Introduction

Metal cutting has come a long way since its early beginnings, evolving from manual processes to the advanced technology we have today. One of the most significant advancements in metal cutting is the introduction of Computer Numerical Control (CNC) machines. These machines offer numerous benefits, including increased precision and efficiency. SYIL CNC Machines, a leading manufacturer in the industry, specializes in producing high-quality CNC machines that deliver exceptional results.

The Evolution of Metal Cutting

Metal cutting techniques have evolved significantly over time. From ancient civilizations using primitive tools to shape metals manually, we now have sophisticated machinery that can perform precise cuts with minimal human intervention. This evolution has revolutionized industries such as manufacturing, construction, and automotive.

The Benefits of CNC Machines

CNC machines have revolutionized metal fabrication, offering many advantages that make them an essential part of any modern shop. Here's how CNC technology empowers businesses:

- Unmatched Accuracy and Repeatability: CNC machines eliminate human error by following precise computer programs, ensuring consistent and high-quality parts every time.

- Increased Productivity and Speed: CNC machines operate tirelessly and much faster than manual processes, significantly boosting production output.

- Reduced Waste and Material Costs: CNC programming optimizes material usage, minimizing scrap and lowering overall material costs.

- Enhanced Design Complexity: CNC machines can handle intricate designs that would be impossible or highly time-consuming with manual methods.

- Improved Safety: By minimizing manual intervention, CNC machines create a safer work environment for employees.

CNC machines offer a powerful combination of precision, efficiency, and safety, making them an invaluable asset for modern metal fabrication.

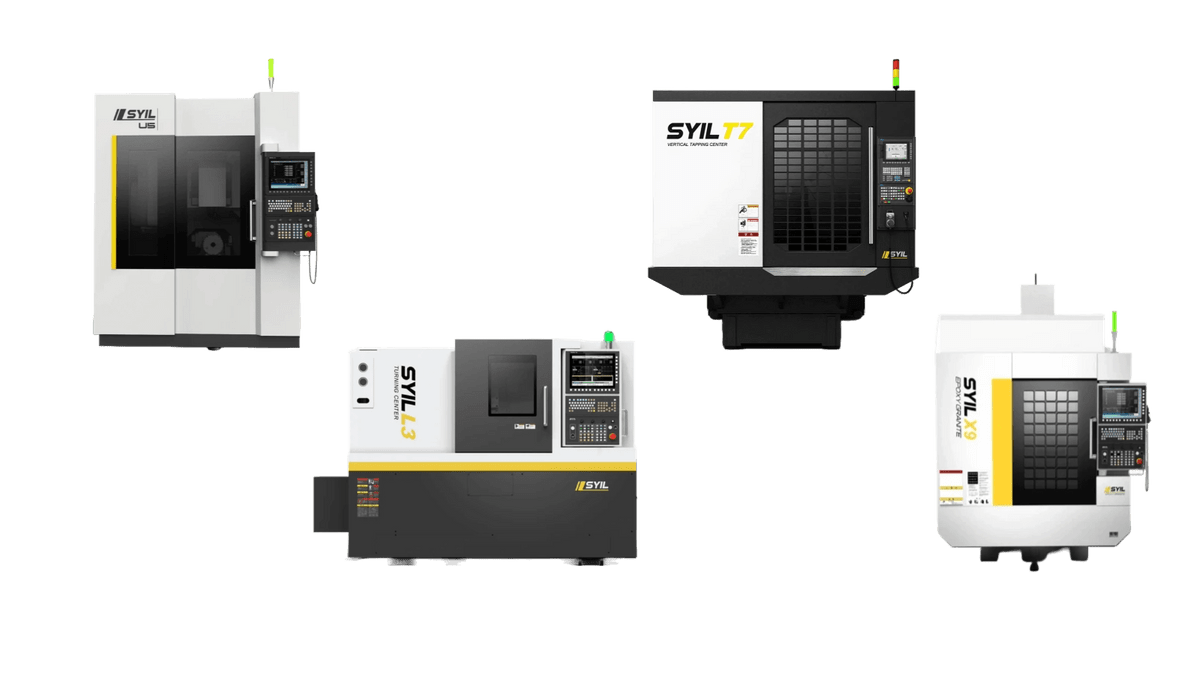

Introducing SYIL CNC Machines: Precision and Quality

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. SYIL CNC Machines are known for their exceptional performance, durability, and user-friendly interface, making them an ideal choice for businesses seeking reliable solutions for their metal cutting needs.

Understanding CNC Cutting

CNC cutting, or Computer Numerical Control cutting, is a precise and efficient method used in metal fabrication. It involves using computer-controlled machines to cut and shape various materials accurately.

How CNC Machines Work

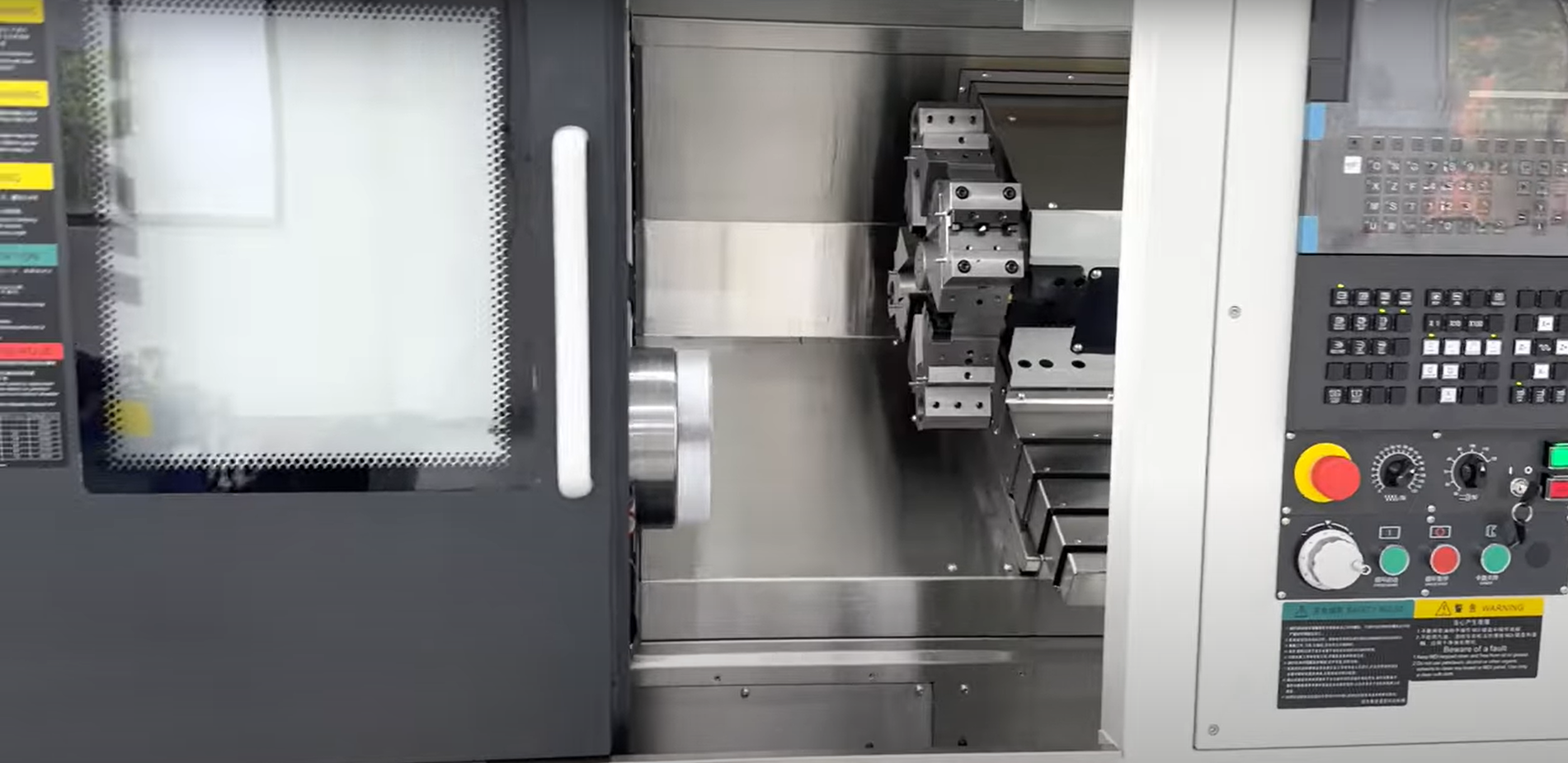

CNC machines operate through a combination of software programming and mechanical movements. The process begins with creating a digital design or blueprint using CAD (Computer-Aided Design) software. This design is then converted into instructions that the CNC machine can understand.

The CNC machine is equipped with motors that control the movement of the cutting tool along different axes, such as X, Y, and Z. These motors receive signals from the computer program and precisely position the tool to make accurate cuts according to the design specifications.

The Advantages of CNC Cutting

CNC cutting offers a revolutionary approach to material processing, bringing significant advantages to various industries. Here are some key benefits:

- Unmatched Precision: Controlled by computers, CNC machines deliver consistent and accurate cuts every single time. This eliminates human error and reduces material waste, guaranteeing high-quality results for every project.

- Boosted Efficiency and Speed: Compared to manual methods, CNC cutting operates much faster. CNC machines can execute complex cuts in a fraction of the time, leading to significant time savings in production processes.

- Design Versatility Unleashed: CNC's magic lies in its design flexibility. The computer program can be effortlessly modified to create intricate patterns or unique shapes that would be extremely difficult, if not impossible, to achieve manually.

CNC cutting offers a powerful combination of precision, speed, and design freedom, making it a valuable tool for businesses seeking to optimize their production processes and elevate the quality of their projects.

Exploring Different CNC Cutting Methods

Various methods are used in CNC cutting, depending on the material being worked on and the desired outcome. Some common techniques include plasma cutting, waterjet cutting, and laser cutting.

Plasma cutting involves using a high-temperature plasma arc to melt through metal materials, producing clean and precise cuts. Waterjet cutting utilizes a high-pressure stream of water mixed with abrasive particles to erode through different materials effectively.

However, one of the most advanced and versatile CNC cutting methods is laser cutting. This technique employs a high-powered laser beam to melt, burn, or vaporize the material, resulting in precise and intricate cuts. Laser cutting offers exceptional speed, accuracy, and flexibility, making it ideal for various applications.

Laser Cutting: The Future of Metal Fabrication

Laser cutting has revolutionized metal fabrication, offering unmatched precision and versatility. This advanced technology utilizes a high-powered laser beam to cut through various materials with incredible accuracy. SYIL CNC Machines, a leading manufacturer in the industry, recognizes the potential of laser cutting and offers state-of-the-art machines to meet the growing demand.

Introduction to Laser Cutting

Laser cutting involves a focused laser beam to melt, burn, or vaporize material along a predetermined path. This process is guided by computer numerical control (CNC) technology, which ensures precise cuts every time. By harnessing the power of lasers, complex shapes and intricate designs can be effortlessly achieved.

The Versatility of Laser Cut Metal

One key advantage of laser cutting is its ability to work with a wide range of metals. Whether it's stainless steel, aluminum, brass, or copper, laser cutters can easily handle them all. This versatility makes laser cutting ideal for various industries, such as automotive, aerospace, and even jewelry making.

Benefits of Laser Cutting Services

Laser cutting has become popular for fabrication projects due to its numerous advantages over traditional cutting methods. Here are some of the key benefits of laser cutting:

- Minimal Material Contact: Laser cutting eliminates the need for physical contact with the material, reducing the risk of damage or contamination to the workpiece. This is particularly beneficial for delicate materials or those prone to warping from heat.

- Clean and Precise Cuts: Lasers produce a highly focused beam, resulting in minimal heat-affected zones and clean edges without any burrs or roughness. This reduces the need for secondary finishing processes, saving time and money.

- Increased Speed and Efficiency: Laser cutters operate at much faster speeds than conventional cutting methods. With high-powered lasers and advanced CNC systems, projects can be completed significantly faster, improving production efficiency.

Laser cutting offers a precise, efficient, and cost-effective solution for a variety of cutting needs across different industries.

SYIL CNC Machines: Leading the Way in Laser Cutting

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Their range includes top-of-the-line laser cutting machines that deliver exceptional performance and reliability.

SYIL's CNC laser cutting machines are equipped with the latest technology, allowing precise and intricate cuts. These machines are designed to handle various metal thicknesses and can accommodate various applications. With SYIL CNC Machines, you can trust that your laser cutting needs will be met with utmost precision and efficiency.

Exploring CNC Laser Cutting

CNC laser cutting is a revolutionary technology that offers precise and efficient metal cutting solutions. A high-powered laser beam controlled by a computer can cut intricate designs with incredible accuracy. This process eliminates the need for manual labor and reduces the risk of human error, resulting in superior quality cuts.

The Basics of CNC Laser Cutting

CNC laser cutting involves using a focused laser beam to melt or vaporize the metal material, creating clean and precise cuts. The laser beam is guided by a computer-controlled system that follows a predetermined path, ensuring accuracy and consistency in every cut. This technology allows for intricate designs and complex shapes to be achieved easily.

Applications of CNC Laser Cutting

The applications of CNC laser cutting are vast and diverse. This technology can be used in various industries, from automotive parts to aerospace components, to create high-quality products. Its versatility allows for cutting different types of metals, including steel, aluminum, brass, and more. Whether for prototyping or mass production, CNC laser cutting provides unmatched precision and efficiency.

Maximizing Efficiency with SYIL CNC Laser Cutting Machines

When it comes to CNC laser cutting machines, SYIL Machine Tools stands out as a leader in the industry. Their state-of-the-art machines are designed to maximize efficiency and productivity while maintaining exceptional precision. With over 12k machines supplied globally, SYIL prioritizes quality and sustainability.

With SYIL's CNC laser cutting machines, you can expect faster turnaround times without compromising quality. Their advanced technology ensures smooth operation and minimal downtime, allowing you to meet tight deadlines and deliver superior results to your clients.

Mastering CNC Cutting Techniques

CNC cutting is a precise and efficient method used in metal fabrication. Mastering the techniques involved can greatly enhance the quality of your cuts. Here are some tips for achieving precise cuts using CNC machines.

Tips for Achieving Precise Cuts

- Proper Tool Selection: Choosing the right cutting tool is crucial for achieving precise cuts. Consider factors such as material type, thickness, and desired finish when selecting tools for CNC cutting.

- Optimize Feed Rates: Adjusting the feed rate of the CNC machine can help achieve precision cuts. Finding the optimal balance between speed and accuracy will ensure clean edges and minimal material waste.

- Use High-Quality Cutting Fluids: Lubrication is vital in CNC cutting, as it helps dissipate heat and reduces friction between the tool and the workpiece. High-quality cutting fluids can improve tool life and prevent chip buildup.

- Regular Maintenance: Maintaining your CNC machine well-maintained is essential for consistently achieving precise cuts. Regularly check and replace worn-out parts, calibrate the machine, and clean any debris affecting its performance.

- Test Cuts: Before running a full production job, it's advisable to perform test cuts on scrap material to fine-tune your settings and ensure accurate results without wasting valuable resources.

Best Practices for CNC Cutting

- Proper Workpiece Fixturing: Securely fastening the workpiece during CNC cutting prevents movement or vibration that could result in inaccurate cuts or damage to the machine.

- Optimal Depth of Cut: Adjusting the depth of cut according to material properties can help achieve precision without putting unnecessary strain on the tool or compromising cut quality.

- Consider Tool Path Optimization: Optimizing tool paths can minimize unnecessary movements, reduce machining time, and improve accuracy by ensuring smooth transitions between different cutting areas.

- Pay Attention to Tool Wear: Regularly inspecting and replacing worn-out cutting tools is crucial for maintaining precision in CNC cutting. Dull or damaged tools can lead to poor cuts and an increased risk of accidents.

- Quality Control Checks: Implementing quality control checks during and after CNC cutting operations can help identify deviations from the desired specifications, allowing immediate adjustments or corrections.

SYIL CNC: Where Precision Meets Perfection

SYIL Machine Tools understands the importance of precision in CNC cutting. With its state-of-the-art CNC machines, it offers unparalleled accuracy and reliability for all your metal fabrication needs. Whether you're looking for milling, drilling, or laser cutting solutions, SYIL CNC machines always deliver exceptional results.

SYIL's commitment to quality and sustainability sets it apart from the competition. Their machines are designed to optimize productivity while minimizing environmental impact, making them an ideal choice for businesses seeking efficient and eco-friendly metal cutting solutions.

By choosing SYIL CNC machines, you can unlock new possibilities in metal fabrication with unmatched precision and reliability. Don't settle for anything less than perfection regarding your CNC cutting needs – trust SYIL Machine Tools to exceed your expectations.

Remember, mastering the techniques involved in CNC cutting takes practice and attention to detail. By following these tips and best practices while utilizing SYIL's advanced CNC machines, you'll be well on your way to achieving precise cuts that meet even the most demanding requirements.

The Advantages of CNC Metal Cutting

CNC metal cutting offers numerous advantages that greatly enhance productivity and save costs in the metal fabrication industry. SYIL CNC Machines, known for their precision and quality, are at the forefront of unleashing metal cutting's potential.

Enhancing Productivity with CNC Machines

One of the key advantages of CNC metal cutting is its ability to enhance productivity significantly. With traditional manual cutting methods, operators have to manually control every aspect of the cutting process, which can be time-consuming and prone to errors. However, with CNC machines, computer programming automates and controls the cutting process.

CNC machines can perform complex cuts with high precision and repeatability, allowing faster production times and increased output. This automation also reduces the need for manual labor, freeing up operators to focus on other tasks or operate multiple machines simultaneously. This increased efficiency ultimately leads to higher productivity levels and improved overall workflow.

Cost Savings with CNC Metal Cutting

Another advantage of CNC metal cutting is its potential for cost savings. While initial investment costs for CNC machines may be higher than traditional manual equipment, the long-term savings outweigh this initial expense.

With manual cutting methods, human error can lead to material waste due to inaccurate cuts or mistakes during the fabrication process. In contrast, CNC machines offer precise and consistent cuts every time, minimizing material waste and reducing costs associated with rework or scrap.

Additionally, CNC machines require less manpower than manual methods, since they can operate continuously without breaks or fatigue. This reduces labor costs and allows businesses to allocate resources more efficiently.

Conclusion

SYIL CNC: Your Partner in Precision Cutting

When it comes to precision cutting, SYIL CNC Machines stands out as a reliable partner. With their expertise in developing and manufacturing high-quality CNC machines for milling and drilling, they have earned a reputation for excellence in the industry. By choosing SYIL CNC Machines, manufacturers can trust that they are investing in top-notch equipment that will deliver accurate and consistent results.

Unlocking New Possibilities with CNC Metal Cutting

CNC metal cutting opens up a world of possibilities for manufacturers. Its ability to create intricate designs and shapes with ease allows for greater creativity in product development. Moreover, by streamlining production processes and reducing waste, CNC metal cutting helps businesses save time and money.

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. By partnering with SYIL CNC Machines, manufacturers can unlock new possibilities in metal fabrication through advanced technology.