Introduction

In today's rapidly evolving metal fabrication industry, the demand for precision and efficiency is higher than ever. That's where CNC machines come into play, offering a revolutionary solution for metal cutting. These machines have become indispensable tools for manufacturers worldwide with their advanced technology and innovative features.

Unleash Your Creativity with CNC Machine for Metal Cutting

Gone are the days when metal cutting was limited to manual processes that were time-consuming and prone to errors. CNC machines have opened up a whole new world of possibilities, allowing you to unleash your creativity like never before. Whether working on intricate designs or complex shapes, these machines provide the precision and accuracy to bring your ideas to life.

Unlocking New Possibilities in Metal Fabrication

With the advent of CNC machines, metal fabrication has significantly transformed. These machines have revolutionized the way manufacturers approach cutting processes by offering unparalleled speed and efficiency. From small-scale projects to large-scale production runs, CNC machines unlock new possibilities in productivity and quality.

Revolutionize Your Metal Cutting Process with CNC Machines

Gone are the days when manual cutting processes were the norm in metal fabrication. Today, CNC machines have taken center stage, revolutionizing the industry with their advanced capabilities. These machines offer unmatched precision and accuracy, allowing manufacturers to streamline their production processes and achieve exceptional results.

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. By incorporating SYIL's CNC machines into your metal cutting process, you can use their cutting-edge technology and enhance your productivity.

Stay tuned for the next section, where we will delve into the evolution of CNC machines in metal cutting and explore their benefits in more detail.

The Evolution of CNC Machines in Metal Cutting

CNC machines have revolutionized the metal cutting industry, offering unmatched precision and efficiency. Let's explore their evolution and understand their impact on metal fabrication.

The History of CNC Machines in Metal Fabrication

The history of CNC machines dates back to the 1940s when they were first introduced for military purposes. These early machines were large and cumbersome, requiring skilled operators to control their movements manually. However, as technology advanced, so did CNC machines.

In the 1970s, computer numerical control (CNC) technology emerged, enabling operators to program instructions into the machine using computer software. This eliminated the need for manual control and significantly improved accuracy and productivity in metal cutting processes.

Advancements in CNC Technology for Metal Cutting

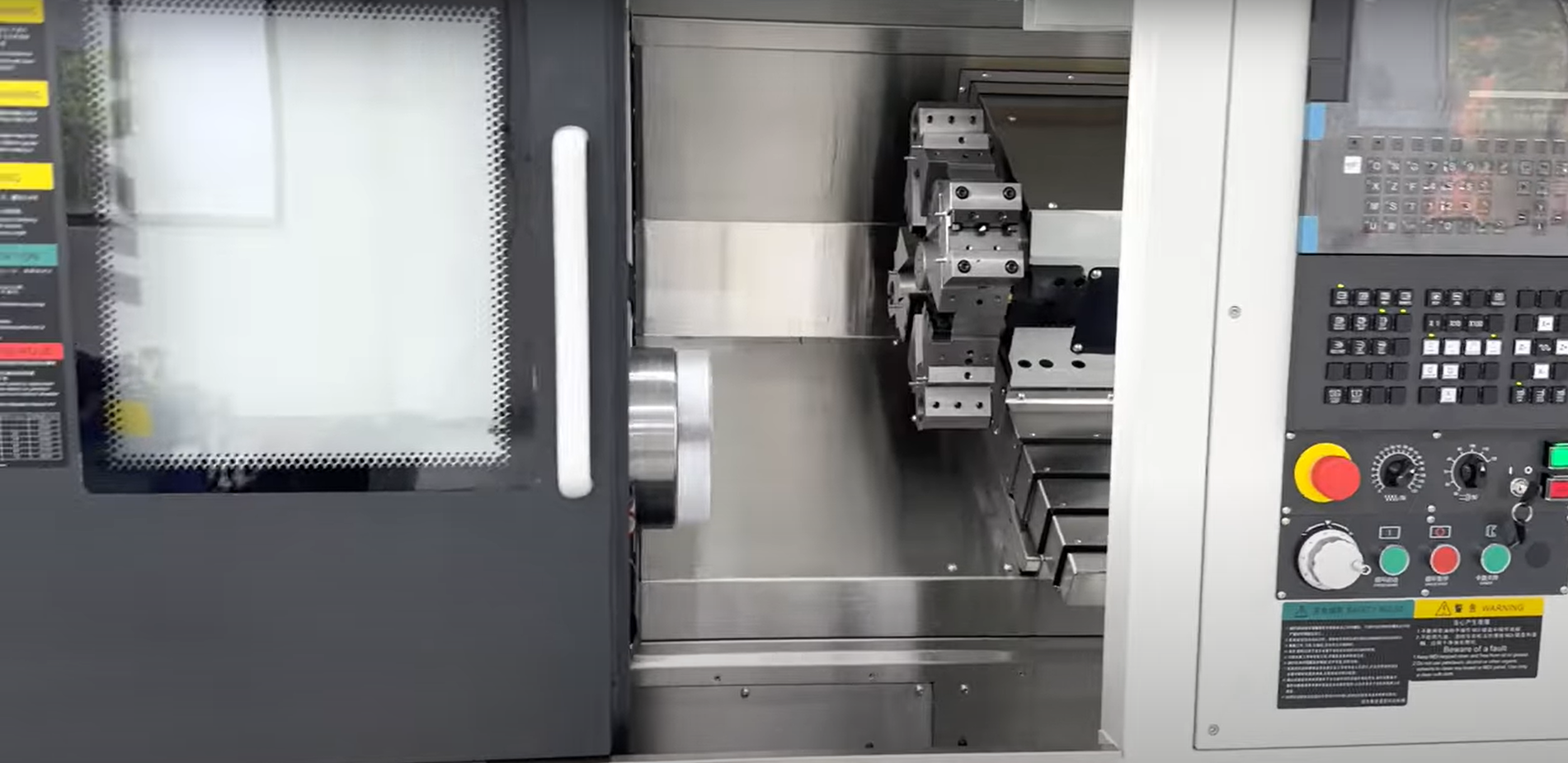

Over the years, CNC technology has continued to evolve rapidly, leading to significant advancements in metal cutting processes. Today's CNC machines have state-of-the-art features like automatic tool changers, high-speed spindles, and advanced motion control systems.

These advancements have enhanced precision, increased cutting speeds, and reduced production times. With improved software capabilities and real-time monitoring systems, operators can now easily achieve complex designs while maintaining exceptional accuracy.

Benefits of Using CNC Machines for Metal Fabrication

CNC machines have revolutionized metal fabrication, offering many advantages over traditional methods.

- Unmatched Precision and Accuracy: CNC machines excel at cutting various metals with incredible precision and accuracy. They can consistently reproduce even the most intricate designs, eliminating deviations or errors that can plague manual processes.

- Enhanced Customization and Flexibility: Gone are the limitations of traditional methods. With advanced software programming, CNC machines offer unmatched customization and flexibility. Operators can easily modify designs or create unique patterns to meet specific requirements, opening doors for innovative metalwork.

- Maximized Efficiency and Cost Savings: CNC machines significantly reduce material waste during operation by optimizing tool paths and minimizing human error. This translates to cost savings for manufacturers while ensuring consistent, high-quality output.

CNC machines are invaluable assets for metal fabrication. They offer superior precision, increased flexibility, and improved efficiency.

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Their machines are designed to meet the diverse needs of metal fabricators, offering cutting-edge technology and exceptional performance.

Exploring the Versatility of CNC Machines for Metal Cutting

CNC machines have revolutionized the metal fabrication industry with their versatility and precision. They offer various capabilities that allow for intricate designs and efficient production processes.

Precision and Accuracy in Metal Fabrication

One key advantage of CNC machines for metal cutting is their exceptional precision and accuracy. These machines are equipped with advanced technology that ensures each cut is made with the utmost precision, producing high-quality finished products.

With CNC machines, tight tolerances, and intricate details that would be nearly impossible to achieve manually can be achieved. The computer-controlled system ensures consistent accuracy throughout production, eliminating human error.

Customization and Flexibility with CNC Machines

CNC machines for metal cutting provide unparalleled customization options. They allow you to create complex designs and shapes that meet your requirements. Whether it's a unique pattern or a personalized logo, these machines can bring your vision to life.

Furthermore, CNC machines offer flexibility in terms of materials used. They can handle various metals, including steel, aluminum, brass, and more. This versatility allows you to work on diverse projects without needing multiple specialized machines.

Maximizing Efficiency with CNC Machines for Metal Cutting

Efficiency is another significant advantage CNC machines offer for metal cutting. These automated systems streamline fabrication by reducing manual labor and increasing productivity.

With their ability to perform multiple operations simultaneously, CNC machines significantly reduce production time compared to traditional methods. This increased efficiency translates into cost savings and faster project turnaround times.

Utilizing small CNC machines for metal cutting, such as those offered by SYIL Machine Tools, can maximize efficiency even in limited workspace environments. These compact yet powerful machines deliver high-performance results while saving valuable floor space.

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. SYIL's small CNC machines for metal cutting combine precision, flexibility, and efficiency to meet the diverse needs of the metal fabrication industry.

Choosing the Right CNC Machine for Metal Cutting

When selecting a CNC machine for metal cutting, several factors must be considered. First and foremost, you need to determine the specific requirements of your metal fabrication process. This includes the size, thickness, and type of metal you will work with. Additionally, you should consider the desired level of precision and accuracy needed for your projects.

Another important factor to consider is the available workspace in your facility. Depending on the size of your operation, you may need to choose a compact or small CNC machine that can fit within limited space constraints. SYIL Machine Tools offers various options catering to different workspace requirements.

Understanding the different types of CNC machines for metal cutting is crucial in making an informed decision. Various types, including milling machines, lathes, plasma cutters, and waterjet cutters, are available. Each type has its advantages and limitations depending on the specific application.

Evaluating the quality and performance of CNC machines is essential before purchasing. Look for machines with high rigidity and stability to ensure precise cutting results. Consider factors such as spindle speed, tool capacity, and control system capabilities.

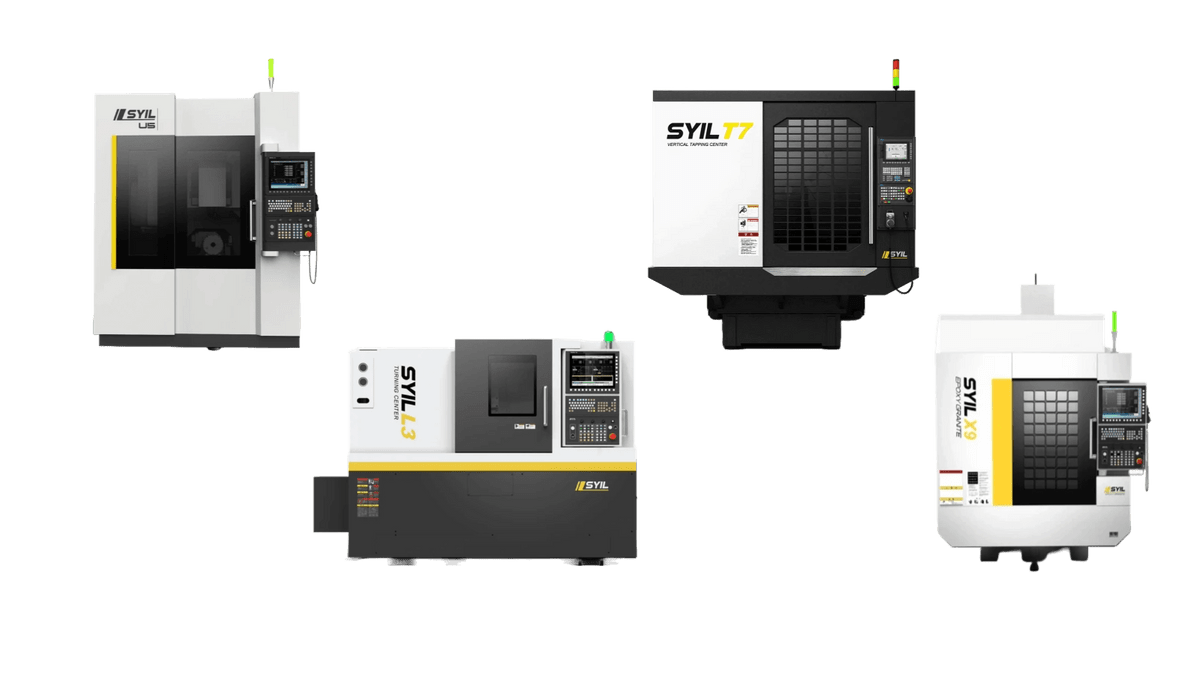

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12,000 machines supplied globally, they prioritize quality and sustainability. Their range of CNC machines for metal cutting includes compact models ideal for small-scale operations or limited workspace environments.

Unleashing Your Creativity with CNC Machine for Metal Cutting

CNC machines have revolutionized how we cut and shape metal in metal fabrication. These machines offer unparalleled precision and accuracy, allowing for intricate designs and complex details that were once impossible to achieve by hand. With CNC machines for metal cutting, you can unleash your creativity and explore limitless possibilities in your projects.

Design Freedom and Limitless Possibilities

One of the greatest advantages of using CNC machines for metal cutting is the design freedom they provide. Certain designs were not feasible with traditional methods due to their complexity or intricacy. However, CNC machines can bring even the most intricate designs to life.

These machines use computer programming to control their movements, allowing for precise cuts and shapes. This means you are not limited by manual dexterity or physical constraints when designing your metal pieces. Whether a complex geometric pattern or an intricate sculpture, a CNC machine can bring your vision to reality.

Incorporating Intricate Details in Metal Fabrication

When it comes to metal fabrication, attention to detail is crucial. Every curve, every angle, and every cut must be precise to achieve the desired outcome. This level of precision can be challenging to achieve manually, but it becomes effortless with a CNC machine for metal cutting.

CNC machines excel at replicating intricate details with utmost accuracy. Whether you're working on jewelry, decorative pieces, or mechanical parts, a CNC machine can flawlessly capture every detail. This opens up a whole new world of possibilities for artists and craftsmen who want to push the boundaries of metal fabrication.

Pushing the Boundaries of Metal Cutting with CNC Machines

Traditional metal cutting methods always limited what could be achieved due to physical constraints or technical limitations. However, CNC machines have changed the game entirely. These machines can push the boundaries of metal cutting and allow for new and innovative techniques.

Using advanced programming and cutting-edge technology, CNC machines can perform complex cuts, angles, and shapes that were once thought impossible. This means you can experiment with new designs, explore unconventional techniques, and create unique pieces that stand out in the competitive metal cutting industry.

SYIL CNC Machines: Quality and Innovation in Metal Cutting

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability.

Introducing SYIL Machine Tools in Precision CNC Machines

SYIL Machine Tools is a leading manufacturer of precision CNC machines for metal cutting. Their state-of-the-art technology and innovative designs have revolutionized the metal fabrication industry. Whether you need to cut intricate designs or produce large quantities of metal parts, SYIL CNC machines deliver exceptional performance and accuracy.

Their range of CNC machines includes small-sized models perfect for hobbyists and large industrial-grade machines suitable for heavy-duty production. With their commitment to quality, SYIL Machine Tools ensures that every machine is built to withstand rigorous use and deliver consistent results.

The SYIL CNC Machine Advantage for Metal Cutting

When it comes to metal cutting, the SYIL CNC machine offers several advantages over traditional methods. First and foremost, these machines provide unmatched precision and accuracy, ensuring that every cut is made with utmost perfection. This level of precision allows for intricate designs and complex shapes to be effortlessly created.

Additionally, the SYIL CNC machine offers unparalleled customization and flexibility. With its advanced software capabilities, operators can easily program the machine to cut any shape or design they desire. This versatility opens up a world of possibilities in metal fabrication, allowing for unique creations that were once thought impossible.

Sustainability and Reliability in SYIL CNC Machines

SYIL Machine Tools understands the importance of sustainability in today's world. Their CNC machines are designed with energy-efficient features that minimize waste and reduce environmental impact. By using these eco-friendly machines, businesses can contribute to a greener future while still achieving excellent results in metal cutting.

Furthermore, reliability is a key factor when choosing a CNC machine for metal cutting operations. SYIL CNC machines are built to last, with durable components and robust construction. This ensures that they can withstand the demands of continuous use and deliver consistent performance over time.

Conclusion

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Their CNC machines for metal cutting provide design freedom, limitless possibilities, and the ability to incorporate intricate details into your projects.

By choosing SYIL CNC machines, you can unlock new possibilities in metal fabrication. Their small CNC machines for metal offer versatility and flexibility to meet your specific needs. With SYIL's commitment to quality and performance, you can trust that their CNC machines will deliver exceptional results.

To stay ahead in the competitive metal cutting industry, it is crucial to embrace CNC technology's advancements. SYIL's CNC machines enhance precision and efficiency in your metal cutting process. Investing in these innovative tools can optimize your production capabilities and achieve superior outcomes.

Incorporating SYIL CNC machines into your metal fabrication process will revolutionize the way you work with metals. Their reliable performance allows you to push the boundaries of what is possible regarding design complexity and intricacy. With SYIL as your partner, you can unleash your creativity without limitations.

So why wait? Embrace innovation and precision with CNC machines for metal cutting today! Empower your metal fabrication process with SYIL's high-quality CNC machines that prioritize sustainability and reliability. Stay ahead in the competitive metal cutting industry by choosing SYIL as your trusted partner.