity of projects you can undertake. With a plethora of options available, it’s essential to find a balance between functionality and user-friendliness that suits your needs.

Popular Software for Desktop CNC Machines

Among the best desktop CNC milling machines, software like Fusion 360 and VCarve Pro tops the list due to their robust features and versatility. These programs allow users to create intricate designs and translate them into precise movements on their affordable desktop CNC machine efficiently.

Another popular choice is Mach3, which offers an intuitive interface that many hobbyists appreciate. For those asking, “Can you use a CNC machine for metal?” the answer is a resounding yes, especially with software tailored for metal operations like SheetCam or LinuxCNC. These tools provide specialized functionalities that help maximize the capabilities of Metal Desktop CNC Machines.

Integrating CAD/CAM Solutions

Integrating CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) solutions is crucial when using a desktop CNC mill effectively. Many modern software options seamlessly combine these two functions, allowing users to design parts and generate toolpaths in one go—making your workflow much smoother. This integration is particularly beneficial when working with materials like steel; so if you've ever wondered, “Can a desktop CNC cut steel?” rest assured that with the right software setup, it absolutely can!

Moreover, having CAD/CAM solutions ensures that even complex designs are accurately translated into commands for your machine without losing detail or precision. If you're looking at various Metal Desktop CNC Machines, consider those that support popular CAD/CAM programs; this compatibility will save time and reduce frustration during projects. Ultimately, investing in good software will enhance both productivity and creativity in your machining endeavors.

User-Friendly Interfaces and Features

User-friendly interfaces are vital when navigating through intricate designs on any desktop CNC machine for metal work; after all, who wants to wrestle with confusing menus? Look for software that prioritizes simplicity while still offering advanced features—this way you won’t feel overwhelmed as you learn how to operate your new equipment effectively! Many top-rated options come with tutorials or community support forums where users share tips on maximizing their affordable desktop CNC machine's potential.

Moreover, features like drag-and-drop design elements or real-time simulation help demystify the process of programming your machine; they make it accessible even for beginners who might be intimidated by technical jargon often associated with machining software. Additionally, having customizable tool libraries allows users to tailor settings specifically suited to their projects—whether you're crafting intricate details or cutting larger components on one of the best desktop CNC milling machines available today.

In conclusion, choosing suitable software plays an integral role in enhancing your experience with any desktop CNC machine designed for metalwork applications. By understanding what’s out there—from popular programs to integrated solutions—you’ll be well-equipped to tackle any project thrown your way!

Conclusion

As we wrap up our exploration of desktop CNC machines for metal, it’s clear that investing wisely in CNC technology can significantly enhance your crafting and manufacturing capabilities. With the rise of affordable desktop CNC machines, even hobbyists and small businesses can access tools that were once reserved for large-scale operations. By selecting the right machine, you can ensure that your investment pays off in precision, efficiency, and versatility.

Investing Wisely in CNC Technology

When considering which desktop CNC milling machines to purchase, it's essential to weigh your options carefully. Look for features that align with your specific projects and budget; after all, not every affordable desktop CNC machine will meet the rigorous demands of metalworking. Remember, a well-chosen desktop CNC machine for metal can open doors to new possibilities in design and production.

Maximizing Your Desktop CNC Experience

To truly get the most out of your metal desktop CNC machines, familiarize yourself with their capabilities and limitations. Understanding what a desktop CNC mill can do will help you push its boundaries while avoiding potential pitfalls. Regular maintenance and updates to software will also maximize performance—ensuring that whether you're asking “Can a desktop CNC cut steel?” or “Can you use a CNC machine for metal?”, you’ll be ready to tackle any challenge.

The Future of Affordable CNC Machines

The future looks bright for affordable desktop CNC machines as advancements continue to make these tools more accessible to everyone—from makerspaces to professional workshops. Innovations in technology promise increased precision and efficiency at lower price points, making it easier than ever to integrate these devices into various industries. As the market evolves, expect even better options among the best desktop CNC milling machines tailored specifically for metalwork enthusiasts.