Introduction

In the world of manufacturing and DIY projects, affordable CNC routers for metal have become a game changer. With the rise of CNC technology, hobbyists and professionals alike can now engage in precision work that was once reserved for high-end industrial settings. This guide will delve into the ins and outs of CNC milling machines, helping you understand their capabilities and benefits.

Affordable CNC Routers for Metal

When considering a cnc milling machine for metal, affordability is often at the forefront of buyers' minds. Fortunately, there are numerous options available that provide excellent performance without breaking the bank. Whether you're looking to create intricate designs or perform heavy-duty tasks, an affordable CNC router can meet your needs efficiently.

Benefits of CNC Technology

CNC technology offers several benefits that make it an attractive choice for both hobbyists and professionals. One major advantage is precision; with a cnc milling machine for metal, you can achieve meticulous accuracy in your cuts and designs. Additionally, automation allows users to produce consistent results over time—perfect for those wondering, Can you use a CNC machine for metal? The answer is a resounding yes!

Overview of CNC Milling Machines

So what exactly is a cnc milling machine used for? These versatile machines are designed to cut various materials with high precision through computer-controlled movements. From creating complex parts to engraving detailed designs on metal surfaces, they serve multiple purposes across industries. However, potential buyers often ask themselves: How expensive is a CNC mill? Understanding price points can help you make informed decisions tailored to your budget while ensuring quality output in your projects.

Understanding CNC Milling Machines

CNC milling machines are the unsung heroes of modern manufacturing, bridging the gap between creativity and precision. These machines transform raw materials into intricate designs with the help of computer numerical control technology. Whether you're a hobbyist or a professional, understanding what a CNC milling machine is used for can unlock new possibilities in your projects.

What is a CNC Milling Machine Used For?

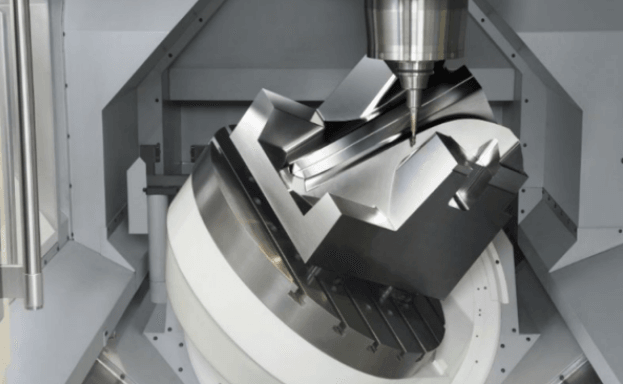

A CNC milling machine is primarily used for shaping and cutting materials into desired forms, making it indispensable in various industries. From creating complex parts for aerospace to crafting custom furniture, the applications are virtually limitless. If you've ever wondered, What is a CNC milling machine used for? think of it as your go-to tool for precision machining across multiple materials.

The versatility doesn’t stop there; these machines can also be programmed to perform repetitive tasks with impeccable accuracy. This makes them ideal for both prototyping and mass production scenarios where consistency is key. So whether you're looking to manufacture small components or large-scale projects, a CNC milling machine has got you covered.

Can You Use a CNC Machine for Metal?

Absolutely! One of the most common inquiries among budding machinists is, Can you use a CNC machine for metal? The answer is a resounding yes! In fact, many professionals rely on CNC milling machines specifically designed to handle metals like aluminum, brass, and even steel.

Using specialized tooling and appropriate settings allows these machines to cut through metal with ease while maintaining high levels of precision. If you're considering venturing into metalworking with your CNC router or mill, rest assured that these machines are equipped to take on such challenges—just make sure you have the right specifications in place!

How Expensive is a CNC Mill?

For those just starting out or operating on tighter budgets, there are affordable options that still deliver solid performance without breaking the bank. It’s essential to weigh what you need against what you’re willing to spend; remember that investing in quality often pays off in terms of reliability and longevity.

Top Affordable CNC Router Brands

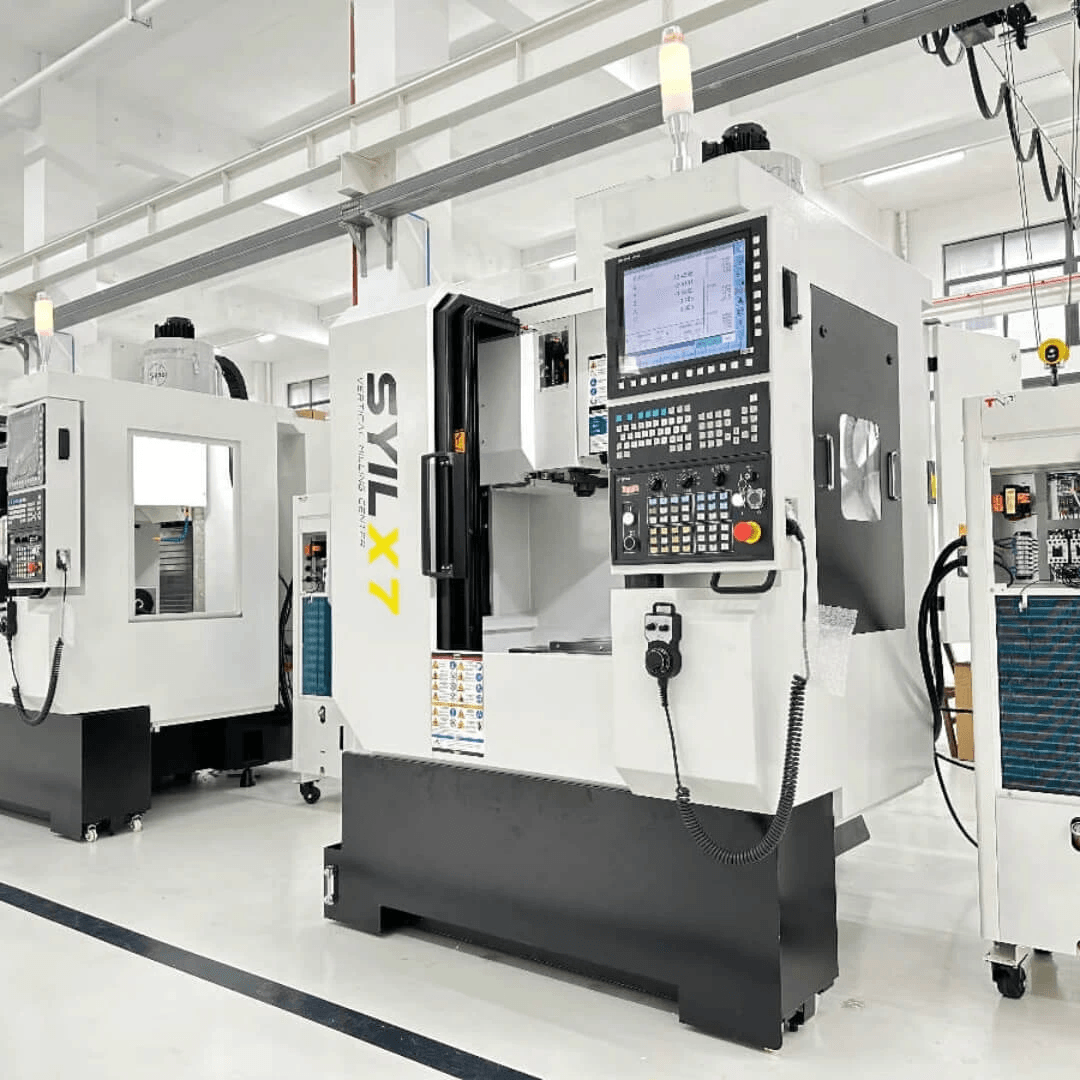

SYIL CNC Machines Overview

SYIL has made waves in the industry by providing high-quality yet budget-friendly options for those looking to delve into CNC milling machines for metal. Their machines are designed with precision and reliability in mind, making them an excellent choice for both hobbyists and professionals alike. But what is a CNC milling machine used for? Primarily, it's employed to cut and shape materials with incredible accuracy—ideal for projects involving metals.

One of the standout features of SYIL's offerings is their versatility; many users ask, Can a CNC mill cut steel? The answer is yes! With robust construction and powerful motors, SYIL machines can handle various metals effectively. As you explore your options, consider how expensive a CNC mill can be; SYIL provides competitive pricing without sacrificing performance or durability.

In addition to their affordability, SYIL's customer service and support are often highlighted in reviews from satisfied users. Many enthusiasts appreciate the ease of use and software compatibility that come with these machines. If you're serious about investing in a reliable cnc milling machine for metal that won’t break the bank, SYIL deserves your attention.

Features to Consider in CNC Routers

When diving into the world of CNC routers, especially those designed for metalwork, there are several features that can significantly impact your experience and results. Understanding what to look for in a CNC milling machine for metal is crucial to making an informed decision. Let's break down the key features you should consider before making a purchase.

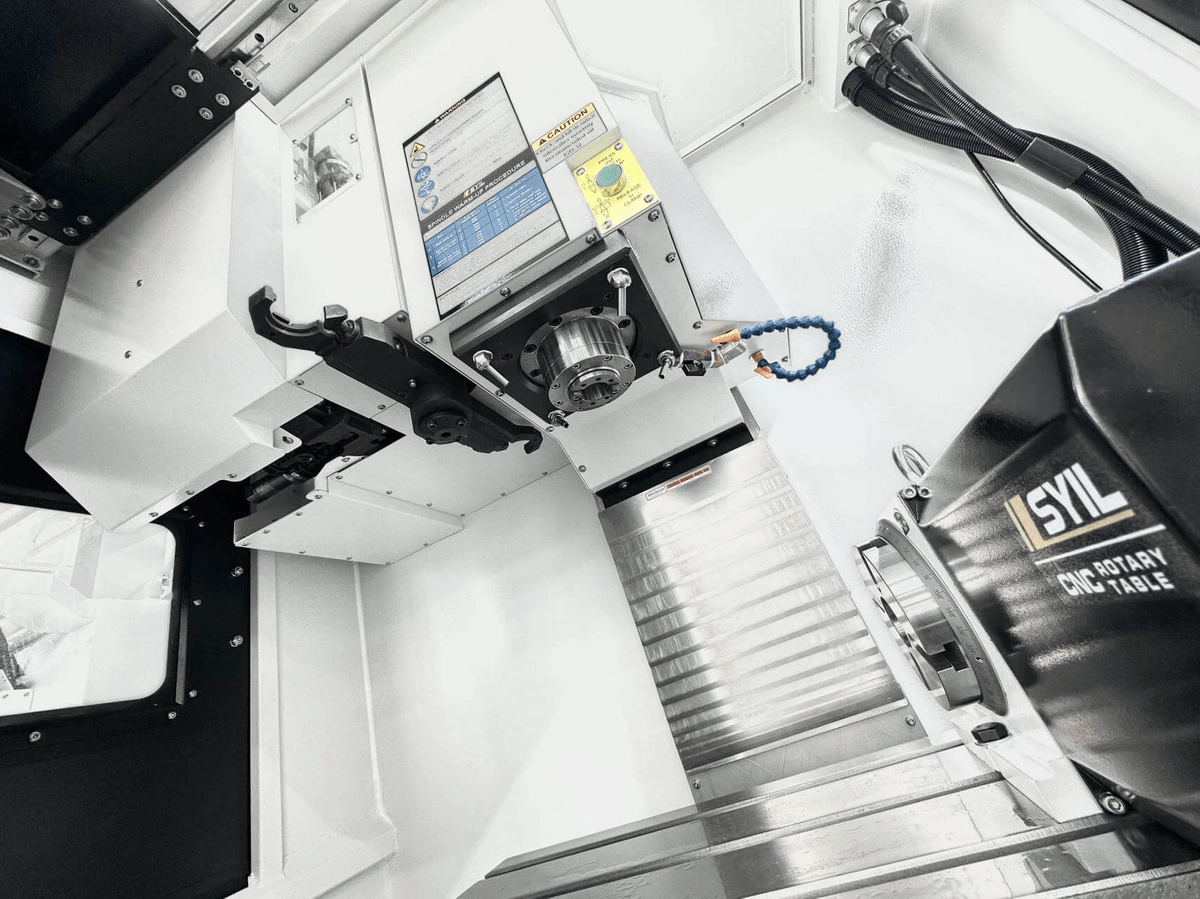

Precision and Accuracy

Precision and accuracy are paramount when it comes to a CNC milling machine for metal. The ability of a machine to produce parts that meet exact specifications can make or break your project, especially in industries where tolerances are tight. When asking yourself, What is a CNC milling machine used for? remember that its primary role is to create high-quality components with minimal deviation from design plans.

Speed and Power Requirements

Speed and power requirements are essential factors when evaluating how expensive a CNC mill can be. Generally speaking, more powerful machines tend to come at a higher price point but offer better performance when cutting through tougher materials like steel. If you're wondering, Can you use a CNC machine for metal? the answer lies heavily in its power capabilities; not all routers have the muscle needed for heavy-duty tasks.

When assessing speed requirements, consider both rapid traverse rates (how fast the tool moves without cutting) and cutting speeds (how quickly it can actually cut through material). A good balance between these two metrics will help maximize productivity while maintaining quality output. Remember that while speed is important, it shouldn't compromise precision—after all, what's the point of cutting quickly if you're not getting accurate results?

Software Compatibility

Software compatibility is another critical consideration when choosing your ideal CNC milling machine for metal work. The software you use dictates how effectively you can design parts and control your machinery during operation; thus, ensuring compatibility with popular CAD/CAM programs should be high on your priority list. Many users often overlook this aspect until they realize their chosen router doesn’t support their preferred software—leading to frustration down the line.

Furthermore, some machines come bundled with proprietary software that may limit your options or require additional training time before you can start producing parts efficiently. Be sure to check whether updates are provided regularly by manufacturers as technology evolves rapidly within this field! Ultimately, having seamless integration between hardware and software ensures smooth operations—allowing you more time crafting masterpieces rather than troubleshooting issues.

Comparing Price and Performance

Budget vs. Features

Budget constraints are a common concern when shopping for a CNC milling machine for metal. While it might be tempting to go for the cheapest option available, this could lead to compromises in features that are critical for your projects. For example, entry-level models may lack the precision or power necessary for more demanding tasks, prompting the question: Can you use a CNC machine for metal? The answer is yes, but only if you choose one equipped with adequate specifications.

Investing in a higher-end model may seem daunting at first glance due to the upfront costs; however, consider it as an investment in quality and longevity. Machines that offer advanced features like better precision and faster speeds can save you time and material costs in the long run. Therefore, when weighing budget against features, aim for a balance that aligns with both your financial capacity and your project requirements.

What to Expect from Entry-Level Models

Entry-level CNC milling machines can serve as excellent starting points for hobbyists or small businesses venturing into metalwork. However, expectations should be managed regarding their capabilities; they typically excel at basic tasks but may struggle with more complex projects involving harder materials like steel. If you're asking yourself What is a CNC milling machine used for?—the answer varies widely from simple engraving to intricate machining tasks.

These models usually come equipped with enough power to handle softer metals such as aluminum or brass effectively but might not be suitable if you're specifically looking at cutting steel regularly. Additionally, while they provide an accessible entry point into CNC technology without breaking the bank, users should remain aware of their limitations concerning speed and precision compared to mid-range or professional machines.

Ultimately, entry-level models are great learning tools but may require an upgrade as your skills develop or project demands increase.

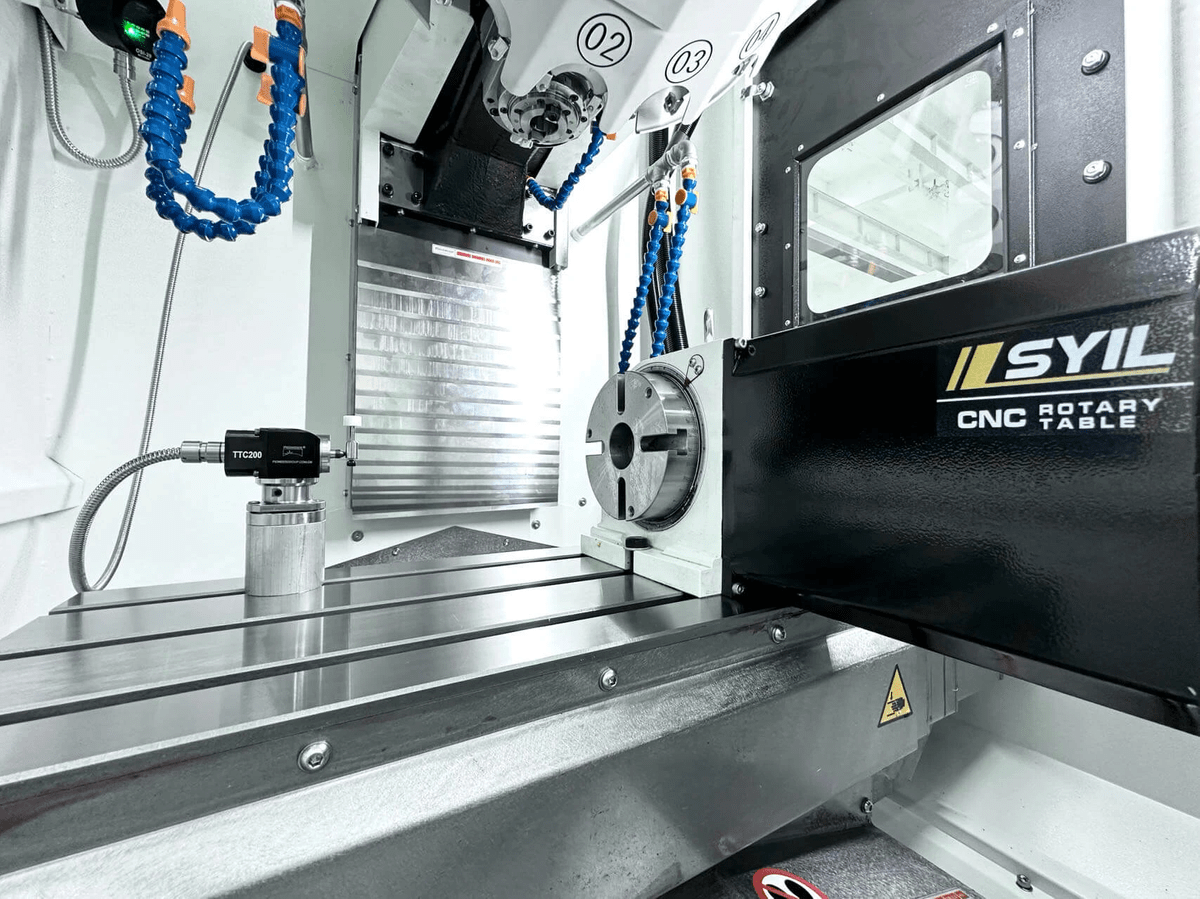

Can a CNC Mill Cut Steel?

Before making any purchase decisions about your next CNC milling machine for metal, check its compatibility with various types of steel alloys you'll likely encounter in your work environment. It’s also wise to invest in high-quality tooling designed explicitly for cutting through harder materials; this can drastically improve efficiency while minimizing wear on both tools and machinery alike.

In summary, while many affordable options exist on the market today capable of handling various metals—including steel—ensure you choose wisely based on both performance metrics and specific project needs.

User Reviews and Recommendations

When it comes to investing in a CNC milling machine for metal, user reviews provide invaluable insights that can guide potential buyers. Many customers have shared their experiences with SYIL CNC machines, highlighting both their strengths and weaknesses. Overall, users appreciate the precision and versatility of these machines, often noting how they can tackle various materials beyond just metal.

Customer Experiences with SYIL

Customers who have purchased SYIL CNC milling machines frequently rave about their reliability and performance. Users report that these machines excel in what is a CNC milling machine used for—ranging from intricate designs to heavy-duty projects involving metals like aluminum and even steel. However, some users have raised concerns about the learning curve associated with operating the software; many recommend taking time to familiarize yourself with it to maximize your machine’s capabilities.

In terms of pricing, many customers question how expensive a CNC mill really is when considering SYIL models. While some entry-level options are more affordable, users emphasize that investing in higher-end models pays off in durability and performance over time. Overall, customer feedback suggests that those who take the plunge into SYIL's offerings find them well worth the investment for anyone serious about machining metal.

Best Practices from CNC Enthusiasts

CNC enthusiasts often share best practices that can significantly enhance the user experience when working with a CNC milling machine for metal. One common tip is to prioritize proper maintenance; regular cleaning and lubrication can extend the life of your machine while ensuring consistent results. Additionally, enthusiasts recommend experimenting with different feeds and speeds based on material types—this not only optimizes cutting efficiency but also reduces wear on tools.

Another best practice involves understanding whether you can use a CNC machine for metal effectively by selecting appropriate tooling designed specifically for harder materials like steel or titanium. Enthusiasts suggest starting with softer metals such as aluminum before progressing to more challenging materials; this approach helps build confidence while mastering techniques specific to each type of material. Finally, joining online forums or local clubs allows users to share insights and troubleshoot issues collectively.

Common Issues and Solutions

Like any technology, using a CNC milling machine for metal comes with its own set of challenges—some common issues include tool wear, software glitches, or calibration problems. Users often report experiencing unexpected tool breakage when cutting harder metals like steel; however, proper tool selection combined with correct speed settings usually mitigates this issue effectively. Additionally, keeping an eye on coolant levels during operation helps maintain optimal temperatures while prolonging tool life.

Another frequent concern revolves around understanding how expensive a CNC mill can be regarding operational costs beyond initial purchase price—such as tooling replacements or software updates—which can add up quickly if not anticipated correctly. To address this concern, many experienced users suggest budgeting for these ongoing costs upfront instead of viewing them as surprises later down the line. By being proactive about maintenance routines and budgeting wisely for consumables associated with running your machine efficiently ensures longevity in your investment.

Conclusion

In wrapping up our exploration of affordable CNC routers for metal, it's essential to weigh your options carefully. Choosing the right CNC machine can significantly impact your projects, whether you're a hobbyist or a professional. By understanding what is a CNC milling machine used for and how it fits your needs, you can make an informed decision that aligns with your budget and performance expectations.

Choosing the Right CNC Machine

When considering which CNC milling machine for metal to purchase, think about the specific tasks you'll be performing. Can you use a CNC machine for metal? Absolutely! However, not all machines are created equal; some are better suited for softer materials while others excel at cutting steel with precision. Evaluate factors like size, power requirements, and software compatibility to ensure that the machine you choose meets your operational demands.

Understanding how expensive a CNC mill can be is also crucial in this decision-making process. Entry-level models may be more budget-friendly but could lack features necessary for heavy-duty tasks like cutting steel effectively. Ultimately, balancing cost with functionality is key—investing in a reliable machine now may save you from costly upgrades down the road.

The Value of Investing in CNC Technology

Investing in a quality CNC milling machine for metal can yield significant returns over time. These machines not only enhance precision but also improve efficiency and reduce waste during production processes. When asking yourself Can a CNC mill cut steel? remember that modern machines are designed to handle various metals with ease, making them versatile tools in any workshop.

Moreover, adopting CNC technology allows businesses to stay competitive in an increasingly automated world. As industries evolve towards smarter manufacturing solutions, having access to advanced machinery will set you apart from competitors still relying on traditional methods. With proper training and maintenance, these machines can serve their owners well for years.

Future Trends in CNC Milling Machines

Looking ahead, several trends are shaping the future of CNC milling machines that every potential buyer should consider. The integration of artificial intelligence and automation technologies promises enhanced capabilities—think predictive maintenance alerts or real-time adjustments during machining processes based on material behavior!

Additionally, advancements in software compatibility mean that future models will likely offer seamless integration with various design programs, making it easier than ever to transition from concept to finished product efficiently. As manufacturers continue innovating around materials and techniques suitable for cutting metals like steel or aluminum effectively using these machines, staying informed about emerging trends will help you make smarter investment choices.