Introduction

Are you familiar with the different types of CNC machines? These computer numerical control devices have revolutionized manufacturing and production processes. From CNC milling machines to CNC lathe machines, their versatility is truly remarkable. Let's explore the various CNC machine categories and explore their applications and benefits.

Understanding the Different Types of CNC Machines

There are many types of CNC machines to choose from. Each machine is designed for specific tasks, such as precision cutting, drilling, or shaping materials. Technological advancement has led to the development of more sophisticated CNC machine models catering to diverse industrial needs. In addition to traditional CNC machines, hybrid machines combine additive and subtractive manufacturing processes, providing greater flexibility and efficiency in production. These hybrid machines are becoming increasingly popular in industries where complex parts must be manufactured with high precision and speed.

Exploring CNC Machine Categories

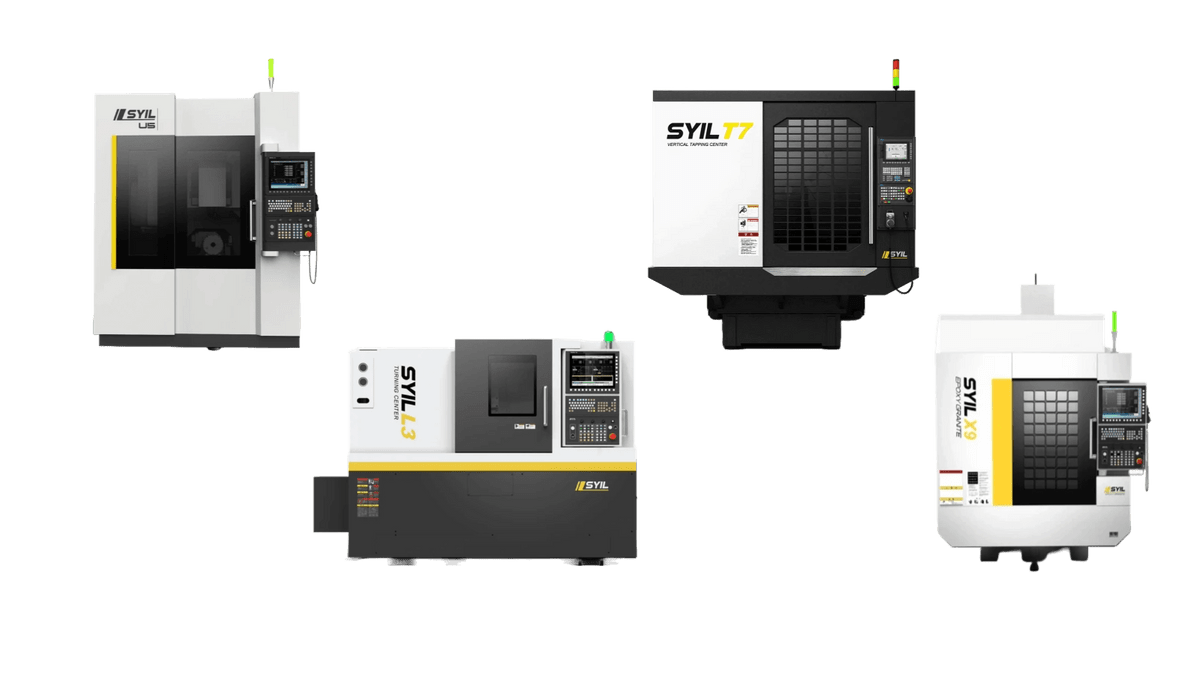

CNC machine categories encompass a range of equipment, including milling machines, lathe machines, drill tap center machines, and 5-axis milling machines. Each category offers unique capabilities and advantages that cater to different manufacturing requirements. Understanding these categories is essential to making informed decisions when investing in CNC equipment.

When considering milling machines, it's important to note that they are versatile and can perform a wide range of tasks, from simple drilling to complex cutting and shaping. On the other hand, lathe machines are ideal for cylindrical or spherical shaping of materials, making them suitable for producing items such as crankshafts and camshafts. Additionally, drill tap center machines are explicitly designed for drilling, tapping, and milling operations in a single setup, offering efficiency and precision in manufacturing processes.

The Versatility of CNC Devices

CNC machines are revolutionizing manufacturing with their unparalleled versatility. Here's why:

- Unmatched Accuracy and Consistency: CNC machines perform complex operations with precise control, minimizing human error and ensuring consistent results.

- Enhanced Productivity: Automation streamlines production, significantly boosting output compared to manual machining.

- Cost Efficiency: Reduced waste, faster production times, and minimal human intervention contribute to lower overall manufacturing costs.

In essence, CNC machines are the backbone of modern manufacturing, enabling precision engineering and high-speed production. This understanding paves the way for exploring specific machine types, including milling machines, lathes, and more, offered by leading manufacturers like SYIL.

Exploring CNC Milling Machines

Introduction to CNC Milling

CNC milling is a computer numerical control (CNC) machine that utilizes rotating cutting tools to remove material from a workpiece. SYIL's CNC milling machines are designed with precision and efficiency in mind, making them ideal for a wide range of applications.

CNC milling machines offer unparalleled precision and accuracy, allowing for effortless production of intricate and complex parts. With SYIL's CNC milling machines, you can achieve tight tolerances and high surface finishes, making them perfect for the aerospace, automotive, and medical industries. Whether you need to produce prototypes or mass-produce parts, these machines always deliver consistent and reliable results.

Advantages of SYIL CNC Milling Machine

SYIL CNC milling machines are popular for hobbyists and professionals due to their impressive capabilities. Here's what makes them stand out:

- Exceptional Precision: SYIL machines deliver high accuracy, ensuring your projects meet exact specifications.

- Fast Production: Rapid production cycles allow you to complete projects efficiently, saving valuable time.

- Complex Designs Made Easy: SYIL machines easily handle intricate shapes and designs, expanding your creative possibilities.

- User-Friendly Interface: A user-friendly interface makes SYIL machines accessible to beginners and experienced users.

- Robust Construction: Their robust build ensures long-lasting performance and reliability.

- Seamless CAD/CAM Integration: Advanced software allows for smooth integration with CAD/CAM systems, streamlining the workflow from design to production. This translates to greater efficiency and precision in manufacturing a wide range of parts.

SYIL CNC milling machines combine precision, speed, design flexibility, user-friendliness, and robust construction, making them a top choice for anyone looking to bring their projects to life.

Applications of CNC Milling Machines

SYIL CNC milling machines are known for their versatility and precision, making them a valuable asset for various industries. Here's what makes them stand out:

- Industry Versatility: SYIL's machines are used in a wide range of applications, from aerospace and automotive to medical device manufacturing.

- Reliable Production: They deliver consistent results with minimal downtime, ensuring efficient prototyping or mass production operation.

- Investment in Quality: Choosing a SYIL CNC milling machine is an investment in top-tier equipment, enhancing your production capabilities while guaranteeing precision and reliability.

- Scalability for All: Whether you're a seasoned professional or new to the machining world, SYIL offers solutions to fit your experience level.

SYIL CNC milling machines provide versatility, reliability, and precision, making them a smart choice for businesses of all sizes and experience levels.

Delving into CNC Lathe Machines

Introduction to CNC Lathe

When it comes to the types of CNC machines, the computer numerical control (CNC) lathe machine stands out for its precision and efficiency. With SYIL’s top-notch CNC lathe machine, you can expect nothing less than exceptional performance and accuracy in your machining operations. Whether you’re working on prototypes or large-scale production runs, a CNC lathe machine is a valuable asset in any workshop. Additionally, SYIL’s precision CNC lathe machine offers advanced features such as automatic tool changers and high-speed spindles, allowing for seamless and efficient machining processes. This means you can increase productivity and reduce downtime, ultimately leading to cost savings for your business.

SYIL’s Precision CNC Lathe Machine

SYIL takes pride in offering a precision CNC lathe machine designed to meet modern manufacturing demands. With advanced features and cutting-edge technology, our CNC lathe machines deliver unparalleled results, making them the perfect choice for businesses looking to elevate their productivity and quality standards.

Our precision CNC lathe machines have state-of-the-art controls and software, allowing for easy programming and precise execution of complex machining tasks. This means that businesses can streamline their production processes and reduce the margin for error, ultimately leading to higher efficiency and cost savings. With SYIL’s precision CNC lathe machine, you can stay ahead of the competition by delivering superior quality products promptly.

Uses of CNC Lathe Machines

From creating intricate designs to producing complex parts with utmost precision, the uses of CNC lathe machines are diverse and extensive. Whether you’re in the automotive, aerospace, or medical industry, SYIL’s CNC lathe machines are versatile enough to handle a wide range of applications easily. These machines can also be used for turning, facing, drilling, and threading operations, making them indispensable in various manufacturing processes. With their ability to work with various materials such as metal, plastic, and wood, CNC lathe machines offer endless possibilities for creating custom components and prototypes.

In addition to their versatility in handling a wide range of applications, CNC lathe machines also offer the advantage of high precision and accuracy in producing components. This makes them an ideal choice for industries that require intricate and complex parts, such as the aerospace and medical sectors. The ability to work with various materials further enhances the flexibility of these machines, allowing manufacturers to explore new possibilities and push the boundaries of design and innovation. With CNC lathe machines, businesses can streamline their production processes and consistently deliver high-quality products.

Unveiling CNC Drill Tap Center Machines

Regarding the different types of CNC machines, the CNC drill tap center stands out for its precision and efficiency. This computer numerical control device is designed for high-speed drilling, tapping, and milling operations, making it a versatile tool in various manufacturing processes. With SYIL’s high-performance CNC drill tap center, you can expect exceptional accuracy and productivity in your operations.

Introduction to CNC Drill Tap Center

The CNC drill tap center is a specialized CNC machine that combines drilling and tapping functions in one unit, allowing for seamless production processes. With its advanced technology and user-friendly interface, this machine offers precise control over drilling depths and tapping speeds, resulting in superior-quality output. SYIL’s CNC drill tap center is designed to streamline production processes while maintaining high accuracy and consistency.

SYIL’s High-Performance CNC Drill Tap Center

SYIL’s high-performance CNC drill tap center is equipped with state-of-the-art features that enhance its capabilities for various machining tasks. From rapid tool changes to efficient chip management, this machine is engineered to optimize productivity and minimize downtime. With its robust construction and cutting-edge components, SYIL’s CNC drill tap center delivers exceptional performance that meets the demands of modern manufacturing operations.

Benefits of CNC Drill Tap Center Machines

CNC drill tap centers offer a powerful combination of speed, accuracy, and adaptability for machining operations. Here's how they elevate your production:

- Boosted Efficiency: CNC automation eliminates manual tool changes and streamlines workflows, significantly increasing production rates.

- Reduced Setup Times: Once programmed, the CNC system flawlessly replicates hole patterns and tapping sequences, minimizing setup time between jobs.

- Enhanced Precision: Computer-controlled movements ensure consistent hole placement and thread formation, exceeding manual machining tolerances.

- Material Versatility: CNC drill tap centers easily handle a wide range of materials, from soft aluminum to stricter steel.

- Complex Geometry Mastery: These machines tackle intricate hole patterns and geometries with exceptional accuracy, which is ideal for challenging projects.

By incorporating a CNC drill tap center from a reputable manufacturer like SYIL, businesses can achieve superior quality output, reduce production bottlenecks, and gain a competitive edge. With its versatility and advanced capabilities, this machine becomes a cornerstone of any modern machining facility.

Understanding CNC 5-Axis Milling Machines

CNC 5-axis milling machines are a game-changer in the manufacturing industry, offering unparalleled precision and versatility. With the ability to move along five different axes simultaneously, these machines can quickly produce complex parts. Whether it's aerospace components or intricate molds, CNC 5-axis milling machines can handle a wide range of tasks.

Introduction to CNC 5-Axis Milling

CNC 5-axis milling revolves around the machine's ability to move along five axes – X, Y, Z, and two rotational axes. This allows for multi-sided machining and complex geometries that would be impossible to achieve with traditional 3-axis machines. The result is higher efficiency and accuracy in production processes.

SYIL’s Efficient CNC 5-Axis Milling Machine

SYIL offers a range of highly efficient CNC 5-axis milling machines designed to meet modern manufacturing demands. With state-of-the-art technology and precision engineering, SYIL's machines deliver exceptional performance and reliability. From small-scale workshops to large industrial operations, SYIL's CNC 5-axis milling machines are built to excel in any setting.

Applications of CNC 5-Axis Milling Machines

The applications for CNC 5-axis milling machines are vast and varied. They are commonly used in aerospace, automotive, medical device manufacturing, and other industries. Their ability to produce complex shapes and contours makes them indispensable for creating intricate components that require high precision.

SYIL's Efficient CNC 5-axis Milling Machine handles complex tasks with ease while delivering exceptional precision and efficiency. Its advanced technology makes it ideal for businesses looking to elevate their production capabilities.

Invest in Quality CNC Equipment

In conclusion, when choosing the suitable CNC machine for your needs, it's essential to consider your projects' specific applications and requirements. Whether you need a CNC milling machine for precision cutting or a CNC lathe machine for shaping materials, understanding the different types of CNC machines is crucial in making an informed decision. Investing in quality CNC equipment is essential for ensuring reliable performance and long-term durability. SYIL's range of CNC machines offers versatility, precision, and efficiency, making them an ideal choice for enhancing production processes across various industries.

Choosing the Right CNC Machine for Your Needs

Assessing the specific functions and capabilities required for your projects is essential when selecting a CNC machine. Different types of CNC machines offer unique features and applications, so it's crucial to understand how each type can benefit your production processes. Whether you need computer numerical control for milling, turning, drilling, or multi-axis operations, SYIL provides a comprehensive range of high-quality CNC machines to meet diverse manufacturing needs.

Investing in quality CNC equipment is a strategic decision that can significantly impact the efficiency and productivity of your operations. SYIL's commitment to delivering top-notch precision engineering ensures that its CNC machines are built to withstand rigorous manufacturing demands while maintaining exceptional accuracy and reliability. By choosing SYIL as your trusted supplier of CNC machines, you can rest assured that you're investing in durable equipment designed to optimize performance and deliver consistent results.

Enhancing Production with SYIL CNC Machines

SYIL's innovative range of CNC devices offers advanced features and cutting-edge technology to elevate production capabilities across various industries. From their efficient CNC milling machines to their precision-engineered lathe machines and drill tap centers, SYIL provides versatile solutions that cater to diverse manufacturing requirements. By integrating SYIL's state-of-the-art equipment into your production processes, you can enhance operational efficiency, achieve higher levels of accuracy, and ultimately drive greater success in your manufacturing endeavors.