Introduction

In recent years, the landscape of metalworking has been transformed with the rise of CNC steel mills, making precision engineering more accessible than ever before. These machines have become a staple in both professional workshops and hobbyist garages, allowing users to create intricate parts with remarkable accuracy. But can you CNC mill steel? Absolutely! This guide will delve into the world of CNC steel mills, exploring their functionality and why they’ve captured the interest of DIY enthusiasts.

The Rise of CNC Steel Mills

CNC steel mills have surged in popularity due to advancements in technology that have made them more affordable and user-friendly. Once a tool reserved for industrial applications, hobbyists now find themselves asking how expensive is a CNC mill? Surprisingly, there are options available for various budgets, including Hobby CNC Mill for Metal Milling that cater specifically to those looking to take on personal projects without breaking the bank. As these machines become increasingly integrated into home workshops, they empower creators to push the boundaries of what’s possible in metalworking.

Why Hobbyists Are Embracing CNC

The allure of a CNC steel mill lies not just in its capabilities but also in how it opens up new avenues for creativity and innovation among hobbyists. No longer confined by traditional methods, enthusiasts can produce complex designs with ease and precision that were once thought impractical or impossible. Moreover, many are curious about whether a CNC is a mill or lathe—understanding these distinctions can help hobbyists choose the right tools for their projects while exploring various applications from simple components to elaborate custom pieces.

Understanding CNC Technology

At its core, Computer Numerical Control (CNC) technology revolutionizes the way we approach machining by automating processes through computer programming. This means that users can input designs digitally and watch as their ideas come to life with minimal manual intervention—what's not to love about that? But what is the difference between a CNC machine and a CNC mill? While both utilize computerized controls for operation, a CNC mill specifically refers to machines designed primarily for cutting materials like metal using rotating tools—perfect for those who want precision milling capabilities paired with robust performance.

What is a CNC Steel Mill?

CNC steel mills are the modern marvels of metalworking, combining advanced technology with precision engineering. They allow hobbyists and professionals alike to create intricate designs and components from steel with ease. But what exactly is a CNC steel mill, and how does it differ from traditional milling machines? Let’s dive into the details.

Definition and Functionality

A CNC (Computer Numerical Control) steel mill is a machine that automates the process of cutting, shaping, and machining metal using computer-generated codes. This allows for high levels of precision that manual methods simply can't achieve. With a hobby CNC mill for metal milling, users can produce everything from small parts to complex assemblies without the need for extensive manual labor.

The functionality of a CNC steel mill revolves around its ability to interpret digital designs and execute them with remarkable accuracy. By using software to create a design file, hobbyists can direct the machine on how to move its cutting tools across the material. This automation not only enhances efficiency but also reduces human error in metalworking projects.

Differences from Traditional Mills

When comparing CNC mills to traditional milling machines, several key differences emerge. Traditional mills require manual operation and adjustments, which can lead to inconsistencies in finished products; in contrast, CNC mills operate based on precise programming instructions that ensure uniformity across multiple pieces. So, can you CNC mill steel? Absolutely! The technology allows for consistent results every time you hit start.

Another major difference lies in setup time; while traditional mills may take significant effort to recalibrate for different jobs or materials, a CNC machine allows users to switch between projects quickly by simply uploading new design files. Additionally, many hobbyists wonder: “Is CNC a mill or lathe?” The answer is both! While they serve different purposes—mills cut flat surfaces while lathes shape cylindrical objects—CNC technology applies effectively in both realms.

Common Applications in Hobby Projects

Hobbyists are increasingly finding creative uses for their CNC steel mills across various projects. From custom automotive parts to intricate jewelry designs, these machines open up endless possibilities for innovation and craftsmanship at home workshops or garages. Many enthusiasts also explore creating prototype components or even art pieces that showcase their skills with metalworking.

Another popular application includes DIY projects where individuals craft tools or fixtures tailored specifically to their needs—think custom clamps or jigs that enhance workflow efficiency during other tasks! Furthermore, with readily available CNC mill kits on the market today, getting started has never been easier or more accessible for aspiring makers eager to delve into this exciting world of fabrication.

Benefits of Using a CNC Steel Mill

Precision and Accuracy in Metalworking

One of the standout features of a CNC steel mill is its incredible precision and accuracy. Unlike traditional methods that rely heavily on manual skill, CNC technology ensures that every cut is executed with exact measurements, reducing the chances of human error. This level of detail is crucial for hobbyists who want to create intricate designs or components where fit and finish matter—after all, can you CNC mill steel without being precise?

Time Efficiency for Hobbyists

Time is often the most precious commodity for hobbyists juggling multiple projects or commitments. A CNC steel mill significantly streamlines the milling process, allowing users to complete tasks in a fraction of the time it would take with conventional tools. Whether you're working on a Hobby CNC Mill for Metal Milling or assembling CNC Mill Kits, you'll find yourself spending less time on setup and more time enjoying your craft.

Versatility in Projects and Materials

CNC steel mills are not just limited to one type of project; they open up endless possibilities across various materials beyond just steel. From aluminum to plastics, these machines can tackle diverse tasks tailored to your creative vision. The versatility offered by modern machines makes them essential tools for any hobbyist looking to expand their repertoire—after all, what’s better than having one machine that can do it all?

Choosing the Right CNC Steel Mill

When it comes to selecting a CNC steel mill, it can feel like navigating a maze of options. With various models and features, it's crucial to know what you need for your specific projects. Whether you're looking to create intricate designs or robust components, making an informed choice can elevate your hobbyist experience.

Key Features to Consider

First and foremost, consider the size of the CNC steel mill; this will determine the scale of your projects. Look for features such as spindle speed, which affects how quickly you can cut through materials—higher speeds often mean more efficiency. Additionally, pay attention to the machine's rigidity and build quality; a sturdy construction will enhance precision and reduce vibrations during operation.

Another vital aspect is compatibility with different materials. Can you CNC mill steel? Absolutely! But not all machines are created equal; some may handle softer metals better than harder ones like steel. Lastly, ensure that the software used for design and execution is user-friendly and compatible with your CNC mill kits.

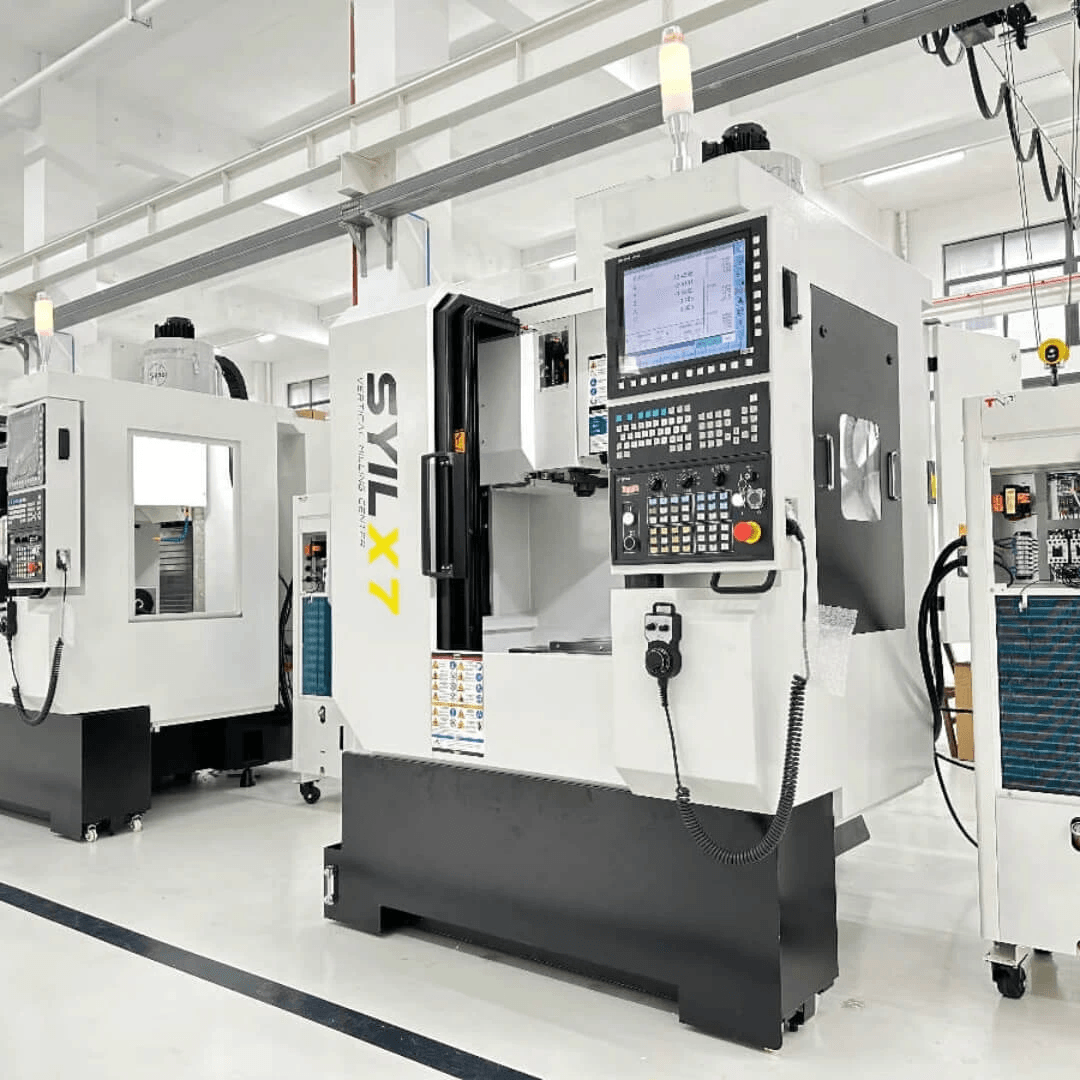

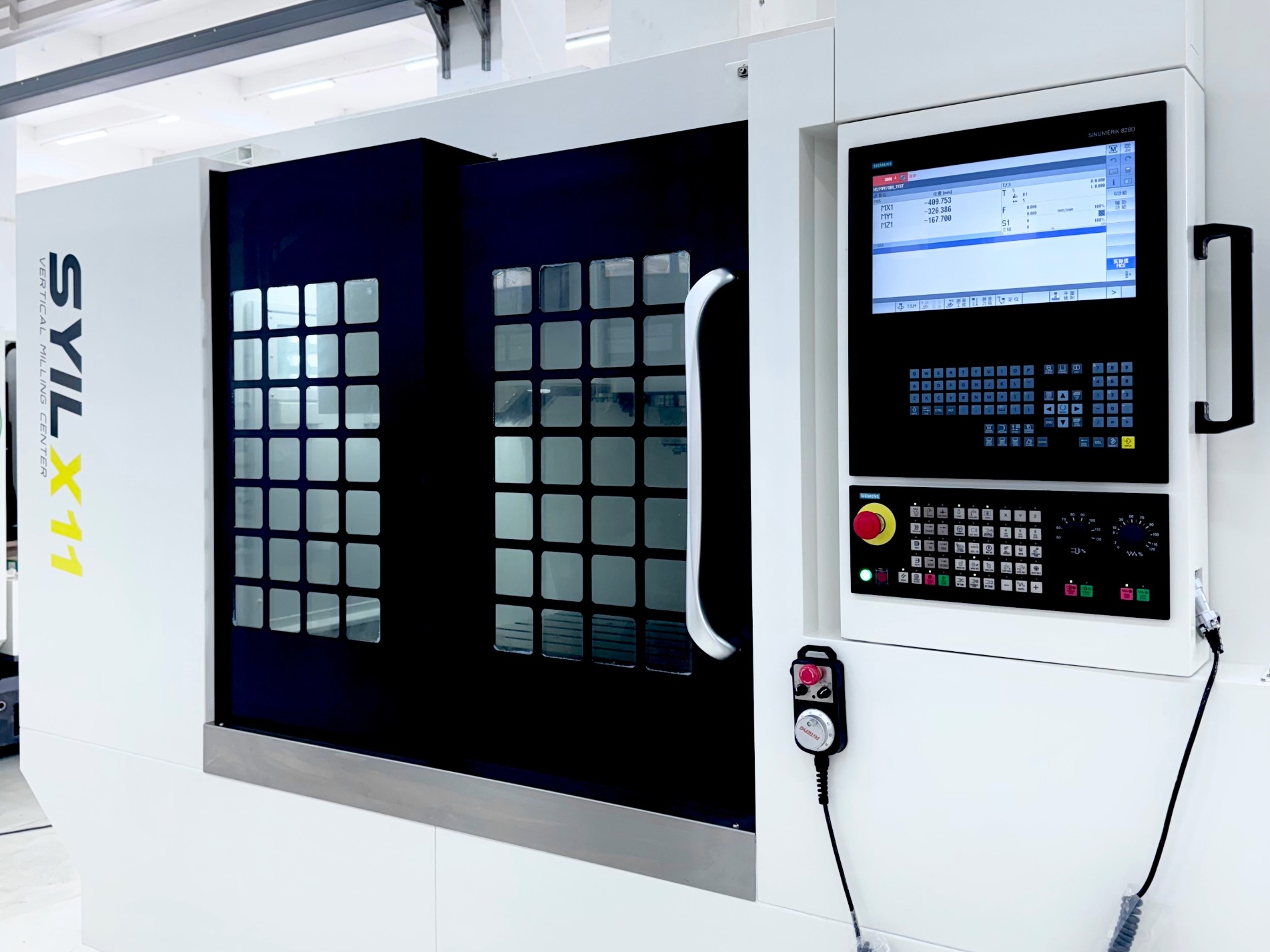

Top Brands: SYIL CNC Machines

When it comes to reliable brands in the market, SYIL CNC Machines stands out as a top contender for hobbyists venturing into metal milling. Known for their robust construction and ease of use, SYIL offers various models tailored specifically for those asking themselves: Is CNC a mill or lathe? The answer lies in understanding that while both are machining tools, a CNC mill specializes in cutting flat surfaces and intricate designs.

SYIL machines provide excellent support resources that make them ideal for beginners looking to dive into their first Hobby CNC Mill for Metal Milling projects. With features designed specifically for versatility and precision, they cater well to both novice makers and seasoned pros alike. So if you're on the hunt for quality without breaking the bank, SYIL is definitely worth considering.

Budgeting for Your CNC Steel Mill

Now let’s tackle one burning question: How expensive is a CNC mill? The answer varies widely based on brand reputation, features, and capabilities—ranging from budget-friendly options to high-end professional machines. It’s essential to set aside funds not just for the machine itself but also consider ongoing costs such as maintenance supplies and software licenses.

A good rule of thumb is to allocate about 20% of your budget towards accessories like tooling or upgrades that may enhance your milling experience further down the line. Don't forget about potential hidden costs such as shipping fees or installation services if you're opting for larger models! Being financially prepared ensures you won’t be left high and dry once you’ve made your purchase.

Essential Tools and Accessories

When diving into the world of CNC steel milling, having the right tools and accessories is crucial for achieving precision and efficiency. A well-equipped workspace can make all the difference in transforming your hobby projects into professional-quality results. From essential tools to software solutions and safety gear, here’s what you need to elevate your CNC experience.

Must-Have Tools for CNC Steel Mills

To get started with a hobby CNC mill for metal milling, there are several must-have tools that will enhance your capabilities. First on the list is a robust set of end mills specifically designed for steel, as they will ensure clean cuts and longevity during operation. Additionally, having a dial indicator can help you calibrate your CNC steel mill accurately, ensuring that every cut is precise.

Don’t forget about clamps and vises; these accessories hold your workpiece securely in place while you mill it down to size. A good quality coolant system is also essential since milling steel generates heat that can wear down both tools and materials quickly. Lastly, investing in a sturdy workbench will provide a stable surface for all your projects, making it easier to maneuver around your equipment.

Software Solutions for Design and Execution

In today’s digital age, software plays an integral role in maximizing the potential of your CNC steel mill. CAD (Computer-Aided Design) software allows you to create detailed designs before they ever touch the metal; popular options include Fusion 360 or SolidWorks which offer powerful features tailored for metalworking enthusiasts. After designing comes CAM (Computer-Aided Manufacturing) software like Mach3 or LinuxCNC that translates those designs into machine-readable instructions.

Understanding how to use these programs effectively can significantly enhance what you can achieve with your CNC mill kits. They not only streamline the design process but also enable complex operations that would be difficult or impossible by hand. So whether you're asking yourself “Can you CNC mill steel?” or pondering “What is the difference between a CNC machine and a CNC mill?”, mastering these software solutions will clarify many aspects of working with metal.

Safety Equipment Every Hobbyist Needs

Safety should always be at the forefront when operating any machinery, especially when working with something as robust as a CNC steel mill. First off, invest in high-quality safety goggles; flying metal shavings are no joke! Additionally, wearing ear protection is wise since milling machines can produce significant noise levels that could harm your hearing over time.

A dust mask or respirator is another essential piece of equipment—steel dust isn’t just unsightly; it’s hazardous too! Lastly, consider having fire extinguishers nearby since sparks can occur during machining operations—better safe than sorry! Remember that while enjoying this exciting hobby of using a CNC steel mill, keeping safety top-of-mind ensures many more successful projects ahead.

Tips for Successful CNC Projects

When diving into the world of CNC machining, especially with a CNC steel mill, planning is your best friend. Proper planning not only saves time but also helps avoid costly mistakes that can arise from miscalculations. Before you fire up your Hobby CNC Mill for Metal Milling, take a moment to sketch out your design and outline each step of the process.

Planning Your Project Effectively

To effectively plan your project, start by determining what you want to create and how complex it will be. Consider the materials you'll use; while many hobbyists wonder, Can you CNC mill steel?, the answer is a resounding yes! However, keep in mind that different materials require different approaches and settings on your CNC steel mill. Once you've established your design and material choice, create a detailed timeline that outlines each phase of the project—from design to execution.

Additionally, invest some time in selecting the right software solutions for design and execution; this can make or break your project’s success. Remember that planning isn't just about getting things done—it's about ensuring quality and precision throughout the process. By taking these steps seriously, you'll set yourself up for success when using a Hobby CNC Mill for Metal Milling.

Common Mistakes to Avoid

Even seasoned hobbyists can fall prey to common pitfalls when working with a CNC steel mill. One major mistake is underestimating the importance of proper machine setup; without precise calibration, even the best designs can yield poor results. Another frequent error is neglecting tool selection; using inappropriate tools can lead to disastrous outcomes—so always ask yourself: How expensive is a CNC mill? before investing in high-quality bits suited for metal milling.

Moreover, many hobbyists overlook safety precautions while engrossed in their projects; always wear appropriate safety gear and ensure your workspace is organized to prevent accidents. Also, remember that patience pays off—rushing through processes often leads to mistakes that could have been easily avoided if given more time and attention. By being aware of these common mistakes and actively working to avoid them, you'll enhance both your skills and enjoyment of using a CNC steel mill.

Maintenance Tips for Longevity

Maintaining your CNC steel mill is crucial if you want it to last through countless projects without breaking down or losing precision over time. Regularly clean all parts of your machine after each use; chips from milling operations can accumulate quickly and lead to malfunctions if left unattended. Additionally, keep an eye on lubrication points as per manufacturer guidelines—this simple step can significantly extend the life of moving components.

Another important aspect of maintenance involves checking software updates regularly; staying current ensures you're utilizing all available features effectively while minimizing bugs or glitches during operation. Lastly, don't forget about periodic inspections—check belts, bearings, and other critical components routinely so any wear-and-tear issues are caught early on before they become major headaches.

By following these maintenance tips diligently alongside effective planning strategies while avoiding common mistakes like improper tool selection or neglecting safety measures will contribute immensely towards achieving successful outcomes with every project undertaken on your Hobby CNC Mill for Metal Milling!

Conclusion

In the rapidly evolving world of metalworking, CNC steel milling stands out as a game-changer for hobbyists and professionals alike. With its precision, efficiency, and versatility, the future of CNC steel milling looks brighter than ever. As technology advances, we can expect even more user-friendly machines and innovative applications that will further democratize access to metalworking.

The Future of CNC Steel Milling

The future of CNC steel milling is poised for exciting developments, especially with advancements in automation and software integration. As more people ask themselves, Can you CNC mill steel? the answer becomes clearer: absolutely! This increased interest will likely lead to a broader range of Hobby CNC Mill for Metal Milling options that cater to various skill levels and budgets.

Moreover, as manufacturers continue to innovate, we can expect greater affordability in the market—leading many enthusiasts to wonder how expensive a CNC mill really is. With competitive pricing and improved functionalities on the horizon, hobbyists will find it easier than ever to dive into this rewarding craft. The evolution of these machines promises not just better performance but also enhanced safety features that make them accessible for everyone.

Getting Started with Your Own Mill

If you're ready to jump into the world of CNC steel milling, getting started with your own mill can be an exhilarating journey! First things first: do your research on different models available in the market—some may be labeled as “CNC mill kits,” which are great for beginners looking for straightforward assembly processes. Understand what is the difference between a CNC machine and a CNC mill; knowing these distinctions will help you choose wisely based on your project needs.

Once you've selected your machine, familiarize yourself with its components and software requirements; this groundwork is crucial before embarking on any projects. Don’t hesitate to start small—practice makes perfect! As you gain confidence in your skills and knowledge about whether or not you can indeed CNC mill steel effectively at home, you'll find yourself tackling increasingly complex projects that truly showcase your capabilities.

Community Resources for CNC Hobbyists

One of the greatest advantages of engaging in hobbies like CNC steel milling is the vibrant community surrounding it! Numerous online forums offer advice ranging from beginner tips to advanced techniques; connecting with fellow hobbyists can provide invaluable insights into maximizing your experience with a Hobby CNC Mill for Metal Milling. Additionally, many local maker spaces host workshops where you can learn hands-on skills while networking with like-minded individuals.

Don’t forget about social media platforms where enthusiasts share their projects and troubleshooting tips—these resources are goldmines for inspiration! Whether you're seeking guidance on common mistakes or brainstorming ideas for new projects using your new equipment or kits, there’s no shortage of support out there. Engaging with community resources will not only enhance your learning curve but also make this journey much more enjoyable!