Introduction

In the world of modern manufacturing, stainless steel CNC machining has emerged as a game-changer, enabling precision and efficiency in fabricating complex parts. This advanced technique leverages the capabilities of CNC machines to manipulate stainless steel with remarkable accuracy, making it a favorite among engineers and manufacturers alike. As we dive deeper into this topic, questions like Can stainless steel be CNC machined? and What is the best steel for CNC machining? will be addressed to provide clarity on this essential process.

Understanding Stainless Steel CNC Machining

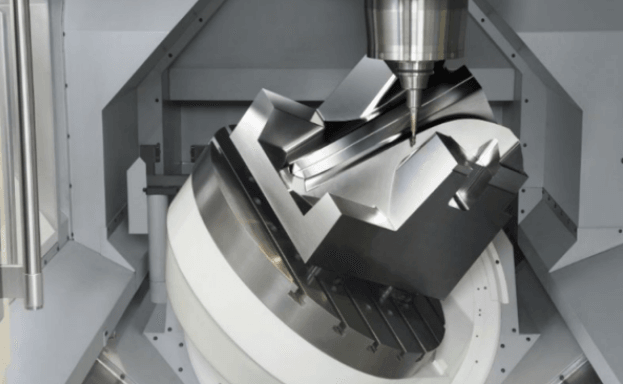

Stainless steel CNC machining involves utilizing computer-controlled machines to cut, shape, and finish stainless steel components. The versatility of stainless steel makes it an ideal material for various applications, from automotive parts to medical devices. However, understanding how these machines work is crucial for achieving optimal results in machining stainless steel.

The Basics of CNC Machines

CNC machines are automated tools that follow programmed instructions to perform precise operations on materials like metal and plastic. These machines can execute complex cuts and shapes that would be impossible or impractical with manual tools. By mastering the basics of how these machines operate, one can unlock their full potential when working with materials such as stainless steel.

Benefits of Using Stainless Steel

Using stainless steel in CNC machining offers numerous advantages, including corrosion resistance, durability, and aesthetic appeal. Its strength-to-weight ratio makes it suitable for demanding environments while maintaining a sleek appearance that appeals to many industries. Additionally, the question Is 304 or 316 easier to machine? often arises when selecting the right grade for specific applications; understanding these distinctions can significantly impact your project's success.

What is CNC Machining?

CNC machining, short for Computer Numerical Control machining, is a modern manufacturing process that utilizes computer software to control machine tools. This technology allows for precise and automated movements of cutting tools, enabling the production of complex parts with minimal human intervention. With its ability to handle various materials, including stainless steel, CNC machining has become essential in industries ranging from aerospace to automotive.

Definition and Overview

At its core, CNC machining involves the use of computer programs to dictate the movements of machinery. These machines can perform various tasks such as milling, turning, and drilling with high accuracy. The integration of stainless steel CNC machines into manufacturing processes has revolutionized how components are produced, ensuring consistent quality and efficiency.

How CNC Machines Operate

CNC machines operate by interpreting a design file created using CAD (Computer-Aided Design) software. Once the design is ready, it is converted into a G-code format that instructs the machine on how to move its cutting tools along multiple axes. This automation not only speeds up production but also reduces errors that can occur during manual machining processes.

Key Components of a CNC Machine

A typical CNC machine comprises several key components that work together seamlessly to achieve precision machining results. The primary elements include the control unit (which houses the computer), drive motors for movement along different axes, and tooling systems designed specifically for cutting materials like stainless steel. Additionally, features such as coolant systems help manage heat generated during machining stainless steel to ensure optimal performance.

Can Stainless Steel Be CNC Machined?

Properties of Stainless Steel

Stainless steel is renowned for its strength, corrosion resistance, and aesthetic appeal. These properties make it a popular choice in various industries, from automotive to aerospace. However, its hardness can pose challenges during machining processes with a stainless steel CNC machine; hence understanding these characteristics is essential for effective machining.

The two most common grades used in CNC machining are 304 and 316 stainless steel. While both offer excellent corrosion resistance, 304 has slightly better machinability due to lower alloy content compared to 316. This leads us into our next point about the challenges faced when working with this resilient material.

Challenges in Machining Stainless Steel

Machining stainless steel can be quite an adventure due to its unique properties that make it different from other metals. One major challenge is work hardening; as you cut into the material, it tends to harden quickly under pressure. This means that if you're not careful with your cutting speeds and feeds on your desktop CNC milling machine or other equipment, you might end up dulling your tools faster than expected.

Another issue is chip formation; stainless steel tends to produce long chips that can wrap around tooling or clog up the machine if not managed properly. Additionally, maintaining proper coolant flow is critical since overheating can lead to poor surface finishes and tool failure. So when asking what machine is used to cut stainless steel?, remember that proper setup and maintenance play vital roles in overcoming these hurdles.

Techniques for Successful Machining

To navigate the challenges of machining stainless steel successfully requires a blend of proper techniques and equipment selection tailored for this tough material. First off, using high-quality cutting tools specifically designed for stainless steels will ensure better performance and longevity during operations on a stainless steel CNC machine. Coated carbide tools are often recommended because they enhance cutting efficiency while reducing friction.

Moreover, selecting appropriate cutting speeds and feeds tailored for specific grades like 304 or 316 can significantly improve results—remember that slower speeds often yield better finishes with less tool wear! Lastly, always keep an eye on coolant usage; effective cooling helps dissipate heat generated during machining while also aiding in chip removal.

By applying these techniques consistently across projects involving machining stainless steel—whether through a desktop CNC machine for metal or larger industrial setups—you’ll pave the way toward achieving high-quality parts efficiently while minimizing common mistakes along the way.

Choosing the Right Stainless Steel Grade

Comparison of 304 and 316 Grades

Grade 304 stainless steel is often referred to as the workhorse of stainless steels, known for its excellent corrosion resistance and good formability. On the other hand, grade 316 is often considered superior due to its added molybdenum content, which enhances its resistance to pitting and crevice corrosion in chloride environments. If you're wondering whether you should use a desktop CNC machine for metal projects involving these grades, both can be effectively machined with the right equipment.

Ease of Machining: 304 vs. 316

When comparing ease of machining between 304 and 316 stainless steel, many machinists find that Is 304 or 316 easier to machine? The answer generally leans towards grade 304 due to its slightly lower hardness and better chip formation during cutting processes. However, advancements in tooling and techniques mean that machining stainless steel—regardless of grade—can be done efficiently with modern CNC machines.

Factors Influencing Your Choice

Several factors will influence your choice between these two grades when working with a stainless steel CNC machine. First off, consider the environment in which your finished product will operate; if it’s exposed to harsh chemicals or marine settings, grade 316 may be worth the extra cost for its durability. Additionally, think about your specific project requirements—what machine is used to cut stainless steel can also impact your choice; some machines handle one grade better than another based on their design features.

Best Machines for Cutting Stainless Steel

Types of Machines for Stainless Steel

Stainless steel CNC machines come in various forms, each designed for specific applications and levels of complexity. Traditional CNC milling machines are popular for their versatility and precision, allowing users to create intricate designs with ease. Additionally, plasma cutting machines are effective for thicker materials, while laser cutters offer high accuracy—ideal when working with thinner sheets of stainless steel.

When considering what is the best steel for CNC machining, it's essential to match the machine type with the material grade you intend to use. For example, harder grades like 316 may require more robust machinery compared to 304 due to their increased toughness. Ultimately, selecting the right machine plays a crucial role in achieving optimal results when machining stainless steel.

The Role of Desktop CNC Machines

Desktop CNC machines have revolutionized how hobbyists and small businesses approach metalworking, especially when it comes to machining stainless steel. These compact devices offer a cost-effective solution without sacrificing quality or precision—perfect for those who might be asking themselves: Can stainless steel be CNC machined? The answer is a resounding yes!

A desktop CNC milling machine can handle various materials but shines particularly bright when working with softer grades like 304 stainless steel. They provide flexibility and ease of use while still delivering impressive results on small-scale projects or prototypes. As more makers turn towards these user-friendly options, they’re discovering that even intricate designs are achievable without needing an industrial setup.

Recommended Brands: SYIL CNC Machine

When searching for reliable brands that specialize in stainless steel CNC machines, SYIL stands out as a top contender in the market. Known for producing high-quality desktop CNC machines tailored specifically for metalworking applications, SYIL has built a reputation among both professionals and hobbyists alike. Their commitment to innovation means you’re not just getting a machine; you're investing in advanced technology designed to make machining stainless steel easier than ever.

With models capable of efficiently handling both 304 and 316 grades, SYIL’s offerings cater to diverse needs within the industry—whether you're looking at small-scale production runs or custom fabrication projects. Additionally, they provide excellent customer support and resources that help users maximize their investment in machinery designed specifically for cutting stainless steel effectively and efficiently.

Tips for Successful Stainless Steel Machining

Tool Selection and Maintenance

Choosing the right tools is paramount when working with a stainless steel CNC machine. High-speed steel (HSS) or carbide tools are often recommended due to their durability and ability to withstand high temperatures generated during machining. Regular maintenance of these tools is equally important; dull or damaged cutting edges can lead to poor surface finishes and increased wear on your machine—nobody wants that!

Additionally, consider using specialized coatings for your tools, such as titanium nitride (TiN), which can enhance their lifespan and performance when machining stainless steel. Remember to keep an eye on tool wear; replacing worn-out tools promptly not only ensures better quality but also helps maintain the integrity of your desktop CNC milling machine. With proper tool selection and maintenance, you’ll be well-equipped for successful stainless steel machining.

Cutting Speeds and Feeds

Understanding cutting speeds and feeds is crucial for effective stainless steel CNC machining. The right combination can significantly impact both the quality of your finished product and the longevity of your tooling—after all, nobody wants to waste time redoing work! Generally speaking, lower speeds are preferred when working with tougher materials like 304 or 316 stainless steel; however, finding that sweet spot requires some experimentation.

For instance, while 304 is generally easier to machine than 316 due to its lower alloy content, understanding how each grade reacts under different conditions will guide you in adjusting speeds accordingly. Don’t forget about feed rates either; too fast can lead to chatter while too slow might cause excessive heat buildup—neither scenario is ideal! By fine-tuning these parameters based on material properties and tooling capabilities, you’ll set yourself up for success with any project.

Common Mistakes to Avoid

Even seasoned machinists can fall prey to common mistakes when working with stainless steel CNC machines—don't be one of them! One frequent error is neglecting proper coolant usage; cooling not only prolongs tool life but also improves surface finish by reducing thermal distortion during machining operations. Always ensure you're using an appropriate coolant designed specifically for metalworking applications.

Another pitfall involves incorrect setup procedures; double-checking work offsets and ensuring fixtures are secure goes a long way in preventing costly errors down the line. Lastly, don’t underestimate the importance of thorough planning before hitting “go” on that desktop CNC machine for metal—skipping this step can lead straight into chaotic territory! By steering clear of these common missteps, you'll find yourself navigating through projects smoothly while achieving stunning results in your stainless steel work.

Conclusion

In wrapping up our exploration of stainless steel CNC machining, it's clear that this process is both a science and an art. Understanding the intricacies of CNC machines and the unique properties of stainless steel is essential for achieving high-quality results. Whether you're a seasoned machinist or a newcomer to the field, knowing how to navigate the challenges associated with machining stainless steel can significantly enhance your projects.

Key Takeaways for CNC Machining

One major takeaway is that stainless steel can indeed be CNC machined effectively, but it requires careful consideration of various factors. The choice between 304 and 316 grades often comes down to specific project needs, with 304 generally being easier to machine than its counterpart. Additionally, selecting the right tools and understanding cutting speeds are crucial for optimizing performance when using a desktop CNC machine for metal.

Future of Stainless Steel Machining

Looking ahead, the future of stainless steel machining seems promising as technology continues to evolve. Innovations in CNC machinery will likely lead to even more efficient processes and better outcomes in terms of precision and quality. As industries demand higher standards, mastering techniques like those used in desktop CNC milling machines will become increasingly important for machinists aiming to stay competitive.

Resources for Further Learning

For those eager to dive deeper into the world of stainless steel CNC machining, there are numerous resources available online and offline. Websites dedicated to machining offer tutorials, forums, and expert advice on questions like What machine is used to cut stainless steel? or Is 304 or 316 easier to machine? Books and courses on metallurgy can also provide valuable insights into choosing the best steel for CNC machining projects.