Introduction

In the realm of modern manufacturing, CNC milling machines stand out as a beacon of precision and efficiency. These advanced tools are not just a luxury for high-end industries; they have become integral to various sectors, transforming how we design and produce everything from intricate jewelry to complex automotive parts. But what is a CNC milling machine used for? This question opens the door to understanding the vast capabilities and everyday applications of this remarkable technology.

Understanding CNC Milling Machines

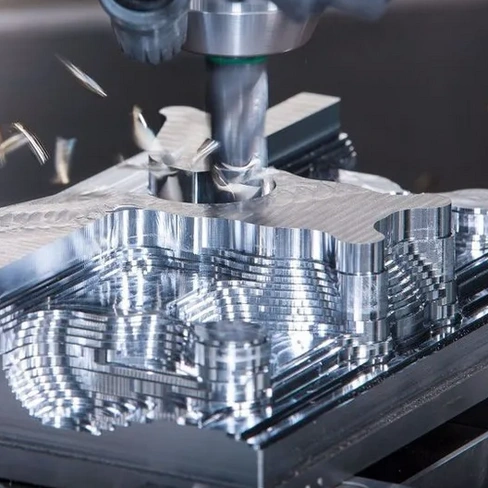

At its core, a CNC milling machine utilizes computer numerical control (CNC) to automate the machining process, allowing for incredibly precise cuts and shapes in materials such as metal, plastic, and wood. Unlike traditional manual lathes or mills, which require direct human intervention, CNC machines operate based on programmed commands that dictate their movements with pinpoint accuracy. So what is the main use of a CNC machine? It's primarily employed in creating detailed components that require exact specifications—an essential aspect across numerous industries.

The Power of Precision Engineering

The beauty of CNC technology lies in its ability to deliver consistent results with minimal human error. Why would you use a milling machine? Because it can produce identical parts at scale without sacrificing quality—something traditional methods struggle to achieve over time. Whether you're crafting prototypes or running high-volume production runs, understanding where CNC milling is used can help businesses leverage this technology effectively for maximum output.

Everyday Applications of CNC Technology

CNC milling has infiltrated various industries, showcasing its versatility through numerous applications—from prototyping new products to engraving personalized designs on items like trophies or electronics casings. In fact, there are countless uses for CNC machining; just consider the 7 uses of CNC machining that span from medical device manufacturing to aerospace components! As we explore further into this guide, we'll delve into specific applications including jewelry making and automotive production that highlight how essential these machines have become in our everyday lives.

Prototyping and Design Models

In the world of manufacturing and design, CNC milling machines play a pivotal role in prototyping and creating design models. These sophisticated tools allow for high precision and versatility, enabling designers to bring their visions to life with remarkable accuracy. So, what is a CNC milling machine used for in prototyping? Essentially, they are employed to create intricate parts quickly and efficiently, making them indispensable in various industries.

What is a CNC milling machine used for in prototyping?

CNC milling machines are primarily used for producing precise prototypes that can be tested before full-scale production begins. By utilizing computer-controlled systems, these machines can carve out materials with incredible accuracy, allowing designers to assess form, fit, and function effectively. This capability not only streamlines the prototype development process but also reduces the risk of costly errors down the line.

The role of CNC mills in product development

The role of CNC mills in product development cannot be overstated; they serve as a bridge between concept and reality. Engineers use these machines to create prototypes that mimic the final product's specifications closely, thus facilitating better testing procedures. Moreover, by employing CNC technology early on in the design phase, teams can iterate more rapidly—a crucial factor when time-to-market is key.

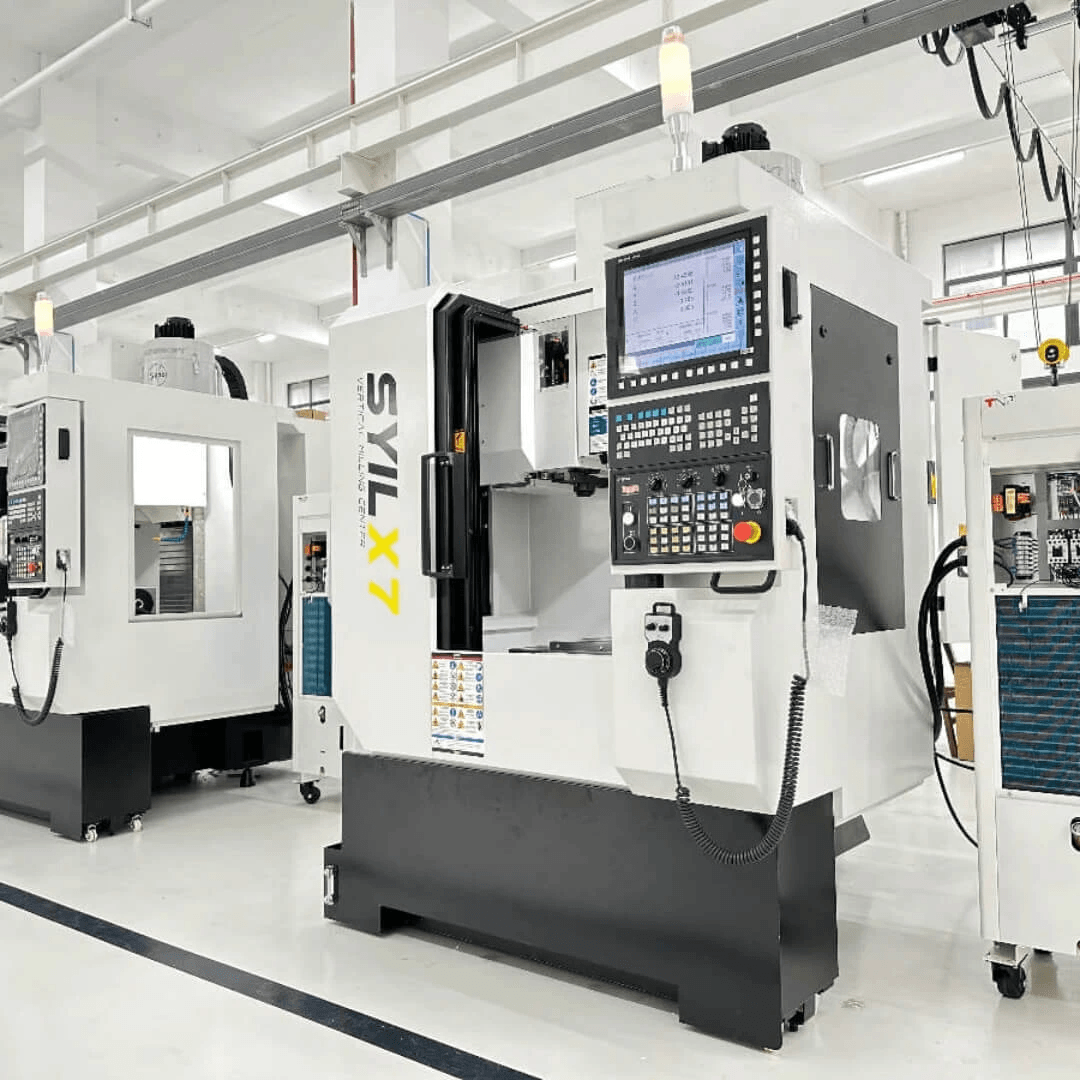

Benefits of using SYIL X5 mini CNC machine for prototypes

When it comes to prototyping specifically, the SYIL X5 mini CNC machine offers several advantages that make it stand out from traditional methods or larger models. Its compact size allows it to fit into smaller workshops while still delivering impressive precision—perfect for creating detailed components or intricate designs often needed during prototype stages. Additionally, this machine is user-friendly and cost-effective; it’s ideal for hobbyists or small businesses looking to explore what is the main use of a CNC machine without breaking the bank.

Precision Engraving and Personalization

CNC milling machines have transformed the landscape of engraving, offering unparalleled precision and versatility. These machines are not only capable of creating intricate designs but also allow for personalization that adds a unique touch to various products. Understanding what is a CNC milling machine used for in engraving can open up new avenues for creativity and craftsmanship.

Why would you use a milling machine for engraving?

Using a milling machine for engraving provides several advantages over traditional methods. First, CNC technology ensures that every design is executed with remarkable accuracy, which is essential when working on detailed projects. Additionally, the ability to automate the engraving process allows for consistent results across multiple items, making it an ideal choice for businesses looking to scale their production.

When considering what is the main use of a CNC machine in engraving, it's clear that customization plays a vital role. From personalized gifts to branded merchandise, CNC mills can engrave logos or names with ease. This capability not only enhances aesthetic appeal but also fosters customer loyalty through unique offerings.

Moreover, why would you use a milling machine? The answer lies in its efficiency and speed compared to manual methods. With CNC technology, engravings can be completed in less time while maintaining high quality—perfect for those tight deadlines!

Detailed engraving capabilities of CNC milling parts

CNC milling parts are equipped with advanced features that enable detailed and complex engravings that would be nearly impossible by hand. These machines can handle various materials such as wood, metal, plastic, and more—each requiring different settings and tools tailored specifically for the task at hand. The precision offered by CNC mills means even the most intricate patterns can be replicated flawlessly.

One significant difference between a CNC machine and a CNC mill is their specific applications; while both utilize computer numerical control technology, mills are particularly adept at cutting shapes into solid materials while simultaneously allowing for fine detailing during engraving processes. This makes them invaluable in industries where precision matters most—think jewelry making or custom sign creation.

The 7 uses of CNC machining extend well into the realm of detailed work as well; from creating architectural models to crafting custom awards or trophies—CNC machines excel at producing high-quality engraved products consistently over time.

Enhancing products with custom designs

Custom designs created through precision engraving elevate products beyond standard offerings into something truly special and memorable. By incorporating personalized elements using what is a cnc milling machine used for in this context, businesses can differentiate themselves from competitors who may offer similar items without customization options.

This personalization isn't just limited to aesthetics; it often carries emotional significance as well—think wedding gifts engraved with names or dates that make them cherished keepsakes! Such thoughtful touches resonate deeply with customers who appreciate unique craftsmanship tailored just for them.

In conclusion, leveraging the capabilities of CNC lathe machines alongside milling technology allows artisans to explore endless possibilities when enhancing products with custom designs. The combination of precision engineering and personal touch creates an exceptional value proposition that keeps customers coming back time after time.

Jewelry Making with CNC Technology

CNC technology is reshaping the landscape of jewelry design, allowing artisans to create pieces that were once thought impossible. This innovation provides jewelers with tools that enhance creativity and precision, making it easier to transform ideas into tangible art. With CNC milling machines at their disposal, designers can achieve intricate details and complex forms, pushing the boundaries of traditional craftsmanship.

How CNC milling is revolutionizing jewelry design

So, what is a CNC milling machine used for in jewelry making? Essentially, it allows for high-precision cuts and engravings that elevate the quality of each piece. By integrating computer-aided design (CAD) software with CNC technology, jewelers can produce custom designs quickly and efficiently, providing personalized options for clients while maintaining consistent quality.

The main use of a CNC machine in this context revolves around its ability to execute designs with remarkable accuracy. Unlike manual techniques that rely heavily on the jeweler's skill level, CNC machines ensure uniformity across multiple pieces. This means that whether creating one ring or a hundred identical pendants, each item will meet the same high standards.

Crafting intricate patterns in metals with precision

CNC milling parts are designed specifically for precision work; they allow jewelers to produce complex geometries without compromising on quality. The automation involved reduces human error significantly while speeding up the production process—perfect for those who want unique pieces without waiting ages for completion. This technological advancement enables designers to experiment more freely with their creativity.

Benefits of CNC lathe machines for jewelers

In addition to milling machines, many jewelers benefit from using CNC lathe machines as well; these tools specialize in creating round shapes and symmetrical designs efficiently. What is the difference between a CNC machine and a CNC mill? While both are controlled by computer programs to ensure precision cuts, lathes focus on rotating materials against cutting tools rather than moving tools against stationary materials like mills do.

Utilizing both types of machinery allows jewelers greater versatility when crafting their creations—resulting in unique items tailored specifically to customer desires. Moreover, these machines enable high-volume production runs without sacrificing detail or craftsmanship quality—a win-win situation! With this combination of technology at their fingertips, artisans can easily explore new styles while meeting market demands effectively.

High-Volume Production Runs

CNC milling machines have become indispensable in high-volume production runs across various manufacturing sectors. From automotive parts to electronics, these machines are utilized for their ability to produce consistent, high-quality components at scale. So, what is a CNC milling machine used for in this context? Primarily, they create precise and intricate parts that meet stringent industry standards while minimizing waste and maximizing efficiency.

Where is CNC milling used in manufacturing?

CNC milling is prevalent in industries such as automotive, aerospace, medical devices, and consumer goods. In these sectors, the question Where is CNC milling used? often leads to answers involving the production of complex components that require exact specifications. Whether it's crafting gears for vehicles or specialized components for aircraft, the versatility of CNC milling parts allows manufacturers to tackle a wide range of applications effectively.

The scalability of CNC machines for production

One of the standout features of CNC technology is its scalability; it can easily adapt to both small batch runs and massive production volumes without compromising quality. This flexibility means that businesses can efficiently ramp up production when demand increases or scale down when necessary without incurring significant downtime or costs. In essence, understanding what is the main use of a CNC machine? reveals its capacity to grow with your business needs while maintaining precision across all products.

Comparing CNC machines and traditional methods

When comparing CNC machines with traditional manufacturing methods, several key differences emerge that highlight why modern manufacturers prefer automation over manual processes. Traditional machining often relies on skilled labor and time-consuming setups; however, CNC machines streamline operations by utilizing computer programming for precision cutting and shaping tasks. Additionally, while you might wonder Why would you use a milling machine? consider that they not only enhance productivity but also reduce human error significantly compared to manual techniques.

Automotive and Aerospace Applications

In the automotive and aerospace industries, CNC milling machines are indispensable tools that streamline the manufacturing process. What is a CNC milling machine used for in these sectors? Simply put, they are utilized for creating complex components with unparalleled precision, ensuring that every part meets strict industry standards. The ability to automate machining processes allows manufacturers to produce high-quality parts efficiently, reducing both time and labor costs.

What is the main use of a CNC machine in these industries?

The main use of a CNC machine in automotive and aerospace applications revolves around producing intricate parts that require high precision and durability. These machines can fabricate everything from engine components to structural elements in aircraft, making them vital for enhancing performance and safety. By employing CNC technology, manufacturers can achieve consistent results while minimizing human error—a crucial factor when dealing with safety-critical components.

Precision components for vehicles and aircraft

Precision is non-negotiable when it comes to automotive and aerospace manufacturing; even the smallest deviation can lead to catastrophic failures. CNC milling parts are designed to meet stringent tolerances, ensuring each piece fits perfectly within larger assemblies. Whether it’s crafting lightweight brackets or complex turbine blades, the accuracy provided by CNC machines ensures that vehicles operate at their best while maintaining fuel efficiency.

The importance of accuracy and reliability in production

Accuracy and reliability are paramount in production settings where lives are at stake—like in cars or airplanes. The question What is the difference between a CNC machine and a CNC mill? often arises; however, both serve essential roles but differ primarily in their applications—CNC mills focus on subtractive manufacturing for more intricate designs compared to other types of CNC machinery like lathes used for cylindrical tasks. Ultimately, utilizing advanced technologies such as a CNC lathe machine or milling allows manufacturers to adhere strictly to specifications while also providing scalability for high-volume production runs.

Conclusion

In the ever-evolving world of manufacturing, CNC milling technology stands as a beacon of precision and versatility. As industries continue to embrace automation and advanced machining processes, understanding what is a CNC milling machine used for becomes increasingly important. The future promises enhancements in speed, accuracy, and adaptability that will further revolutionize how products are designed and produced.

The Future of CNC Milling Technology

The future of CNC milling technology looks bright, with innovations on the horizon that promise to push the boundaries of what's possible. What is the main use of a CNC machine? It's not just about cutting materials anymore; it's about integrating smart technologies that allow for real-time adjustments and improved efficiency. As manufacturing becomes more interconnected through Industry 4.0 principles, we can expect CNC machines to play an even more critical role in high-volume production runs as well as customized projects.

Enhancing Creativity with CNC Applications

Why would you use a milling machine? The answer lies in its ability to transform creative ideas into tangible products with unparalleled precision. With advancements in software and hardware, designers can experiment freely without worrying about limitations imposed by traditional methods. Whether it's crafting intricate jewelry designs or creating prototypes for new gadgets, the possibilities are endless when combining creativity with advanced CNC milling parts.

The Versatility of CNC Milling Machines

Where is CNC milling used? You might be surprised at how many industries rely on this technology—from automotive to aerospace, from prototyping to final production runs. What is the difference between a CNC machine and a CNC mill? While both serve essential functions in manufacturing, mills are specifically designed for cutting complex shapes and features into materials like metals or plastics with high precision. With their adaptability and range of applications—including jewelry making and personalization—CNC machines have become indispensable tools across various sectors.