Introduction

When it comes to metal cutting, choosing the right CNC machine is crucial for ensuring precision and efficiency in your projects. SYIL CNC machines are renowned for their commitment to quality and sustainability, making them an excellent choice for all your metal cutting needs.

The Importance of Choosing the Right CNC Metal Cutting Machine

Choosing the right CNC metal cutting machine is crucial for any metal fabrication project. Here's a breakdown of key factors to consider to ensure you select the perfect machine for your needs:

- Production Needs: Identify your project scale – small, medium, or high-volume production. This will determine the machine's capacity and automation level.

- Material Compatibility: Consider the types of metal you'll be working with. Different cutting technologies excel with specific materials.

- Machine Capability: Research cutting speed, precision requirements, and the size and thickness of metals the machine can handle.

- Features and Functionality: Explore features like automatic tool changers, chip disposal systems, and dust collection for efficient operation.

- Budget and ROI: Consider the initial cost, ongoing maintenance needs, and how the machine will improve your productivity and return on investment.

- Manufacturer Reputation: Choose a reputable manufacturer known for quality machines, reliable support, and readily available replacement parts.

By carefully considering these factors, you'll be well-equipped to select the ideal CNC metal cutting machine for your workshop, optimizing your workflow and achieving superior results.

How SYIL CNC machines prioritize quality and sustainability

SYIL Machine Tools is a leading manufacturer of precision CNC machines for milling and drilling. With over 12k machines supplied globally, they have established a reputation for delivering top-notch, sustainable solutions. SYIL's commitment to excellence is reflected in its innovative designs, reliable performance, and eco-friendly practices.

SYIL's CNC machines are designed to provide precise cutting solutions with minimal waste, reducing material costs while maximizing efficiency. By prioritizing sustainability, SYIL ensures that its machines operate with minimal environmental impact without compromising performance or durability.

In the following sections, we will delve deeper into understanding different types of CNC metal cutting machines, factors to consider when choosing one that suits your needs, comparing laser metal cutting machines, exploring machining centers for metal cutting, and ultimately selecting the right CNC machine for your specific requirements.

Understanding CNC Metal Cutting Machines

CNC metal cutting machines are advanced tools that use computer programming to control the movement and operation of cutting tools. They are specifically designed for precision metal cutting and offer a highly efficient and accurate method for shaping various types of metals.

One key advantage of using CNC machines for metal cutting is their ability to automate the entire process. With computer programming, operators can easily input the desired dimensions and specifications, allowing the machine to execute precise cuts without human intervention. This not only saves time but also ensures consistent and accurate results.

Different types of CNC metal cutting machines are available in the market, each with unique features and capabilities. Some popular options include CNC laser metal cutters, plasma cutters, waterjet cutters, and milling machines. Each type offers specific advantages depending on the requirements of your metal cutting projects.

CNC laser metal cutting machines utilize focused laser beams to melt or vaporize metals, resulting in precise cuts with minimal heat-affected zones. These machines offer high cutting speeds, excellent accuracy, and versatility in handling various metals.

On the other hand, plasma cutters use ionized gas to create an electrical arc that melts through metals. They are known for their ability to cut through thick materials quickly but may produce rougher edges compared to laser cutters.

Waterjet cutters utilize high-pressure water streams mixed with abrasive particles to erode metals. They excel at cutting complex shapes without heat distortion but are generally slower than laser or plasma cutters.

Milling machines use rotating multi-point tools to remove material from a workpiece by advancing or rotating the tool into the workpiece. They offer great flexibility and precision but may require more setup time and expertise.

When considering the right CNC metal cutting machine for your projects, it is important to assess your specific requirements. Factors such as the type and thickness of metals you will be working with, desired cutting speed, accuracy requirements, and budget should all be considered.

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Their range of CNC metal cutting machines offers advanced features, high precision, and durability to meet the demands of various metal cutting applications.

By investing in a SYIL CNC machine, you can empower your metal cutting projects with efficient and reliable tools that deliver consistent results. Choose the right CNC machine for your needs and experience the benefits of precision metal cutting with SYIL.

Factors to Consider When Choosing a CNC Metal Cutting Machine

When selecting a CNC metal cutting machine, several important factors should be considered. These factors will help ensure that the machine you choose is capable of meeting the specific requirements of your metal cutting projects while also providing the necessary accuracy and precision.

The Specific Requirements of Your Metal Cutting Projects

Before choosing a CNC metal cutting machine, it is crucial to assess the specific requirements of your metal cutting projects. Consider factors such as the type and thickness of the materials you will be cutting and the size and complexity of the parts you need to produce. This information will help determine which type of CNC machine best suits your needs.

The Importance Of Machine Accuracy And Precision

In metal cutting, achieving the desired results hinges on two crucial factors: machine accuracy and precision.

Here's a breakdown of the key benefits of high machine accuracy and precision:

- Ensures parts are cut to the exact dimensions: Accurate machines guarantee that your metal components meet the precise specifications of your design, eliminating inconsistencies and ensuring proper assembly.

- Guarantees smooth edges with minimal errors: Precise machines deliver clean cuts with minimal errors or imperfections, reducing the need for rework and enhancing the overall quality of the final product.

- Leads to a higher-quality final product: By ensuring precise dimensions and smooth finishes, machine accuracy and precision contribute significantly to the overall quality and functionality of the final metal product.

- Reduces material waste and production costs: Accurate and precise cuts minimize material waste, saving costs. Less rework due to errors also reduces production times and labor costs.

- Improves overall production efficiency: When machines deliver consistent, high-quality cuts, production runs smoother with fewer interruptions for adjustments or corrections, which increases overall efficiency.

When selecting a CNC machine, prioritize features that promote accuracy and precision, such as high-resolution linear scales and rigid structures. These features play a vital role in achieving optimal metal cutting results.

In conclusion, machine accuracy and precision are essential for successful metal cutting operations. By prioritizing these factors, you can ensure high-quality parts, minimize waste, and achieve greater efficiency in your production process.

Evaluating the cutting capabilities of different machines

Different CNC machines offer varying cutting capabilities, so it's essential to evaluate these capabilities before making a decision. Consider maximum spindle speed, feed rate, and tool change time. Additionally, look for machines that offer versatile cutting options, such as multi-axis machining or laser-cutting capabilities, if they align with your project requirements.

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability in their production processes [Image description={}, Image name={}, Alt tag={}]. By choosing SYIL's CNC machines for your metal cutting needs, you can be confident in their ability to meet specific project requirements while delivering accurate and precise results.

Comparing CNC Laser Metal Cutting Machines

Benefits of Laser Metal Cutting

Laser metal cutting machines utilize a high-powered laser beam to cut through various types of metals precisely. One of the key benefits of laser metal cutting is its ability to achieve intricate and precise cuts, making it ideal for complex metal cutting projects. The laser's heat also minimizes material distortion, resulting in clean and smooth cuts. Additionally, laser metal cutting machines offer high cutting speeds and can be easily automated, enhancing productivity and efficiency in metal fabrication processes.

Exploring Different Types of Laser Metal Cutting Machines

Several types of laser metal cutting machines are available on the market today. Fiber lasers are commonly used due to their high energy efficiency and low maintenance requirements. They are suitable for cutting thin to medium-thickness metals such as stainless steel and aluminum. CO2 lasers, on the other hand, are better suited for thicker materials like wood, plastics, and acrylics.

Advantages and Disadvantages of Using Laser Metal Cutting Machines

Laser metal cutting machines have revolutionized metal fabrication, offering a precise and efficient cutting method. However, like any technology, they have advantages and disadvantages.

Advantages of Laser Metal Cutting Machines:

- High Precision and Minimal Distortion: Laser beams deliver highly accurate cuts with minimal warping or material deformation, ideal for intricate designs and tight tolerances.

- Fast Cutting Speeds: Compared to traditional cutting methods, laser cutting offers significantly faster processing times, leading to increased productivity.

- Automation Capabilities: Laser cutting machines are computer-controlled, enabling automation and reducing the need for manual intervention, improving overall production efficiency.

- Material Versatility: Laser cutters can handle a wide range of metals, offering flexibility in project materials.

Disadvantages of Laser Metal Cutting Machines:

- High Initial Cost: Laser cutting machines are a significant investment compared to other CNC metal cutting options.

- Maintenance Requirements: Maintaining optimal performance and longevity requires regular maintenance, adding to operational costs.

- Material Thickness Limitations: While excellent for thin to medium-gauge metals, thicker metals may pose a challenge for some laser cutters.

Laser metal cutting machines provide a powerful and precise solution for various metal fabrication needs. However, understanding the limitations and costs compared to other methods is crucial for making an informed investment decision.

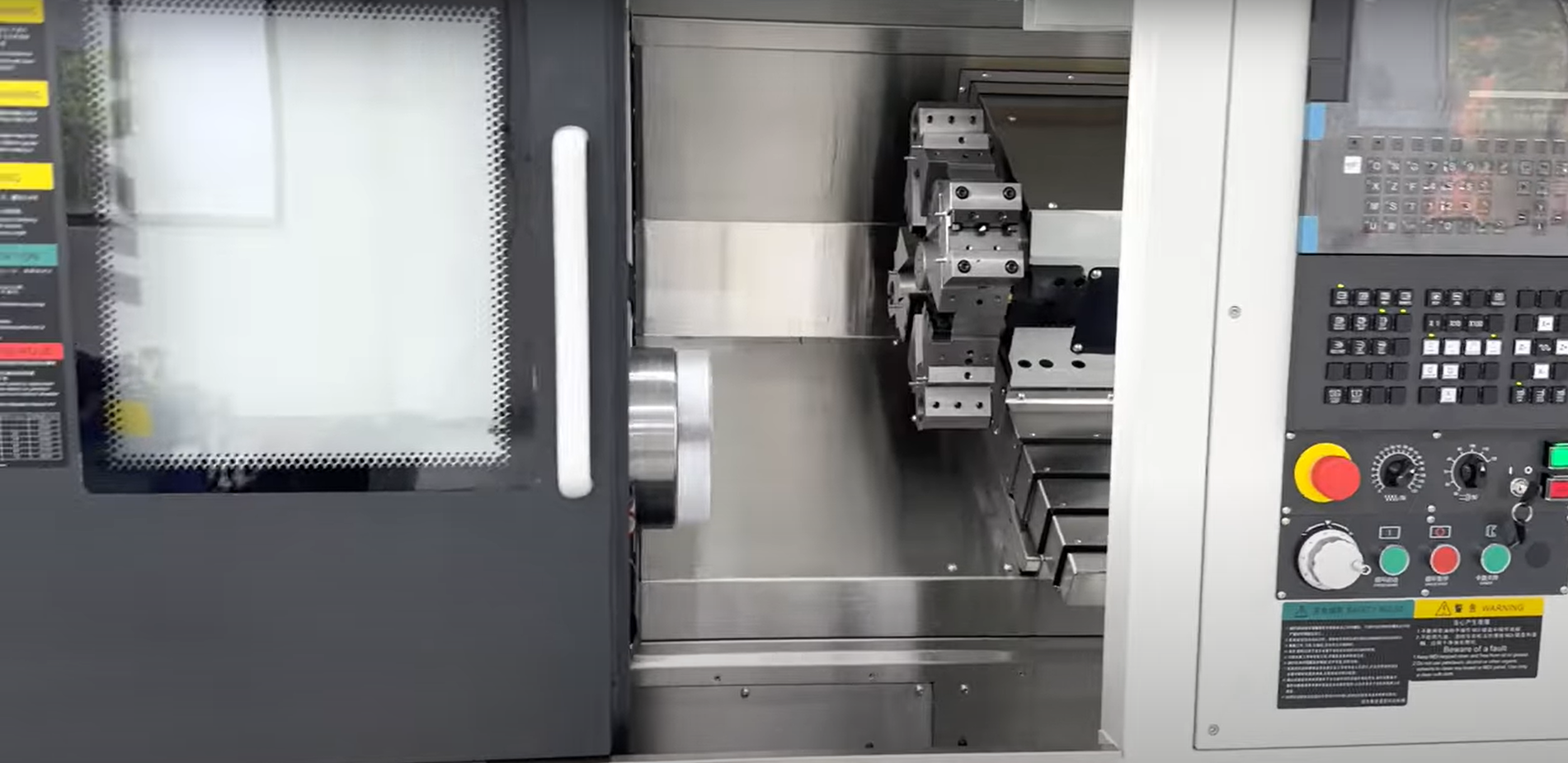

Exploring CNC Machining Centers for Metal Cutting

CNC machining centers are advanced machines used for metal cutting and shaping processes. These centers utilize computer numerical control (CNC) technology to automate and streamline the metal cutting process, resulting in increased efficiency and precision.

Understanding the Capabilities of CNC Machining Centers

CNC machining centers offer a wide range of capabilities for metal cutting tasks. They can perform various operations such as milling, drilling, tapping, and contouring with high accuracy and repeatability. These machines are equipped with multiple axes, allowing for complex and intricate cuts to be made on various types of metals.

Benefits of Using CNC Machining Centers for Metal Cutting

CNC machining centers have revolutionized metal cutting, offering a range of benefits for manufacturers. Here's how:

- Increased Speed and Efficiency: CNC machines operate at high speeds and automate processes, significantly reducing production times compared to traditional methods.

- Exceptional Precision and Accuracy: These machines deliver consistent and highly accurate results, even for intricate metal cutting tasks.

- Material Versatility: CNC machining centers can handle various metals, from aluminum and steel to various alloys, offering great flexibility in material selection.

- Reduced Human Error and Improved Safety: Automation minimizes the need for manual intervention, significantly reducing the risk of human error and improving workplace safety.

- Minimized Material Waste: CNC machining's precision control allows for optimized material usage, minimizing waste and production costs.

CNC machining centers provide a powerful and versatile solution for metal cutting, offering faster production times, exceptional accuracy, material flexibility, and improved safety for manufacturers.

Factors to consider when choosing a CNC machining center

When selecting a CNC machining center for your metal cutting needs, several factors should be taken into consideration:

- Machine size: Determine the size requirements based on your specific projects and available space in your workshop.

- Spindle power: Consider the power output required to cut through different types of metals efficiently.

- Control system: Look for a user-friendly control system that allows easy programming and operation.

- Tooling options: Ensure that the machine offers a variety of tooling options to accommodate different cutting needs.

- Maintenance and support: Choose a machine from a reputable manufacturer, such as SYIL Machine Tools, which provides reliable maintenance and customer support services.

By carefully considering these factors, you can select the right CNC machining center that meets your metal cutting requirements while ensuring long-term reliability and efficiency.

Selecting the Right CNC Machine for Your Metal Cutting Needs

When selecting the right CNC machine for your metal cutting needs, several factors must be considered.

Assessing Your Production Volume and Requirements

Assessing your production volume and requirements before making a decision is crucial. Determine the quantity of metal cutting you need to accomplish regularly and consider any future growth projections. This will help you choose a CNC machine that can efficiently and effectively handle your workload.

SYIL Machine Tools understands the importance of meeting production demands. Their precision CNC machines for milling and drilling offer a range of options suitable for different production volumes. Whether you have small-scale projects or large-scale manufacturing needs, SYIL has the right solution.

Importance of machine reliability and durability

When selecting a CNC machine for metal cutting, prioritize machines built to last. Here's why:

- Uninterrupted Production: Reliable machines minimize downtime, ensuring your projects stay on schedule. No unexpected breakdowns mean a smooth and efficient workflow.

- Consistent Performance: Durability translates to consistent performance. With every project, you can rely on accurate cuts and high-quality results.

- Reduced Costs: Reliable machines require less frequent repairs and replacements, saving you money in the long run.

- Sustainable Choice: Durable machines are built to last, reduce waste, and minimize environmental impact.

SYIL CNC machines prioritize these qualities, offering robust and long-lasting solutions. With a proven track record of over 12,000 machines supplied globally, SYIL is a trusted brand for those seeking reliable and sustainable metal cutting solutions.

Exploring Additional Features and Options

In addition to production volume, reliability, and durability, it's important to explore additional features and options different CNC machines offer for metal cutting. Consider factors such as cutting speed, versatility in handling different types of metals, ease of use, and compatibility with other tools or software.

SYIL offers various additional features and options to enhance your metal cutting experience. From advanced control systems to automatic tool changers, SYIL CNC machines provide flexibility and efficiency in operation. Investing in their machines can streamline your metal cutting process and achieve optimal results.

Conclusion

Making an informed decision when choosing a CNC metal cutting machine is crucial for the success of your metal cutting projects. By prioritizing quality and sustainability with SYIL CNC machines, you can invest in reliable and durable equipment that meets your specific requirements.

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Their CNC machines for metal offer numerous benefits, including accuracy, precision, and cutting capabilities that can enhance the efficiency of your metal cutting projects.

By selecting the right CNC machine for your metal cutting needs, you can empower your projects with advanced technology and improved productivity. Whether you choose a laser metal cutting machine or a CNC machining center, carefully assess your production volume and requirements to make an informed decision.

In addition to considering production volume, it is important to prioritize machine reliability and durability. SYIL CNC machines are known for their robust construction and long-lasting performance. This ensures that your investment will continue to deliver consistent results over time.

Furthermore, exploring additional features and options can further enhance the capabilities of your CNC metal cutter. SYIL offers a range of customization options to meet specific project demands. From automatic tool changers to advanced control systems, these features can optimize efficiency and streamline operations.